Choosing a Boiler for Hard Water Areas: Protection Features

Hard water affects 60% of UK homes, and if you're in one of them, your boiler faces a silent threat. Limescale builds up inside the heat exchanger at a rate of 1-2mm per year in hard water areas, reducing efficiency by 15-20% and cutting boiler lifespan by up to 5 years. The difference between a boiler that lasts 15 years and one that fails at 10 often comes down to how well it handles calcium carbonate deposits.

What Hard Water Does to Boilers

When water contains more than 200mg of calcium carbonate per litre, it's classified as hard. In areas like London, Kent, and parts of Yorkshire, levels regularly exceed 300mg/l. As your boiler heats this water to 60-80°C, calcium and magnesium separate out and form scale deposits on metal surfaces.

The heat exchanger takes the worst hit. Scale acts as an insulator, forcing the boiler to work harder to achieve the same temperature. A 1.6mm layer of limescale reduces heat transfer efficiency by 12%. The boiler cycles more frequently, components overheat, and fuel consumption rises. Gas usage increases of 25% in severely scaled systems compared to clean ones aren't uncommon.

Beyond efficiency, scale causes three specific failures:

Blocked pipes and valves: Scale narrows water passages, reducing flow and triggering low-pressure faults. The diverter valve, which switches between heating and hot water, frequently seizes in hard water areas.

Pump failure: Restricted flow makes pumps work harder. The increased load burns out motors 3-4 years earlier than in soft water regions.

Kettling: When scale covers the heat exchanger, water trapped beneath it boils and creates steam bubbles. The resulting noise sounds like a kettle boiling, but it indicates metal stress that leads to cracks and leaks.

Protection Features That Actually Work

Modern boilers for hard water include several defences against hard water damage. Not all are equally effective.

Stainless Steel Heat Exchangers

Aluminium heat exchangers corrode faster in hard water conditions. Stainless steel resists both corrosion and scale adhesion better. Scale still forms, but it bonds less aggressively to stainless steel surfaces, making chemical cleaning more effective when needed.

Boilers with 316-grade stainless steel heat exchangers show 40% less scale buildup after 5 years compared to aluminium equivalents in identical water conditions. Viessmann's Vitodens range and Worcester Bosch's Greenstar series both use stainless steel heat exchangers as standard.

Pre-Preheat Functions

Some boilers maintain a minimum temperature in the heat exchanger even when idle. This sounds counterintuitive for efficiency, but in hard water areas, it prevents the thermal shock that accelerates scale formation. Rapid heating from cold to 70°C creates ideal conditions for calcium carbonate precipitation.

Boilers with pre-preheat functions heat water gradually, reducing the temperature differential that triggers heavy scaling. The efficiency cost is minimal, typically 1-2% annually, but the protection extends heat exchanger life by 3-5 years.

Automatic Bypass Valves

When radiator valves close and flow becomes restricted, pressure builds in the system. This forces water through the heat exchanger at higher pressure and temperature, creating perfect scaling conditions. An automatic bypass valve releases excess pressure by redirecting water flow, maintaining consistent conditions that reduce scale formation.

Quality boilers include adjustable bypass valves that let installers set the optimal flow rate for your specific system. This matters more in hard water areas because scale-narrowed pipes already restrict flow.

