Condensing Boilers: How They Work and Why They're Efficient

Your heating bill tells a story. If it's climbing year after year despite steady energy prices, your boiler is likely throwing money up the flue. Condensing boilers changed this equation when they entered the UK market in the 1990s, and since 2005, they've been the only type of gas boiler that installers can legally fit in most UK homes. The efficiency difference isn't marginal; it's transformational.

A condensing boiler extracts up to 90% of the heat from fuel, compared to 65-75% from older non-condensing models. That 15-25 percentage point gap translates to £200-£400 annual savings for a typical three-bedroom home. Over a boiler's 15-year lifespan, you're looking at £3,000-£6,000 in reduced energy costs.

How Condensing Boilers Extract More Heat

The breakthrough lies in what older boilers waste. When natural gas burns, it produces water vapour as a byproduct. This vapour contains latent heat, energy that remains locked until the vapour condenses back into liquid water. Non-condensing boilers expel this vapour through the flue at temperatures around 200°C, sending that latent heat straight into the atmosphere.

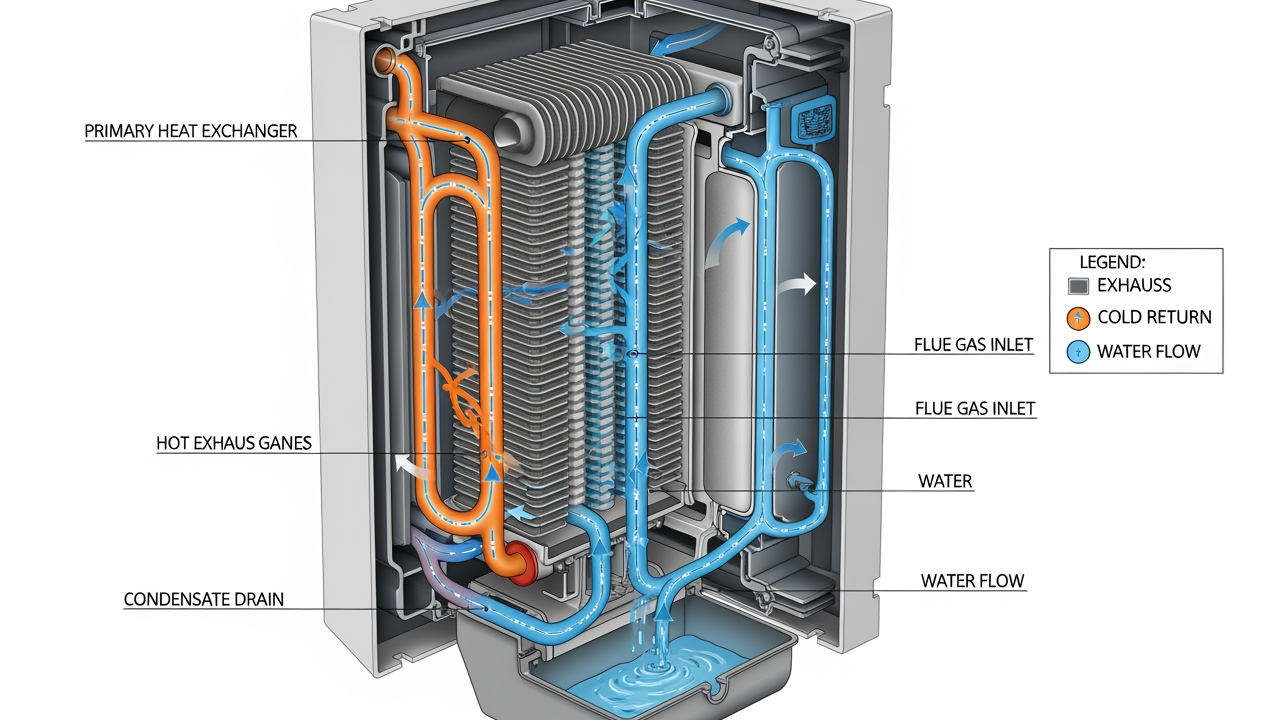

Condensing boilers capture this energy through a secondary heat exchanger. Here's the process:

Primary combustion: Gas burns in the combustion chamber, heating water through the primary heat exchanger, exactly like a traditional boiler.

Flue gas cooling: Instead of venting immediately, exhaust gases pass through a secondary heat exchanger. This component sits in the return water flow from your radiators or underfloor heating.

Condensation: When flue gases cool below approximately 55°C (the dew point for natural gas combustion), water vapour condenses into liquid. This phase change releases latent heat, which transfers to the returning water.

Condensate drainage: The resulting acidic water (pH around 3-5) drains through a dedicated pipe into your household waste system or a neutralising unit.

The flue gases exit at 40-60°C rather than 200°C. That temperature difference represents recovered energy now heating your home instead of warming the sky.

The Role of Return Temperature

Condensing boiler efficiency depends heavily on return water temperature, the temperature of water coming back to the boiler from your heating system. The colder this return water, the more efficiently your boiler operates.

