How to Plan Heating Layouts During a Renovation

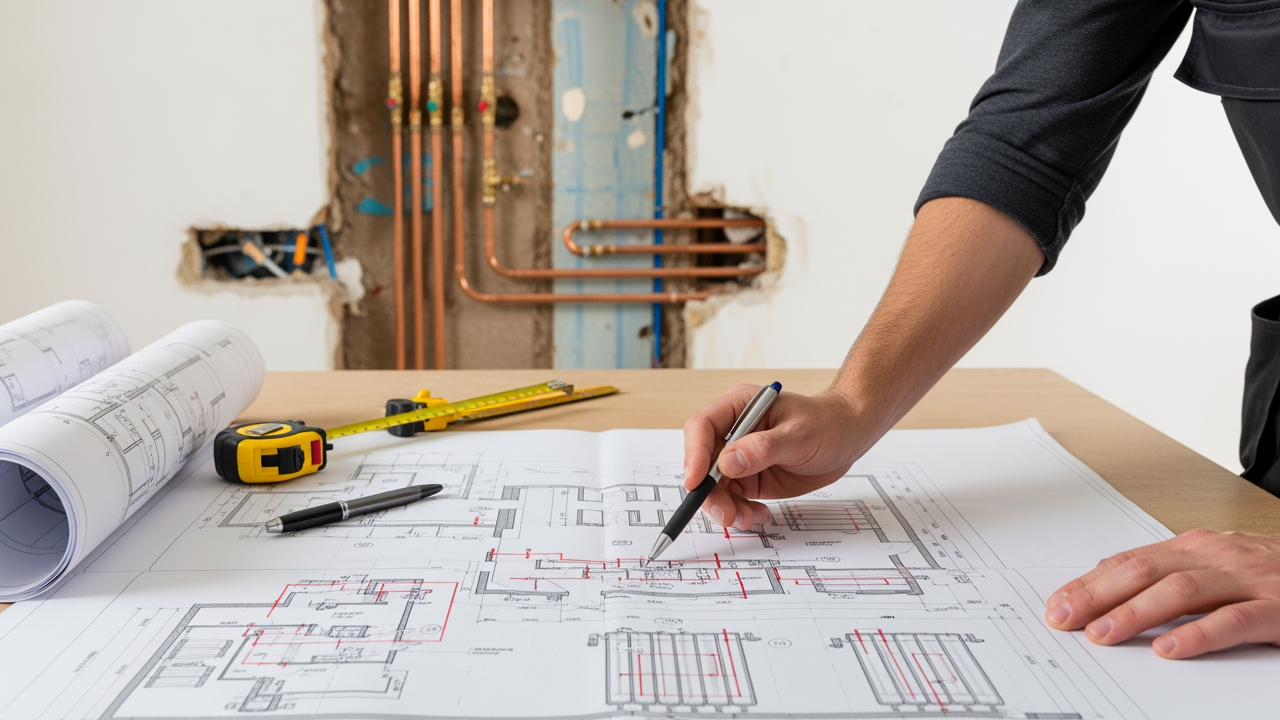

Undertaking a property renovation presents the ideal opportunity to reassess and optimise heating systems for improved comfort, efficiency, and running costs. Proper heating layout design transforms how warmth is distributed throughout living spaces while addressing inefficiencies that plague older installations. This comprehensive guide explores the critical considerations for creating effective heating systems during renovation projects, from initial assessment through to final commissioning.

Assessing Your Current Heating System

Understanding Existing Infrastructure

Before developing a renovation heating plan, thoroughly evaluate the current heating system's performance, condition, and capacity. Document radiator locations, pipe routes, boiler specifications, and control arrangements to identify opportunities for improvement. Many older properties suffer from inadequate heat output, poor zoning, and inefficient distribution that renovation projects can address systematically.

At Heating and Plumbing World, our extensive range of heating components supports both minor upgrades and complete system redesigns during renovation work.

Examine existing radiators for signs of corrosion, cold spots indicating internal sludge build-up, and inadequate sizing for room dimensions. Testing the current system's heat distribution reveals cold rooms, oversized radiators wasting energy, and areas where additional heat emitters would improve comfort levels significantly.

Calculating Heat Loss Requirements

Accurate heat loss calculations form the foundation of effective heating layout design. Room-by-room assessments consider wall construction, insulation levels, glazing types, air change rates, and exposure to prevailing winds. These calculations determine the heat output required from each radiator or underfloor heating zone to maintain comfortable temperatures during winter conditions.

