Boiler Ignition Electrodes: Cleaning and Replacement

Your boiler fires up dozens of times a day, and you probably never give it a second thought until it doesn't. That clicking sound when your heating kicks in? That's the ignition electrode doing its job, creating the spark that lights the gas and warms your home. When this small but critical component fails, you're left with no hot water, no heating, and often a hefty callout fee.

We've handled thousands of boiler repairs across the UK, and faulty boiler ignition electrodes rank among the most common culprits for ignition failure. The good news? Many electrode problems stem from simple issues you can address yourself with basic maintenance. Understanding when to clean and when to replace this component saves time, money, and the discomfort of a cold house.

What Ignition Electrodes Actually Do

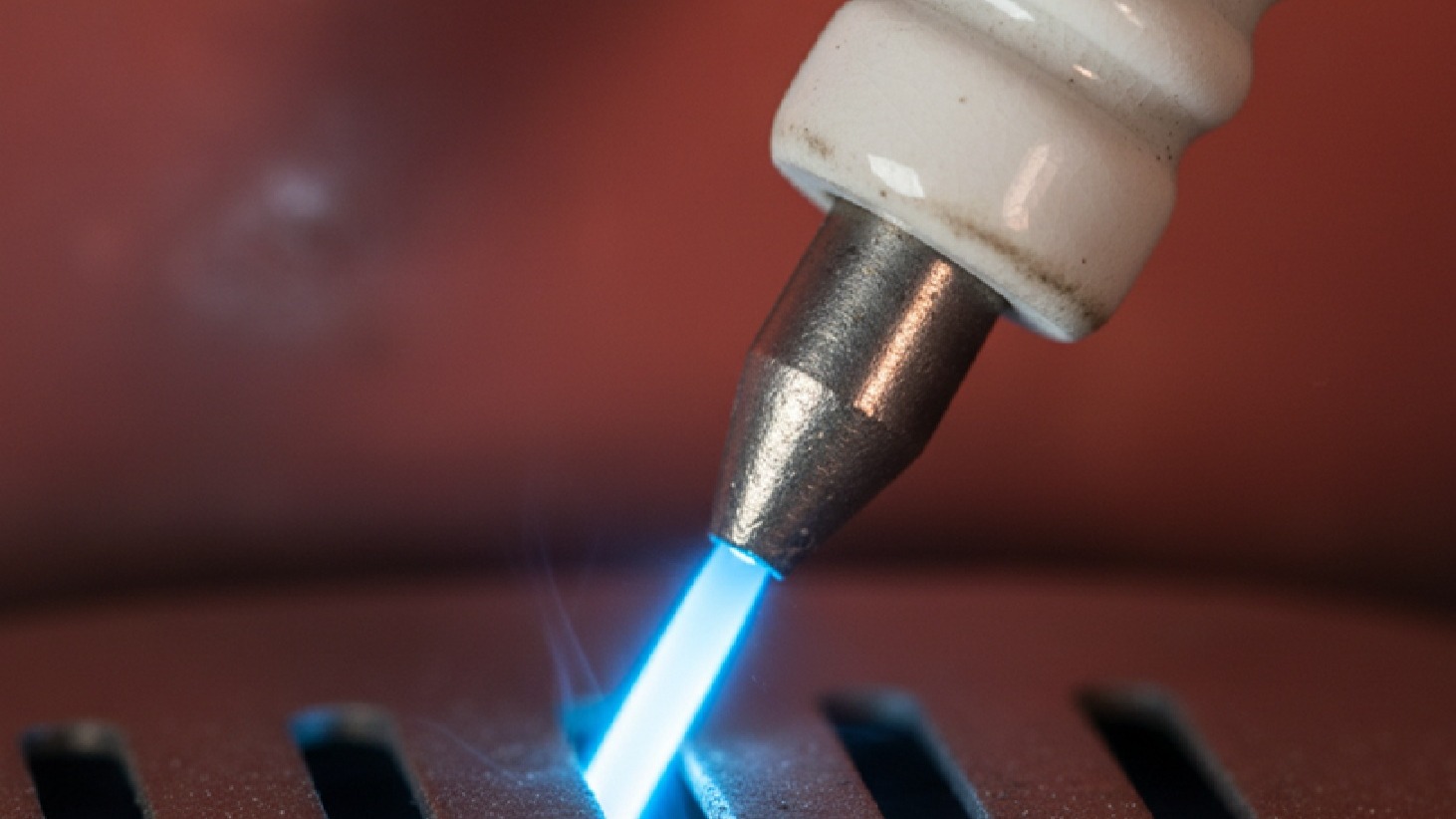

The ignition electrode sits near your boiler's burner, positioned to create a spark that ignites the gas. When your thermostat calls for heat, the boiler's control board sends voltage to the electrode, generating a spark across a small gap. This spark lights the gas, and once the flame is established, the electrode's job is done until the next heating cycle.

Modern boilers use either a single electrode for ignition or a dual-purpose electrode that both ignites the gas and monitors the flame. The electrode tip needs to maintain a precise gap from the burner and remain free from debris to spark effectively. When carbon deposits, dust, or corrosion build up on the electrode, the spark weakens or fails entirely.

The component itself looks deceptively simple: a ceramic insulator surrounding a metal rod, connected by a wire to the control board. Despite this simplicity, the electrode operates in harsh conditions. It endures repeated heating and cooling cycles, exposure to combustion byproducts, and occasional moisture. Over time, these factors degrade performance.

Signs Your Electrode Needs Attention

Boilers rarely fail without warning. Before an electrode stops working completely, you'll typically notice several telltale signs that something isn't right.

Repeated ignition attempts represent the most obvious symptom. You'll hear the boiler clicking multiple times as it tries to light, sometimes succeeding after several attempts, sometimes giving up and displaying an error code. This pattern suggests the spark is weak or intermittent, often caused by contamination on the electrode surface.

Lockout codes appear when the boiler makes several ignition attempts without detecting a flame. Different manufacturers use different codes, but they all indicate the same problem: the burner isn't lighting within the expected timeframe. Whilst this could point to gas supply issues or faulty gas valves, electrode problems cause the majority of these faults.

