Flue Gas Temperature Sensors: Monitoring Boiler Efficiency

When your boiler suddenly stops working efficiently, one of the first things a heating engineer checks is the flue gas temperature. This single measurement reveals more about your boiler's health than almost any other diagnostic reading. Yet most homeowners have never heard of flue gas temperature sensors, despite these small devices playing a crucial role in keeping heating systems safe, efficient, and compliant with regulations.

Flue gas temperature sensors measure the heat level of exhaust gases leaving your boiler through the flue. If these readings are too high, your boiler is wasting energy and money. If they're too low, you might face condensation problems and potential damage to the flue system. Getting this balance right matters enormously, particularly as energy costs continue to climb and environmental regulations become stricter.

What Flue Gas Temperature Sensors Actually Do

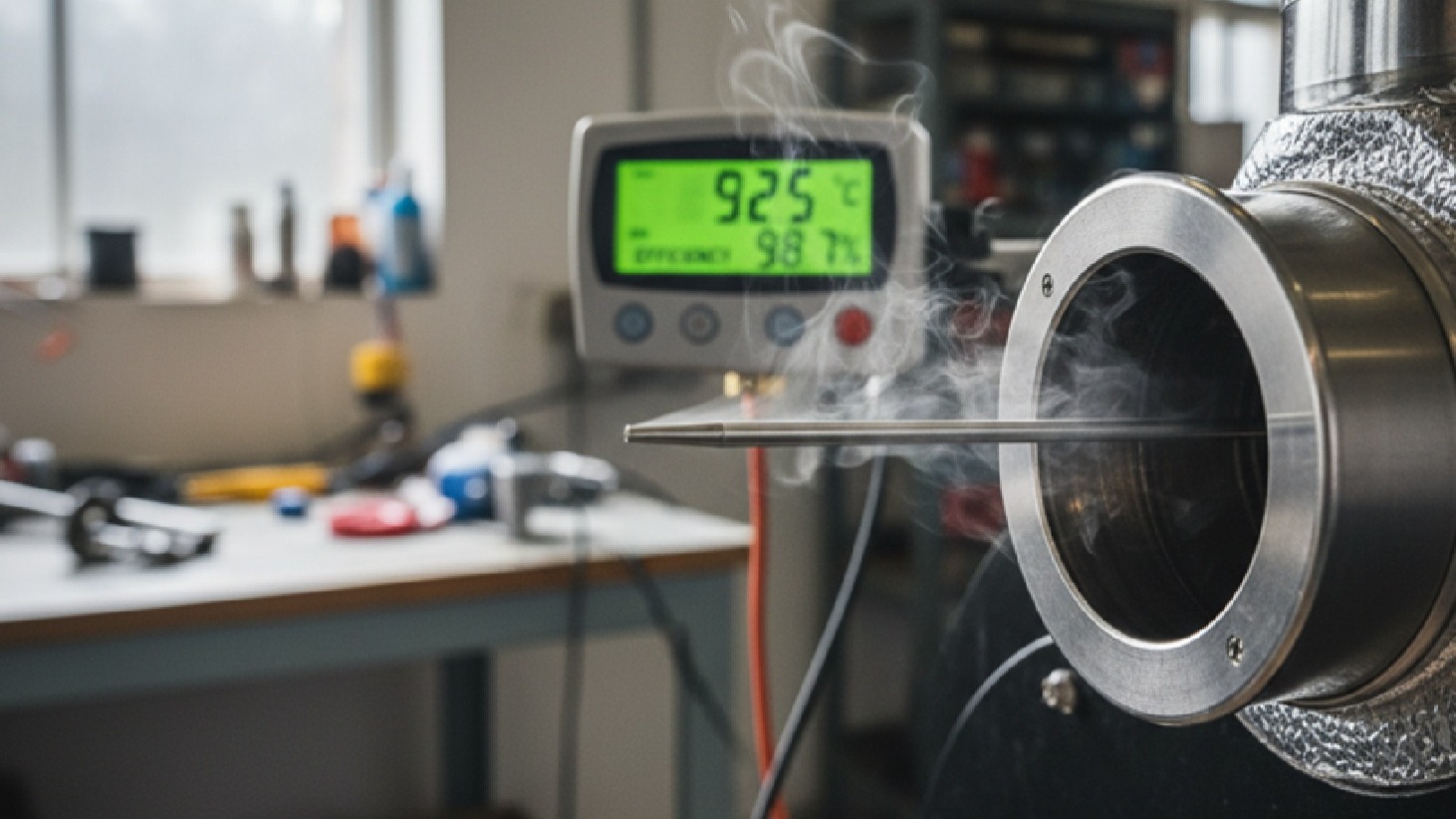

These sensors work by positioning a probe in the path of exhaust gases as they exit the boiler. The probe contains a thermocouple or resistance temperature detector that converts heat into an electrical signal. This signal feeds back to the boiler's control system, which uses the data to optimise combustion and flag potential problems.

Modern condensing boilers rely heavily on accurate flue gas readings. The entire condensing process depends on extracting as much heat as possible from exhaust gases before they leave the system. When flue gas temperatures drop below the dew point (typically around 55°C), water vapour condenses and releases latent heat back into the system. This process can boost efficiency by 10-15% compared to non-condensing boilers.

The sensor provides real-time feedback that allows the boiler to adjust the air-to-fuel ratio continuously. Too much air creates excess heat loss through the flue. Too little air leads to incomplete combustion, producing carbon monoxide and sooty deposits. Quality heating controls from Honeywell use these temperature readings alongside other parameters to maintain optimal combustion across different operating conditions.

Why Flue Gas Temperature Matters for Efficiency

Every degree of excess flue gas temperature represents wasted energy. Industry studies show that for every 20°C above the optimal temperature, you lose roughly 1% efficiency. This might sound trivial, but across a heating season, these losses add up significantly.

A properly functioning boiler should maintain flue gas temperatures between 50-65°C for condensing models during normal operation. Non-condensing boilers typically run between 150-250°C. Readings outside these ranges signal something needs attention.

