Differential Pressure Gauges for Filter Monitoring

Filter blockage doesn't announce itself with flashing lights or alarm bells. It creeps in gradually. A slight increase in energy consumption here, a minor drop in airflow there, until suddenly you're dealing with a system failure, an angry facilities manager, and a call-out that could have been avoided. Differential pressure gauges solve this problem by giving you a simple, visual indicator of when a filter needs changing, long before it causes damage to expensive equipment or compromises indoor air quality.

These gauges measure the pressure drop across a filter, comparing the pressure on the dirty side (upstream) to the clean side (downstream). As the filter captures particulates and debris, the pressure difference increases. When it reaches a predetermined threshold, you know it's time to service or replace the filter. It's straightforward, reliable, and removes the guesswork from maintenance schedules.

For heating engineers, plumbers, and HVAC technicians working on commercial installations or residential systems with mechanical ventilation, understanding how these gauges work and how to specify them correctly can save significant time and money.

Why Measuring Differential Pressure Matters

Think of a filter like drinking through a straw. When the straw's clear, liquid flows easily. Pack it full of debris, and you're sucking harder for the same amount of liquid. That extra effort is exactly what happens to your fan or pump when a filter clogs.

In an HVAC air filters system, a clogged filter can reduce airflow by 30-50%, forcing the fan motor to run at higher speeds or for longer periods. On a commercial air handling unit (AHU), that's not just a minor inefficiency. It's a measurable hit to your client's energy bills and a potential breach of building performance standards. Worse, reduced airflow can lead to inadequate ventilation, poor temperature control, and even frozen evaporator coils in cooling systems.

Differential pressure gauges provide an early warning system for filter blockage monitoring. They let you monitor filter condition in real time, so you can plan maintenance proactively rather than reactively. Instead of changing filters on an arbitrary schedule (which either wastes money by replacing them too early or risks system damage by leaving them too long), you change them based on actual performance data. That's professional filter blockage monitoring, not guesswork.

For comprehensive filtration monitoring across all system types, Heating and Plumbing World stocks the differential pressure gauges and instrumentation that help you maintain peak performance.

How Differential Pressure Gauges Work

The operating principle is simple. The gauge connects to two pressure taps, one on the upstream (dirty) side of the filter and one on the downstream (clean) side. The difference between these two readings is the differential pressure, typically measured in Pascals (Pa) measurement, inches of water column (in. W.C.), or millibars (mbar).