Inconsistent operation shows itself when your boiler works fine one day but struggles the next, particularly in damp weather. Moisture can create tracking paths on dirty electrodes, where the electrical charge follows the contamination instead of jumping the gap to create a spark. This intermittent behaviour frustrates homeowners because the boiler often works perfectly when the engineer arrives.

Visible damage to the electrode becomes apparent during inspection. Cracks in the ceramic insulator, erosion of the metal tip, or obvious carbon buildup all indicate problems. If you're comfortable removing your boiler's front panel and can safely access the burner area, a quick visual check often reveals the issue.

Cleaning Your Boiler's Ignition Electrode

Before rushing to order replacement parts, cleaning often restores electrode function. We've revived countless boilers with nothing more than careful cleaning, saving customers the cost of unnecessary replacements.

Safety comes first. Turn off your boiler at the main switch and at the fused spur. Wait at least five minutes for capacitors to discharge. If you're not confident working inside your boiler, stop here and contact a Gas Safe registered engineer. Working with gas appliances requires proper training and certification.

Remove the boiler's front panel according to the manufacturer's instructions. You'll typically find the electrode near the burner, easily identified by its ceramic body and metal tip pointing toward the burner ports. Take a photo before disconnecting anything so you can reference the correct position during reassembly.

Inspect the electrode carefully. Look for cracks in the ceramic insulator, which render the component unsafe and require immediate replacement. Check that the mounting bracket holds the electrode firmly and that the tip sits at the correct distance from the burner. Most manufacturers specify a gap of 3-5mm for electrode gap adjustment, though this varies by model.

Use fine emery cloth or very fine sandpaper to gently clean the metal tip. Work carefully around the tip's circumference, removing carbon deposits and corrosion without aggressive scrubbing that could damage the metal. Some engineers use a wire brush, but we find this too abrasive for the delicate electrode tip.

Clean the ceramic insulator with a dry cloth or soft brush. Don't use water or cleaning solutions, as moisture trapped in the ceramic can cause problems. If you notice oily residue, use a cloth dampened with methylated spirits and allow it to dry completely before reassembly.

