Flame Failure Devices in Gas Fires: How They Work

A gas fire that suddenly cuts out can leave you cold and confused. Behind this safety feature sits a small but crucial component: the flame failure device. This mechanism protects thousands of UK homes from potentially dangerous gas leaks every day, yet most homeowners know little about how it actually works.

Understanding your gas fire's flame failure device helps you recognise when something needs attention and why regular servicing matters. We'll walk through the mechanics, common issues, and maintenance tips that keep these safety devices functioning properly.

What Makes a Flame Failure Device Essential

Every gas appliance in your home needs a way to detect whether the flame is actually burning. Without this detection, gas could continue flowing into an unlit appliance, creating a dangerous buildup that could lead to an explosion or carbon monoxide poisoning.

The gas fire flame failure device acts as a safety switch. When it detects no flame, it automatically shuts off the gas supply within seconds. This simple action prevents approximately 95% of potential gas-related accidents in UK homes.

Modern building regulations require all gas fires to include these devices. The Gas Safety (Installation and Use) Regulations 1998 made them mandatory for all new installations, though many older appliances were retrofitted for safety.

The Science Behind Flame Detection

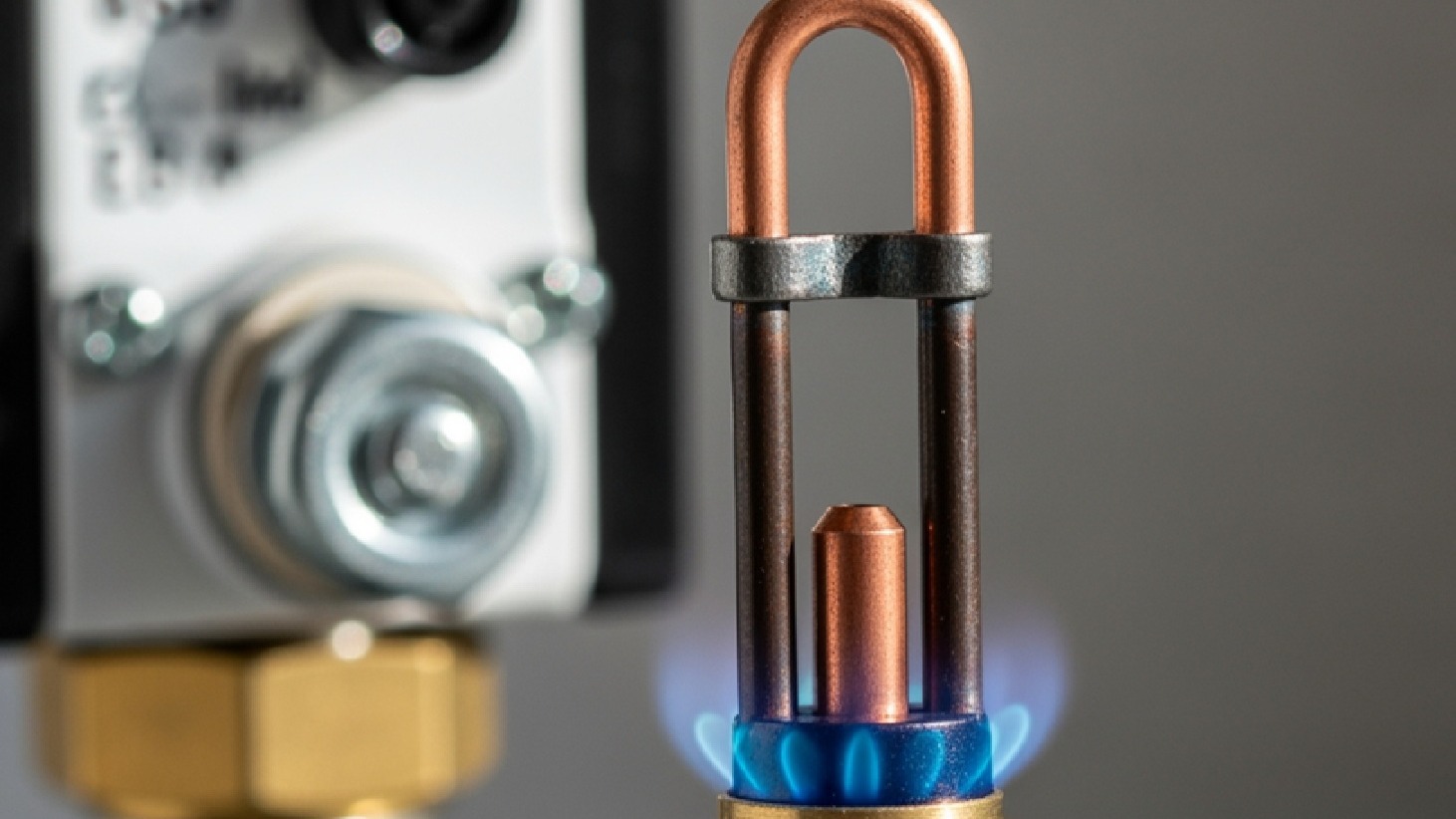

Flame failure devices work through thermoelectric generation, a process where heat creates electrical current. At the heart of the system sits a thermocouple, a probe made from two different metals joined at one end.

When you light your gas fire, the flame heats the thermocouple tip to around 300°C. This temperature difference between the hot tip and cool base generates a small electrical current, typically 20-30 millivolts. This tiny current flows through a circuit to an electromagnet in the gas valve.

The electromagnet holds the gas valve open as long as current flows. Remove the flame, and the thermocouple cools within 30-60 seconds. The current stops, the magnet releases, and a spring snaps the gas valve shut.

Components That Work Together

Your gas fire's safety system involves several parts working in harmony:

The Thermocouple: This copper-coloured probe sits directly in the pilot flame. Quality thermocouples from manufacturers like Honeywell typically last 5-10 years with proper maintenance.

The Gas Valve: Contains the electromagnet and spring mechanism. When energised by the thermocouple, it allows gas flow. Without power, springs force it closed.

The Pilot Assembly: Houses the pilot jet and provides a mounting point for the thermocouple. Proper positioning ensures the flame hits the thermocouple tip correctly.