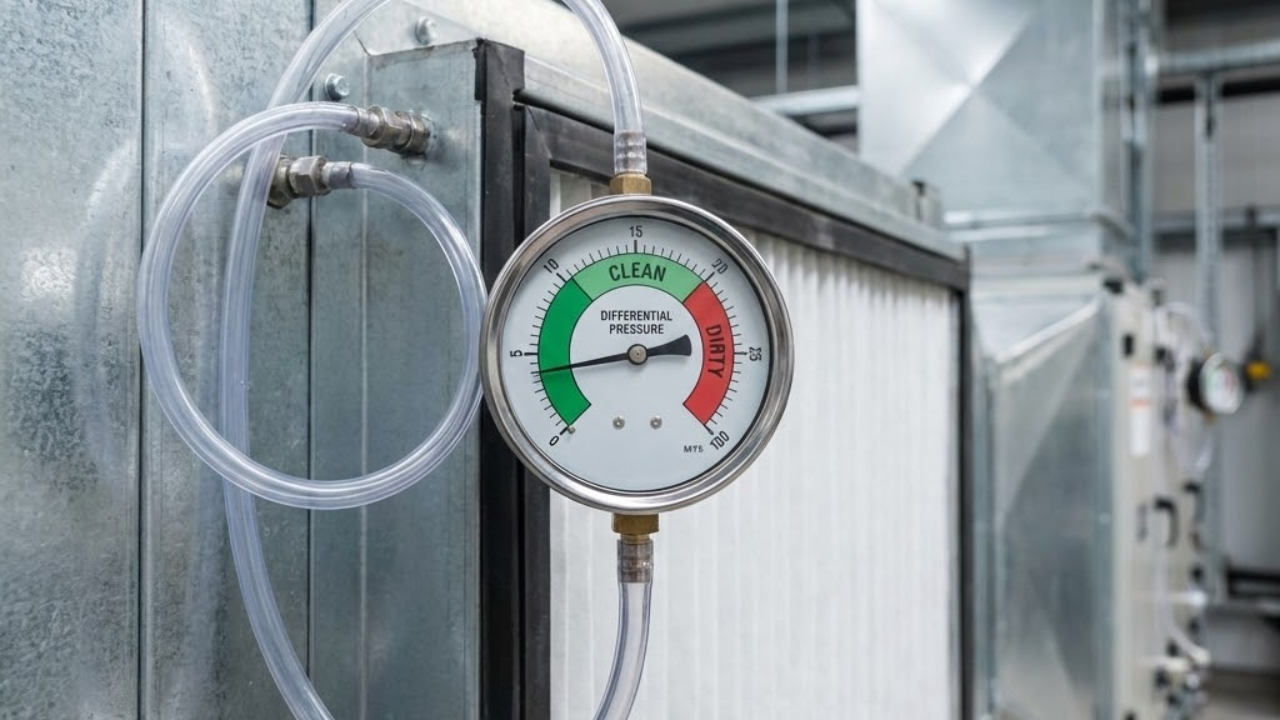

When the filter is new, the differential pressure is low, often just a few Pascals. As the filter loads with particulates, the differential pressure rises. Most differential pressure gauges feature a colour-coded dial or scale with green, amber, and red zones. Green indicates the filter is clean and operating efficiently. Amber signals that the filter is approaching the end of its service life. Red means the filter is blocked and needs immediate replacement.

A Magnehelic gauge is among the most common mechanical devices in HVAC applications. It uses a diaphragm that responds to pressure changes, moving a pointer across a dial. These gauges are robust, require no power supply, and are easy to read at a glance. However, they're not suitable for environments with high vibration or where remote monitoring is required.

Some systems use electronic differential pressure transmitters instead of mechanical gauges. These devices convert the pressure difference into an electrical signal that can be fed into a building management system (BMS) or SCADA interface. This allows for remote monitoring, automated alerts, and data logging. Useful on large commercial sites where you're managing dozens of AHUs or process filters across multiple buildings. BMS integration transforms standalone monitoring into comprehensive facility management.

Choosing the Right Gauge for the Application

Not all differential pressure gauges are created equal. The right choice depends on the system type, filter media, and operating environment.

Magnehelic gauges dominate HVAC air filters applications. They're mechanical devices with a diaphragm that responds to pressure changes, moving a pointer across a dial. They're robust, require no power supply, and are easy to read at a glance during routine inspections. The dial face typically shows Pascals (Pa) measurement with color zones for quick status assessment. However, they're not suitable for environments with high vibration or where remote monitoring is required.

Digital gauges and transmitters offer greater accuracy and can interface with control systems. They're ideal for critical applications like cleanrooms, pharmaceutical manufacturing, or data centres, where maintaining precise environmental conditions is non-negotiable. These devices often include features like adjustable alarm setpoints, data logging, and Modbus or BACnet communication protocols for BMS integration. When you need automated alerts sent to maintenance staff phones or integration with energy management systems, digital transmitters are the answer.

Portable differential pressure meters are useful for commissioning and diagnostic work. If you're troubleshooting a system or verifying that a newly installed filter is performing correctly, a handheld meter lets you take quick readings without installing permanent instrumentation. They're essential tools for any commercial HVAC engineer's kit.

For pump and circulator installations where air quality depends on proper filtration, Grundfos equipment benefits from accurate differential pressure monitoring to ensure optimal system performance.

When specifying a gauge, pay attention to the pressure range. A typical HVAC air filters installation might operate with a clean differential pressure of 50-100 Pa and a dirty pressure of 200-250 Pa. Choose a gauge with a range that covers this span without being overly sensitive. A gauge with a 0-500 Pa range is often a good fit for standard air filters. For high-efficiency HEPA filters, you might need a 0-1000 Pa range, as these filters have higher inherent resistance even when clean.

Installation Best Practices

Proper installation is critical for filter blockage monitoring accuracy. If the pressure taps are positioned incorrectly or the tubing is kinked, you'll get false readings that undermine the entire purpose of the gauge.

Position the upstream tap at least 1.5 times the duct diameter before the filter. This ensures you're measuring static pressure in a relatively stable airflow zone, not turbulent pressure near the filter face. The downstream tap should be at least 1 diameter after the filter, again to avoid turbulence. These spacing requirements aren't arbitrary. They're based on fluid dynamics principles that ensure you're measuring actual filter resistance, not flow disturbances.

