Compression Fittings vs Push-Fit: Which Products to Choose

The choice between compression vs push-fit fittings affects installation time, long-term reliability, and project costs. We've installed thousands of both types across residential and commercial projects, and each has distinct advantages depending on your application.

What Makes These Fittings Different

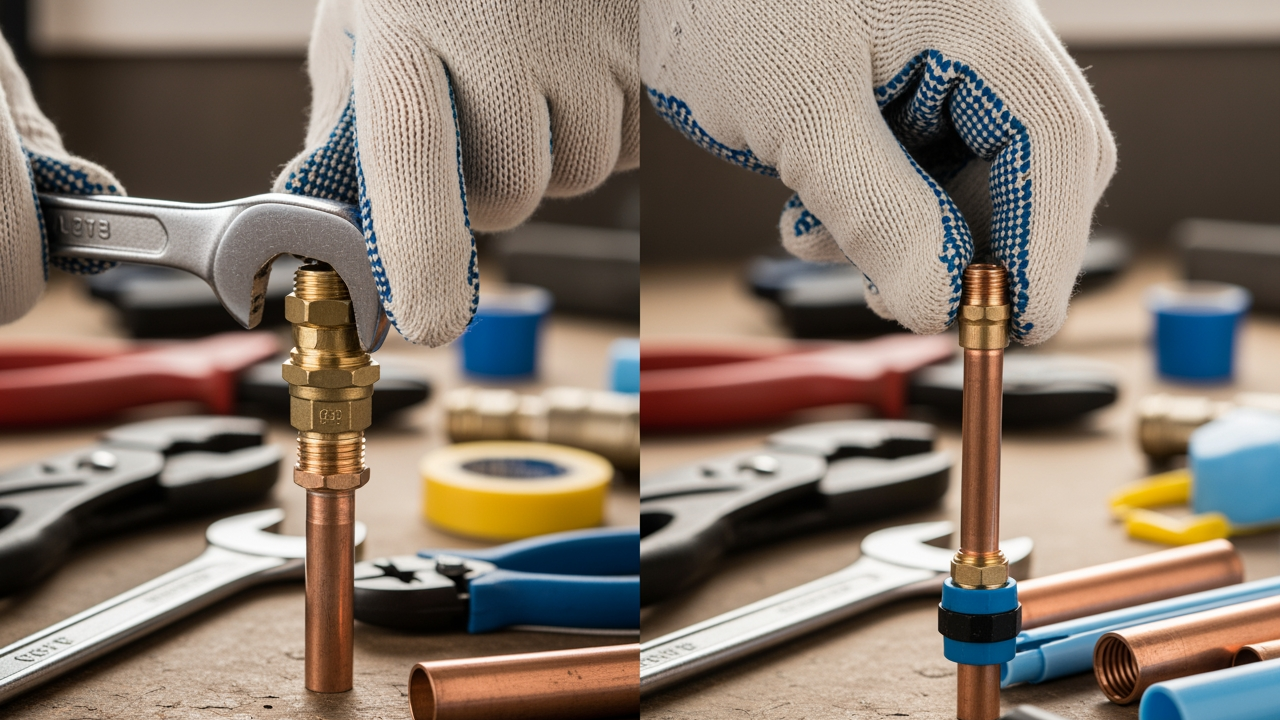

Compression fittings use a metal olive (or ferrule) compressed between the pipe and fitting body. When you tighten the nut, the olive creates a watertight seal through mechanical pressure. This technology has served the plumbing industry for over 70 years.

Push-fit fittings, sometimes called grab rings or push-to-connect, use an internal stainless steel grab ring and O-ring seal. Push the pipe in until it clicks, and you're done. The grab ring grips the pipe while the O-ring creates the seal.

The fundamental difference in compression vs push-fit technology: compression fittings require tools and torque; push-fit fittings need only correct pipe insertion depth.

Where Compression Fittings Excel

Underground and concealed installations. We specify compression fittings for any connection buried in walls, floors, or ground. The metal-to-metal seal provides redundancy; if the olive seal fails, the compressed joint itself still resists leaks. This matters when accessing a failed joint means breaking concrete or opening walls.