High flue gas temperatures often indicate scaling on the heat exchanger, which acts as an insulating layer preventing heat transfer. Instead of warming your radiators and hot water, that heat escapes through the flue. Boilers running 40-50°C hotter than specification burn through hundreds of pounds in wasted gas annually.

Low temperatures in non-condensing systems create different problems. Flue gases contain sulphur compounds that form corrosive acids when they condense. These acids attack metal flue components and can cause premature failure. The sensor helps maintain temperatures above the acid dew point (typically 120-140°C) to prevent this damage. Think of it like keeping your car engine at the right temperature; too hot causes overheating damage, too cold prevents efficient operation.

Common Sensor Failures and Their Warning Signs

Temperature sensors don't last forever. Constant exposure to hot, corrosive gases gradually degrades the sensing element. Most sensors have a working life of 5-8 years, though this varies based on boiler usage and combustion quality.

The first sign of sensor failure is usually erratic boiler behaviour. The system might short-cycle (turning on and off frequently) or fail to modulate properly. You might notice the boiler running at full output even when minimal heat is needed, or conversely, struggling to reach temperature on cold mornings.

Error codes related to flue temperature are another clear indicator. Different manufacturers use various codes, but they generally point to readings outside expected parameters. Sometimes the sensor itself hasn't failed but has simply become coated in soot or deposits that skew its readings. Proper servicing includes cleaning or replacing the sensor as needed.

Physical damage can occur when sensors are positioned incorrectly or when flue components shift during installation or maintenance. Sensors pushed out of the gas stream entirely become useless for accurate measurement. Regular servicing by qualified engineers catches these issues before they cause serious problems.

How Sensors Improve Combustion Control

Modern boilers use sophisticated control algorithms that adjust combustion based on multiple inputs. Flue gas temperature is one of the most important. The control system compares actual flue temperature against target values and makes real-time adjustments to the gas valve and fan speed.

This feedback loop allows the boiler to adapt to changing conditions. When you first fire up a cold boiler, the control system runs it harder to reach operating temperature quickly. As the system warms up, it reduces output to maintain steady-state efficiency. The flue gas sensor provides crucial data that prevents overshooting or undershooting the target.

