Choosing Between Sealed and Open Vent Boiler Systems

Your boiler system determines how water circulates through your heating setup, how pressure stays regulated, and what maintenance you'll face for the next 15-20 years. The choice between sealed vs open vent boilers isn't about which is "better", it's about which matches your property's layout, your budget, and how much ongoing attention you want to give your heating.

Both systems have clear strengths and predictable weak points when it comes to daily operation and long-term reliability.

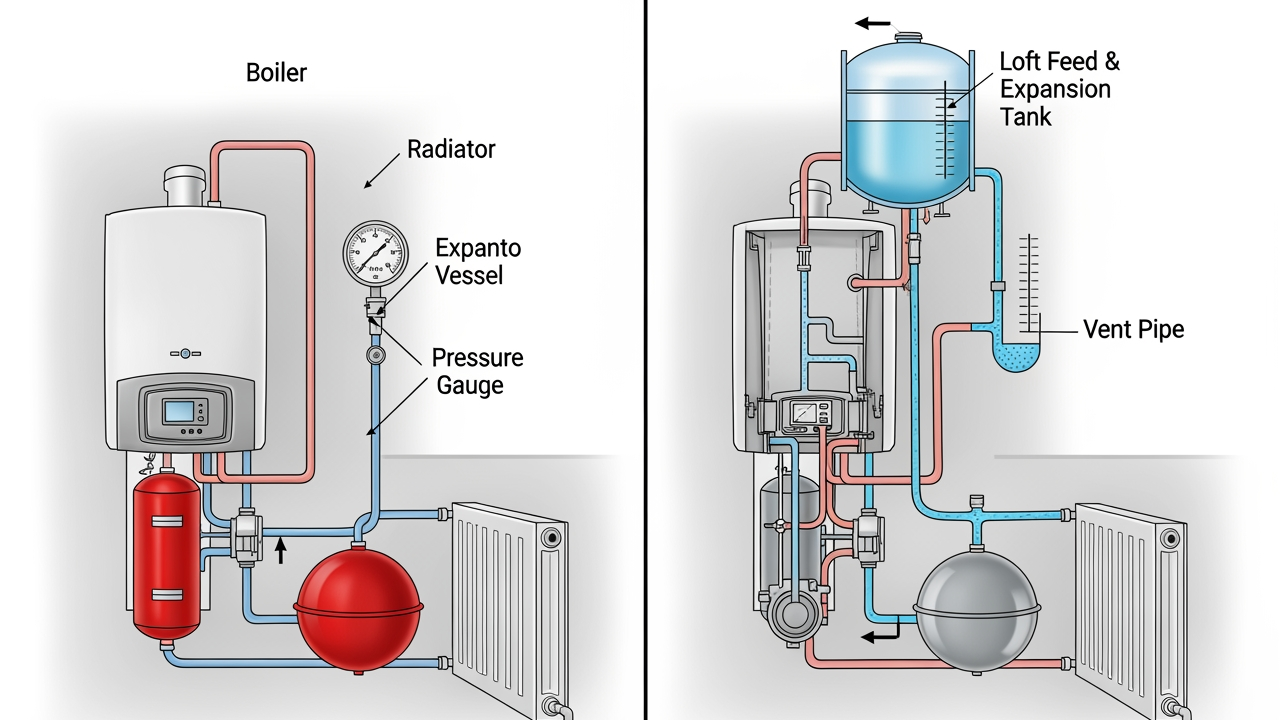

How Sealed Systems Work

Sealed system boilers (also called pressurised systems) contain water in a closed loop. No part of the system connects to atmospheric air. A pressure vessel, typically a red expansion vessel mounted near the boiler, absorbs the expansion that happens when water heats up.

Pressure stays between 1 and 1.5 bar during normal operation. When water heats and expands, it compresses air inside the expansion vessel's rubber diaphragm. This prevents pressure from climbing too high. A pressure relief valve opens automatically if pressure exceeds 3 bar, dumping water outside through a discharge pipe.

You'll see a filling loop, usually a flexible braided hose with two valves, somewhere near the boiler. This connects the heating system to your mains water supply. When pressure drops below 1 bar, you open both valves for 10-15 seconds to top up the system, then close them again.

Modern combination boilers are almost always sealed systems. The boiler itself contains all the components needed: expansion vessel, pressure gauge, relief valve, and automatic air vents. Heating and Plumbing World stocks sealed system boilers from manufacturers like Grundfos with integrated expansion vessels and controls.