Check the electrode lead connection at both ends. Corrosion in these connections causes weak sparks even when the electrode itself is clean. If the spade connector shows signs of corrosion, clean it gently or replace it. The connection must be tight and secure.

Before reassembling everything, verify the electrode gap using a gap gauge or ruler. The measurement should match your boiler manufacturer's specification, typically found in the installation manual. An incorrect gap distance prevents reliable ignition even with a perfectly clean electrode.

When Replacement Becomes Necessary

Cleaning solves many electrode problems, but some situations demand replacement. Recognising when you've reached this point prevents wasted effort and repeated failures.

Cracked ceramic insulators cannot be repaired. The crack allows electrical current to track along the surface instead of jumping the gap to create a spark. Even hairline cracks compromise electrode function and present safety risks. Replace immediately if you spot any ceramic damage.

Eroded electrode tips result from years of sparking. The repeated electrical discharge gradually wears away the metal, changing the tip's shape and reducing spark intensity. If the tip appears rounded, pitted, or significantly thinner than a new electrode, replacement is due.

Persistent problems after cleaning indicate the electrode has reached the end of its service life. If you've thoroughly cleaned the component, verified correct gap spacing, and checked all connections, but the boiler still struggles to ignite, the electrode's internal characteristics have likely degraded.

The age of your boiler provides context for replacement decisions. Boiler ignition electrodes typically last 5-10 years, depending on usage patterns and water quality in your area. If your boiler is approaching or past this age and you're experiencing ignition problems, replacement makes more sense than repeated cleaning attempts.

Sourcing Replacement Electrodes

Finding the correct replacement electrode requires precise information about your boiler. Using the wrong part wastes money and won't solve your problem.

Locate your boiler's model number on the data badge, usually found inside the front panel or on the boiler's side. You need the complete model number, not just the brand name, as manufacturers often use different electrodes across their product ranges.

Quality replacement parts from suppliers like Heating and Plumbing World ensure proper fit and reliable operation. Systems from manufacturers like Andrews, Halstead, or Morco require genuine or approved equivalent parts for optimal performance.

The electrode should arrive with installation instructions and the correct gap specification if it doesn't, download the installation manual from the manufacturer's website before starting work. Some electrodes require specific torque settings on mounting bolts or a particular routing of the electrode lead.

Installing a New Electrode

Electrode replacement follows similar steps to cleaning, with additional attention to positioning and electrical connections.

Start with the same safety precautions: power off at all isolation points and wait for residual charge to dissipate. Remove the old electrode, noting its exact position and orientation. The angle and distance matter significantly for reliable ignition.

Fit the new electrode to match the original position precisely. Hand-tighten the mounting bracket first, then adjust the electrode to achieve the correct gap from the burner. Use a gap gauge to verify the measurement before final tightening. Over-tightening can crack the ceramic insulator, so follow the torque specifications if provided.

Connect the electrode lead, ensuring the spade connector seats fully onto the terminal. A loose connection here causes intermittent sparking and frustrating fault-finding later. Give the lead a gentle tug to confirm it's secure.

Route the electrode lead away from hot surfaces and moving parts. The lead should have some slack but shouldn't touch the burner, heat exchanger, or fan assembly. Improper lead routing can cause insulation damage and electrical faults.

Test before closing up. With the boiler cover still removed, restore power and set the thermostat to call for heat. Watch the electrode as the boiler attempts ignition. You should see a strong, consistent spark jumping to the burner. If the spark appears weak or inconsistent, recheck your gap measurement and connections.

Once you've confirmed proper operation, replace the boiler cover and run several heating cycles to ensure reliable starting. Monitor the boiler over the next few days for any return of ignition problems.

Preventing Future Electrode Problems

Regular maintenance extends electrode life and prevents unexpected failures. These simple practices reduce the frequency of cleaning and replacement.

Annual servicing by a Gas Safe registered engineer includes electrode inspection and cleaning. This professional attention catches problems early, before they leave you without heating. The service also addresses other issues that affect electrode performance, such as incorrect gas pressure or ventilation problems.