Brands like Grundfos integrate pump speed with temperature data to optimise flow rates through the heat exchanger. If flue temperatures rise, the system might increase pump speed to extract more heat before gases exit. This coordination between components separates good efficiency from excellent efficiency.

The sensor also enables adaptive combustion tuning. Over time, boilers drift from their factory settings due to wear, changes in gas pressure, or component degradation. Systems with active monitoring can compensate for these changes automatically, maintaining efficiency without manual adjustment. This feature has become increasingly important as natural gas composition varies seasonally.

Regulatory Requirements and Compliance

Building regulations require boilers to operate within specific efficiency parameters. Flue gas temperature monitoring helps demonstrate compliance during installation, commissioning and periodic inspections. Gas Safe engineers use flue gas analysers during servicing to verify proper combustion, and these readings must fall within manufacturer specifications.

The Boiler Plus legislation, introduced in 2018, raised minimum efficiency standards for new boiler installations. Meeting these standards requires precise combustion control, which depends on accurate temperature sensing. Systems from manufacturers like Andrews and Halstead incorporate advanced sensors to meet these stricter requirements.

Commercial installations face even more stringent monitoring requirements. Large boiler plants often need continuous emissions monitoring systems (CEMS) that record flue gas temperature sensor data alongside other parameters. These records prove compliance with environmental permits and help identify efficiency degradation before it becomes costly.

Maintaining Sensor Accuracy Over Time

Like any measuring instrument, flue gas temperature sensors need periodic verification. During annual servicing, engineers compare sensor readings against independent measurements using a calibrated flue gas analyser. Discrepancies of more than 10-15°C suggest the sensor needs replacement.

Flue Gas Sensor Cleaning

Flue gas sensor cleaning extends sensor life considerably. Soot and deposits from poor combustion coat the sensor, creating an insulating layer that slows response time and reduces accuracy. Regular servicing includes cleaning the sensor probe and checking its position in the flue gas stream.

A heating engineer once serviced a five-year-old boiler that was using 25% more gas than expected. The homeowner had maintained annual services, but the previous engineer had rushed through cleaning. When the sensor was properly cleaned, revealing a 3mm layer of carbon deposits, flue gas readings dropped by 35°C. The boiler immediately returned to specification, and the homeowner's next gas bill reflected £40 monthly savings.

Water quality affects sensor longevity in condensing boilers. Scale formation on heat exchangers forces the boiler to work harder, increasing flue gas temperatures and stressing the sensor. Fitting a scale inhibitor or using a magnetic filter protects not just the heat exchanger but also the temperature sensor downstream.

The electrical connections to temperature sensors are surprisingly vulnerable. Vibration from the burner and pump can loosen terminals over time. Moisture ingress corrodes connections, creating intermittent faults that are difficult to diagnose. Thorough servicing includes checking these connections and applying appropriate protection where needed.

Choosing Replacement Sensors

When replacement becomes necessary, using the correct sensor type is essential. Sensors are calibrated for specific temperature ranges and response times. Fitting an incorrect sensor might give readings that are technically accurate but don't match the boiler's control algorithm expectations.

Original equipment manufacturer (OEM) sensors are the safest choice. They're designed specifically for your boiler model and tested to work with its control system. Third-party sensors can work well but require careful specification matching. Heating and Plumbing World stocks a comprehensive range of heating system components from Danfoss that meet OEM standards, whilst offering good value.

Consider the sensor's mounting method when ordering replacements. Some use compression fittings, others require specific brackets or clips. The probe length must position the sensing element in the correct location within the flue gas stream. Too short and it misses the hottest gases; too long and it might interfere with flue components.

Response time specifications matter for boilers with rapid modulation. A slow sensor can't keep up with fast changes in firing rate, leading to control instability. Modern condensing boilers typically need sensors with response times under 10 seconds for optimal performance.