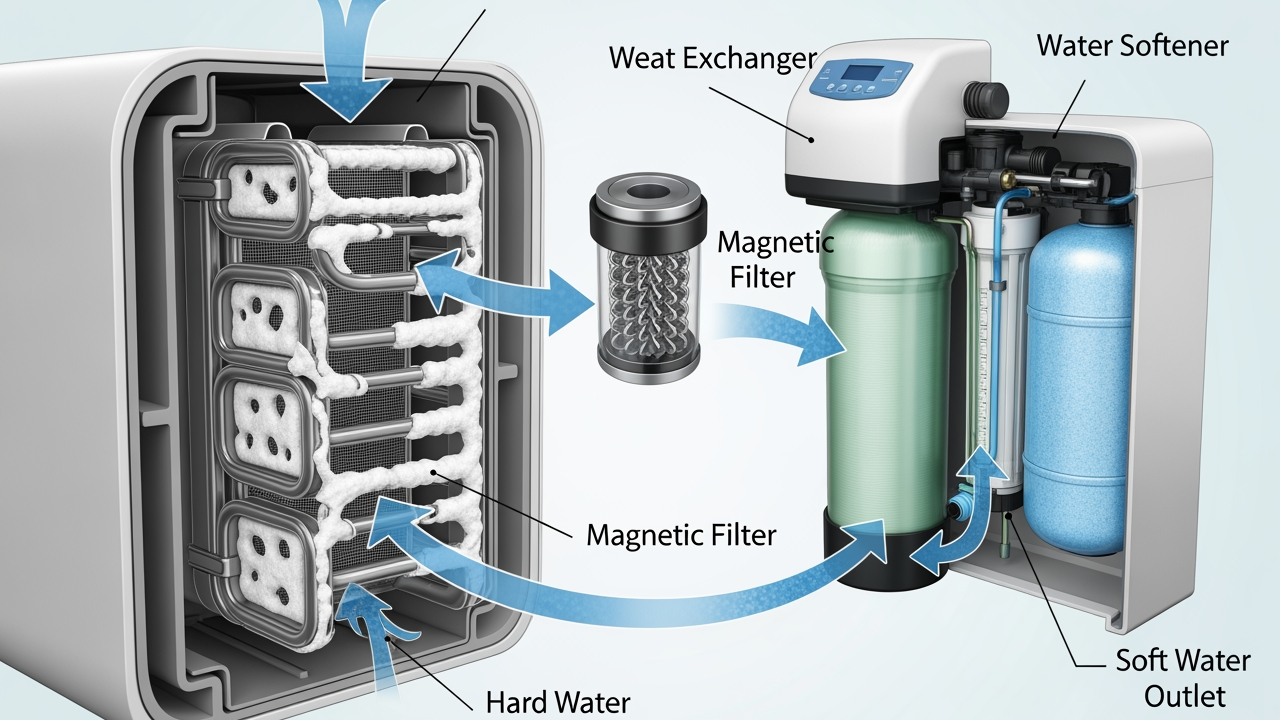

System Filters

While not part of the boiler itself, a magnetic system filter catches scale particles and corrosion debris before they reach the heat exchanger. The Adey MagnaClean and Fernox TF1 are industry standards.

Boilers after 3 years in hard water areas, those with magnetic filters show 60% less internal scale than unprotected systems. The filter doesn't prevent scale formation, but it captures loose particles that would otherwise accumulate in narrow passages and on the heat exchanger surface.

Hard Water Boilers Built for Longevity

Certain manufacturers design specifically for hard water performance.

Vaillant ecoTEC Plus: Uses a stainless steel heat exchanger and includes scale-reduction technology that varies water temperature to minimise calcium carbonate precipitation. The built-in filter protects the heat exchanger from debris. In hard water field tests, these boilers maintained 92% efficiency after 7 years versus 78% for standard models.

Worcester Bosch Greenstar 8000: Features a 3-stage scale protection system, stainless steel heat exchanger, automatic bypass, and pre-heat function. The manufacturer extends the warranty to 10 years when installed with a scale reducer in hard water areas, which indicates genuine confidence in the protection measures.

Viessmann Vitodens 200-W: Includes Inox-Radial stainless steel heat exchanger technology with a spiral design that promotes turbulent flow. This turbulence reduces scale adhesion by 35% compared to straight-passage designs. The MatriX cylinder burner maintains consistent heat distribution, preventing the hot spots where scale forms fastest.

Ideal Logic Max: Budget-friendly option with stainless steel heat exchanger and 12-year warranty. While it lacks advanced pre-preheat functions, the robust heat exchanger design and good warranty coverage make it viable for hard water areas when combined with external protection measures.

External Protection Systems

Even the best boilers for hard water benefit from water treatment in hard water areas.

Scale Reducers vs Water Softeners

Scale reducers (also called scale inhibitors) use polyphosphate crystals or electromagnetic fields to alter calcium carbonate structure. The calcium remains in the water but forms powder rather than hard scale. These cost £100-300 installed and require no drainage or electricity (for magnetic types).

Water softeners use ion exchange to remove calcium and magnesium completely, replacing them with sodium. They cost £400-1,200 installed, require electricity and drainage, and need salt refills every 2-3 months. But they protect the entire house, not just the heating system.

For boiler-only protection, scale reducers work well enough. Quality polyphosphate units achieve a 70-80% reduction in scale formation. For whole-house protection and maximum boiler lifespan, water softeners deliver better results; boilers in softened water show negligible scale buildup even after 10 years.

Chemical Inhibitors

Central heating inhibitor fluid prevents corrosion and scale formation inside the system. Fernox F1, Sentinel X100, and Adey MC1+ are proven formulas. These cost £15-40 for enough to treat a typical system.

The inhibitor must be correct for hard water. Standard inhibitors focus on corrosion prevention. Hard water formulas include scale inhibitors that keep calcium in suspension. Every system in hard water areas should be dosed with Sentinel X200 or equivalent, which combines corrosion and scale protection.

The inhibitor loses effectiveness over time. In hard water areas, testing and refreshing every 3-4 years is recommended rather than the standard 5-6 year interval.

Power Flushing

Before installing a new boiler in a hard water area, power flushing removes existing scale and sludge. This costs £300-500 but prevents contaminating the new boiler with debris from old pipes.

New boilers have failed within 18 months because installers skipped power flushing. Scale particles from the existing system lodge in the new heat exchanger, creating nucleation sites where fresh scale forms rapidly. The £400 power flush protects a £2,000+ boiler investment.

