Air Pressure Switches in Condensing Boilers

Modern condensing boilers are remarkably efficient machines, but they rely on a network of safety components to operate properly. Among these, the air pressure switch plays a critical role that many heating engineers and property managers take for granted until something goes wrong.

This small but essential component monitors the flow of air through your boiler's combustion chamber, ensuring safe operation before allowing the unit to fire up. When it fails, your boiler simply won't start, leaving you without heating or hot water. Understanding how these switches work and what causes them to fail can save significant downtime and help you make informed decisions about maintenance and replacement.

What Air Pressure Switches Actually Do

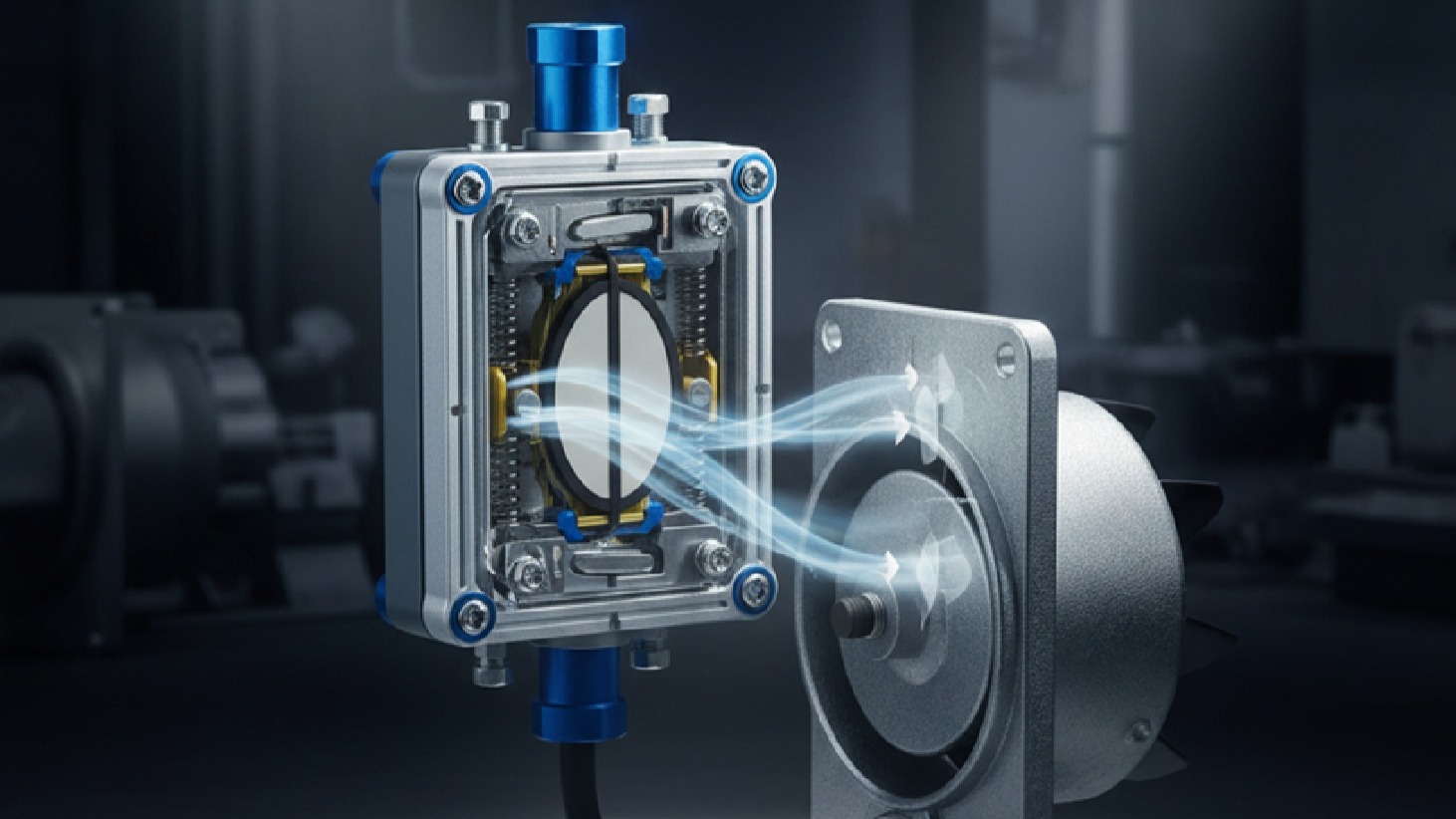

Condensing boiler air pressure switches serve as gatekeepers for your condensing boiler's ignition sequence. Before combustion begins, the boiler's fan spins up to create a flow of air through the combustion chamber. The air pressure switch detects this airflow through a change in pressure, then signals the control board that it's safe to ignite the gas.

The switch connects to the fan housing via a small rubber or silicone tube. As the fan operates, it creates negative pressure that pulls a diaphragm or membrane inside the switch. This movement closes an electrical contact, completing a circuit that tells the boiler's control system everything is ready for ignition.

Without this verification, the boiler won't attempt to light. This prevents potentially dangerous situations where gas could accumulate in the combustion chamber without proper ventilation, or where incomplete combustion could produce carbon monoxide.

Think of it as a simple yes-or-no question the boiler asks itself: "Is air flowing properly through my combustion chamber?" Only when the answer is yes does the ignition sequence continue.

Why Condensing Boilers Need Them

Older non-condensing boilers often used simpler safety mechanisms, but condensing boilers operate under different conditions that demand more sophisticated monitoring. These units extract additional heat from exhaust gases, which means they produce cooler flue temperatures and more condensate. This creates unique challenges.

The combustion process in a condensing boiler requires precise air-to-gas ratios to achieve the efficiency ratings these units are known for. Too little air, and combustion becomes incomplete, wasting fuel and potentially creating dangerous gases. Too much air, and you lose efficiency as excess air carries heat away.

