Boiler Efficiency Ratings Explained: SEDBUK and ErP Labels

Shopping for a new boiler means confronting efficiency ratings that look like alphabet soup. Two labels matter: SEDBUK and ErP. Understanding them saves you hundreds of pounds annually and prevents the frustration of buying an underperforming system.

What SEDBUK Ratings Actually Measure

SEDBUK (Seasonal Efficiency of Domestic Boilers in the UK) measures how much of your fuel converts to usable heat over an entire heating season. A boiler rated at 90% SEDBUK converts 90p of every pound spent on gas into heat for your home. The remaining 10p escapes through the flue or gets lost in the system.

The rating accounts for conditions including cold starts, cycling on and off, and varying outdoor temperatures. This differs from laboratory tests that measure peak performance under ideal conditions.

Modern condensing boilers typically achieve 88-94% SEDBUK ratings. Non-condensing boilers from the 1990s and early 2000s often rate between 65-75%. That 20-point gap translates to £200-400 extra on annual heating bills for an average three-bedroom home.

How ErP Labels Changed Boiler Standards

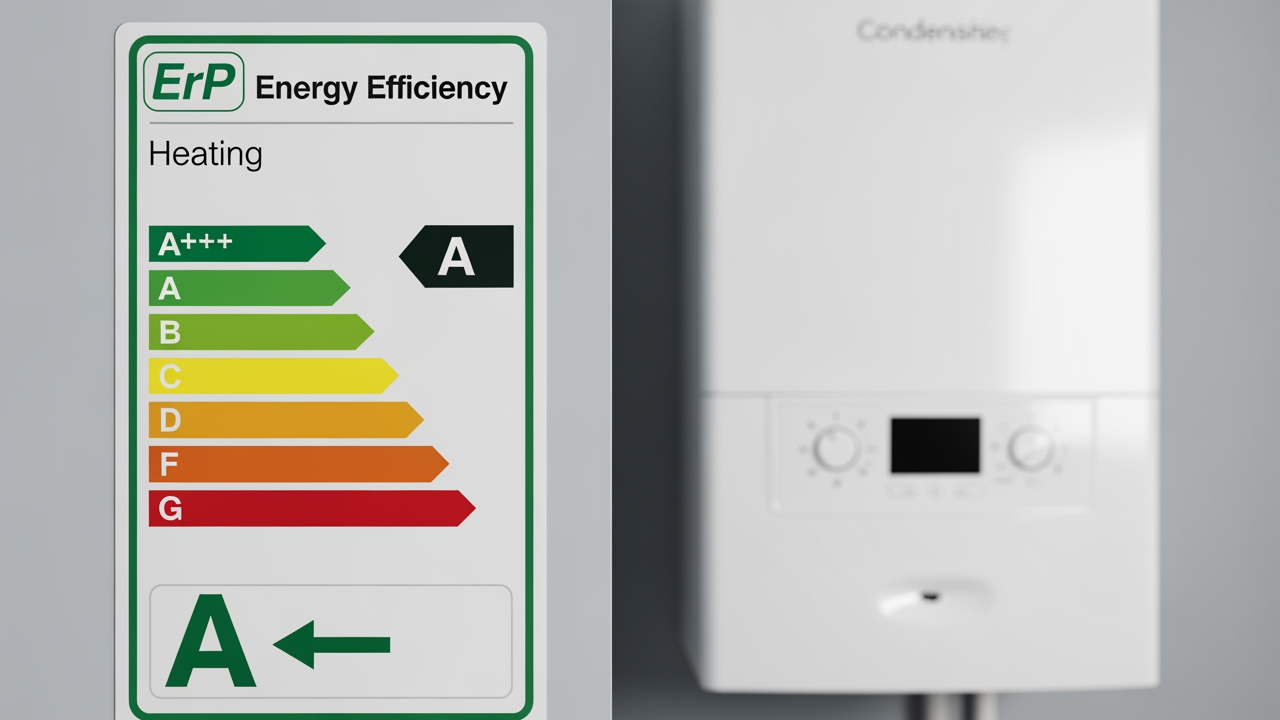

Energy-related Products (ErP) labels became mandatory in 2015 across the EU and UK. These colourful stickers rate boilers from A+++ (most efficient) to G (least efficient), similar to refrigerator labels.

