Danfoss Oil Pumps: Product Range and Applications

When your oil-fired heating system stops working on a freezing January morning, the culprit is often a failed oil pump. These small but critical components keep fuel flowing from your tank to the burner, and when they fail, everything grinds to a halt. Danfoss has been manufacturing oil pumps for decades, building a reputation for reliability that heating engineers across the UK have come to trust.

Oil pumps might not be the most glamorous part of a heating system, but they're absolutely essential. They create the pressure needed to atomise fuel oil into a fine mist that can burn efficiently. Without proper atomisation, you get incomplete combustion, sooty burners, and wasted fuel. A quality pump like those in the Danfoss range ensures consistent pressure, clean combustion, and years of trouble-free operation.

What Makes Danfoss Oil Pumps Different

The Danish engineering behind Danfoss oil pumps shows in the details. These aren't generic pumps rebadged for different markets. Each model has been designed with specific applications in mind, from small domestic boilers to large commercial installations.

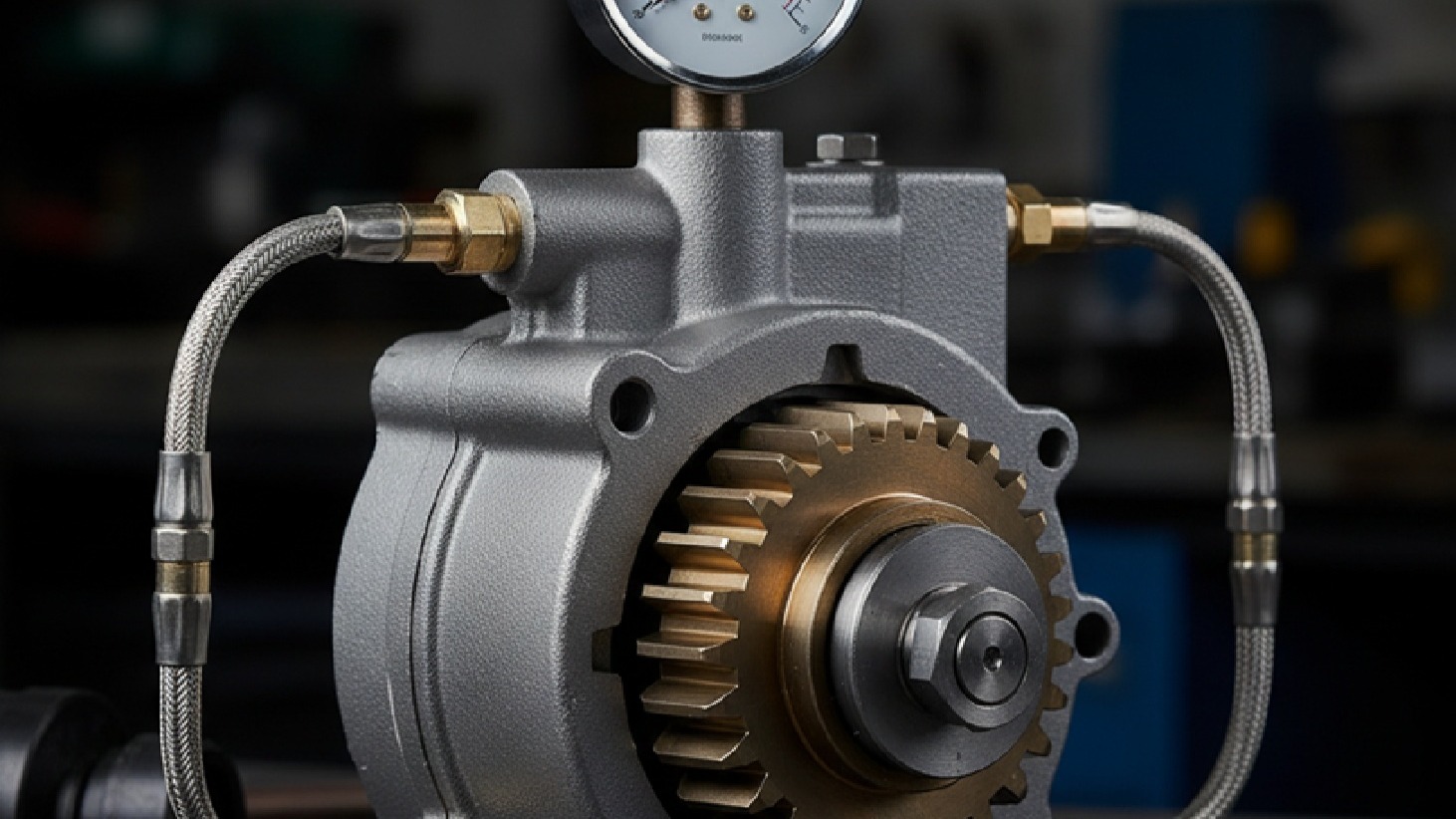

The build quality stands out immediately when you handle one. The cast iron bodies resist corrosion far better than aluminium alternatives, particularly important given that heating oil contains trace amounts of water and sulphur compounds. The shaft seals use materials that maintain flexibility across a wide temperature range, preventing leaks that plague cheaper pumps after a few years of service.

The integrated pressure regulating valve maintains consistent fuel pressure regardless of variations in supply or demand. Some budget pumps require external regulators, adding complexity and potential failure points to the system. Danfoss builds this functionality directly into the pump body, simplifying installation and improving reliability.

The magnetic coupling between the motor and the pump gear set is another thoughtful design element. This eliminates the need for shaft seals on the motor side, reducing maintenance requirements and preventing oil leaks into the motor housing. It's these engineering decisions that extend service life from five years to fifteen or more.

Understanding the BFP Range

The BFP series represents Danfoss's most widely used oil pump family. You'll find these fitted to the majority of domestic oil boilers and burners across the UK. The 'BFP' designation stands for 'Burner Fuel Pump', and the series includes several variants optimised for different applications.