Air pressure switches ensure the fan is working correctly before ignition occurs. A failed fan or blocked flue could prevent proper air supply, making combustion impossible or dangerous. The switch catches these problems before they become hazards.

Many heating controls now integrate with pressure switch diagnostics, allowing for more sophisticated monitoring of boiler performance over time.

Common Failure Points and Symptoms

Air pressure switch faults occur for several predictable reasons, most of which relate to the harsh environment inside a boiler and the delicate nature of the sensing mechanism.

The small sensing tube that connects the switch to the fan housing accumulates condensate over time. This water blocks the pressure signal from reaching the switch, preventing it from closing even when the fan operates correctly. You'll notice this as a boiler that runs its fan but never attempts to ignite.

The diaphragm or membrane inside the switch can develop cracks or lose flexibility, especially in boilers that cycle frequently. Once compromised, the switch won't respond reliably to pressure changes. Sometimes it works, sometimes it doesn't, creating intermittent faults that frustrate diagnosis.

Electrical contacts inside the switch corrode or pit from repeated operation. Even when the mechanical portion functions correctly, the switch may fail to complete the electrical circuit. This produces the same symptom as a blocked sensing tube; the fan runs, but ignition never occurs.

Physical damage to the sensing tube from maintenance work or component movement can create leaks that prevent proper pressure sensing. A tube that's pulled loose, kinked, or perforated won't transmit pressure changes effectively.

Some switches simply wear out from age. The internal components fatigue after thousands of cycles, and the switch becomes unreliable. This typically happens gradually, with increasing failure rates over weeks or months before complete failure.

Testing and Diagnosis Methods

Proper diagnosis requires understanding what you're testing for. The switch needs to perform two functions: respond mechanically to pressure changes and complete an electrical circuit when activated.

Start with visual inspection. Check the sensing tube for obvious damage, kinks, or disconnection. Look for water or condensate inside the tube, hold it up to light, and you'll often see liquid blocking the passage. If you find water, the tube needs cleaning or replacement.

With the boiler powered and calling for heat, listen to the fan. It should spin up to full speed before the boiler attempts ignition. If the fan sounds weak or struggles, the problem might not be the switch at all, but rather the fan itself or a blocked flue system.

