Gas Fire Piezo Ignition Systems: Maintenance and Replacement

The click of a gas fire igniter failing to spark can turn a cosy evening into a frustrating repair job. That familiar clicking sound without the whoosh of ignition often points to one culprit: a faulty piezo ignition system. These small but crucial components keep millions of UK homes warm, yet most homeowners know little about maintaining or replacing them.

Gas fire piezo ignition systems have revolutionised gas fire safety and convenience since their introduction in the 1960s. Unlike older pilot light systems that burn constantly, piezo igniters create a spark on demand, saving gas and reducing carbon monoxide risks. Understanding how these systems work and when they need attention can save you from cold nights and expensive emergency callouts.

What Makes Piezo Ignition Different

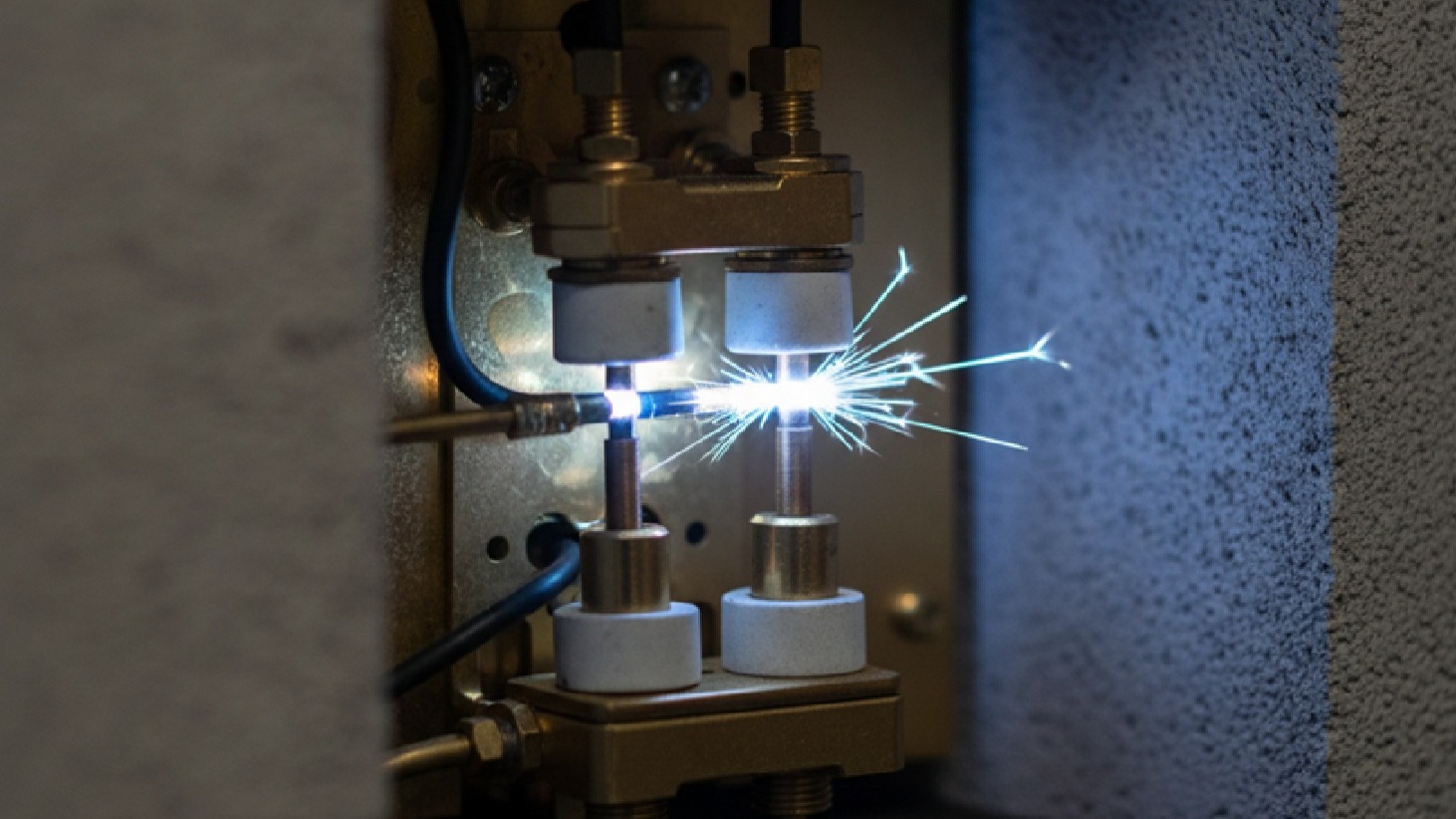

Piezo ignition systems generate electricity through mechanical pressure. When you press the igniter button, it compresses a piezoelectric crystal that produces a spark of 15,000 to 20,000 volts. This high-voltage spark jumps across a gap near the gas outlet, igniting the fuel instantly.