ErP ratings don't replace SEDBUK; they complement it. Whilst SEDBUK gives a percentage, ErP considers the complete heating package: boiler efficiency, controls, and hot water storage. A 92% efficient boiler with poor controls might rate lower than an 88% efficient model with smart thermostats and optimised hot water cylinders.

The label breaks down into sections:

Heating Efficiency: Most condensing boilers achieve A-rated status (90%+). Some reach A+ through advanced heat exchangers that extract more energy from flue gases.

Hot Water Efficiency: This varies widely. Combi boilers providing instant hot water typically rate B or C. System boilers paired with well-insulated cylinders from Gledhill or Kingspan can achieve A ratings.

Sound Power: Measured in decibels. Useful if your boiler sits near bedrooms or living spaces. Most modern units operate at 40-50 dB, quieter than normal conversation.

The regulations banned the installation of new non-condensing boilers in most UK properties. Only condensing models meet minimum ErP standards, pushing the entire market toward higher efficiency.

Reading the Numbers: What Different Ratings Mean for Your Bills

A boiler rated at 70% efficiency wastes 30p of every pound spent on gas. At current prices (approximately 6p per kWh), a typical home using 15,000 kWh annually spends £900 on heating. That 70% boiler wastes £270.

Upgrade to a 90% efficient model and waste drops to £90, a £180 annual saving. Over the boiler's 15-year lifespan, that's £2,700 saved, easily covering the £2,000-3,000 installation cost.

The calculation shifts for larger homes. A four-bedroom detached property using 25,000 kWh annually saves £300 per year with the same efficiency upgrade. Payback happens within 7-10 years.

Smaller flats using 8,000 kWh save roughly £95 annually. The payback period extends to 20+ years, longer than most boiler lifespans. This explains why efficiency upgrades make less financial sense for small, well-insulated properties with low heating demands.

Why Two Different Rating Systems Exist

SEDBUK emerged in 1998 as a UK-specific standard. British engineers developed it to account for the country's climate, housing stock, and heating patterns. It became the industry benchmark for comparing boiler performance.

ErP launched across Europe to standardise energy labelling. The EU wanted consumers to compare heating systems as easily as washing machines or televisions. The colour-coded A-G scale achieves this better than percentage ratings.

Neither system replaced the other because they serve different purposes. SEDBUK provides technical accuracy for engineers calculating heat loss and sizing systems. ErP offers consumer-friendly comparison at the point of sale.

Manufacturers must display both ratings. The ErP label appears on showroom displays and marketing materials. SEDBUK data lives in technical specifications and boiler installation manuals.

Condensing vs Non-Condensing: The Efficiency Gap

Condensing boilers achieve high efficiency through a second heat exchanger that captures energy from water vapour in flue gases. When this vapour condenses back to liquid, it releases latent heat, energy that non-condensing boilers vent outside.

This process adds 10-15 percentage points to efficiency. A non-condensing boiler might achieve 78% efficiency. The same design with condensing technology reaches 90-92%.

The catch: condensing only works when return water temperatures stay below 54°C. Above this threshold, water vapour doesn't condense, and the boiler performs like a standard model. Oversized radiators from Myson or underfloor heating systems maintain lower return temperatures, maximising condensing operation.

Poorly designed systems with undersized radiators force higher flow temperatures. The boiler spends less time condensing, and efficiency drops below the rated figure. Systems achieving only 82% efficiency despite 92% SEDBUK ratings occur, the design, not the boiler, causes the shortfall.

What A+++ Ratings Actually Deliver

A+++ boilers don't exist in isolation. The rating requires a complete system: a highly efficient boiler, weather compensation controls, room thermostats, and optimised hot water storage.

Weather compensation adjusts boiler output based on outdoor temperature. On mild days, it lowers flow temperature, increasing condensing time and efficiency. During cold snaps, it raises output to maintain comfort. This dynamic control adds 3-5 percentage points to seasonal efficiency.

Smart thermostats from Honeywell or EPH Controls contribute another 2-4 points by preventing overheating and reducing cycling. Older mechanical thermostats have 1-2°C dead bands; rooms swing from 19°C to 23°C before the boiler responds. Modern digital controls maintain ±0.5°C accuracy, cutting wasted heat.

High-efficiency hot water cylinders with 50mm+ insulation lose less than 1 kWh daily to standing losses. Basic cylinders with 25mm foam lose 2-3 kWh. Over a year, this 2 kWh daily difference costs £40-50.

