Boiler Condensate Neutraliser Granules: pH Balance Products

Modern condensing boilers work brilliantly for energy efficiency, but they create a problem that catches many property owners off guard: acidic condensate. This wastewater, with a pH often between 2.0 and 4.0, can corrode pipes, damage drainage systems, and breach building regulations if discharged untreated. Countless cases show that neglecting this issue leads to expensive repairs and compliance headaches.

The solution? Condensate neutraliser granules. These pH-balancing products transform acidic discharge into safe, neutral water that meets regulatory standards. Understanding how they work and when you need them can save thousands in potential damage whilst keeping your heating system compliant.

What Makes Boiler Condensate So Acidic?

When condensing boilers extract heat from flue gases, they produce condensate as a byproduct. This liquid contains carbonic, nitric, and sulphuric acids formed during the combustion process. The pH level typically sits around 3.0 to 4.0, making it roughly as acidic as vinegar or orange juice.

That might not sound dramatic until you consider what happens when this acidic water flows through your drainage system daily. Plastic pipes can withstand it reasonably well, but older metal pipes, concrete drainage systems, and even some modern materials deteriorate over time. Property inspections reveal cases where untreated condensate ate through copper pipes in under five years.

The volume matters too. A typical domestic condensing boiler produces between 2 to 3 litres of condensate per hour during operation. Commercial systems generate far more. Over a heating season, that's thousands of litres of acidic water flowing through your drainage infrastructure.

When Building Regulations Require Neutralisation

UK Building Regulations don't mandate neutralisation for every installation, but specific circumstances trigger the requirement. Understanding these situations prevents non-compliance issues during inspections or property transactions.

Commercial and industrial installations almost always require neutralisation. Any boiler or system of boilers with a combined output exceeding 50kW typically needs condensate treatment before discharge. This threshold catches most commercial properties, from small office buildings to large industrial facilities.

Older drainage systems present another scenario where neutralisation becomes necessary. Properties with cast iron, copper, or concrete drainage pipes need protection from acidic condensate. Many pre-1970s buildings fall into this category, though some newer developments with specific drainage materials do too.

Special Installation Requirements

Septic tank systems require careful consideration. The acidic condensate can disrupt the bacterial balance essential for septic tank operation. Water authorities and environmental regulators often specify neutralisation for properties not connected to mains drainage.

Sensitive discharge locations trigger requirements as well. If condensate discharges into soakaways, surface water drains, or environmentally sensitive areas, neutralisation protects local ecosystems and water quality.

