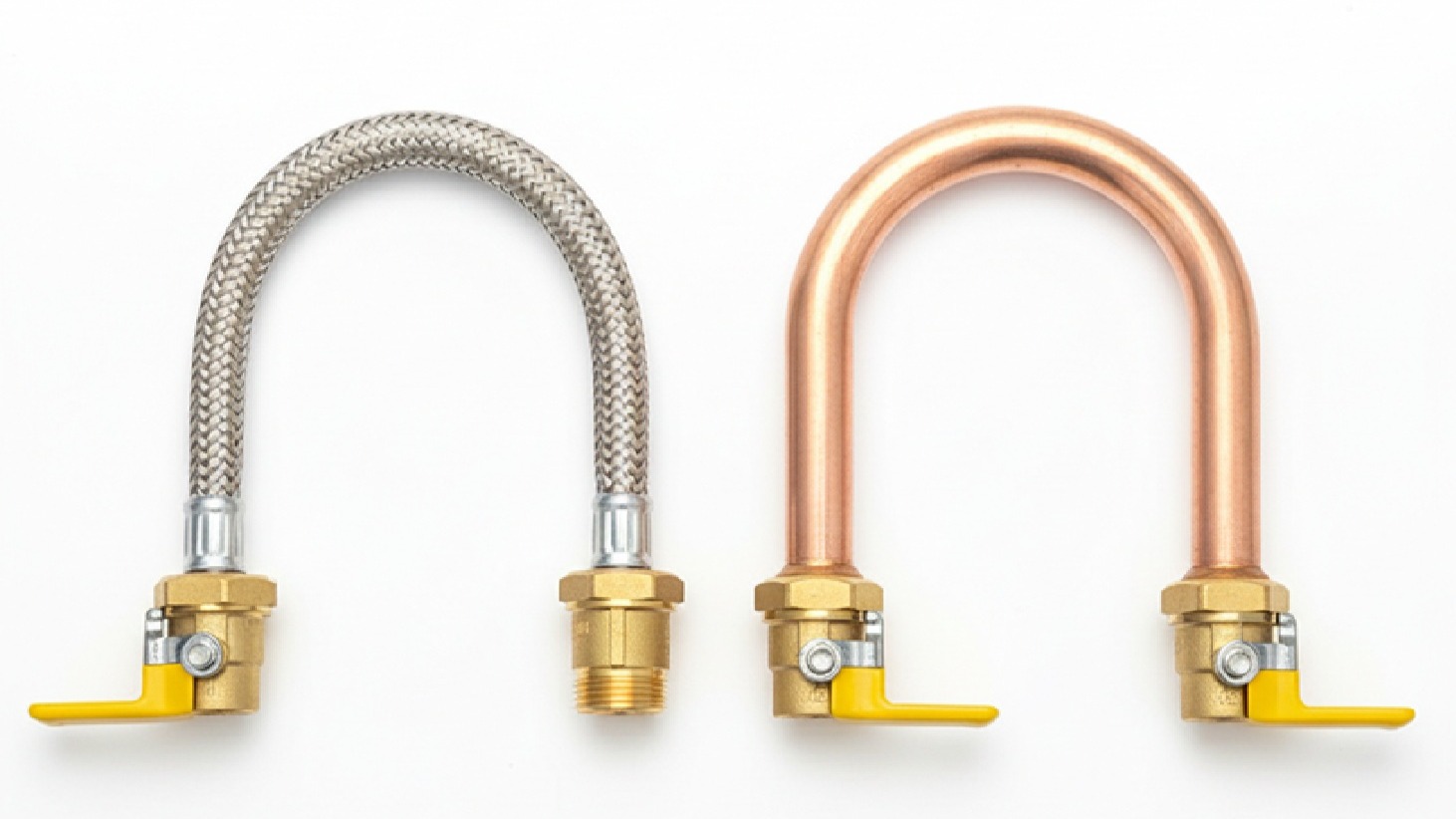

Boiler Filling Loop Replacement: Braided vs Rigid Types

A boiler filling loop might seem like a small component, but when it starts dripping water onto your kitchen floor at 6 am, it suddenly becomes the most important piece of kit in your home. We've replaced hundreds of these over the years, and the first question customers always ask is whether they should go for a braided or rigid replacement.

The choice matters more than you'd think. Pick the wrong type for your setup, and you'll be back under that boiler within months, dealing with the same leak or worse. Let's walk through exactly what you need to know to make the right decision the first time.

What Actually Goes Wrong With Filling Loops

Every filling loop eventually fails. The rubber seals inside the valves perish after years of pressure changes. The braided hoses develop tiny splits where they flex. Rigid copper loops crack at the compression joints when boilers vibrate during operation.