Keep the area around your boiler clean and dust-free. Dust drawn into the combustion chamber settles on the electrode and burner, gradually degrading ignition performance. A quick wipe of the boiler exterior and surrounding area during regular cleaning prevents buildup.

Water quality affects electrode life in ways that aren't immediately obvious. Hard water causes scale buildup in the heat exchanger, which changes combustion characteristics and increases deposits on the electrode. If you live in a hard water area, consider a water softener or magnetic scale reducer. Quality plumbing components and systems from Kingspan or Gledhill work with proper water treatment for optimal system performance.

Monitor your boiler's performance throughout the heating season. Catching changes early, when the boiler takes an extra attempt to light or makes unusual noises during ignition, allows for simple cleaning before problems escalate to component failure.

Understanding Related Components

Electrode problems sometimes mask issues with other ignition system components. Understanding these relationships helps you diagnose problems accurately.

The ignition transformer or control board supplies voltage to the electrode. If this component fails, the electrode receives insufficient power to create a spark even when perfectly clean. You can test for spark at the electrode tip using an insulated screwdriver held near the electrode during ignition attempts, but this requires care and proper safety equipment.

Gas valves control fuel flow to the burner. A faulty gas valve might allow insufficient gas during ignition, causing the boiler to fail even with a strong spark. If you smell gas during failed ignition attempts, the valve might be opening before the spark occurs, flooding the combustion chamber and preventing lighting.

The flame sensor (often integrated with the electrode in modern boilers) confirms successful ignition. If this sensor fails, the boiler might light briefly, then shut down, appearing similar to electrode problems. Cleaning the sensor portion of the electrode often resolves these shutdown issues.

Control boards from manufacturers like Honeywell and EPH Controls manage the entire ignition sequence. Board failures can mimic electrode problems, making proper diagnosis essential before ordering parts. Quality pumps from Grundfos and system components work together to ensure reliable boiler operation.

Professional Help vs DIY Approach

Knowing when to tackle electrode maintenance yourself and when to call for professional help protects both your safety and your boiler's warranty.

Gas Safe regulations exist for good reason. Any work involving gas connections, burner removal, or modification to gas-carrying components requires certification. Cleaning an electrode that's easily accessible without disturbing gas connections falls within homeowner's capability, but pushing beyond this risks serious consequences.

Boiler warranties typically require annual professional servicing. DIY work that damages components or creates safety issues can void warranty coverage, leaving you liable for expensive repairs. Check your warranty terms before attempting any maintenance.

Complex fault-finding benefits from professional experience. If you've cleaned the electrode, verified connections, and checked obvious issues but the boiler still won't light reliably, multiple factors might be interacting. Engineers have diagnostic tools and experience that quickly identify problems that would take homeowners hours of trial and error.

The cost of a service call often proves less than the combined expense of parts ordered through trial and error, time spent troubleshooting, and potential damage from incorrect repairs. We've repaired many boilers where well-intentioned DIY attempts created additional problems beyond the original fault.

Maintaining Reliable Ignition

Boiler ignition electrodes represent a small component with an outsized impact on your home comfort. These simple devices endure harsh conditions to light your boiler thousands of times each year reliably. Understanding how they work, recognising failure symptoms, and knowing when cleaning suffices versus when replacement becomes necessary empowers you to maintain your heating system effectively.

Regular inspection and cleaning prevent many electrode failures, whilst prompt replacement when degradation occurs prevents extended periods without heating. Whether you choose to handle basic maintenance yourself or rely on professional service, attention to this critical component ensures your boiler operates reliably throughout the heating season.

The key lies in matching your approach to your capabilities and comfort level. Simple cleaning of accessible electrodes falls within most homeowners' skills, but more complex diagnosis and any work involving gas connections demands professional expertise. By understanding these boundaries and maintaining your boiler proactively, you'll minimise unexpected failures and extend the life of your heating system.

For quality boiler ignition electrodes and replacement parts, Heating and Plumbing World stocks genuine components for all major boiler brands. Technical guidance on electrode gap adjustment and installation procedures is available. Get in touch for professional support with your heating system maintenance.

-

-