How Open Vent Systems Work

Open vent systems (also called conventional or traditional systems) use a feed and expansion tank in your loft. This small tank, typically 20-50 litres, sits above the highest point of your heating system and connects to it through two pipes.

The system is open to atmospheric pressure through a vent pipe that rises above the tank. When water heats and expands, it pushes up into the feed and expansion tank. When it cools and contracts, water flows back down. The tank also has a ball valve connected to your mains supply, automatically topping up the system when water levels drop.

These systems need a separate hot water cylinder; you can't use a combination boiler. The setup requires a cold water storage tank (usually 230 litres) in the loft as well, feeding the hot water cylinder.

Pressure throughout the system depends purely on height, the vertical distance between radiators and the feed and expansion tank. Ground floor radiators typically operate at 0.3-0.5 bar, which is enough for effective circulation.

Pressure and Performance Differences

Sealed system boilers maintain consistent pressure regardless of where the radiators sit in your property. A radiator on the ground floor experiences the same 1-1.5 bar as one on the second floor. This makes them effective in properties with multiple storeys or complex layouts.

The higher pressure also means faster heat-up times. Water circulates more forcefully through the system, transferring heat to the radiators quickly. Measurements during commissioning show sealed systems typically reach the target temperature 15-20% faster than equivalent open vent setups.

Open vent systems rely on gravity-fed pressure. Each metre of height between the feed and expansion tank and a radiator adds roughly 0.1 bar. If your loft tank sits 3 metres above a ground-floor radiator, that radiator operates at about 0.3 bar.

This works fine for most homes, but creates challenges in properties with low loft space or radiators positioned high in the building. Loft conversions where the new radiators sit level with or above the feed tank simply won't heat properly.

Installation Costs and Complexity

Converting from an open vent to a sealed system costs £800-1,500 in most properties. This includes installing an expansion vessel (if not built into the boiler), adding a filling loop, fitting a pressure relief valve with external discharge, and removing or capping the loft tanks.

The work takes 1-2 days. The main cost comes from labour, draining the system, making the conversion, refilling, and bleeding all radiators properly.

Going the other direction, sealed to open vent, costs more, typically £1,200-2,000. You're installing tanks in the loft, running new pipework, and ensuring proper support for tanks that will hold 250+ litres when full. Most people only do this when replacing a combination boiler with a conventional boiler and cylinder setup to get better hot water flow rates.

New installations show a clearer cost picture. A sealed system combination boiler install runs £1,800-2,500 for a straightforward swap. A conventional boiler with a cylinder and loft tanks costs £2,500-3,500 because you're installing more components and running more pipework. Quality cylinders from Gledhill or Kingspan support both system types.

Maintenance Requirements

Sealed systems need annual pressure checks. Most homeowners can do this themselves. If the gauge shows below 1 bar, you open the filling loop valves briefly. The entire process takes 30 seconds.

The expansion vessel's diaphragm eventually fails, usually after 8-12 years. When this happens, pressure drops frequently, and you'll find yourself topping up monthly, then weekly. Replacing an external expansion vessel costs £150-250, including labour. If it's built into the boiler, expect £200-350. Expansion vessels from Altecnic Ltd provide reliable performance in sealed heating systems.

Pressure relief valves can start weeping after 5-10 years, especially in hard water areas where scale builds up. You'll notice water dripping from the external discharge pipe. Replacement costs £120-180.

Open vent systems need different attention. The feed and expansion tank requires checking every 6-12 months. Ball valves stick or fail, causing overflow through the vent pipe. You'll hear water running constantly in the loft, and see dripping from the overflow pipe outside.

Ball valve replacement costs £80-120, but you need loft access and someone comfortable working around water tanks. Emergency calls for failed ball valves occur more frequently than any other open vent component.

The cold water storage tank needs similar monitoring. Insulation around both tanks degrades over time, raising freeze risk in cold winters. Frozen and burst loft tanks appear every winter; damage typically runs £500-800 once you factor in water damage to ceilings.

Sludge accumulates faster in open vent systems because the feed and expansion tank introduces small amounts of fresh oxygenated water continuously. This oxygen promotes corrosion inside radiators and pipework. Power flushing every 5-6 years for open vent systems versus 7-8 years for sealed systems maintains optimal performance.