Combining these elements pushes system efficiency to 94-96%. The boiler itself might rate 92%, but the complete package achieves A+++ status. Installing a 92% boiler with basic controls only delivers B-rated performance.

How Controls Impact Your Actual Efficiency

Controls determine whether your boiler operates at rated efficiency or falls short. Three factors matter most:

Load compensation matches boiler output to heat demand. Without it, the boiler fires at full power until the thermostat is satisfied, then shuts off. This cycling wastes energy through repeated startups and heat loss during off periods. Load compensation modulates output continuously, maintaining steady operation in the condensing range.

Zoning divides the home into independently controlled areas. Heating unused bedrooms during the day wastes 15-20% of energy in typical homes. Programmable thermostatic radiator valves (TRVs) or multi-zone systems prevent this waste without occupant intervention.

Setback programming reduces temperature overnight and during absences. Each 1°C reduction cuts heating costs by 8-10%. Dropping from 21°C to 16°C overnight saves 40-50%, but only if the system recovers efficiently in the morning. Poorly timed setback causes morning boost periods that cancel savings.

Identical boilers can achieve 88% efficiency in one home and 76% in another. The difference comes entirely from the control strategy. The 88% system uses weather compensation and zoning. The 76% system relies on a single on/off thermostat.

SEDBUK Bands: What the Letters Mean

Boiler efficiency ratings translate to letter bands:

- A-rated: 90%+ (modern condensing boilers)

- B-rated: 86-90% (early condensing models)

- C-rated: 82-86% (efficient non-condensing or condensing with issues)

- D-rated: 78-82% (efficient non-condensing boilers)

- E-rated: 74-78% (standard non-condensing boilers)

- F-rated: 70-74% (older non-condensing models)

- G-rated: Below 70% (boilers 20+ years old)

Most boilers installed before 2005 rate D or below. The Building Regulations now require A-rated boilers for replacements in most situations. Exceptions exist for properties where condensate drainage proves impossible, though these cases are rare.

Checking your current boiler's rating takes 30 seconds. Find the model number on the front panel or inside the casing. Search "[manufacturer] [model] SEDBUK rating" to find the percentage. Anything below 80% costs you significant money annually.

When Higher Ratings Don't Matter

Efficiency obsession can override practical considerations. Three scenarios where chasing maximum ratings makes little sense:

Properties with minimal heating demand: A well-insulated flat using £300 annually on heating saves £30 per year, upgrading from 90% to 94% efficiency. The added cost of A+++ controls (£400-600) takes 15-20 years to recover.

Homes with imminent renovations: Installing an oversized boiler now, because you might add an extension later, wastes money. Oversized boilers cycle frequently, reducing efficiency below ratings. Size for current needs, then upgrade when you extend.

Properties with incompatible heating systems: Achieving A+++ ratings with old single-pipe radiator systems requires replacing the entire distribution network. The £8,000-12,000 cost for a typical home never pays back through efficiency savings alone. An A-rated boiler with existing radiators delivers 85-90% of the theoretical savings at 30% of the cost.

Focus on getting a properly sized, well-controlled A-rated system. The jump from A to A+++ costs £800-1,200 but saves only £30-50 annually in most homes.

How Manufacturers Game the Ratings

ErP testing happens under standardised conditions that don't reflect all homes. Manufacturers optimise for test parameters, sometimes at the expense of performance.

Test temperature assumptions: ErP ratings assume average outdoor temperatures of 8-10°C. Scottish homes experiencing colder winters see lower actual efficiency than southern properties. The rating doesn't account for this geographic variation.

Hot water testing: The standard assumes 200 litres of hot water usage daily. Families using 300+ litres find combi boilers deliver lower hot water efficiency than the label suggests. The boiler spends more time in less-efficient rapid heating mode.

Cycling losses: Laboratory tests use steady-state operation. Homes experience frequent on-off cycling, especially in mild weather. Cycling reduces efficiency by 3-8 percentage points, depending on boiler mass and control quality.

Actual efficiency in installed systems using heat metres and gas consumption data shows A-rated boilers typically deliver 85-90% seasonal efficiency, below their 92-94% laboratory ratings, but still substantially better than older models.

The gap doesn't indicate fraud. Testing standards must remain consistent for fair comparison. Labels show potential performance, not guaranteed results.