At return temperatures below 55°C, full condensing occurs. The boiler achieves its rated efficiency of 88-94%. Between 55-70°C, partial condensing happens, with efficiency dropping to 80-88%. Above 70°C, minimal condensing occurs, and performance resembles a non-condensing boiler.

Your heating system design directly impacts these temperatures:

Underfloor heating operates at 35-45°C flow temperature with returns around 30-35°C. This keeps the boiler in full condensing mode almost constantly, achieving 92-94% efficiency.

Oversized radiators can deliver adequate heat at lower flow temperatures (50-60°C), producing return temperatures of 40-50°C. Efficiency holds at 90-92%.

Standard radiators sized for older boilers typically require 70-80°C flow temperatures, with returns at 60-70°C. Efficiency drops to 82-88%, though still far better than non-condensing alternatives.

Older systems with small radiators may need 80-85°C flow temperatures, pushing returns above 70°C and limiting condensing operation. Efficiency falls to 78-85%.

This explains why simply replacing an old boiler with a condensing model doesn't always deliver maximum savings. The system design matters as much as the boiler technology.

Condensate Management

Every hour of operation, a condensing boiler produces approximately 2 litres of condensate per 30kW of output. For a typical 24kW boiler running six hours daily during winter, that's roughly 300 litres monthly.

This acidic water requires proper drainage. Most installations connect the condensate pipe to internal waste plumbing, either a sink waste or dedicated drainage point. The pipe must maintain a slight downward slope (minimum 3° angle) to prevent pooling.

External condensate pipes present a winter challenge. When temperatures drop below freezing, condensate can freeze inside the pipe, blocking drainage and shutting down the boiler. Building regulations now require external condensate pipes to be insulated and sized at minimum 32mm diameter to reduce freezing risk. Some installers add trace heating cables for exposed runs in vulnerable locations.

If your boiler stops working during a cold snap and displays a fault code, a frozen condensate pipe is the likely culprit. The temporary fix involves carefully thawing the pipe with warm (not boiling) water poured along its length. The permanent solution requires better insulation or rerouting the pipe internally.

Efficiency Ratings Explained

You'll see two efficiency figures for condensing boilers:

Gross efficiency measures heat output against the total energy in the fuel, including latent heat from water vapour. This figure runs 88-94% for condensing boilers.

Net efficiency excludes latent heat from the calculation, treating it as unavailable. By this measure, condensing boilers can show efficiencies above 100%, which sounds impossible but simply reflects the different accounting method.

UK regulations and ErP ratings use gross efficiency, so that's the figure to compare. The ErP (Energy-related Products) label rates boilers from A+++ to G, with all modern condensing boilers achieving at least A-rating (90-94% efficiency).

Seasonal Efficiency of Domestic Boilers in the UK (SEDBUK) ratings account for conditions including cycling losses, standing losses, and varying heat demands. These ratings run 1-2 percentage points lower than laboratory test results but better represent actual performance.

Modulation and Part-Load Efficiency

Heating demand varies throughout the day and season. On a mild autumn evening, your home might need just 4kW of heat. On a January morning, it could require 18kW. Older boilers ran at fixed output, cycling on and off to match demand, an inefficient approach that causes temperature swings and wear.

Modern condensing boilers modulate their output, adjusting flame size to match demand in real-time. A boiler with a 5:1 modulation ratio can operate anywhere between its maximum (say, 24kW) and minimum (4.8kW) output without cycling.

Wide modulation ranges deliver several benefits:

Sustained condensing: The boiler runs continuously at lower output rather than cycling at full blast. This maintains low return temperatures and keeps the unit in condensing mode.

Temperature stability: Your home temperature holds steady rather than swinging between too hot and too cool.

Reduced wear: Fewer start-stop cycles mean less stress on components and longer service life.

Better efficiency: Part-load efficiency often exceeds full-load efficiency because heat loss through the boiler casing represents a smaller percentage of total output.

Premium boilers offer 10:1 modulation ratios, allowing a 30kW boiler to run as low as 3kW. This flexibility proves especially valuable in well-insulated modern homes with low heat demand.

Why Condensing Boilers Sometimes Don't Condense

Installations sometimes deliver disappointing savings. The boiler works fine, but efficiency remains stuck around 80% instead of the promised 90%+. Three factors typically explain this gap:

Oversized boiler: An installer calculated heat loss at 15kW but fitted a 35kW boiler "for safety margin." The oversized unit cycles frequently, never settling into steady condensing operation. Right-sizing matters more than having extra capacity.

High flow temperatures: The boiler runs at 75-80°C because the radiators were sized for an old boiler. Return temperatures stay above 65°C, preventing condensation. Adding one or two radiators or fitting larger replacements would enable lower flow temperatures.