We see three main failure patterns. First, the isolation valves start weeping. You'll notice a small puddle forming under your boiler, usually getting worse when the heating fires up. Second, the hose itself develops pinhole leaks, often where it bends sharply or rubs against the boiler casing. Third, and most dramatically, the entire connection can blow off if the pressure relief valve fails and the system pressure spikes above 3 bar.

The average filling loop lasts 5-7 years before showing signs of wear. In hard water areas, that drops to 3-5 years as limescale accelerates seal degradation. We've pulled loops from 20-year-old boilers that looked like geological specimens, completely furred up inside.

Braided Filling Loops: The Flexible Option

Braided loops dominate the boiler filling loop replacement market for good reason. They're essentially reinforced rubber hoses with stainless steel mesh sleeves, connecting via standard 15mm compression fittings. The flexibility makes installation straightforward, especially in tight spaces where rigid pipework would require multiple joints.

The best braided loops use EPDM rubber cores. This synthetic rubber handles temperature swings from frozen condensate pipes to 80°C flow temperatures without degrading. The stainless steel braid prevents the hose from ballooning under pressure while allowing enough movement to absorb boiler vibrations.

Installation takes minutes rather than hours. You can bend the loop to fit awkward angles without special tools. This flexibility proves invaluable when working with older boilers where nothing quite lines up as it should. Quality braided loops from suppliers like Altecnic Ltd consistently outlast cheaper alternatives.

However, braided loops have limitations. The rubber eventually perishes, no matter the quality. UV light from nearby windows accelerates degradation. Sharp bends create stress points where leaks develop. And while the initial cost seems reasonable at £15-30, you'll likely replace it twice before a rigid loop would need attention.

Rigid Filling Loops: Built to Last

Rigid loops use solid copper pipe bent into shape, connected with compression fittings and incorporating isolation valves at each end. They look more professional and, when installed correctly, last significantly longer than braided alternatives.

The copper construction eliminates perishing concerns. A well-installed rigid loop can easily survive 15-20 years, often outlasting the boiler itself. The solid construction handles pressure spikes better, with no flexible sections to balloon or burst. In commercial settings where reliability trumps convenience, rigid loops remain the standard.

Installation demands more skill and time. You'll need pipe benders, cutting tools, and patience to create smooth bends without kinking the copper. Each joint must be perfectly aligned to avoid stress that leads to cracking. The initial parts cost runs higher too, typically £40-60 for quality components.

Space constraints can make rigid installation impossible. Modern combination boilers pack components so tightly that threading rigid pipework becomes a puzzle with no solution. Older system boilers with generous clearances suit rigid loops perfectly.

Making the Right Choice for Your System

Your boiler's location drives the decision more than any other factor. Tight cupboard installations almost always need braided loops. The flexibility allows routing around obstacles that would require multiple joints in rigid pipework. Each additional joint introduces another potential leak point, negating the longevity advantage of copper.

Water quality in your area matters too. Hard water accelerates seal degradation in both types, but braided loops suffer more. The limescale builds up where the rubber meets the metal fittings, creating gaps that eventually leak. Rigid loops handle hard water better, though the isolation valves still need occasional service.

Consider your long-term plans. If you're selling within five years, a quality braided loop makes sense. Planning to stay put? The extra investment in rigid pipework pays off through reduced maintenance. We've seen too many emergency callouts from failed braided loops to recommend them for forever homes.

System pressure plays a role too. Older boilers running at standard 1-1.5 bar suit either type. Modern high-efficiency boilers often run closer to 2 bar, putting more stress on braided components. Combination boilers with their rapid pressure changes particularly punish flexible connections. Systems from manufacturers like Andrews or Gledhill benefit from proper filling loop selection matched to their operating characteristics.

Professional Installation vs DIY

Replacing a filling loop sits within most competent DIYers' abilities, but several factors warrant professional installation. Gas Safe regulations don't specifically cover filling loops, but any work on gas boilers requires extreme caution. One wrong move could damage gas connections or create dangerous leaks.

The main challenge comes from accessing the connection points. Modern boilers cram components into impossibly tight spaces. What looks like a simple swap often requires removing multiple parts for access. We regularly attend callouts where DIY attempts created more problems than they solved.

Water damage from failed installations costs far more than professional fitting. A filling loop that blows off can dump litres of water per minute into your home. By the time you notice and shut off the mains, carpets, ceilings, and electrics may need replacing. Our installation includes pressure testing and checking all connections under operating conditions.

Professional installation also identifies underlying issues. That leaking loop might indicate excessive system pressure from a failed expansion vessel. Or the pipework configuration might create stress points, guaranteeing repeated failures. We spot these problems during filling loop replacement, saving future headaches.