Choosing the Right Efficiency Level for Your Home

Match efficiency investment to your heating costs:

High heating users (£1,000+ annually): Maximise efficiency. Install A+ or A+++ systems with weather compensation and zoning. Payback happens within 5-8 years. Consider high-efficiency radiators to maintain low return temperatures.

Average users (£600-1,000 annually): A-rated boilers with good controls from Danfoss deliver optimal value. Add weather compensation if budget allows, but skip multi-zone systems unless your layout clearly wastes heat. Standard boiler thermostats provide adequate control.

Low users (under £600 annually): Basic A-rated systems suffice. Spending £1,000 extra on controls saves £40 annually, a 25-year payback. Invest in insulation instead; it delivers faster returns.

Consider replacement timing. Boilers typically last 12-15 years. If yours is 10+ years old and rated D or below, replacement makes financial sense even if still functioning. Waiting for complete failure often means emergency replacement with limited model choice.

The Hidden Costs of High Efficiency

A+++ systems introduce complexity that increases maintenance requirements:

Condensate drainage: Condensing boilers produce acidic water that needs drainage. Properties without nearby drains require condensate pumps costing £150-250. These pumps fail every 5-8 years, requiring replacement.

Additional controls: Weather compensation sensors, multiple zone valves, and smart thermostats create more failure points. Complex systems show 15-20% higher service callout rates versus basic setups.

Specialist servicing: Not all engineers understand advanced controls. Annual servicing costs £90-120 for standard boilers but £120-150 for systems with weather compensation and load management. The £30-40 annual difference offsets some efficiency savings.

Replacement parts: Proprietary controls cost more than standard components. A basic room thermostat costs £40-60. A weather compensation controller costs £150-250. When controls fail outside warranty, replacement eats into accumulated savings.

Factor £50-80 extra annual costs for A+++ systems versus basic A-rated setups. This reduces net savings from £80 to £20-30 in average homes, extending payback periods significantly.

Checking Your Boiler's Actual Performance

Ratings predict performance, but installation quality and system design determine actual efficiency. Three ways to verify your boiler delivers promised results:

Annual gas consumption: Read your metre on the same date each year. Divide annual kWh by heated floor area (square metres). Well-insulated homes use 50-80 kWh/m² annually. Poorly insulated properties use 100-150 kWh/m². If consumption exceeds expectations despite a high-efficiency boiler, investigate heating system balancing and insulation gaps.

Flue gas analysis: Annual servicing should include flue gas testing. Combustion efficiency above 90% indicates proper condensing operation. Results below 85% suggest problems: incorrect gas pressure, dirty heat exchangers, or excessive return temperatures.

Return temperature monitoring: Install a pipe thermometer on the boiler return pipe. During normal operation, return temperatures should stay below 55°C. Consistent readings above 60°C mean the system isn't condensing, regardless of boiler rating. This indicates oversized boilers, undersized radiators, or incorrect control settings.

Systems where 92% SEDBUK boilers delivered only 78-82% efficiency have been corrected with simple fixes, adjusting radiator lockshield valves, reducing boiler flow temperature, or adding weather compensation, restoring performance to 88-90%.

Conclusion

SEDBUK percentages tell you how much fuel becomes heat. ErP labels show how complete systems, boiler plus controls plus hot water storage, perform under standardised conditions. Both ratings matter, but neither guarantees results without proper installation and system design.

For most homes, an A-rated condensing boiler with weather compensation and zone control delivers the best balance of efficiency, cost, and reliability. Chasing A+++ ratings makes sense only for high heating users where £150+ annual savings justify added complexity and maintenance costs.

Your current boiler's efficiency matters more than splitting hairs between A+ and A+++. If you're running a D-rated or lower boiler, any modern condensing system cuts your heating bills by 20-40%. That's where the savings live, not in the difference between 92% and 94% efficiency.

Check your boiler's model number, look up its SEDBUK rating, and calculate your potential savings. Anything below 80% efficiency costs you serious money every winter. Upgrading pays for itself faster than expected, especially with energy prices unlikely to fall significantly in the coming years.

For comprehensive support on boiler efficiency ratings and selecting the right system for your home, Heating and Plumbing World offers expert guidance. Whether you need circulation pumps from Grundfos or replacement parts from Halstead Spares, this boiler efficiency guide helps you make informed decisions.

-

-