Poor controls: A basic on/off timer with no weather compensation or room thermostat causes the boiler to overshoot temperature targets. Advanced controls from Honeywell, Danfoss, or EPH Controls that modulate based on outdoor temperature and room-by-room demand keep the system in efficient operating ranges.

Installations where the condensate pipe was fitted incorrectly, sloping upward or with insufficient fall, also occur. Condensate pooled in the pipe triggers nuisance shutdowns. The boiler works intermittently but never achieves its efficiency potential because it spends half its time locked out.

Weather Compensation and Load Compensation

These control strategies maximise condensing boiler efficiency by matching boiler output to actual demand.

Weather compensation uses an outdoor temperature sensor to adjust flow temperature. When it's 10°C outside, the boiler might run at 55°C flow temperature. When it drops to -3°C, flow temperature increases to 70°C. This keeps return temperatures as low as possible whilst maintaining comfort.

Field studies show that weather compensation improves seasonal efficiency by 8-12% compared to fixed-temperature operation. The boiler spends more time in full condensing mode during the shoulder seasons (spring and autumn) when homes need less heat.

Load compensation monitors how quickly rooms reach the target temperature. If the temperature rises faster than expected, the system reduces output. If it lags, output increases. This responds to variables like solar gain, internal heat from cooking and occupants, and wind chill.

Combined weather and load compensation, along with room-by-room zoning through thermostatic radiator valves, creates a system that rarely overshoots and constantly optimises for condensing operation.

Maintenance Requirements

Condensing boilers need annual servicing to maintain efficiency and safety. The service includes:

Combustion analysis: A flue gas analyser measures oxygen, carbon monoxide, and carbon dioxide levels to verify complete combustion. Readings outside specification indicate burner problems or heat exchanger fouling.

Heat exchanger inspection: The secondary heat exchanger can accumulate scale or sludge, reducing heat transfer and preventing condensing. Chemical cleaning or mechanical flushing restores performance.

Condensate trap cleaning: The trap prevents flue gases from escaping through the condensate drain. Debris can block the trap, causing shutdowns. Annual cleaning takes five minutes and prevents mid-winter failures.

Pressure testing: The sealed heating system should maintain 1.0-1.5 bar pressure. Slow leaks indicate problems with the expansion vessel from suppliers like Altecnic Ltd, pressure relief valve, or system pipework.

Controls calibration: Temperature sensors drift over time. Verifying and recalibrating sensors ensures the boiler receives accurate information for modulation and condensing operation.

Skipping annual service costs more than the £80-120 service fee. Efficiency drops 2-4% annually without maintenance as combustion drifts out of specification and heat exchangers foul. Over five years, you'll spend an extra £100-200 on energy whilst increasing breakdown risk.

The Carbon Reduction Impact

Beyond personal savings, condensing boilers significantly reduce carbon emissions. A typical home replacing a 70% efficient boiler with a 90% efficient condensing model cuts gas consumption by 22%.

For a home using 15,000 kWh of gas annually, that's 3,300 kWh saved, equivalent to 610kg of CO₂ emissions prevented each year. Across the UK's 27 million homes, widespread adoption of condensing technology has eliminated approximately 16 million tonnes of CO₂ annually since the 2005 regulations took effect.

The environmental case strengthens when condensing boilers integrate with renewable technologies. A condensing boiler paired with solar thermal panels operates at even lower flow temperatures, pushing efficiency toward 95%. Heat pumps, which become economically viable in well-insulated homes, can work alongside condensing boilers in hybrid systems; the heat pump handles base load whilst the boiler covers peak demand.

Conclusion

Condensing boilers transformed home heating efficiency through elegant engineering, capturing energy that older boilers wasted and converting it into useful heat. The 90%+ efficiency isn't marketing hyperbole; it's achievable when the boiler, heating system, and controls work together properly.

The efficiency gap between condensing and non-condensing technology is wide enough that regulations now mandate condensing boilers for most installations. But maximum performance requires more than just fitting the right equipment. Return temperatures matter. System design matters. Controls matter. A condensing boiler paired with oversized radiators, fixed-temperature operation, and poor controls might achieve 82% efficiency. The same boiler with right-sized radiators, weather compensation, and proper commissioning reaches 92% efficiency, a difference worth £150-200 annually.

If you're replacing an old boiler, focus on the complete system rather than just the boiler specification. Right-size the unit based on actual heat loss calculations. Consider upgrading radiators to enable lower flow temperatures. Invest in weather compensation controls. Ensure the installer properly commissions the system and sets up condensing operations.

For existing condensing boiler owners seeing disappointing performance, the solution often lies in optimisation rather than replacement. Adjusting flow temperatures, improving controls, or adding radiator capacity can unlock the efficiency your boiler was designed to deliver. Annual servicing maintains that performance year after year, protecting both your investment and your heating bills.

Brands like Andrews offer reliable condensing boiler options, whilst circulation pumps from Grundfos can optimise system performance. For expert advice on maximising your condensing boiler efficiency, Heating and Plumbing World provides comprehensive technical support.

-

-