Single-stage pumps work well for most domestic installations where the oil tank sits higher than the burner or within a few metres horizontally. These pumps create enough suction to draw oil from nearby tanks and generate the 10-12 bar pressure needed for proper atomisation. The BFP 21 series handles flow rates up to 14 litres per hour, suitable for typical domestic burners up to about 50kW output.

Two-stage pumps become necessary when oil must be lifted vertically or drawn over longer distances. These use two sets of gears in series, with the first stage creating strong suction and the second stage building pressure. The BFP 52 series can pull oil from tanks up to 4 metres below the burner or draw from tanks 10 metres away horizontally. Commercial installations almost always require two-stage pumps due to the distances involved.

The BFP range includes both right-hand and left-hand rotation models. This matters when replacing pumps on existing burners, as the rotation direction must match the motor. Installing a pump with the wrong rotation direction will result in no fuel delivery, though it won't damage the pump. Verifying rotation direction before ordering replacement units prevents installation problems.

Commercial and Industrial Applications

Larger heating installations require pumps that can deliver higher flow rates and work reliably under continuous operation. The RSA and RSH series from Danfoss oil pumps serve these demanding applications.

RSA pumps handle flow rates from 15 to 40 litres per hour, making them suitable for commercial boilers in hotels, hospitals, and industrial facilities. These pumps feature heavier construction than domestic models, with larger bearings and more robust gear sets. The pressure range extends up to 25 bar for applications requiring particularly fine atomisation.

RSA pumps installed in continuous operation situations run for months during winter, something that would quickly wear out a domestic pump. The key difference lies in the bearing design and lubrication system. Commercial pumps use larger oil reservoirs and more efficient splash lubrication to keep components cool and properly lubricated under sustained loads.

RSH pumps represent the heavy-duty end of the Danfoss range. These handle flow rates up to 113 litres per hour for very large burners. You'll find these in industrial boilers, large process heating systems, and district heating plants. The construction uses hardened steel gears and oversized bearings designed for 24/7 operation over many years.