How Neutraliser Granules Actually Work

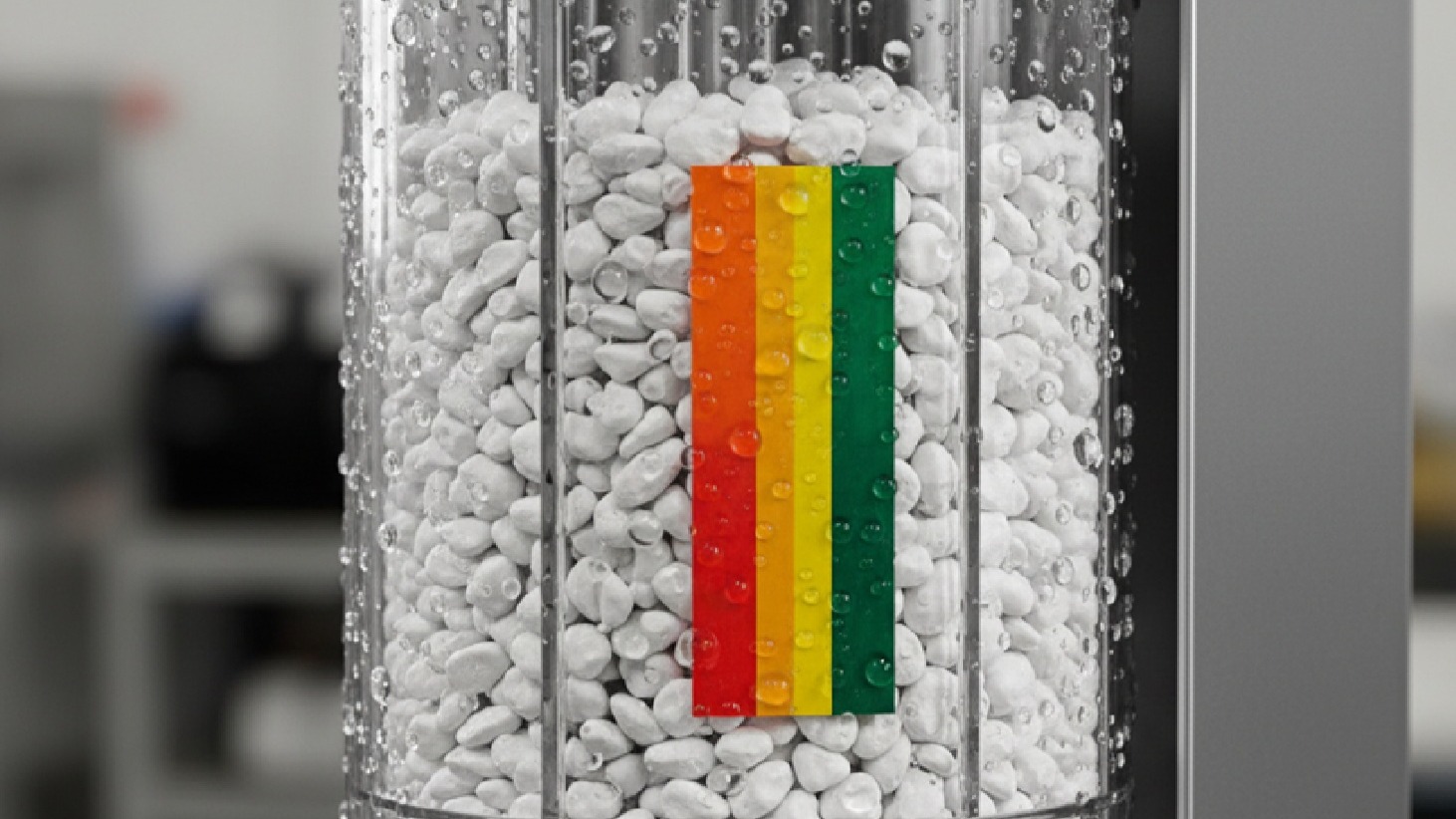

The chemistry behind condensate neutraliser granules is straightforward yet effective. These granules typically contain alkaline materials like calcium carbonate, magnesium oxide, or dolomitic limestone. When acidic condensate flows through them, a neutralisation reaction occurs.

The acidic water dissolves small amounts of the alkaline material, raising the pH level towards neutral (pH 7.0). This reaction happens gradually and continuously as condensate passes through the neutraliser unit. The granules don't need electricity or complex mechanisms, just contact time between the acidic water and alkaline medium.

Calcium carbonate granules remain the most common choice. They're cost-effective, widely available, and produce calcium bicarbonate as a byproduct, which poses no environmental concerns. The reaction rate suits most domestic and light commercial applications perfectly.

Magnesium oxide alternatives work faster and handle higher acid loads. Commercial installations with multiple boilers often use these because they neutralise more condensate per kilogram of material. They're more expensive initially but last longer in high-demand situations.

The granules gradually dissolve during use, which means they need a periodic condensate neutraliser refill. How often depends on boiler output, operating hours, and the neutraliser unit's capacity. Most domestic installations need refilling every 12 to 24 months, whilst commercial systems might require attention every 6 to 12 months.

Choosing the Right Neutraliser System

Selecting an appropriate neutraliser involves matching the system capacity to your boiler output and usage patterns. Under-sized units require frequent maintenance and risk discharge compliance failures. Oversized systems waste money without providing additional benefits.

Calculate your condensate production first. A 24kW domestic boiler running 8 hours daily produces roughly 16 litres of condensate per day. Over a year, that's approximately 5,840 litres. Your neutraliser needs the capacity to handle this volume between service intervals.

Consider the installation location carefully. Neutraliser units need gravity drainage, so they typically sit lower than the boiler's condensate outlet. Space constraints in plant rooms or boiler cupboards sometimes dictate which unit designs work practically. Various Altecnic expansion vessels and accessories complement condensate management systems in tight spaces.

Regulatory and Application Considerations

Check discharge regulations for your specific location. Some water authorities have particular requirements about pH levels or testing frequencies. Your neutraliser system should include sampling points for testing if regulations require periodic verification.

Match granule type to your application. Standard calcium carbonate works for most domestic situations. Commercial installations benefit from faster-acting magnesium oxide formulations, especially when multiple boilers discharge into a shared neutraliser.

Installation Best Practices That Prevent Problems

Proper installation determines whether your neutraliser system works reliably or creates maintenance headaches. Remedying poorly installed systems shows how simple oversights cause recurring issues.

Position the unit correctly in relation to your boiler. The condensate pipe must slope continuously downward from the boiler to the neutraliser without any dips or horizontal sections where water can pool. Trapped water in cold areas freezes during winter, blocking drainage and potentially damaging the boiler.