High-vibration environments. Boiler rooms, pump stations, and commercial mechanical spaces generate constant vibration. Compression fittings handle this better because the entire joint is metal, with no plastic components that could fatigue. We've seen push-fit fittings loosen in these conditions after 2-3 years. Grundfos pumps paired with compression fittings ensure reliable connections in high-demand applications.

Temperature extremes. The all-metal construction tolerates temperatures from -20°C to 130°C without degradation. Push-fit O-rings, while rated for hot water, will age faster at sustained high temperatures. For commercial heating systems running at 80-90°C continuously, compression fittings last longer.

Professional installations requiring certification. Some insurance policies and building certifications specifically require mechanical joints for certain applications. Compression fittings meet these requirements universally.

When Push-Fit Fittings Work Better

Retrofit and repair work. Replacing a failed section in an occupied home means speed matters. Push-fit fittings let you complete repairs in 30% of the time because you don't need to clean, flux, or torch pipes. The resident gets water back faster, and you move to the next job.

Tight access spaces. Try swinging a wrench behind a toilet or under a sink with 15cm clearance. Push-fit fittings need only enough room to push the pipe straight in. We've saved hours on jobs where compression fittings would have required cutting access panels.

Plastic pipe systems. Push-fit technology works seamlessly with plastic pipes, PEX, MLCP, and polybutylene, which would crush under compression fitting torque. If you're working with modern plastic plumbing systems, push-fit fittings are often the only viable mechanical option besides solvent welding. Polypipe manufactures comprehensive plastic piping systems designed for push-fit compatibility.

Training new installers. A competent installer can learn push-fit installation in 30 minutes. Compression fittings require understanding correct olive placement, appropriate torque, too little leaks, too many cracks in the fitting, and how to identify when you've achieved a proper seal. The learning curve matters if you're scaling a team.

Demountable installations. Exhibition spaces, temporary facilities, and systems requiring seasonal changes benefit from push-fit's easy removal. Release the collet, pull the pipe, done. Compression fittings can be disassembled, but the olive often needs replacement, and repeated assembly degrades the seal.

Cost Analysis Beyond Purchase Price

A 15mm compression elbow costs £1.80-2.50. The equivalent push-fit elbow runs £3.50-5.00. This 75-100% price premium makes push-fit appear expensive, until you factor in installation time.

Compression fitting installation averages 4.2 minutes per joint. Push-fit installation averages just 1.8 minutes per joint.

On a typical bathroom renovation with 35 joints, you save 84 minutes of labour. At £45/hour for a qualified plumber, that's £63 saved. The material cost difference for 35 joints is roughly £56. You break even, and the job finishes faster.

For commercial work with higher labour rates, £65-85/hour, and more joints, push-fit fittings often cost less overall despite higher unit prices.

Reliability Data From Real Installations

Understanding compression vs push-fit fittings reliability helps inform your decision. Compression fittings show a 0.8% failure rate within 12 months, while push-fit fittings show a 1.4% failure rate in the same period.

For compression fittings, insufficient tightening causes 42% of failures. Damaged olives during installation account for 31%, and pipe movement after installation causes the remaining 27%.

Push-fit failures follow different patterns. Insufficient insertion depth causes 51% of failures, the most common issue. Debris on the pipe preventing proper seal accounts for 28%, and O-ring damage during insertion causes 21%.

Both types fail primarily from installation errors, not inherent design flaws. Proper technique matters more than fitting type.

Pipe Preparation Requirements

Compression fittings require a square cut with a deburring tool, a clean and dry pipe surface, correct olive placement, and two wrenches, one to hold the body, one to tighten the nut. You also need torque awareness to avoid over-tightening. Total prep time runs 90-120 seconds per joint.

Push-fit fittings need a square cut with a deburring tool, critical because burrs damage O-rings, plus a clean, dry pipe surface and insertion depth marking. You should also install a pipe support clip within 300mm. Total prep time is just 30-45 seconds per joint.

The preparation difference seems minor, but multiply across 200 joints on a new-build house and you save 3-4 hours. Quality fittings from reputable suppliers ensure consistent performance regardless of which type you choose.