An industrial client runs four 500kW burners for process heating, each fitted with an RSH 190 pump. These units have been operating continuously for over eight years with only routine filter changes. That's the kind of reliability that justifies the higher initial cost of quality components.

Selecting the Right Pump for Your Application

Choosing the correct oil pump involves more than matching flow rate to burner size. Several factors influence which model will work best for a particular installation.

Tank location affects whether you need a single or two-stage operation. Measure both the vertical lift (if any) and horizontal distance from tank to burner. A tank 2 metres below the burner requires two-stage pumping, even if it's only 3 metres away horizontally. Similarly, a tank at the same level but 12 metres away also needs two-stage capability.

Oil viscosity changes with temperature, affecting how easily pumps can draw fuel. Standard 28-second kerosene flows easily, but heavier oils like 35-second gas oil become thick in cold weather. If your tank sits outside or in an unheated outbuilding, consider this when sizing the pump. Two-stage pumps handle cold, viscous oil more reliably than single-stage units working at their limit.

Nozzle pressure requirements vary between burner designs. Most domestic burners operate at 10-12 bar, but some commercial units require 15-20 bar for proper atomisation. Check your burner specifications before selecting a pump. Installing a pump that can't reach the required pressure results in poor combustion and sooty deposits.

Rotation direction must match your motor. Most UK burner motors rotate clockwise when viewed from the motor end, requiring right-hand rotation pumps. However, some European burners use anticlockwise motors. If you're unsure, check the existing pump or motor nameplate before ordering.

The Danfoss range covers virtually every domestic and commercial application. When replacing an existing pump, matching the model number ensures compatibility. For new installations or upgrades, an appropriate pump specification based on system requirements ensures optimal performance.

Installation and Commissioning Considerations

Proper installation makes the difference between a pump that lasts fifteen years and one that fails after three. Oil pumps are relatively simple devices, but they're sensitive to certain installation errors.

Suction line sizing matters more than many installers realise. Undersized pipes create excessive vacuum at the pump inlet, causing the oil to release dissolved air. These tiny bubbles interfere with gear lubrication and reduce pump life. For single-stage pumps, use a minimum of 10mm copper or 3/8" steel pipe. Two-stage pumps drawing from distant tanks should use 12mm or larger. Quality pipe fittings and connectors ensure reliable connections throughout the fuel supply system.

Filter placement protects pumps from debris that would quickly destroy the precision gear sets. Position filters in the suction line before the pump, using inline filters with replaceable elements. Check filters during annual service and replace when discoloured or when pressure drop increases. A blocked filter starves the pump of oil, causing wear and eventual failure.

Vacuum gauges on the suction line help diagnose problems. Excessive vacuum (more than 0.4 bar) indicates restrictions in the supply line, filters, or tank pickup. This diagnostic tool costs less than £20 but can save hours of troubleshooting when problems arise.

Pressure adjustment requires care during commissioning. Danfoss pumps include an adjustment screw that sets the outlet pressure. Use a pressure gauge connected to the pump's pressure port, and adjust while the burner runs. Standard domestic settings run 10-12 bar, but check burner specifications. Over-pressure wastes energy and stresses seals; under-pressure causes poor atomisation.

Danfoss Pump Troubleshooting

Danfoss pump troubleshooting begins with systematic checks that identify whether problems lie in the pump itself or elsewhere in the system.

No fuel delivery usually indicates wrong rotation direction, a blocked filter, or an empty tank. Check rotation first, with the power off, rotate the pump coupling by hand in the expected direction. If the pump binds or feels wrong, rotation might be incorrect. Blocked filters cause the pump to run but deliver no fuel. Empty tanks seem obvious, but account for surprising numbers of service calls.

Inconsistent pressure suggests air in the suction line, worn gears, or a failing pressure regulator. Connect a vacuum gauge to the suction side. Readings that fluctuate indicate air leaks at joints or through the tank pickup tube. Steady high vacuum points to restrictions. Pressure that drops slowly over time indicates internal wear requiring pump replacement.