Many modern boilers display fault codes that specifically indicate pressure switch issues. These codes tell you the control board isn't receiving the expected signal from the switch. However, remember that the fault might lie with the tube, the fan, or the flue system rather than the switch itself.

For electrical testing, you'll need a multimeter. Disconnect power to the boiler first. Locate the switch's electrical connections and test for continuity across the terminals. With no pressure applied, the switch should show an open circuit. When you gently blow into the sensing tube, you should hear a click and see the circuit close. This confirms that the mechanical and electrical portions both function.

Testing under operating conditions requires more caution. With the boiler running and the fan active, the switch should show a closed circuit. If it doesn't, either the fan isn't generating sufficient pressure or the switch has failed.

Replacement Considerations

Not all condensing boiler air pressure switches are interchangeable, even within the same boiler brand. Switches are calibrated to specific pressure thresholds that match the fan output and flue system design of particular boiler models.

Using an incorrect switch might create a situation where the boiler operates unsafely. A switch that closes at too low a pressure might allow ignition when airflow is insufficient. One that requires too much pressure might prevent the boiler from firing even when everything else works correctly.

Always match replacement switches to the manufacturer's specifications. The part number matters. Generic replacements exist for some common models, but verify compatibility before installation.

Quality varies significantly among replacement parts. Original equipment manufacturer (OEM) switches typically offer better reliability and longer service life than budget alternatives. Given that labour costs for replacement often exceed parts costs, choosing a reliable switch makes economic sense.

When sourcing replacement components, consider suppliers that specialise in heating equipment. Pressure switches from manufacturers like Honeywell and quality components for systems from Andrews or Halstead ensure compatibility with major boiler models.

Installation Best Practices

Replacing an air pressure switch requires attention to several details that affect long-term reliability.

Routing the sensing tube properly prevents problems. The tube should slope gently downward from the switch to the fan connection, allowing condensate to drain toward the fan rather than pooling in the tube. Avoid creating low spots where water can accumulate.

Mount the switch in the correct orientation. Most switches have a specific up-down orientation that affects how condensate drains away from the sensing mechanism. Installing it sideways or upside down can trap water and cause premature failure.

Ensure electrical connections are clean and tight. Corroded or loose connections create intermittent faults that are difficult to diagnose. Some switches use spade terminals that should snap firmly into place. Others use screw terminals that require proper torque.

After installation, test the complete ignition sequence multiple times. Watch for smooth, consistent operation. The boiler should progress from fan startup through ignition without hesitation or multiple attempts.

Preventive Maintenance Strategies

Regular maintenance extends pressure switch life and reduces unexpected failures. The key is addressing the environmental factors that cause deterioration.

Annual boiler services should include inspection of the sensing tube and switch. Remove the tube and check for blockages. Clean or replace it if necessary. This simple step prevents many air pressure switch faults.

Check the condensate drain system during service visits. A blocked condensate trap can cause water to back up into areas where it shouldn't be, including around the pressure switch and sensing tube. Proper drainage keeps these components dry.

Monitor boiler cycling frequency. Units that short-cycle due to oversizing or poor system design put extra wear on all components, including pressure switches. Addressing the root cause of excessive cycling protects the entire system.

Keep the boiler room or cupboard well-ventilated and dry. Excessive humidity accelerates corrosion of electrical contacts inside switches. Good ventilation also helps the boiler operate more efficiently overall.

For systems with particularly hard water or aggressive condensate chemistry, consider more frequent inspection intervals. Some installations create harsher conditions that accelerate component wear.

Integration With Modern Boiler Controls

Contemporary condensing boilers use increasingly sophisticated control systems that interact with pressure switches in complex ways. Understanding these relationships helps with both diagnosis and system optimisation.

Many newer boilers monitor how long the fan runs before the pressure switch closes. If this time exceeds expected parameters, the control board may flag a developing problem before complete failure occurs. This predictive capability reduces emergency breakdowns.