Quality Components Make the Difference

Not all filling loops are created equal. Budget options from DIY stores use inferior materials that fail prematurely. The rubber perishes faster, the braiding corrodes, and the valves seize after minimal use. Spending an extra £10-15 on quality components from established manufacturers like Honeywell or Danfoss typically doubles the service life.

Look for WRAS approval on any loop you're considering. This certification confirms the materials won't contaminate your drinking water. Cheaper imports often lack this approval and may leach chemicals into your system. The few pounds saved aren't worth the health risks.

Isolation valve quality matters enormously. Cheap quarter-turn valves seize solid within years, making future maintenance difficult. Quality full-bore valves with removable handles stay operational far longer. When you need to drain the system for maintenance, working isolation valves save hours of frustration.

The connection type affects longevity, too. Compression fittings create reliable seals when properly installed, but require perfect alignment. Push-fit connections seem convenient but introduce another failure point. Quality fittings from reliable suppliers ensure long-term performance. We've removed countless push-fit loops where the O-rings degraded, causing persistent weeps.

Common Installation Mistakes to Avoid

Over-tightening compression fittings ranks as the most common DIY error. The olive only needs compressing enough to create a seal. Excessive force distorts the olive, creating gaps that leak immediately or develop over time. The fitting should feel firm but not require excessive force.

Kinking flexible loops during installation weakens the braiding and creates stress points. The loop should follow smooth curves without sharp bends. If you can't achieve the required routing without kinking, you need a longer loop or a different configuration.

Forgetting to check system pressure after installation causes premature failures. The loop might hold at 1 bar but leak at normal operating pressure. Always test at 1.5 times operating pressure and monitor for pressure drops indicating small leaks.

Using jointing compound on compression fittings often causes more problems than it solves. Modern olives create adequate seals without help. A compound can prevent proper compression and hide poor joint preparation. If a dry joint won't seal, the problem lies with component alignment or olive condition.

Maintenance Tips for Maximum Lifespan

Regular visual inspections catch problems early. Check monthly for signs of corrosion, weeping valves, or hose degradation. Green deposits around fittings indicate slow leaks that will worsen. White crusty deposits suggest limescale buildup requiring attention.

Exercise the isolation valves quarterly to prevent seizing. Turn them fully closed and open several times. If they feel stiff, a drop of penetrating oil on the spindle helps. Seized valves make emergency repairs difficult and often require complete loop replacement.

Monitor system pressure weekly. Frequent pressure drops indicate leaks somewhere in the system. The filling loop valves should remain closed during normal operation. If you're constantly topping up pressure, investigate the cause rather than accepting it as normal.

Keep the area around the loop clear and dry. Moisture accelerates corrosion, while clutter makes inspection difficult. We've seen loops fail prematurely because they sat in puddles from condensate pipe drips or washing machine overflows.

When to Call the Professionals

Some symptoms demand immediate professional attention. Water spraying from the loop requires shutting off both isolation valves and the mains supply immediately. The system pressure has likely exceeded safe limits, indicating expansion vessel or pressure relief valve failures.

Persistent pressure loss despite valve replacement suggests system-wide issues. The loop might function perfectly while hidden leaks elsewhere cause problems. Professional leak detection equipment saves time and prevents water damage from worsening.

Gas smells near the boiler require immediate action. While filling loops don't carry gas, DIY attempts sometimes disturb gas connections. Turn off the gas supply, open windows, and call Gas Safe engineers immediately. Never ignore gas odours or assume they're unrelated to recent work.

Repeated loop failures indicate installation or system problems. If you're replacing loops annually, something's wrong. High system pressure, vibration, or poor water quality might be the culprit. We diagnose root causes rather than repeatedly treating symptoms. Quality pumps from Grundfos and proper system components from Kingspan work together to maintain stable system pressure.

Choosing the Right Replacement

Choosing between braided and rigid filling loops comes down to your specific situation. Braided loops excel in tight spaces and temporary installations, while rigid copper provides superior longevity in accessible locations. Quality components and proper installation matter more than the type you choose.

The real key to avoiding repeated failures lies in understanding why the original loop failed. Address underlying pressure problems, water quality issues, or installation stress points before fitting the replacement. A £30 loop installed correctly outlasts a £60 loop fitted poorly every time.

Whether you tackle the job yourself or call professionals, don't ignore early warning signs. That tiny drip becomes a major flood surprisingly quickly. Regular maintenance and timely replacement prevent water damage that costs far more than any filling loop.

For quality boiler filling loop replacement components and expert advice on choosing the right type for your system, Heating and Plumbing World stocks trusted brands including flexible and rigid options. Pipe systems from Polypipe and quality fittings ensure reliable connections. Technical guidance on filling loop replacement procedures is available. Get in touch for professional support.

The right parts, properly installed, keep your heating system running reliably for years to come.

-

-