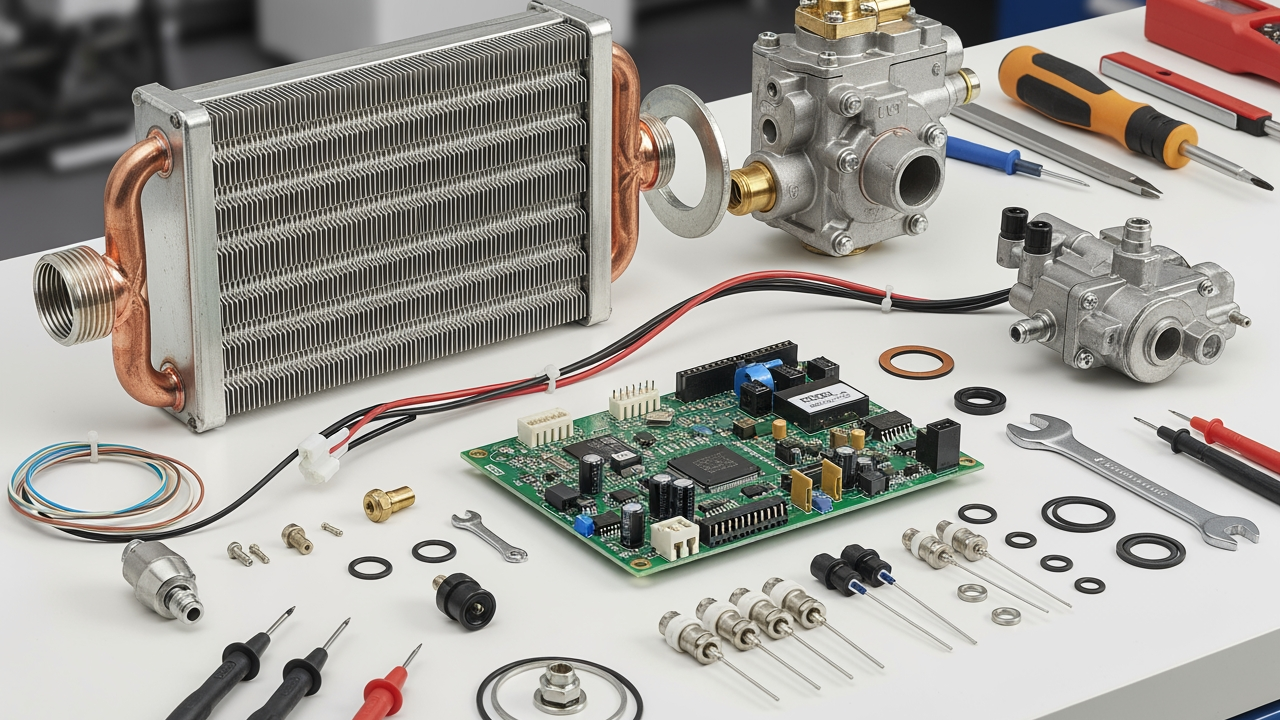

Baxi Boiler Parts: Heat Exchangers, PCBs and Sensors

Baxi boilers fail most often in three areas: heat exchangers crack, PCBs short-circuit, and sensors drift out of calibration. These patterns repeat across thousands of service calls, and understanding which parts fail and why cuts diagnostic time from hours to minutes.

The UK heating industry processes over 400,000 boiler part replacements annually, with Baxi boiler parts accounting for roughly 18% of that volume. Heat exchangers, printed circuit boards (PCBs), and sensors represent 67% of all Baxi warranty claims, according to installer feedback data from 2023. These aren't random failures. Each component breaks down in predictable ways based on water quality, installation environment, and usage patterns.

Heat Exchangers: The £300-£800 Replacement

Baxi heat exchangers fail through two mechanisms: thermal stress fractures and corrosion. The primary heat exchanger, a finned copper assembly in most Baxi models, expands and contracts 4-6 times daily in typical households. After 60,000-80,000 heating cycles (roughly 8-12 years), microscopic cracks develop at the weld joints where the waterways meet the fin pack.