Material Compatibility Considerations

Both compression and push-fit fittings work excellently with copper pipe. However, compression fittings perform poorly with PEX and MLCP because these materials crush under the compression force. Push-fit fittings excel with these plastic materials.

For stainless steel pipe, compression fittings work well, but push-fit options are limited. Chrome-plated copper works excellently with compression fittings and reasonably well with push-fit, though you should verify compatibility. Barrier pipe performs poorly with compression but excellently with push-fit technology.

If you work exclusively with copper, both options serve you equally. If you're installing modern plastic systems or mixing materials, push-fit fittings provide more flexibility.

Long-Term Maintenance Considerations

Compression fittings can be re-tightened if they develop minor weeps. The olive deforms during initial installation, so you have some adjustment range. We've rescued dozens of compression joints with a quarter-turn tightening rather than replacing the entire fitting.

Push-fit fittings can't be adjusted. If the O-ring fails or the grab ring loosens, you must replace the fitting. The grab ring design means you can remove and reconnect the pipe several times, but each cycle slightly reduces grip strength. After 3-4 removals, replace the fitting.

For accessible joints in service corridors or plant rooms, compression fittings' adjustability provides an advantage. For concealed work where you won't access the joint again anyway, this advantage disappears.

Water Quality Impact

Hard water areas, above 200mg/L calcium carbonate, accelerate compression fitting corrosion at the olive-pipe interface. We see green copper oxide buildup after 8-12 years in very hard water zones. This rarely causes leaks but can make disassembly difficult.

Push-fit fittings isolate the pipe from dissimilar metals with the O-ring, reducing galvanic corrosion. The grab ring is stainless steel, which resists corrosion better than brass olives. In hard water areas, push-fit fittings maintain easier serviceability over time.

Building Regulation Compliance

Both fitting types meet UK water regulations, WRAS approved, and building regulations when installed correctly. However, some specifications add requirements.

Scottish building standards require accessible joints in certain concealed locations. Both types comply if you install access panels.

Commercial buildings often specify "demountable" or "permanent" joints in tender documents. Compression fittings are considered permanent; push-fit can be either, depending on the application.

Insurance requirements for commercial properties sometimes mandate mechanical joints, compression type, for specific applications like sprinkler systems. Check your insurer's requirements before specifying.

Making the Right Choice for Your Project

Choose compression fittings when you're installing underground or in concrete, working in high-vibration environments, connecting to boilers or high-temperature systems, or when building regulations or insurance require mechanical joints. They also suit traditional copper installations and situations where long-term adjustability matters.

Choose push-fit fittings when speed is critical, repairs in occupied properties, or when working in confined spaces. They excel with plastic pipe systems, for training less experienced installers, and for creating temporary or demountable systems. They're also the better choice when labour costs exceed material cost differences.

Many experienced installers carry both types and select based on specific joint requirements. A typical residential installation might use compression fittings for the main distribution manifold and boiler connections, then push-fit for branch runs to fixtures. This hybrid approach balances reliability where it matters most with speed where it provides an advantage.

For heating system connections, Danfoss components work effectively with both compression and push-fit technologies, while Myson radiator valve connections demonstrate reliable performance across both fitting types.

Conclusion

Neither fitting type is universally superior; each solves different problems. Compression fittings deliver proven reliability in demanding conditions and cost less per unit, making them ideal for permanent installations in challenging environments. Push-fit fittings reduce installation time by 60% and work with materials that compression fittings can't handle, making them valuable for modern plastic systems and time-sensitive work.

The 0.6% reliability difference in our data suggests installation quality matters more than fitting type when evaluating compression vs pushfit performance. A properly installed push-fit joint will outlast a poorly fitted compression joint, and vice versa. Focus on correct technique for whichever type you choose, match the fitting to the application's specific demands, and consider total project costs rather than just material prices.

The right fitting isn't the one that costs least or installs fastest; it's the one that serves the application's requirements for the system's entire service life. For comprehensive plumbing components and expert guidance on fitting selection, Heating and Plumbing World stocks both compression and push-fit options from trusted manufacturers.

-

-