Traditional battery-powered igniters drain power constantly and need regular battery changes. Piezo systems require no external power source, making them more reliable in most situations. The technology mirrors the spark mechanism in cigarette lighters but scaled up for home heating applications.

The crystal inside a piezo igniter typically consists of quartz or ceramic materials. These crystals generate electricity when compressed, a phenomenon discovered by Pierre and Jacques Curie in 1880. Modern gas fires use this century-old principle combined with precision engineering to create reliable ignition systems that last 10-15 years with proper care.

Common Signs Your Piezo Igniter Needs Attention

A healthy piezo igniter produces a sharp clicking sound followed by immediate gas ignition. When problems develop, you'll notice specific warning signs before complete failure occurs.

Weak or inconsistent sparking indicates the piezoelectric crystal has begun deteriorating. You might need to press the button multiple times before achieving ignition. The spark might appear orange or yellow instead of bright blue-white, suggesting insufficient voltage generation.

Physical damage often shows as cracks in the igniter button or loose mounting brackets. Water damage from cleaning or spills can corrode internal connections, reducing spark intensity. If you smell gas without successful ignition after several attempts, stop immediately and ventilate the room.

Carbon buildup around the spark electrode creates another common issue. This black residue acts as insulation, preventing the spark from jumping properly to ignite gas. Regular cleaning prevents this problem, but excessive buildup might indicate incomplete combustion requiring professional attention.

Essential Maintenance Steps

Proper maintenance extends piezo igniter life significantly. Start by turning off the gas supply at the isolation valve before any maintenance work. Wait 30 minutes for residual gas to dissipate before beginning.

Clean the spark electrode monthly during heating season using a soft brass brush. Avoid steel brushes that can damage the electrode tip. Remove any spider webs, dust, or debris from the ignition area. These materials can block gas flow or insulate the spark path.

Check the spark gap quarterly using a business card as a gauge. The gap should measure approximately 3-4mm. Too wide a gap prevents sparking; too narrow risks electrode damage. Adjust carefully by bending the ground electrode, never the spark electrode itself. Think of it like adjusting the points on an old car distributor; precision matters for reliable sparking.

Inspect wiring connections annually for corrosion or looseness. The high-voltage cable from the piezo unit to the electrode deteriorates over time, developing invisible cracks that leak voltage. Replace any cable showing stiffness, cracking, or burn marks.

Testing Your Piezo System

Testing the piezo function requires basic observation skills rather than expensive equipment. First, ensure the gas supply remains off during electrical testing for safety.

Press the igniter button whilst watching the electrode tip in a darkened room. A healthy system produces a visible blue-white spark jumping to the ground electrode. Weak or absent sparks indicate replacement time.

Listen for the characteristic sharp click during button press. Mushy or quiet clicks suggest mechanical wear inside the piezo unit. The button should offer firm resistance and spring back immediately when released.

For thorough testing, remove the high-voltage lead from the electrode and hold it 5mm from a metal surface whilst pressing the igniter. This isolates the piezo unit from potential electrode or wiring problems. No spark here confirms piezo unit failure.

Replacement Parts and Compatibility

Piezo igniters aren't universal despite their similar appearance. Manufacturers design specific units for their gas fire models, considering factors like mounting dimensions, spark gap requirements, and gas valve integration.

Honeywell produces piezo systems for many UK gas fire brands. Their Q345A and Q347A series fit numerous models but require checking specific part numbers. Original equipment manufacturer (OEM) parts ensure proper fit and reliable operation.

Generic replacement igniters tempt with lower prices but often disappoint. Incorrect spark timing, weak voltage output, or poor build quality can create dangerous situations. The small savings rarely justify the risks and frustration of repeated failures.

When ordering replacements, note your gas fire's model number, serial number, and existing piezo part number. Many units hide identification labels behind removable panels or underneath the firebox. Take clear photos of the old unit's mounting points and wire routing before removal. Heating and Plumbing World stocks genuine OEM piezo components for most major gas fire manufacturers.

Professional Installation Considerations for Piezo Ignition Repair

Whilst competent DIY enthusiasts can replace piezo igniters, gas work regulations require careful consideration. The Gas Safety (Installation and Use) Regulations 1998 govern all gas appliance work in the UK.

Simple piezo button replacement without disturbing gas connections falls within the homeowner's capabilities. However, any work involving gas pipes, valves, or safety devices requires a Gas Safe registered engineer. This includes situations where the piezo unit integrates with the gas valve assembly.