Professional heat loss software accounts for thermal bridging, ventilation heat losses, and temperature lift requirements between external and internal environments. Manual calculations using simplified methods may underestimate requirements, leading to undersized systems that struggle during cold weather, while oversizing wastes energy and increases installation costs unnecessarily.

Design Principles for Optimal Heating Layouts

Radiator Placement Strategies

Strategic radiator positioning maximises heat distribution while minimising installation costs and visual impact. Traditionally, radiators sit beneath windows to counteract cold downdrafts and prevent condensation on glazing. However, modern double glazing reduces this necessity, allowing greater flexibility in radiator placement for aesthetic and practical considerations.

Corner locations, alcoves beside chimney breasts, and internal walls offer alternative mounting positions that may better suit renovated room layouts. Avoid placing radiators behind furniture, curtains, or within enclosed spaces that restrict air circulation and reduce heat emission effectiveness.

Underfloor Heating Integration

Underfloor heating systems deliver superior comfort through even heat distribution and lower operating temperatures compared to traditional radiators. These systems suit renovation projects involving floor-level changes, structural work, or complete room reconfigurations, where pipe installation becomes practical during construction phases.

Wet underfloor heating systems circulate warm water through pipes embedded in floor screeds, requiring adequate floor depth and appropriate floor finish selection. Electric mat systems offer faster installation in shallow floor construction,s but typically cost more to operate than water-based alternatives for whole-house heating applications.

Zoning and Control Layouts

Effective heating zones match occupancy patterns and usage requirements across different property areas. Separating bedrooms, living spaces, and ancillary rooms enables independent temperature control, reducing energy consumption while improving comfort. A well-considered renovation heating plan incorporates appropriate zoning from the outset rather than attempting retrofits later.

Manifold systems supplying underfloor heating naturally facilitate room-by-room zoning through individual circuit control. Radiator systems achieve zoning through thermostatic radiator valves (TRVs) or zone valves controlling circuit groups, with programmable thermostats providing time and temperature management for each zone.

Boiler Selection and Positioning

Choosing the Right Boiler Type

Boiler selection significantly impacts heating layout design through flow rate capabilities, installation space requirements, and system compatibility. Combi boilers eliminate separate hot water cylinders, freeing valuable space while providing instant hot water, though flow rates may limit simultaneous outlet usage in larger properties.

System boilers work alongside sealed heating systems and separate hot water cylinders, delivering higher flow rates for multiple bathrooms while maintaining compact boiler dimensions. Regular boilers suit properties retaining traditional open-vented systems with cold water storage tanks and hot water cylinders in roof spaces.

Heat pumps increasingly replace conventional boilers in renovation projects aiming for reduced carbon emissions and lower running costs. These systems require larger heat emitters operating at lower temperatures, making them ideal candidates for underfloor heating installations or oversized radiator specifications within renovation heating plans.

Optimal Boiler Location Considerations

Boiler positioning affects installation costs, maintenance access, and aesthetic impact throughout renovated properties. Kitchen installations remain popular through established practice and convenient hot water proximity, though utility rooms, garages, and loft spaces offer alternative locations, reducing visual intrusion in living areas.

External combination boilers mounted on outside walls minimise internal space requirements while providing easy access for servicing. However, frost protection considerations and potential weather exposure require careful product selection and installation to ensure reliable operation throughout British winter conditions.

Flue routing often dictates viable boiler positions, with horizontal flues requiring specific clearances from boundaries, windows, and ventilation openings. Vertical flues through roofs provide greater positioning flexibility but involve additional installation complexity and potential roof weatherproofing challenges during renovation work.

Pipework Design and Installation Methods

Microbore vs. Standard Bore Systems

Pipe sizing decisions influence installation complexity, system efficiency, and future maintenance requirements within heating layout design strategies. Microbore systems using 8mm or 10mm pipes reduce installation material costs and enable easier routing through restrictive spaces, though higher flow resistance requires careful system design to prevent circulation issues.

Standard 15mm and 22mm copper pipes deliver lower flow resistance and greater flow capacity, supporting larger radiators and longer pipe runs without circulation problems. These conventional pipe sizes simplify future modifications and repairs through universal fitting availability and familiar installation techniques.

Plastic pipe systems, including PEX and multi-layer composites, offer installation advantages through flexibility, corrosion resistance, and reduced joint counts. Push-fit connections accelerate installation while eliminating hot works requirements, making them particularly suitable for occupied property renovations where fire risks and disruption need minimising.