Some systems adjust fan speed based on flue length and configuration, which changes the pressure characteristics the switch must respond to. These modulating fans require pressure switches with specific response curves matched to the control strategy.

Smart controls from manufacturers like EPH Controls can log pressure switch behaviour over time, revealing patterns that indicate developing issues. This data helps distinguish between switch failures and problems elsewhere in the system.

Integrated diagnostics often differentiate between various pressure-related faults. A control board might distinguish between "pressure switch didn't close," "pressure switch stuck closed," and "pressure switch opened during operation." Each point refers to different underlying causes.

The Broader System Context

Air pressure switches don't operate in isolation. Their performance depends on and affects other system components in ways that matter for overall reliability.

The fan itself must generate adequate pressure for the switch to respond. Fan bearings wear over time, reducing speed and pressure output. A marginal fan might cause intermittent pressure switch faults even when the switch itself is fine. Quality pumps from Grundfos and Lowara ensure consistent system performance that reduces stress on all components.

Flue systems affect the pressure dynamics significantly. Longer flues, multiple bends, or partial blockages increase resistance, requiring the fan to work harder. This can push operating conditions outside the range the pressure switch was designed for.

The combustion chamber and heat exchanger conditions matter too. Soot buildup or scale formation restricts airflow, changing pressure patterns throughout the system. A pressure switch problem might actually be a symptom of poor combustion or maintenance neglect.

Even the gas valve interacts with the pressure switch operation. Some control sequences won't energise the gas valve until the pressure switch confirms adequate airflow. Understanding this sequence helps diagnose situations where multiple components appear to fail simultaneously.

When Professional Assessment Makes Sense

Whilst pressure switches are relatively simple components, the systems they protect are not. Several situations warrant professional evaluation rather than simple part replacement.

If a new switch fails quickly, something else is wrong. Repeated pressure switch failures indicate underlying problems with the fan, flue system, or condensate management that need proper diagnosis.

When fault codes point to pressure switch issues but the switch tests correctly, the problem lies elsewhere in the sensing circuit or control logic. Tracking down these issues requires an understanding of the specific boiler's control strategy.

Intermittent faults that come and go can be particularly challenging. These often involve marginal components that work sometimes but not others, or environmental factors that vary with weather or system demand.

If you're uncomfortable working with gas appliances or electrical systems, professional service is always the right choice. The modest cost of professional diagnosis is worthwhile insurance against incorrect repairs that could create safety hazards.

Ensuring Safe Operation

Condensing boiler air pressure switches represent a perfect example of how small components enable safe, efficient operation of complex heating systems. These unassuming devices prevent potentially dangerous conditions whilst remaining largely invisible during normal operation.

Understanding their function helps you recognise problems early, make informed decisions about repairs, and maintain systems for maximum reliability. Whether you're managing a commercial property with multiple boilers or maintaining residential heating equipment, knowledge of pressure switch operation reduces downtime and improves safety.

The key takeaways centre on prevention and proper diagnosis. Regular maintenance that keeps sensing tubes clean and checks switch operation catches most problems before they cause breakdowns. When failures do occur, systematic diagnosis that considers the entire system context leads to effective repairs rather than repeated parts replacement.

Quality matters in replacement components. Choosing switches from reputable manufacturers and ensuring proper specifications prevents premature failures and callbacks. The modest additional cost of quality parts pales compared to the expense and inconvenience of repeated service visits.

For those maintaining heating systems, keeping spare pressure switches for common boiler models in stock makes sense. The parts are relatively inexpensive and compact, but having them on hand dramatically reduces repair time when failures occur outside normal business hours.

As condensing boilers continue to dominate new installations and replacements, understanding components like air pressure switches becomes increasingly important. These units deliver impressive efficiency, but that performance depends on all safety and control components functioning correctly. For genuine condensing boiler air pressure switches and related components, Heating and Plumbing World stocks parts for all major boiler brands. Technical support for diagnosing air pressure switch faults and system issues is available. Get in touch for professional guidance.

The pressure switch sits at the heart of this safety system, quietly ensuring that every ignition sequence proceeds only when conditions are right for safe, efficient combustion.

-

-