The Broader Picture of Boiler Monitoring

Flue gas temperature is just one piece of the efficiency puzzle. Complete boiler monitoring includes return water temperature, flow rates, gas pressure, and combustion air readings. Together, these measurements paint a complete picture of system health.

Systems like those available from EPH Controls integrate multiple sensors to provide comprehensive monitoring and control. This approach catches problems earlier and enables more sophisticated optimisation strategies than single-point monitoring.

The data from temperature sensors increasingly feeds into smart heating systems that learn your usage patterns and weather conditions. These systems use historical fuel temperature data to predict when servicing is needed, shifting from reactive to predictive maintenance. This approach reduces emergency breakdowns and extends equipment life.

Making the Investment Work

Quality flue gas temperature sensors typically cost between £30 and £ 80 for domestic boilers, with commercial units running higher. This modest investment protects a heating system worth thousands of pounds and prevents efficiency losses that cost far more than the sensor itself.

Efficiency improvements of 3-5% from replacing a failed or degraded sensor are common. In a typical household spending £1,200 annually on heating, that's £36-60 saved every year. The sensor pays for itself within the first heating season, then continues delivering savings for years.

Beyond direct fuel savings, accurate temperature monitoring reduces wear on other components. Boilers running too hot stress pumps, valves, and heat exchangers. Those running too cool risk condensation damage. Proper monitoring keeps everything operating in the sweet spot where efficiency meets longevity.

Practical Steps for Homeowners

You can't directly check your flue gas temperature sensor without specialist equipment, but you can watch for warning signs. Note any changes in how your boiler operates, unusual cycling, error codes, or higher-than-normal gas consumption all warrant investigation.

During your annual service, ask the engineer about flue gas readings. They should measure actual temperatures and compare them against specifications. If readings are borderline, consider proactive sensor replacement rather than waiting for complete failure.

Keep service records that include flue gas measurements. Tracking these readings over time reveals gradual efficiency degradation before it becomes obvious. A steady upward trend in flue temperature suggests developing problems with the heat exchanger or combustion settings.

The Future of Temperature Monitoring

Sensor technology continues advancing. Wireless sensors eliminate wiring issues and enable easier retrofitting to existing systems. Some new sensors include built-in diagnostics that detect their own degradation and alert homeowners before accuracy suffers.

Integration with smart home systems lets you monitor boiler efficiency from your phone. You'll receive alerts when flue temperatures drift outside normal ranges, potentially catching problems before they cause breakdowns. This connectivity transforms a simple temperature sensor into part of a comprehensive home energy management system.

Artificial intelligence is beginning to analyse patterns in flue gas temperature data. These systems learn what's normal for your specific installation and detect subtle changes that human analysis might miss. Early trials show this approach can predict component failures weeks in advance, enabling truly proactive maintenance.

Protecting Your Heating Investment

Flue gas temperature sensors might be small components tucked away inside your boiler, but their impact on efficiency, safety, and running costs is substantial. These sensors enable modern condensing boilers to achieve the high efficiency ratings expected whilst protecting systems from the damage that comes from running outside design parameters.

Regular maintenance that includes checking sensor accuracy and proper flue gas sensor cleaning keeps your heating system running at peak efficiency. When replacement becomes necessary, using quality components from established manufacturers ensures continued reliable operation. The modest cost of sensors and servicing pays dividends through lower fuel bills, fewer breakdowns, and extended equipment life.

Understanding how these sensors work and why they matter helps you make informed decisions about your heating system. Whether you're specifying a new boiler installation, troubleshooting efficiency problems, or simply trying to reduce your heating bills, flue gas temperature monitoring deserves attention. The data these sensors provide is fundamental to achieving the comfort and efficiency modern heating systems promise.

For anyone managing heating systems, whether in a single home or across multiple properties, investing in proper temperature monitoring and control represents one of the most cost-effective efficiency measures available. The technology is proven, the benefits are measurable, and the return on investment is clear. Your heating system works hard to keep you comfortable, giving it the sensors it needs to work efficiently just makes good sense.

For technical guidance on boiler efficiency monitoring or sensor replacement, contact us for expert support from qualified heating engineers.

-

-