Safety Interlock Switch: On many modern fires, this prevents the main burner from operating unless the pilot flame is established.

Recognising Common Problems

When gas fire flame failure devices malfunction, specific symptoms appear:

The pilot won't stay lit: You can light it, but it goes out as soon as you release the control knob. This usually indicates a failing thermocouple that can't generate enough voltage to hold the gas valve open.

Delayed shutoff: If the pilot takes longer than 60 seconds to shut off after the flame goes out, the thermocouple may be partially functioning but needs replacement.

Main burner won't light: Even with a healthy pilot flame, the main burner refuses to ignite. This often points to a faulty safety interlock switch.

Intermittent operation: The fire works sometimes but cuts out randomly. Carbon buildup on the thermocouple tip frequently causes this issue.

Testing Your Flame Failure Device

Regular flame failure device testing ensures your safety system functions correctly. Here's a simple monthly check you can perform:

Light your gas fire following the manufacturer's instructions. Once the main burner operates normally, blow out the pilot flame (on fires where this is accessible). The gas supply should stop within 60 seconds, and you should hear a distinct click as the valve closes.

If the gas continues flowing or takes longer than a minute to stop, contact a Gas Safe registered engineer immediately. Never attempt repairs yourself, gas appliances require professional servicing.

For a more thorough test, engineers use a multimeter to measure thermocouple output. A healthy thermocouple produces 25-35 millivolts when heated. Readings below 20 millivolts indicate replacement is needed.

Maintenance That Prevents Failures

Proper care extends the life of flame failure devices and ensures reliable operation:

Annual servicing: A Gas Safe engineer should inspect and clean all components yearly. They'll check thermocouple alignment, clean carbon deposits, and test electrical output.

Keep pilots clean: Dust and debris affect pilot flame quality. A weak or incorrectly shaped pilot flame won't heat the thermocouple properly.

Check flame colour: A healthy pilot burns blue with a defined inner cone. Yellow flames indicate incomplete combustion that produces excess carbon.

Avoid moisture: Thermocouples corrode when exposed to dampness. Ensure adequate ventilation prevents condensation around your gas fire.

Quality replacement parts make a difference when components need changing. Brands like EPH Controls and Danfoss manufacture reliable flame failure components that meet current safety standards.