Size the pipework appropriately. Condensate pipes should be at least 22mm in diameter for domestic boilers, increasing to 32mm or larger for commercial installations. Under-sized pipes restrict flow and increase freezing risk. Many manufacturers, including Grundfos, provide specific guidance for their boiler models.

Critical Installation Details

Include an air break where condensate enters the neutraliser. This prevents siphoning and ensures the boiler's condensate trap maintains its water seal. Without this detail, combustion gases can escape through the condensate pipe, creating safety hazards and efficiency losses.

Provide access for maintenance. The neutraliser unit needs regular inspection and granule replacement. Installing it in an inaccessible location guarantees it won't receive proper maintenance. Position units where you can easily remove the lid, check granule levels, and replace media without major disruption.

Ensure proper sealing of all connections. Leaking condensate creates water damage and wastes the neutralisation treatment. Use appropriate jointing compounds for plastic pipes and ensure compression fittings are properly tightened. Quality plumbing fittings ensure leak-free connections.

Maintenance Requirements and Schedules

Regular maintenance keeps neutraliser systems performing reliably. The primary task involves monitoring granule levels and performing condensate neutraliser refill when needed.

Check granule levels quarterly for domestic installations, monthly for commercial systems. Most units have inspection windows or translucent chambers showing media depth. When granules dissolve to roughly one-third of their original depth, schedule a refill.

Test discharge pH periodically, especially for commercial installations or where regulations require documentation. Simple litmus paper provides a quick indication, whilst digital pH metres offer precise readings. Discharge pH should measure between 6.0 and 8.0 after neutralisation.

Replace granules completely rather than topping up partially depleted media. Old granules may have compacted or become coated with mineral deposits, reducing effectiveness. Complete replacement ensures optimal performance and predictable service intervals.

Documentation and Compliance

Document all maintenance activities, particularly for commercial properties. Record dates of granule replacement, pH test results, and any system modifications. This documentation proves compliance during building inspections and supports environmental management protocols.

Budget for ongoing media costs. Condensate neutraliser granules typically cost £15-40 per refill for domestic systems, £50-150 for commercial installations. Factor these recurring costs into heating system operating budgets to avoid maintenance deferrals.

Signs Your Neutraliser Needs Attention

Several indicators suggest your neutraliser requires service or troubleshooting. Recognising these signs prevents system failures and compliance issues.

Visible granule depletion through inspection windows provides the most obvious warning. When media depth drops significantly, schedule a refill before complete exhaustion allows acidic discharge.

Unusual odours around the neutraliser unit can indicate stagnant water or bacterial growth. This happens when condensate flow stops for extended periods or when drainage becomes partially blocked. Flush the system and check for proper flow.

Boiler lockouts or drainage issues might trace to neutraliser blockages. Granule fines can accumulate downstream, restricting flow. Some installations benefit from in-line strainers to catch these particles before they cause problems.

pH test failures indicate insufficient neutralisation capacity. Either the granules have depleted beyond effective levels, or condensate production exceeds system capacity. Test before and after the neutraliser to isolate the issue.

Cost Considerations and Economic Impact

Understanding total ownership costs helps evaluate neutraliser investments properly. Initial equipment costs represent just one component of long-term expenses.

Basic neutraliser units cost £80-200 for domestic installations, £300-800 for commercial systems. Add installation labour (£150-400), initial granule fill (£20-60), and any drainage modifications needed.

Annual operating costs include granule replacement (£15-150 depending on system size) and periodic testing supplies (£10-30). Commercial properties may need professional service contracts (£100-300 annually), ensuring compliance and documentation.

Compare these costs against potential damage from untreated condensate. Replacing corroded drainage pipes costs £1,000-5,000, depending onthe extent and accessibility. Regulatory penalties for non-compliant discharge range from warnings to substantial fines.

Property value implications matter during sales or refinancing. Building control compliance documentation, including proper condensate treatment, increasingly influences property transactions. Missing or inadequate systems create negotiation points that reduce sale prices or delay completions.

Environmental Responsibilities Beyond Compliance

Meeting minimum regulatory requirements represents just the baseline. Responsible condensate management protects local water quality and ecosystems whilst demonstrating environmental stewardship.

Untreated acidic condensate entering surface water systems or soakaways acidifies soil and groundwater. This affects plant life, aquatic organisms, and the broader ecosystem balance. Proper neutralisation prevents these impacts entirely.

The materials used in neutralisation themselves carry environmental considerations. Calcium carbonate and magnesium oxide occur naturally and break down into environmentally benign compounds. The resulting neutralised discharge contains minerals already present in natural water systems at safe concentrations.

Commercial properties with environmental management systems or sustainability certifications should document condensate treatment as part of their water management protocols. This demonstrates due diligence and supports broader environmental commitments.