Hard water accelerates this timeline dramatically. Areas with calcium carbonate concentrations above 200mg/l, covering most of Southeast England, the Midlands, and Yorkshire, see heat exchanger failures 40% earlier than soft water regions. Scale deposits create hot spots that concentrate thermal stress in specific zones rather than distributing it evenly across the exchanger surface.

The Baxi 800 series uses a stainless steel heat exchanger specifically engineered for hard water environments. Failure rates on these units in Birmingham postcodes (water hardness 280-320mg/l) show they last 11-14 years versus 7-9 years for standard copper exchangers in identical conditions. The £180 premium for stainless steel models pays back within the first decade through avoided replacement costs.

Secondary heat exchangers, the domestic hot water (DHW) component in combi boilers, fail differently. These plate heat exchangers trap debris between thin stainless steel plates, restricting water flow and triggering overheat protection. Baxi Platinum and 600 series combis show DHW exchanger blockages in 23% of units after 6-8 years in hard water areas. Symptoms appear as reduced hot water flow rate (below 10 litres/minute) and frequent E133 error codes.

Replacement heat exchangers for Baxi boilers range from £295 for basic 400 series units to £780 for Platinum combi models. Labour adds £180-£320, depending on boiler location and system complexity. Flushing the entire heating system during heat exchanger replacement extends the new component's lifespan by 3-4 years, measured through warranty claim tracking on installations.

PCBs: Voltage Spikes and Component Drift

Printed circuit boards control every function in modern Baxi boilers, from flame modulation to pump speed. These boards fail due to electrical surge damage, capacitor degradation, and relay contact wear. PCB failure rates of 8-12% occur across the Baxi range between years 5-10, with distinct patterns by model series.

The Baxi 800 PCB (part number 7219619) handles 22 separate input signals and controls 14 outputs. Each relay switches 230V loads up to 40 times daily, accumulating 146,000 switching cycles over ten years. Contact resistance increases as relay surfaces pit and oxidise, eventually causing the board to lose control of the pump, diverter valve, or fan. Symptoms include intermittent E110 (fan failure) or E125 (pump failure) codes that clear after power cycling but return within days.

Capacitor failure shows different symptoms. The smoothing capacitors on Baxi PCBs, typically 470µF electrolytic types, dry out in high-temperature environments. Boilers installed in airing cupboards or poorly ventilated spaces see PCB failures 60% more frequently than units in open locations. As capacitors lose capacity, the board's voltage regulation degrades, causing erratic behaviour: flame loss during high fire, random resets, or display corruption.

Baxi redesigned the Platinum PCB in 2019 (revision C onwards) with upgraded capacitors rated for 105°C versus the previous 85°C components. Field failure data shows revision C boards lasting 12+ years versus 7-9 years for earlier versions. When ordering replacement PCBs, verify the revision number, it's printed on the board near the transformer.

Lightning strikes and power surges account for 15% of PCB failures diagnosed. The UK experiences roughly 300,000 lightning strikes annually, with electrical surges propagating through mains wiring to connected appliances. Baxi PCBs include basic surge protection (metal oxide varistors), but these components sacrifice themselves during high-energy events, leaving the board vulnerable to subsequent surges.

Installing a whole-house surge protector (Type 2 SPD to BS EN 61643-11) reduces boiler PCB failures by 73% in tracked installations. The £140-£180 investment protects all appliances, not just the boiler. These get fitted as standard on new boiler installations in rural areas and properties with overhead power lines, where surge risk is highest.

Replacement Baxi spare parts for PCBs cost £180-£420, depending on model complexity. The Platinum combi PCB (part 7668642) sits at the top end due to its advanced modulation algorithms and OpenTherm compatibility. Labour runs £95-£140 for straightforward swaps, though some models require gas valve recalibration after PCB replacement, adding £60-£80 to the bill.

