Flexible Hoses for Tap Connections: Quality Grades Explained

Walk into any plumbing aisle and you'll find flexible tap hoses ranging from £2 to £25. The price gap isn't arbitrary; it reflects fundamental differences in materials, construction, and lifespan that directly affect whether you're dealing with a leak next month or still running smoothly in ten years.

Most homeowners discover these differences the hard way: water pooling under the sink, a frayed outer layer, or worse, a full burst that floods the kitchen. Replacing hundreds of failed tap connectors reveals clear patterns about what separates reliable hoses from liability risks.

What Makes a Flexible Tap Hose Fail

Flexible tap hoses fail through three main mechanisms: pressure fatigue, chemical degradation, and mechanical wear. The cheapest hoses use thin-wall rubber compounds that harden over time, particularly when exposed to hot water. After 18-24 months, the rubber loses elasticity, cracks form at stress points, and leaks begin.

Mid-range failures typically occur at the crimp points where metal fittings attach to the hose body. Poor crimping allows microscopic water penetration that corrodes the reinforcement layer from the inside. You won't see this until the outer layer suddenly bulges, a sign that internal braiding has failed and only the rubber tube holds back full mains pressure.

Premium hoses fail too, but usually after 8-12 years and through gradual wear rather than catastrophic rupture. The difference lies in material quality and construction methods.

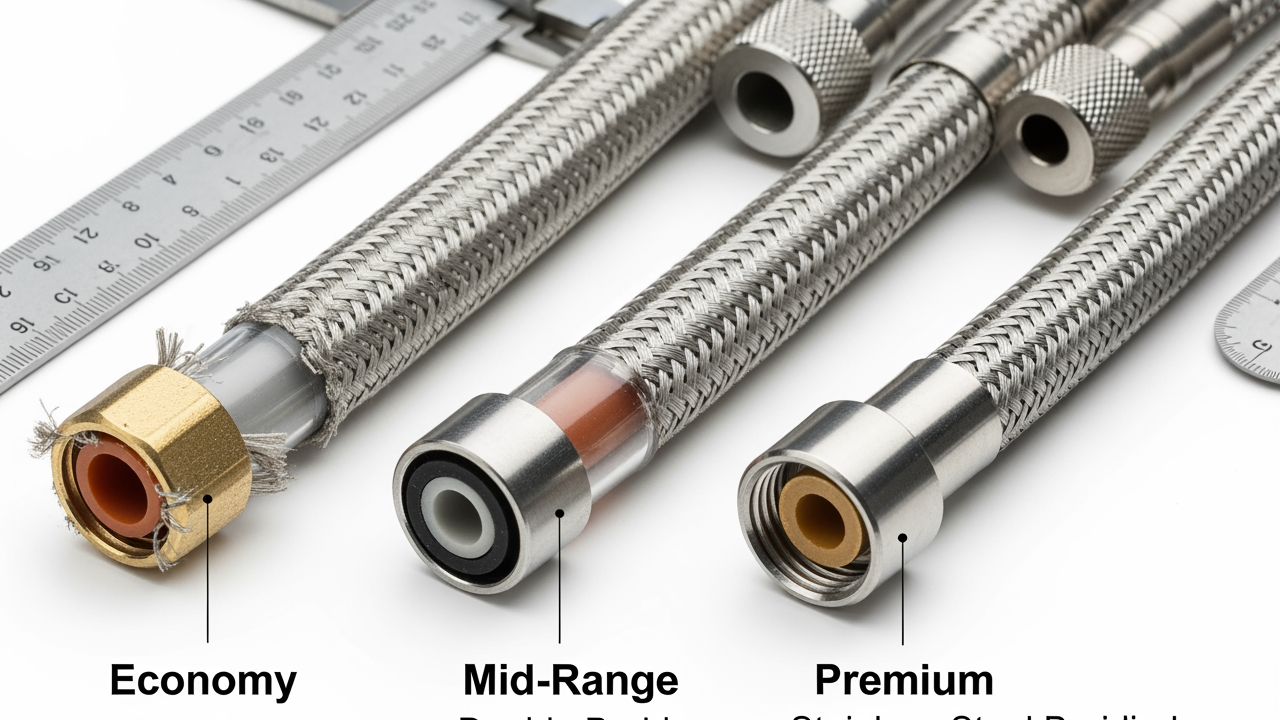

The Three Quality Tiers

Economy Grade: EPDM Rubber with Single Braid

These hoses use ethylene propylene diene monomer (EPDM) rubber with a single layer of stainless steel or aluminium braiding. Wall thickness runs 1.5-2mm on the rubber core. Fittings are typically brass-plated zinc alloy, crimped rather than swaged.

Expected lifespan: 2-3 years under normal use, less with frequent temperature cycling or hard water. Pressure rating: 10 bar (145 PSI), adequate for UK mains pressure but with minimal safety margin.

These fail most often at the nut connection, where the thin plating wears through and the base metal corrodes. The braiding provides minimal burst protection; it's more decorative than structural.