Pipe Routing Strategies

Efficient pipe routing minimises material usage, reduces installation time, and limits future maintenance complications. Two-pipe systems supplying flow and return connections to each radiator provide balanced heat distribution and straightforward troubleshooting, though they require more extensive pipework than single-pipe arrangements.

Manifold distribution systems increasingly feature in modern installations, running individual pipes from central manifolds to each heat emitter. This approach eliminates multiple joints within floor voids and walls while enabling precise flow balancing and easier fault diagnosis compared to traditional ring main configurations.

Concealing pipework within floor screeds, wall chases, and ceiling voids creates neat installations but complicates future access for modifications or repairs. Accessible routes through cupboards, beneath floorboards, and within service ducts balance aesthetic preferences against practical maintenance requirements during renovation projects.

System Components and Controls

Essential Safety Devices

Sealed heating systems require expansion vessels accommodating thermal expansion without over-pressurising pipework and components. Correct vessel sizing ensures adequate expansion capacity across the system's operating temperature range while pre-charge pressures suit the installation's static head requirements.

Pressure relief valves provide critical over-pressure protection, automatically discharging water if system pressure exceeds safe limits. Regular testing and periodic replacement according to manufacturer schedules maintain these safety devices' reliability throughout the heating system's service life.

Automatic air vents eliminate trapped air, preventing circulation and reducing radiator heat output. Strategic vent positioning at system high points enables automatic air release during filling and operation, reducing manual intervention requirements while maintaining optimal system performance.

Advanced Heating Controls

Smart heating controls transform system efficiency through learning algorithms, remote access, and integration with broader home automation platforms. These systems adjust heating schedules automatically based on occupancy patterns, weather compensation, and user preferences developed through machine learning over time.

Weather compensation controls modulate boiler flow temperatures according to external temperatures, reducing gas consumption while maintaining comfort levels. This technology proves particularly effective with condensing boilers and low-temperature heat emitters where reduced flow temperatures increase condensing operation and efficiency gains.

Pump Sizing and Selection

Circulation pump specifications directly impact heating layout design effectiveness through their ability to overcome system resistance while delivering required flow rates. Oversized pumps waste electricity and may generate excessive flow noise, while undersized units compromise heat distribution and system performance during cold weather.

Variable speed pumps automatically adjust output to match system demands, reducing energy consumption during partial load conditions common throughout heating seasons. Modern pumps incorporate differential pressure control, maintaining constant pressure across system zones despite varying demands from thermostatic valves and zone controls.

Special Considerations for Period Properties

Working with Existing Architectural Features

Period property renovations demand sensitive heating layout design respecting original architectural features while delivering modern comfort standards. Ornate cornices, picture rails, and decorative plasterwork constrain pipe routing options, requiring creative solutions balancing aesthetic preservation against practical heating requirements.

Column radiators complement Victorian and Edwardian properties through period-appropriate styling while delivering heat outputs matching modern efficiency standards. These vertical radiators suit narrow wall sections between windows, while their traditional appearance harmonises with original features better than contemporary panel designs.

Addressing Solid Wall Construction

Solid wall properties lacking cavity insulation present unique challenges for renovation heating plans through higher heat losses and limited opportunities for pipe concealment. External wall insulation dramatically reduces heat requirements while creating opportunities for concealed pipe routing within insulation build-ups, though planning permissions and conservation area restrictions may limit this approach.

Internal insulation solutions sacrifice internal floor area but avoid external appearance changes unacceptable in listed buildings or conservation areas. These approaches create new wall surfaces suitable for concealed pipework while improving thermal performance, though careful moisture management prevents interstitial condensation problems.

Heating System Commissioning and Testing

Balancing and Testing Procedures

Proper commissioning ensures heating systems perform according to design specifications throughout renovated properties. Systematic balancing procedures adjust individual radiator lockshield valves to achieve design flow rates and temperature drops across each heat emitter, distributing heat proportionally according to room requirements.

System flushing removes installation debris, flux residues, and mill scale that would otherwise circulate through new installations, causing blockages and corrosion. Power flushing older systems during renovation removes accumulated sludge deposits, restoring full radiator outputs and preventing contamination of new components during system extensions.