Integrating Neutralisers with Modern Heating Systems

Contemporary heating installations increasingly combine multiple technologies, condensing boilers, thermal stores, heat pumps, and renewable systems. Condensate management must accommodate these complex arrangements.

Multiple boiler installations require appropriately sized shared neutralisers or individual units for each boiler. Calculate total condensate production across all units and select capacity accordingly. Systems incorporating Halstead or similar commercial boilers need careful capacity planning.

Cascade systems with modulating boilers produce variable condensate volumes. The neutraliser must handle peak production during maximum demand whilst remaining effective during low-flow periods. This requires careful specification and possibly a larger capacity than simple calculations suggest.

Complex System Configurations

Heat pump integration with backup condensing boilers creates intermittent condensate production patterns. The neutraliser granules remain effective during idle periods, but ensure the system design prevents stagnant water issues that could cause odours or bacterial growth.

Renewable energy combinations often include thermal storage from manufacturers like Gledhill or Kingspan. These systems might reduce boiler running hours, decreasing condensate production but extending intervals between granule replacements. Adjust maintenance schedules accordingly rather than following generic recommendations.

Selecting Quality Products for Reliable Performance

The neutraliser market includes products ranging from basic functional units to sophisticated systems with monitoring capabilities. Quality differences significantly affect long-term reliability and maintenance requirements.

Construction materials determine longevity. High-density polyethene chambers resist chemical attack and physical damage better than cheaper alternatives. Stainless steel fittings outlast brass or plastic connections in commercial environments.

Chamber design affects neutralisation efficiency. Units with baffles or media baskets ensure condensate contacts granules thoroughly rather than channelling through. This maximises media utilisation and extends replacement intervals.

Capacity markings and inspection windows simplify maintenance. Clear minimum fill indicators and transparent sections let you check granule levels without opening the unit. These features reduce maintenance time and improve compliance with service schedules.

Manufacturer Support and Standards

Manufacturer support matters when problems arise. Established brands provide technical assistance, replacement parts availability, and documented compliance with UK regulations. Products from trusted manufacturers like Danfoss demonstrate reliable performance across their ranges.

Certification and standards compliance ensure products meet regulatory requirements. Look for units tested to relevant British or European standards. Documentation supporting building control approval simplifies installation sign-off.

Making Neutralisation Work for Your Specific Situation

Every property presents unique circumstances affecting neutraliser selection and installation. Tailoring the solution to your specific needs ensures optimal performance and value.

Domestic properties with single condensing boilers need straightforward systems sized for annual granule replacement. Prioritise easy access for homeowner inspection and simple maintenance procedures. The system should work reliably without requiring specialist knowledge.

Commercial buildings demand robust systems handling higher volumes with documented maintenance schedules. Consider units with monitoring capabilities that alert facility managers when service becomes due. Integration with building management systems adds convenience for larger properties.

Industrial applications might produce condensate with additional contaminants beyond standard combustion acids. Specialist neutraliser formulations handle these situations, but require proper specification based on fuel type and combustion conditions.

Retrofit and New Construction Approaches

Retrofit situations often present space constraints and existing drainage limitations. Compact neutraliser designs and flexible pipe configurations help overcome these challenges. Sometimes, creative routing or pump-assisted drainage solves difficult installations where gravity drainage proves impossible. Polypipe systems offer flexible drainage solutions.

New construction offers opportunities to design optimal condensate management from the outset. Coordinate with architects and drainage designers to position neutralisers conveniently, provide adequate access, and integrate with overall building services strategies.

Protecting Your Heating Investment

Condensate neutraliser granules perform a simple but essential function in modern heating systems. They protect drainage infrastructure, ensure regulatory compliance, and prevent environmental damage from acidic discharge. The modest investment in equipment and maintenance delivers substantial value through avoided problems and peace of mind.

Selecting the right system requires understanding your boiler's output, condensate production, and site-specific requirements. Proper installation ensures reliable operation, whilst regular condensate neutraliser refill keeps the system performing effectively year after year. Quality products from established manufacturers provide the reliability and support needed for long-term success.

Whether you're installing a new condensing boiler, upgrading an existing system, or ensuring compliance in a commercial property, condensate neutralisation deserves proper attention. The consequences of neglecting this aspect of heating system design range from expensive repairs to regulatory penalties. Getting it right from the start prevents these problems entirely whilst demonstrating responsible environmental stewardship.

For neutraliser systems and granules suitable for applications from small domestic installations to large commercial properties, Heating and Plumbing World stocks products from manufacturers known for quality and reliability. Need technical advice on selecting the right solution for your specific needs or guidance on maintenance schedules? Get in touch with heating specialists who understand condensate management and regulatory compliance.

-

-