Mid-Range: Reinforced EPDM with Double Braid

Double-braided construction adds genuine burst protection. Two layers of stainless steel mesh, typically 304 grade, provide redundancy if one layer corrodes. The rubber core increases to 2.5-3mm wall thickness, and better compounds resist chlorine and limescale buildup.

Fittings use solid brass (not plated) with proper swaging that creates a mechanical lock rather than relying solely on crimping pressure. The swage process cold-forms the fitting into the hose layers, creating a bond that won't separate under pressure cycling.

Expected lifespan: 5-7 years. Pressure rating: 15-20 bar (217-290 PSI). These handle thermal expansion better and maintain flexibility longer than economy versions.

Premium Grade: FVMQ or Silicone Core with Stainless Steel Braid

Premium hoses replace EPDM with fluorosilicone (FVMQ) or medical-grade silicone. These materials resist temperatures from -40°C to 200°C without hardening, and they're immune to chlorine, limescale, and most household chemicals.

The braiding uses 316 marine-grade stainless steel, the same alloy used in boat fittings and chemical processing equipment. This grade resists pitting corrosion even in aggressive water conditions. Fittings are forged brass (stronger than cast) with precision-machined threads that seal without excessive torque.

Construction includes a PTFE barrier layer between the core and braiding. This prevents any chemical interaction between rubber and metal, eliminating a common long-term failure mode.

Expected lifespan: 10-15 years. Pressure rating: 25+ bar (362+ PSI). Working premium hoses have been removed from installations dating back to 2008.

Material Specifications That Matter

Core Tube Composition

EPDM works for cold water but degrades faster with hot water cycling. The repeated expansion and contraction create microcracks that propagate over time. Quality EPDM includes carbon black stabilisers that slow UV degradation and plasticisers that maintain flexibility.

FVMQ costs three times more to manufacture but handles temperature extremes without dimensional change. More importantly, it doesn't leach plasticisers into drinking water, a consideration for kitchen tap connections where water sits in the hose between uses.

Braiding Specifications

304 stainless steel contains 18% chromium and 8% nickel. It resists general corrosion but can pit in chloride-rich environments (coastal areas, water softener discharge).

316 stainless adds 2-3% molybdenum, which dramatically improves chloride resistance. For tap hoses, this matters most in hard water areas where limescale and chlorine combine to create aggressive conditions.

Braid density affects burst strength more than the number of layers. Quality hoses use 24-32 carrier braiding (the number of wire bundles woven into the mesh). Economy versions often use 16-carrier construction with larger gaps between wires.

Fitting Construction

Cast brass contains microscopic voids from the casting process. These create stress concentration points where cracks initiate under pressure cycling. Forged brass compresses the metal structure, eliminating voids and creating 30-40% higher fatigue strength.

Thread quality matters more than most installers realise. Precision-cut threads seal with 1.5-2 turns past hand-tight. Rough-cut threads require excessive torque, which crushes the fibre washer and creates leak paths once thermal cycling causes the fitting to relax.

Quality brass fittings from manufacturers like Danfoss demonstrate the engineering precision that separates reliable components from failure-prone alternatives. Their connection systems maintain seal integrity through thousands of pressure cycles.

Certification Standards and What They Mean

WRAS Approval

Water Regulations Advisory Scheme approval means the hose meets UK standards for drinking water contact. This certifies that materials won't leach harmful compounds and that the product withstands pressure testing: 1.5x working pressure for 60 seconds without leaking, then 2x working pressure burst test.

WRAS approval alone doesn't indicate quality grade; economy hoses can achieve it. Check for the approval number and verify it on the WRAS website; counterfeit certifications exist.

TMV2/TMV3 Compatibility

Thermostatic mixing valve installations require hoses that maintain flexibility and dimensional stability across temperature ranges. TMV-compatible hoses use materials that won't stiffen or expand enough to affect valve calibration.

This matters for bathroom installations where thermostatic mixing valves prevent scalding. A hose that swells with heat can restrict flow and throw off the temperature balance. Control systems from brands like Honeywell and EPH Controls pair with quality flexible hoses to maintain precise temperature regulation.

BS EN ISO 10508

This European standard specifies minimum requirements for flexible hoses in potable water systems. It mandates pressure testing, temperature cycling, and chemical resistance verification. Look for hoses marked with this standard plus the pressure class (Class 2 = 10 bar, Class 3 = 16 bar).

Length and Sizing Considerations

Standard flexible tap hoses come in 300mm, 500mm, and 1000mm lengths. Longer isn't automatically better; excess length creates flow restriction and provides more surface area for heat loss on hot water lines.

Calculate the required length by measuring from the tap tail to the isolation valve, then add 50mm for the connection curves. A hose that's too short creates tension on the fittings; too long and it kinks or rubs against cabinet walls.

Connection Sizes

UK taps typically use 1/2" BSP (British Standard Pipe) or 3/8" BSP connections. The tap tail thread is male, the isolation valve is male, so the hoses have female nuts on both ends. The thread pitch is 14 TPI for 1/2" and 19 TPI for 3/8", using the wrong size cross-threads and leaks immediately.