Noisy operation stems from several causes. Cavitation from excessive suction vacuum produces a rattling sound as air bubbles collapse inside the gear set. Worn bearings create grinding noises that worsen over time. A failing magnetic coupling sometimes produces clicking sounds. Distinguishing between these requires experience, but abnormal noise always warrants investigation.

Shaft seal leaks appear as oil weeping from around the drive shaft. This indicates seal wear and requires pump replacement. Seal kits exist but cost nearly as much as new pumps, making replacement more economical. Operating with leaking seals allows oil to contaminate the motor, potentially causing electrical failures.

Pressure fluctuation during operation suggests the pressure regulating valve has debris or wear. Some pumps allow regulator cleaning, but most benefit from replacement. Fluctuating pressure causes burner cycling and reduces efficiency.

Quality boilers from manufacturers like Andrews and Morco rely on consistent pump performance. Regular maintenance and prompt attention to developing problems prevent expensive burner damage.

Maintenance Best Practices

Pressure testing during annual service catches problems before they cause failures. Connect a gauge and verify that pressure remains stable under operation. Pressure that drops slowly indicates worn gears or seals. Pressure that fluctuates suggests air in the suction line or a failing strainer.

Regular filter changes prevent contamination from reaching pump internals. Replace inline filters annually at a minimum, more frequently in systems with known contamination issues. A £10 filter protects a £100 pump; the economics are straightforward.

Visual inspection during service reveals developing problems. Look for oil weeping from seals, corrosion on the pump body, or loose mounting hardware. Check electrical connections for signs of overheating or corrosion. These simple checks take minutes but prevent unexpected failures.

System Integration Considerations

The Grundfos heating circulation pumps available for water circulation serve different purposes than oil pumps, but both types contribute to overall system performance. Understanding how different pump types work together helps optimise heating efficiency.

While oil pumps deliver fuel to burners, water circulation pumps from Grundfos or Lowara distribute heat throughout the property. Both require proper specification and maintenance for optimal system performance.

Compatibility with Modern Heating Controls

Today's heating systems use sophisticated controls for efficiency and comfort. Oil pumps must integrate properly with these control systems to function reliably.

Most modern boilers use two-stage control, where the burner fires at a high or low rate depending on demand. This requires pumps that maintain stable pressure across varying flow rates. Danfoss oil pumps handle this well, with pressure regulators that compensate automatically for changes in flow.

Some advanced systems use modulating burners that continuously vary firing rate. These require pumps capable of maintaining consistent pressure from minimum to maximum flow. The BFP series handles modulation ranges up to 4:1 (for example, 3.5 to 14 litres per hour). Wider modulation ranges may require electronic pressure regulation rather than mechanical valves.

Solenoid valve integration allows the control system to shut off fuel flow independently of the pump. Many installers fit external solenoid valves, but several Danfoss models include integrated solenoids. This simplifies wiring and reduces potential leak points. The integrated design also ensures the solenoid receives proper cooling from oil flowing through the pump body.

Pressure switches monitor oil pressure and shut down the burner if pressure drops below safe levels. This protects against running out of fuel or pump failure. Danfoss pumps include a pressure port for connecting switches. Setting the switch about 2 bars below normal operating pressure provides reliable fault detection without nuisance trips.

Working with EPH Controls and other modern heating control systems requires understanding how oil pumps interact with electronic controls. The pump itself remains a mechanical device, but its integration with sensors and control valves determines system performance.

Integration with programmable thermostats from manufacturers like Honeywell ensures oil pumps operate only when heating is genuinely needed, maximising efficiency while maintaining comfort.

Environmental and Efficiency Considerations

Oil heating faces increasing scrutiny over environmental impact, making efficiency more important than ever. While the pump itself consumes minimal energy (typically 60-150 watts), its effect on combustion efficiency significantly impacts overall system performance.

Consistent pressure enables proper atomisation, which directly affects combustion efficiency. Poorly atomised fuel burns incompletely, wasting energy and producing more emissions. A quality pump maintaining stable pressure ensures the burner can achieve its designed efficiency, typically 85-90% for modern condensing oil boilers.