Use rigid tubing or high-quality flexible tubing for the pressure lines connecting to your differential pressure gauges. Avoid long runs where possible, as this can introduce lag in the reading. If you must use long runs, ensure the tubing is supported and protected from damage. In systems with high humidity or where condensation is a risk, install the gauge above the pressure taps and loop the tubing downward before connecting it to the gauge. This prevents condensate from accumulating in the gauge and causing inaccurate readings or internal corrosion.

For systems requiring sophisticated control, brands like Danfoss offer control solutions that integrate seamlessly with differential pressure monitoring, helping you maintain optimal filter blockage monitoring performance.

Mount the gauge in a visible, accessible location. There's no point installing a Magnehelic gauge if maintenance staff can't see it without climbing a ladder or opening a locked panel. Ideally, it should be at eye level near the filter access door, so it's checked every time someone services the filter. Visibility drives compliance. If the gauge is easy to see, it gets checked. Hidden gauges get ignored.

Interpreting Gauge Readings

A common mistake is assuming that any increase in differential pressure means the filter is failing. In reality, a gradual increase is normal and expected. What you're looking for is the point at which the pressure drop exceeds the manufacturer's recommended threshold.

Most filter manufacturers specify a maximum allowable differential pressure, typically between 200-250 Pa for standard pleated filters used in HVAC air filters systems. Exceeding this limit doesn't just waste energy. It can damage the filter media itself. High differential pressure can cause the filter to collapse inward, allowing unfiltered air to bypass around the edges. You've probably seen this on site: a filter that looks like it's been crushed, with the pleats flattened and the frame distorted. That's what happens when differential pressure gauges readings are ignored.

If the gauge shows a sudden spike in differential pressure, that's a red flag for filter blockage monitoring. It could indicate a blockage (perhaps a plastic bag or piece of insulation sucked into the intake), or it might mean the filter has been installed incorrectly, with the airflow direction reversed. Check the filter orientation and inspect for obstructions before assuming the filter is simply dirty.

On the other hand, if the differential pressure remains very low even after months of operation, it might suggest that the filter isn't sealing properly. Air could be bypassing the filter entirely, rendering it useless for filter blockage monitoring purposes. Verify that the filter is seated correctly in its frame and that the gaskets or seals are intact.

Common Applications Beyond HVAC

Whilst HVAC air filters systems are the most obvious application, differential pressure gauges are used across a wide range of systems where filtration is critical.

In commercial boiler houses, they monitor fuel oil filters and water treatment filters. A blocked oil filter can starve a burner of fuel, causing incomplete combustion, soot buildup, and potential lockouts. Monitoring differential pressure lets you schedule filter changes during planned maintenance windows rather than dealing with emergency shutdowns. That's the difference between a £30 filter change on Tuesday morning and a £500 emergency callout on Saturday night.

Compressed air systems rely on multiple stages of filtration to remove moisture, oil, and particulates. Each filter stage can be monitored with a differential pressure gauge. In a manufacturing environment where compressed air powers critical machinery, filter failure can halt production. A simple gauge provides an early warning that keeps the line running. When production downtime costs £1,000 per hour, a £60 Magnehelic gauge is the best investment you'll make.

Water filtration systems, whether for process water, potable water, or wastewater treatment, also benefit from differential pressure monitoring. As sediment, rust, or biological material accumulates in a filter cartridge, the pressure drop increases. In large commercial or industrial installations, differential pressure transmitters can trigger automatic backwash cycles or alert operators when manual intervention is needed.

For expansion vessel and pressurisation applications where water quality affects system longevity, Altecnic Ltd equipment benefits from proper filtration monitoring to prevent contamination damage.

Even in domestic settings, differential pressure gauges are increasingly common. High-end mechanical ventilation with heat recovery (MVHR) systems often include gauges to monitor the condition of supply and extract air filters. Homeowners can check the gauge during routine inspections and replace filters as needed, ensuring the system operates efficiently and maintains good indoor air quality. That's proactive home maintenance, not reactive crisis management.

Maintenance and Calibration

Differential pressure gauges are low-maintenance devices, but they're not maintenance-free. Mechanical Magnehelic gauges can drift over time, especially if exposed to vibration, temperature extremes, or corrosive environments. Check the gauge periodically against a known reference or a calibrated portable meter to ensure accuracy.

If you're working with electronic transmitters for BMS integration, follow the manufacturer's calibration schedule, typically annually for critical applications. Many modern transmitters include self-diagnostic features that alert you to sensor faults or calibration errors, but don't rely on these alone. Physical verification is always worth the effort, particularly on systems where filter blockage monitoring affects building safety or compliance.