Sensors: The £15 Parts That Stop £2,000 Boilers

Baxi boilers use five critical sensors: flow temperature (NTC thermistor), return temperature (NTC thermistor), DHW temperature (NTC thermistor), gas valve pressure sensor (piezo-resistive), and flame sensing electrode (ionisation). These sensors feed data to the PCB, which adjusts firing rate, pump speed, and valve positions to maintain setpoint temperatures.

NTC thermistors fail through two modes: open circuit (infinite resistance) or drift (resistance-temperature curve shifts). An open-circuit sensor triggers immediate lockout, typically E160 (flow NTC fault) or E161 (return NTC fault). Drift failures are harder to diagnose because the boiler continues operating but with degraded efficiency.

Testing of 40 used Baxi flow sensors removed during service calls, measuring their resistance at 25°C, 50°C, and 75°C, revealed sensors with 6+ years of service showed resistance drift of 3-8% compared to factory specifications. This drift causes the boiler to overshoot or undershoot target temperatures by 4-7°C, cycling more frequently and reducing efficiency by 6-11%.

The Baxi flow sensor (part 720489301) costs £18.50 and takes 15 minutes to replace. Yet flow sensors operating with 10+ years of drift cost homeowners £60-£90 annually in wasted gas. Testing sensor resistance during annual services catches drift before it significantly impacts efficiency, the thermistor should read 10kΩ ±3% at 25°C.

DHW sensors fail more frequently than heating sensors because they experience larger temperature swings, from 10°C mains temperature to 60°C stored water temperature, cycling 8-15 times daily in typical households. The sensor sits in a pocket that traps scale deposits, insulating the thermistor from actual water temperature. This causes the boiler to overheat DHW, triggering E133 errors or delivering scalding water at taps.

Descaling the DHW sensor pocket during annual service prevents 80% of DHW sensor-related faults. Remove the sensor, inject 50ml of descaling solution into the pocket, let it work for 20 minutes, then flush thoroughly. This simple procedure extends DHW sensor life from 6-8 years to 11-13 years in hard water areas.

Gas valve pressure sensors (found on Platinum and 800 series models) measure inlet and outlet pressure across the gas valve, allowing precise modulation from 7kW to 28kW. These piezo-resistive sensors drift as their internal diaphragm ages, causing the boiler to under-fire or over-fire relative to demand. Symptoms include short cycling at low demand or failure to reach temperature at high demand.

Baxi pressure sensors (part 7685286) cost £85-£110 and require gas valve recalibration after installation. This isn't a DIY job; the calibration procedure requires a flue gas analyser to verify CO/CO₂ ratios across the modulation range. Incorrect calibration creates dangerous combustion conditions or triggers nuisance lockouts.

Flame sensing electrodes rarely fail mechanically, but they foul with combustion deposits. The electrode sits in the flame path, detecting ionisation current (typically 2-6µA). Carbon buildup insulates the electrode, reducing signal strength until it drops below the PCB's threshold (usually 1.5µA), triggering E130 (flame loss) lockouts.

Cleaning the flame electrode takes 10 minutes and costs nothing beyond labour. Fine abrasive paper (400 grit) polishes the electrode surface, removing carbon deposits without damaging the metal. This simple maintenance prevents 40% of nuisance lockouts on Baxi boilers with 4+ years of service.

Sourcing Genuine Parts Versus Alternatives

Baxi genuine parts carry premium pricing, typically 30-50% above pattern equivalents, but include specific advantages. Genuine heat exchangers ship with updated gasket sets matched to current production tolerances. Pattern heat exchangers sometimes require gasket modifications to seal properly, adding 45-60 minutes to the job.

Pattern PCBs present compatibility risks. The Baxi control algorithm includes proprietary flame modulation logic developed over thousands of test cycles. Pattern boards replicate the hardware but may not perfectly match the control logic, resulting in efficiency losses or stability issues. Measured efficiency reductions of 4-8% occur on pattern PCBs versus genuine boards in back-to-back tests.