Nozzle wear accelerates when pumps deliver inconsistent pressure or contaminated fuel. Worn nozzles spray poorly, reducing efficiency and increasing emissions. Quality pumps with effective filtration extend nozzle life from one year to three or more, reducing maintenance costs and improving average efficiency over time.

System tightness matters for both efficiency and environmental protection. Oil leaks waste fuel, and create environmental hazards. Danfoss pumps use high-quality seals and gaskets that maintain integrity over many years. The magnetic coupling design eliminates one potential leak path entirely.

The UK government's push towards low-carbon heating makes oil system efficiency increasingly important. While heat pumps and hydrogen receive more attention, millions of UK homes will continue using oil heating for decades. Maximising the efficiency of these systems through quality components like Danfoss pumps reduces environmental impact during the transition to alternative technologies.

Cost Considerations and Value

Quality oil pumps cost more upfront than budget alternatives, but the total cost over their service life tells a different story. A Danfoss BFP pump might cost £80-120, while generic alternatives sell for £40-60. However, the cheaper pump typically lasts 5-7 years, while the Danfoss unit often exceeds 15 years.

Replacement costs include more than just the pump price. Each replacement requires a service visit, system shutdown, and recommissioning. For a domestic property, the labour and travel costs easily exceed £100. For commercial properties, the cost of heating system downtime can be substantial. A pump that lasts twice as long saves not just the replacement part cost but also the installation labour.

Efficiency losses from worn pumps gradually increase fuel consumption. A pump delivering inconsistent pressure might reduce combustion efficiency by 2-3%, costing £50-100 annually in wasted fuel for a typical home. Over ten years, this adds up to more than the cost of a quality pump.

Warranty coverage differs significantly between brands. Danfoss provides comprehensive warranty support through authorised distributors. Budget pumps often have limited or unclear warranty terms, and getting warranty replacements can prove difficult.

A comprehensive range of heating components including oil pumps demonstrates how quality parts reduce callbacks and keep customers' systems running reliably. The modest additional investment in quality pumps pays back through reduced service calls and longer system life.

Supporting Components for Oil Systems

Complete oil heating systems require more than just pumps. Quality cylinders from manufacturers like Gledhill and Kingspan store hot water efficiently, while proper system pressurisation components from Altecnic maintain optimal operating conditions.

Understanding how all components work together, from fuel pumps to heat distribution to hot water storage, ensures comprehensive system performance and reliability.

Achieving Long-Term Reliability

Danfoss oil pumps represent proven engineering refined over decades of practical use. Whether maintaining a domestic oil boiler or specifying components for a commercial heating system, understanding the range and applications helps select the right pump for reliable, efficient operation.

The BFP series handles the majority of domestic applications, with single-stage models for straightforward installations and two-stage units for challenging tank locations. Commercial and industrial applications benefit from the RSA and RSH ranges, which provide the flow rates and durability required for continuous operation.

Proper selection, installation, and maintenance determine whether a pump provides five years or fifteen years of service. Taking time to size suction lines correctly, install adequate filtration, and verify pressure settings during commissioning prevents the most common problems. Annual filter changes and pressure checks catch developing issues before they cause failures.

The initial cost difference between quality pumps and budget alternatives is modest compared to the total cost of ownership. When you factor in replacement labour, system downtime, and efficiency losses from worn pumps, quality components like those in the Danfoss range deliver better value over their service life.

Oil heating continues serving millions of UK properties, particularly in rural areas without mains gas access. While the technology may not be the latest trend, it remains practical and efficient when properly implemented. Quality components ensure these systems deliver reliable, efficient heating for years to come.

For quality Danfoss oil pumps and comprehensive Danfoss pump troubleshooting support, Heating and Plumbing World supplies certified products suitable for both domestic and commercial oil heating installations. If you need specific advice on pump selection or system diagnostics, get in touch for expert guidance tailored to your heating system requirements.

-

-