Clean the pressure taps and tubing as part of your filter maintenance routine. Dust and debris can block the taps, leading to false readings that undermine filter blockage monitoring effectiveness. A simple puff of compressed air or a quick wipe with a damp cloth is usually sufficient. This takes 30 seconds during a filter change and prevents the "gauge stopped working" complaints six months later.

Integrating with Building Management Systems

On larger commercial projects, standalone differential pressure gauges are useful, but integrating differential pressure monitoring into a BMS offers significant advantages through comprehensive BMS integration. You can set up automated alerts that notify maintenance staff when a filter reaches its service threshold. Historical data lets you track filter performance over time, identify patterns, and optimise replacement schedules.

For example, if you notice that filters in one AHU need changing every three months whilst others last six months, it might indicate an issue with the intake location. Perhaps it's near a loading bay where diesel fumes and particulates are higher. Adjusting the intake or upgrading to a higher-grade pre-filter can reduce maintenance frequency and improve system performance. That's the power of data-driven filter blockage monitoring.

BMS integration also supports energy management initiatives. By correlating differential pressure data with fan energy consumption, you can quantify the cost of running a system with dirty filters and justify investment in more frequent maintenance or higher-quality filtration media. Many organisations are surprised to discover that the energy penalty of running clogged filters far exceeds the cost of the filters themselves.

For systems requiring sophisticated control, brands like Honeywell offer control solutions that integrate seamlessly with differential pressure gauges and filter blockage monitoring systems, helping you maintain optimal performance.

Real-World Example: The Value of Proactive Monitoring

A facilities manager at a mid-sized office building once called about one floor that was consistently too warm in summer and too cold in winter. The AHU serving that floor was running, the thermostat settings were correct, and the ductwork appeared sound. When the engineer checked the differential pressure gauge on the AHU, it was buried deep in the red zone, well over 300 Pa.

The filter hadn't been changed in over a year. Airflow was so restricted that the heating and cooling coils couldn't transfer enough energy to condition the space properly. The fan motor was drawing 40% more current than it should have been, and the bearings were starting to fail from the excessive load. Replacing the filter cost £80. Replacing the motor would have been closer to £1,200, plus downtime and labour.

That's the value of a differential pressure gauge and proper filter blockage monitoring. It's a simple device, but it provides critical information that prevents expensive failures and keeps systems running efficiently. The Magnehelic gauge showed the problem instantly. No diagnostic equipment needed, no guesswork, just a clear visual indication that the filter was restricting airflow to dangerous levels.

Selecting the Right Supplier

When sourcing differential pressure gauges, choose a supplier that understands the technical requirements of your application. Heating and Plumbing World stocks a range of gauges and transmitters suitable for HVAC, heating, and plumbing systems, backed by technical support to help you select the right device for your project.

If you're specifying equipment for a new build or retrofit, consider the long-term benefits of investing in quality instrumentation. A cheap gauge might save £20 upfront, but if it fails or provides inaccurate readings for filter blockage monitoring, the cost of system downtime or inefficient operation will quickly dwarf that initial saving.

Conclusion

Differential pressure gauges are one of those unsung components that quietly prevent problems rather than solving them. They won't make your system run faster or more powerfully, but they'll keep it running efficiently, reliably, and safely. For the small investment of a gauge and a few minutes of installation time, you gain visibility into filter condition through effective filter blockage monitoring, reduce energy waste, and avoid unexpected breakdowns.

Whether you're working on a commercial AHU with HVAC air filters, a residential MVHR system, or an industrial filtration setup, specifying and installing a differential pressure gauge is a mark of professional practice. It shows you're thinking beyond the immediate installation and considering the long-term performance and maintainability of the system. That's the difference between a job done and a job done right.

The Magnehelic gauge remains the industry standard for reliable filter blockage monitoring, whilst digital solutions with BMS integration offer advanced capabilities for larger facilities. Proper pressure taps positioning and Pascals (Pa) measurement accuracy ensure you get the data you need to maintain peak system performance and avoid the costly consequences of neglected HVAC air filters maintenance.

For complex projects or if you need advice on integrating differential pressure monitoring into a BMS with proper pressure taps and BMS integration, don't hesitate to contact us for guidance. Getting the specification right at the design stage is always easier and cheaper than retrofitting later.

-

-