Different Types for Different Fires

Not all gas fires use the same flame detection technology:

Thermocouple systems: Most common in older fires and decorative flame models. Simple, reliable, but require pilot flames.

Flame rectification: Uses the flame itself as an electrical conductor. More sensitive than thermocouples but needs electronic control boards.

Optical sensors: Detect ultraviolet light from flames. Common in commercial installations but rare in domestic fires.

Thermopile systems: Generate more power than single thermocouples, allowing battery-free remote controls. Popular in modern high-efficiency fires.

Each type has specific maintenance requirements and failure modes. Your fire's manual identifies which system you have.

When Replacement Becomes Necessary

Flame failure devices don't last forever. These signs indicate replacement time:

- Thermocouple readings consistently below 20 millivolts

- Visible corrosion or physical damage

- Repeated pilot outages despite cleaning

- Age over 10 years (preventive replacement)

Professional replacement typically costs £60-150 including parts and labour. Given the safety implications, this represents excellent value. Attempting DIY replacement risks gas leaks, improper operation, and invalidates insurance. Genuine spare parts for systems from Andrews or Morco ensure proper compatibility and safety.

Understanding Pilot Light Behaviour

The pilot light provides more than just ignition, it's your visual indicator of proper flame failure device operation:

A steady blue flame touching the thermocouple tip shows normal operation. The flame should envelop approximately 10mm of the tip for optimal heating.

Flickering or lifting flames indicate draught problems that prevent proper thermocouple heating. Check for blocked ventilation or excessive room air movement.

A pilot that goes out in windy weather suggests inadequate wind shielding. Modern fires include baffles to protect pilots, but older models may need upgrading.

Integration With Modern Controls

Today's gas fires often combine traditional flame failure devices with sophisticated electronic controls:

Remote control systems still require flame proving but add convenience features. Thermopile-powered remotes need no batteries or mains connection, drawing power from multiple thermocouples.

Programmable timers must verify flame presence before allowing scheduled operation. This prevents dangerous situations where fires attempt to light when no one's home.

Smart home integration brings app control to gas fires. These systems include additional safety features like room temperature monitoring and automatic shutoff timers.

Leading control manufacturers produce integrated systems that maintain safety whilst adding modern conveniences.

Troubleshooting Without Tools

Before calling an engineer, these checks might solve common problems:

Pilot won't light: Ensure gas supply is on. Hold the control knob down for 30 seconds after lighting, thermocouples need time to heat up.

Pilot lights but won't stay lit: Clean the pilot orifice with compressed air. Check the thermocouple sits correctly in the flame.

Main burner won't light despite good pilot: Verify the control knob fully engages. Listen for the click indicating safety interlock activation.

Random shutdowns: Look for draughts affecting the pilot. Check ventilation isn't blocked, causing oxygen starvation.

Remember, if simple checks don't resolve issues, professional help is essential. Gas appliances aren't suitable for DIY repairs.

The Future of Flame Safety

Flame failure technology continues advancing:

New ionisation sensors respond faster than thermocouples, shutting off gas in under 10 seconds. These appear in premium fires but will become standard as costs decrease.

Wireless monitoring allows engineers to diagnose problems remotely. Some systems alert homeowners to issues before complete failure occurs.

Self-diagnostic features in electronic controls identify specific faults. Error codes guide engineers to problems quickly, reducing repair time and cost.

Carbon monoxide integration adds another safety layer. Combined CO and flame detection shuts down fires if dangerous gases accumulate.

Ensuring Continued Safety

Gas fire flame failure devices stand as silent guardians in your gas fire, preventing potentially catastrophic accidents through simple but effective engineering. Understanding how these devices work helps you maintain them properly and recognise when professional attention is needed.

Regular servicing by qualified engineers keeps these safety systems functioning reliably. Quality replacement parts from established suppliers ensure your gas fire continues protecting your home for years to come. For genuine flame failure device components and professional-grade parts, Heating and Plumbing World supplies Gas Safe registered engineers throughout the UK. Technical support for specific installations and flame failure device testing requirements is available, get in touch for expert guidance.

The small investment in proper maintenance and timely repairs pays enormous dividends in safety and peace of mind. Your flame failure device works tirelessly to protect your family, understanding its operation helps you return the favour through proper care.

-

-