Space Considerations

Sealed systems save space. You need nothing in the loft except perhaps the boiler itself (if it's a system boiler rather than a combination). This matters increasingly as people convert lofts into living space.

Loft conversions often require removing the cold water storage, feed, and expansion tanks. Converting to a sealed system combination boiler frees up 1-2 square metres of usable floor space.

Cold water storage tank: 1.2m × 0.6m × 0.6m. Feed and expansion tank: 0.6m × 0.4m × 0.4m. Hot water cylinder (if in loft): 1.5m × 0.5m diameter

You also need access to space around tanks for maintenance. Building regulations require permanent safe access to any water storage.

Reliability and Failure Modes

Sealed systems fail in predictable ways. Expansion vessels lose pressure, relief valves weep, and filling loops develop leaks. These failures rarely cause property damage; they just stop the system from working until you fix them.

The most common issue is gradual pressure loss from micro-leaks at radiator valves or pipe joints. Homeowners notice they're topping up pressure monthly. Finding these leaks takes time, but they're usually straightforward to repair once located.

Open vent systems have different failure patterns. Ball valve failures cause overflow, potentially damaging ceilings. Frozen tanks burst in cold weather, dumping 250+ litres into your loft. Blocked vent pipes create pressure in supposedly unpressurised systems, sometimes splitting the feed and expansion tank.

The vent pipe is critical; it must rise continuously from the highest point of the heating system to terminate above the feed tank. Installations where the vent pipe had dips or horizontal sections create airlocks that prevent proper venting. This causes kettling (boiling sounds in the boiler) and can split pipes.

However, open vent systems tolerate small leaks better. If a radiator valve weeps slightly, the ball valve in the feed tank automatically tops up the system. You might not notice the leak for months. In a sealed system, that same leak causes obvious pressure drops within days.

Which System Suits Your Property

Choose sealed systems when:

- Installing a combination boiler for instant hot water

- Converting your loft and need to remove tanks

- Heating a multi-storey property where some rooms sit high in the building

- Comfortable topping up pressure occasionally

- Working with limited loft space

Choose open vent systems when:

- Need high hot water flow rates (multiple bathrooms running simultaneously)

- Have an existing conventional system that works well

- Want a system that tolerates minor leaks without immediate intervention

- Prefer avoiding any pressurised components

- Have adequate loft space and access

Properties with solar thermal panels often work better with open vent systems. The feed and expansion tank accommodates the significant expansion that happens when solar panels heat water to high temperatures. Sealed systems need larger expansion vessels and more careful pressure management.

Listed buildings sometimes require open vent systems to preserve original pipework layouts and avoid pressure that could stress old pipes. Conservation officers should be consulted before converting heritage heating systems.

Making the Switch

If you're replacing a boiler, that's the natural time to consider switching system types. The boiler replacement already requires draining the system, so conversion work adds minimal extra disruption.

Switching without replacing the boiler makes less sense economically unless you have specific reasons, a loft conversion, persistent problems with the current setup, or preparation for future changes.

When converting systems, always install a magnetic filter at the same time. This captures iron oxide particles before they circulate through the new components. The filter costs £100-150 installed but prevents premature failures in expansion vessels and pressure relief valves.

Treating the system water with an inhibitor is also recommended. This costs £30-50 for enough inhibitor to treat a typical home system, and significantly extends component life by preventing internal corrosion.

Conclusion

Sealed system boilers suit modern properties and lifestyles. They work in any building layout, save space, and need minimal ongoing attention beyond occasional pressure top-ups. Component failures happen but rarely cause property damage.

Open vent systems remain relevant for properties needing high hot water volumes, those with heritage considerations, or situations where the existing setup works well. They require more monitoring but tolerate minor leaks better and avoid pressurised components entirely.

Your decision should factor in your property layout, whether you're replacing the boiler anyway, how you use hot water, and honestly assessing whether you'll actually check loft tanks twice yearly. Neither system is universally superior; they're different tools for different situations.

Most combination boiler installations now use sealed systems by default because the components come integrated in the boiler. If you're keeping a conventional boiler and cylinder setup, the case for converting from open vent to sealed becomes weaker unless you need the loft space or face persistent problems with the current system. For expert advice on sealed vs open vent boilers and which system suits your property, contact us for professional recommendations.

-

-