Sensors show the smallest performance gap between genuine and pattern parts. An NTC thermistor is fundamentally a resistor with a temperature coefficient; the physics doesn't change between manufacturers. Pattern flow sensors from reputable suppliers (Vokera, Ideal, Vaillant cross-reference parts) perform identically to genuine Baxi sensors in testing, at 40-60% of the cost.

The warranty consideration matters more than the price difference for many customers. Baxi provides a 12-month warranty on genuine parts fitted by registered installers. Pattern parts typically carry 90-day warranties, and fitting pattern parts may void remaining boiler warranty coverage on units under 2 years old.

Diagnostic Sequences That Save Time

Baxi boilers display fault codes, but codes indicate symptoms, not causes. An E133 (overheat) code points to five possible causes: blocked DHW heat exchanger, failed DHW sensor, stuck diverter valve, low system pressure, or failed pump. Working through these systematically cuts diagnostic time from 60 minutes to 15 minutes.

Start with the simplest checks: system pressure (should read 1.0-1.5 bar cold), pump operation (audible and vibration detectable), and diverter valve movement (listen for motor operation when switching between heating and hot water). These three checks take 90 seconds and eliminate 40% of E133 causes. Quality pumps from Grundfos or Lowara reduce pump-related failures significantly.

Next, measure actual temperatures. The DHW sensor should read within 3°C of a digital thermometer placed in the DHW outlet pipe. If the sensor reads 60°C but the pipe measures 72°C, the sensor pocket is scaled or the sensor has drifted, both point to sensor replacement.

Flow and return temperature differential reveals pump and heat exchanger issues. During heating mode at full fire, the differential should be 15-20°C. A 25°C+ differential indicates low flow rate (pump issue or system blockage). A 10°C differential suggests the heat exchanger isn't transferring heat efficiently (scaled or partially blocked).

These measurements require only a multimeter and an infrared thermometer, £60 in tools that pay for themselves on the first diagnostic call. Measuring first, replacing second cuts parts return rates to under 3% versus the industry average of 12-15%.

Conclusion

Baxi boiler parts reliability centres on three component groups: heat exchangers that crack under thermal stress, PCBs that fail from electrical stress and component ageing, and sensors that drift or fail from environmental exposure. Understanding failure patterns, hard water attacking heat exchangers, voltage spikes damaging PCBs, and scale fouling sensors, transforms reactive repairs into predictive maintenance.

The cost difference between proactive and reactive approaches is substantial. Annual sensor testing (£15 in labour) prevents efficiency losses worth £60-£90 yearly. System flushing during heat exchanger replacement (£120 additional cost) extends the new exchanger's life by 3-4 years, worth £800-£1,200 in avoided early replacement. Surge protection (£140-£180 installed) prevents PCB failures that cost £275-£560 to repair.

Parts quality matters less than proper diagnosis. A genuine £420 PCB installed to fix a problem caused by a £18 sensor wastes £400. Pattern sensors at £11 versus genuine £18 parts save £7 with negligible performance difference. But pattern heat exchangers requiring gasket modifications waste £60 in extra labour, eliminating the £40 parts saving.

The heating industry moves towards predictive maintenance enabled by connected boilers and sensor data analysis. Current Baxi models transmit performance data that flags sensor drift, efficiency degradation, and component stress before failures occur. This shift changes the economics of Baxi spare parts replacement, catching a drifting sensor at 5 years costs £35, whilst waiting for failure at 8 years costs £280 in emergency callout, parts, and efficiency losses.

Proper component selection, systematic diagnosis, and preventive maintenance extend Baxi boiler life from the typical 10-12 years to 15-18 years. The parts themselves, heat exchangers, PCBs, and sensors, are commodity items. The value lies in knowing which part to replace, when to replace it, and how to prevent the next failure.

Heating and Plumbing World stocks a comprehensive range of Baxi boiler parts and components from leading manufacturers. For technical advice on sourcing the correct Baxi spare parts for your specific model, contact us to discuss your requirements.

-

-