Professional installation costs £75-150 for straightforward replacements. This includes parts, labour, and safety testing. Engineers also inspect the entire ignition system, potentially catching other developing issues before they cause failures.

Manufacturers often void warranties when unqualified persons perform repairs. Consider this before attempting DIY piezo ignition repair on newer appliances.

A homeowner once attempted to replace their own piezo igniter on a three-year-old gas fire still under warranty. The replacement worked initially, but six months later, the gas valve failed. When they claimed warranty coverage, the manufacturer inspected the unit and found evidence of non-professional repair. The £85 they saved on professional installation cost them £450 in valve replacement, plus the original £45 for the piezo unit they'd installed themselves.

Troubleshooting Beyond the Piezo

Sometimes clicking without ignition stems from problems beyond the piezo system. Understanding these related issues prevents unnecessary parts replacement.

Blocked gas injectors prevent fuel from reaching the ignition point despite healthy sparks. Dust, corrosion, or spider webs commonly block these tiny orifices. Professional cleaning restores proper gas flow without damaging precision-drilled holes.

Faulty thermocouples or flame supervision devices shut off gas flow as a safety measure. These components ensure gas only flows when a flame exists. Even a perfect piezo operation cannot overcome a failed safety device.

Gas pressure problems affect ignition reliability. Low pressure might produce weak flames that extinguish easily. High pressure can blow out the spark before ignition occurs. Only Gas Safe engineers should adjust gas pressures.

Air mixture issues create similar symptoms. Yellow flames, soot deposits, or difficulty maintaining flame indicate combustion problems requiring professional attention. These issues pose carbon monoxide risks if ignored.

Modern Alternatives and Upgrades

Technology advances offer alternatives to traditional gas fire piezo ignition systems. Battery-powered electronic ignition provides consistent sparks regardless of button wear. These systems typically use AA batteries lasting 1-2 years.

Danfoss manufactures electronic ignition controls with diagnostic features. LED indicators show battery status, successful ignition, and fault codes. This technology simplifies troubleshooting compared to basic piezo systems.

Remote control ignition systems eliminate manual button pressing entirely. Radio frequency or infrared signals trigger ignition from across the room. Whilst convenient, these systems cost significantly more and require periodic battery changes in both fire and remote units.

Hot surface igniters represent another alternative, using electrical resistance to create ignition temperatures. These systems prove extremely reliable but require mains electricity connection, limiting installation flexibility.

Cost-Effective Maintenance Strategies

Preventing piezo failure costs far less than emergency replacements. Annual professional servicing typically runs £60-80, including full safety checks beyond just ignition systems.

Create a simple maintenance log noting cleaning dates, parts replaced, and any unusual observations. This history helps identify developing patterns and proves valuable when selling your home.

Stock basic spares like electrodes and high-voltage leads if you own multiple gas appliances. Bulk purchasing from suppliers reduces per-unit costs. Store spares in dry locations to prevent deterioration. EPH Controls offers reliable replacement components for various ignition systems.

Consider upgrading extremely old piezo systems before failure. Units over 15 years old have exceeded their typical lifespan. Planned replacement avoids winter evening emergencies when engineers charge premium rates.

Environmental and Safety Benefits

Modern piezo systems contribute to reduced household emissions. Eliminating standing pilot lights saves approximately 75 cubic metres of gas annually per appliance. This reduction equals roughly 140kg of CO₂ emissions.

Instant ignition reduces unburned gas release during lighting attempts. Older pilot light systems often required multiple attempts, releasing methane into the room air. Piezo ignition's reliable spark minimises this wastage.

Safety improvements prove equally significant. No continuous flame means reduced fire risk from curtains, papers, or curious pets. Carbon monoxide production drops dramatically without constant pilot combustion.

Insurance companies increasingly recognise these safety benefits. Some offer premium reductions for homes with modern ignition systems versus outdated pilot lights. Check with your provider about potential savings.

Maintaining Reliable Ignition

Gas fire piezo ignition systems represent elegant engineering solutions that most homeowners take for granted until failure occurs. Regular maintenance, proper testing, and timely replacement keep these crucial components functioning reliably for years. Whilst the technology seems simple, the precision required for consistent 20,000-volt sparks demands respect.

Understanding your gas fire's ignition system empowers informed decisions about maintenance and repairs. Whether performing basic cleaning yourself or recognising when professional help is needed, this knowledge prevents cold evenings and potentially dangerous situations.

The small investment in proper piezo system care returns comfort, safety, and efficiency throughout your gas fire's lifetime. As heating technology continues advancing, these reliable mechanical marvels remain the preferred ignition method for millions of UK homes, proving that sometimes the simplest solutions endure.

For technical support on piezo ignition repair or replacement parts, contact us for expert guidance from Gas Safe-registered professionals.

-

-