Installation Details That Matter

How your installer sets up the boiler affects hard water performance.

Flow temperature: Running the boiler at 75-80°C increases scale formation by 40% compared to 60-65°C operation. Modern condensing boilers achieve best efficiency at lower temperatures anyway. Set the flow temperature to 60°C for underfloor heating or 65°C for radiators unless your system specifically requires higher temperatures.

System volume: Oversized systems hold more water, which means more calcium circulating and more opportunities for scale formation. Proper radiator sizing and pipe layout minimise system volume without compromising heat output.

Pump speed: Running the pump faster than necessary increases turbulence and heat transfer, both of which accelerate scaling. Set the pump to the lowest speed that maintains adequate flow, typically speed two on a 3-speed pump for most domestic systems.

Pressure relief valve: In hard water areas, the PRV should be checked annually. Scale buildup prevents proper sealing, causing dripping that wastes water and reduces system pressure. A faulty PRV costs £40-60 to replace, while the water damage from a failed valve costs thousands.

Maintenance Schedule for Hard Water Areas

Standard boiler service intervals don't account for hard water conditions. This schedule is recommended:

Year 1: Full service including combustion analysis and safety checks. Inspect heat exchanger for early scale formation. Check inhibitor concentration.

Year 2: Full service plus magnetic filter cleaning. Test a water sample for hardness and inhibitor levels. Top up inhibitor if needed.

Year 3: Full service plus heat exchanger inspection with endoscope camera. If scale exceeds 1mm thickness, chemical descaling is due. Clean or replace magnetic filter.

Years 4-6: Repeat the 3-year cycle. Most hard water boilers need chemical descaling every 3-4 years in hard water areas versus 5-7 years in soft water regions.

Scale reducer maintenance: Polyphosphate cartridges last 6-12 months depending on water usage. Mark the installation date on the unit and set a phone reminder. A £15 cartridge replacement prevents thousands in boiler damage.

Cost Analysis: Protection vs Replacement

A combi boiler costs £2,000-3,000 installed. In hard water areas without protection, average lifespan is 8-10 years. With proper protection, the same boiler lasts 12-15 years.

Protection costs break down as:

- Scale reducer: £150-300 (one-time) plus £30/year for cartridges

- Quality system filter: £100-150 installed

- Power flush before installation: £300-500

- Hard water inhibitor: £30 every 3-4 years

- Annual service with hard water focus: £90-120

Total first-year cost: £700-1,200

Annual ongoing cost: £120-180

Over 15 years, you'll spend approximately £2,500 on protection measures. Without protection, you'll replace the boiler 5 years earlier at £2,500+ for the new installation, plus higher fuel bills from reduced efficiency. The protected boiler saves £3,000-4,000 over its extended lifespan while running more efficiently throughout.

Warranty Considerations

Most boiler warranties include a clause about water quality. Worcester Bosch explicitly states that warranty claims may be denied if the system contains excessive scale or debris. Vaillant requires annual servicing by a registered engineer, and in hard water areas, they recommend water treatment.

Some manufacturers extend warranties when you install approved water treatment:

- Worcester Bosch: 10-year warranty (vs 7-year standard) with approved scale reducer

- Viessmann: 10-year warranty with water treatment and annual servicing

- Ideal: 12-year warranty (vs 10-year) with system filter and inhibitor

The extended warranty isn't just marketing. These manufacturers know water treatment dramatically reduces warranty claims in hard water areas, so they're willing to cover the boiler longer when you install protection.

Hard water will damage any boiler eventually, but the right combination of boiler design and water treatment extends lifespan from 8-10 years to 12-15 years while maintaining efficiency. Choose a boiler with a stainless steel heat exchanger as the baseline requirement. Add a magnetic system filter, dose with hard water inhibitor, and install a scale reducer or water softener based on your budget and whole-house needs.

The protection measures cost £700-1,200 initially and £120-180 annually, but they prevent a premature £2,500 boiler replacement while cutting fuel bills by 15-20% compared to a scaled system. In hard water areas, protection isn't optional; it's the difference between a boiler that reaches its design life and one that fails years early with expensive repair bills along the way.

Power flush before installing the new boiler, set flow temperatures to 60-65°C, and service annually with specific attention to scale formation. Check your water hardness through your water supplier's website or with a £10 test kit, then choose protection measures that match the severity of your water conditions. The boiler you install today will either serve you well for 15 years or become an expensive problem in 8, the choice depends entirely on how seriously you take hard water protection.

Heating and Plumbing World supplies boilers and protection systems from leading manufacturers, including Grundfos circulation pumps, Honeywell heating controls, Danfoss valves, and Altecnic expansion vessels. For technical guidance on selecting the right boiler and water treatment system for your hard water area, get in touch with the team.

-

-