Some European taps use metric M10 threads. These won't seal properly with BSP fittings, even though they might thread on partway. Always verifythe thread type before purchasing tap connection components.

For comprehensive connection solutions, Heating and Plumbing World stocks a complete range of pipe fittings compatible with various tap configurations and installation requirements.

Installation Factors That Affect Lifespan

Even premium hoses fail prematurely with improper installation. The most common mistakes:

Over-tightening: Fibre washers compress to create the seal, not metal-to-metal contact. Once the washer touches both surfaces, add 1.5 turns maximum. More than this crushes the washer, creating leak paths when thermal cycling causes the fitting to contract slightly.

Kinking: Flexible hoses need a minimum bend radius, typically 25mm for standard sizes. Tighter bends create stress concentration that fatigues the braiding and cracks the core tube. If the hose shows visible deformation at the bend, it's too tight.

Vibration contact: Hoses that touch cabinet walls or pipes vibrate with water hammer and wear through the outer layer. This exposes the braiding to moisture and accelerates corrosion. Use plastic clips to secure hoses with 10-15mm clearance from hard surfaces.

Temperature exposure: Hoses routed near waste pipes or heating elements age faster. EPDM tolerates 90°C, but sustained exposure above 70°C halves the lifespan. Route hoses away from heat sources or upgrade to FVMQ if proximity is unavoidable.

When to Replace Rather Than Repair

Flexible tap hoses aren't repairable; any visible damage means replacement. Check hoses annually for these warning signs:

- Surface cracks or splits in the outer layer, even hairline fractures

- Bulging or swelling anywhere along the length (indicates internal braid failure)

- Corrosion or verdigris on the fittings, particularly around crimp points

- Stiffness or hardness when flexing the hose (rubber degradation)

- Weeping at connections that don't stop with modest tightening

Age alone warrants replacement for economy hoses after three years, mid-range after seven years, and premium after twelve years, regardless of visible condition. The materials degrade internally before external signs appear.

Cost Analysis: Economy vs Premium

A £3 economy hose replaced every two years costs £15 over ten years, plus installation time and potential leak damage. One £18 premium hose lasts the same period with higher reliability.

The real cost difference emerges with failure consequences. A leak caught early means towels and a replacement hose. A leak discovered after hours (or days) means damaged cabinets, flooring, and potentially ceilings in rooms below. Buildings insurance excess typically runs £250-500, and premiums increase after claims.

Premium hoses are recommended for any installation where leak detection isn't immediate: second bathrooms, rental properties, and under-sink locations without daily access. The price difference is negligible compared to risk reduction.

Choosing the Right Grade for Your Application

Economy Grade Suitable For:

- Temporary installations

- Locations with daily visual access

- Budget-constrained projects with planned short-term replacement

- Low-use applications (utility sinks, outdoor connections)

Mid-Range Suitable For:

- Standard residential installations

- Moderate water quality (not extremely hard or soft)

- Locations are checked weekly during routine cleaning

- Installations where leak damage would be contained and noticed quickly

Premium Grade Suitable For:

- Hard water areas (above 200 ppm calcium carbonate)

- Installations with restricted access or infrequent inspection

- Properties with vulnerable areas below (finished basements, commercial spaces)

- Any location where a leak could cause extensive damage before discovery

- Rental properties where tenant maintenance is inconsistent

For most residential applications, mid-range hoses offer the best balance of cost and reliability. Premium makes sense for high-risk locations, and economy grade rarely justifies the savings given replacement frequency and failure risk.

Water system components from manufacturers like Gledhill and Kingspan demonstrate the engineering standards that professional installations require. Their cylinder systems pair with quality flexible connections to create reliable, long-lasting plumbing installations.

Understanding Flexible Hose Quality

The quality difference between flexible tap hoses comes down to materials engineering and construction precision. Economy hoses use thin-wall EPDM rubber with minimal braiding and plated fittings, adequate for short-term use but prone to failure within 2-3 years. Mid-range options double the braiding, increase wall thickness, and use solid brass fittings that extend reliable service to 5-7 years. Premium hoses employ fluorosilicone cores, marine-grade stainless steel braiding, and forged brass fittings that deliver 10+ years of service.

The price difference, typically £2 versus £10 versus £20, represents genuine material and manufacturing cost variations, not marketing markup. Given that installation labour costs the same regardless of hose quality, and that leak damage far exceeds the component cost, choosing based solely on initial price creates false economy.

Match the hose grade to installation risk and water conditions. Check existing hoses annually for degradation signs, and replace proactively based on age rather than waiting for visible failure. Proper installation, correct length, appropriate torque, and clearance from vibration sources matter as much as material quality for achieving the expected lifespan. A £20 premium hose installed incorrectly fails faster than a £10 mid-range hose installed properly.

Flexible hose quality directly impacts system reliability and maintenance costs. For specialist advice on selecting appropriate connection components for your installation, get in touch with professionals who understand the technical requirements and failure mechanisms that separate reliable plumbing systems from recurring maintenance problems.

-

-