Chemical treatment with corrosion inhibitors and biocides protects new installations from internal corrosion and bacterial contamination. Regular water quality testing and inhibitor top-ups during annual servicing maintain protection throughout the heating system's service life, preventing premature component failures and efficiency losses.

Performance Verification

Comprehensive performance testing validates heating systems meet design requirements before completing renovation projects. Temperature measurements across all rooms verify adequate heat delivery while control system testing confirms proper zone operation, timing functions, and user interface responsiveness.

Energy efficiency measurements establish baseline performance data for future comparison during routine maintenance visits. Modern boiler diagnostics provide combustion efficiency readings, system pressure recordings, and fault code histories supporting proactive maintenance strategies that prevent breakdowns and maintain optimal performance.

Common Heating Layout Mistakes to Avoid

Undersizing Heat Emitters

Inadequate radiator sizing represents the most common heating layout error, leaving renovated rooms perpetually cold despite efficient boiler operation. Conservative heat loss calculations accounting for actual insulation levels, ventilation rates, and temperature requirements prevent this costly mistake, requiring remedial radiator replacements or supplementary heaters.

Allowing generous radiator output margins accommodates colder-than-average winters and personal comfort preferences without significant cost penalties. Modern radiators deliver impressive outputs from compact dimensions, enabling adequate sizing without dominating wall spaces or conflicting with interior design intentions.

Poor Control System Integration

Installing sophisticated heating systems without appropriate controls wastes the efficiency potential that modern components offer. Thermostatic radiator valves provide minimum control requirements, though programmable room thermostats and smart controls deliver superior efficiency through precise temperature management and scheduling capabilities.

Failing to match control strategies to occupancy patterns and property characteristics undermines even well-designed heating layouts. Open-plan living areas benefit from different control approaches than traditional cellular room arrangements, requiring thoughtful control zone design during renovation planning stages.

Inadequate System Flushing

Rushing commissioning procedures and skipping thorough system flushing contaminates new components with installation debris and existing system deposits. This contamination accelerates corrosion, blocks narrow waterways in modern boilers, and reduces heat exchanger efficiency through scale accumulation and sludge deposits.

Professional power flushing equipment removes stubborn deposits that simple drain-and-refill procedures leave behind. The modest additional cost of proper flushing prevents expensive future repairs while protecting manufacturer warranties that often require evidence of commissioning to specification, including appropriate water treatment.

Future-Proofing Your Heating Layout

Preparing for Heat Pump Conversion

Properties undergoing renovation present ideal opportunities for future heat pump compatibility through appropriate radiator sizing and pipe routing provisions. Specifying radiators with 20-30% additional output beyond current heat loss requirements accommodates future heat pump operation at lower flow temperatures without requiring complete radiator replacement.

Installing larger diameter pipework and reducing pipe lengths where practical minimises system resistance, supporting efficient heat pump operation when future conversions occur. These modest additional investments during renovation avoid extensive remedial works when heat pumps become mandatory or financially attractive through energy cost changes.

Renewable Energy Integration

Solar thermal systems supplement conventional heating during warmer months, reducing fuel consumption while providing abundant hot water. Renovation projects should incorporate cylinder provisions, pipe routes, and control interfaces supporting future solar thermal additions, even if immediate installation remains unaffordable or impractical.

Thermal storage systems enabling economy tariff exploitation or renewable energy buffering require space provisions and appropriate pipe sizing during initial installations. Planning these provisions during renovation phases costs little but enables straightforward future upgrades responding to changing energy markets and government incentives.

Professional Planning and Installation

Successful renovation heating plans require careful coordination between architects, heating engineers, builders, and other trades. Early heating system design input during renovation planning prevents costly modifications, addressing conflicts discovered during installation phases. Professional heating engineers bring valuable experience identifying potential problems before they materialise, saving time and money throughout renovation projects.

Competent heating system design considers current building regulations, future legislation changes, and best practice guidance, ensuring installations remain compliant and efficient throughout their service lives. Cutting corners on design quality or installation standards creates problems that persist for decades beyond initial cost savings, ultimately costing more through remedial works and poor performance.

Quality component selection from reputable manufacturers provides reliability and performance throughout demanding renovation projects. Sourcing boiler spares and heating components from established suppliers ensures genuine products backed by comprehensive warranties and technical support when questions arise during complex installations.

For expert guidance on heating layout design and comprehensive support throughout your renovation project, contact us today. Our experienced team can help develop efficient, future-proof heating solutions perfectly matched to your property's specific requirements and renovation objectives.

-

-