Innovations in Self-Cleaning Heating Systems

Modern heating technology has transformed how homeowners and businesses maintain their systems. Traditional boilers and central heating units require regular manual cleaning to prevent efficiency losses, breakdowns, and safety hazards. Self-cleaning heating systems represent a significant advancement, offering automated maintenance that reduces labour costs whilst maintaining optimal performance year-round. Heating and Plumbing World provides access to cutting-edge heating components that support both traditional and self-maintaining system configurations.

The Problem with Traditional Heating System Maintenance

Conventional heating systems accumulate dirt, scale, and debris over time. Heat exchangers become coated with mineral deposits, reducing thermal transfer efficiency by up to 30%. Burners collect carbon buildup that affects combustion quality. Filters clog with dust and particles, restricting airflow and forcing systems to work harder. This degradation increases energy consumption, shortens component lifespan, and elevates the risk of system failure during peak demand periods.

Manual cleaning requires specialist knowledge and regular scheduling. Homeowners often delay maintenance due to cost or inconvenience, allowing problems to compound. Engineers must disassemble components, apply chemical cleaners, and reassemble systems - a time-intensive process that leaves heating unavailable for hours. The cycle of neglect and reactive maintenance drives up long-term costs whilst compromising system reliability and heating efficiency.

How Self-Cleaning Heating Systems Work

Self-cleaning heating systems integrate automated mechanisms that continuously or periodically remove contaminants without human intervention. These innovations address the root causes of performance degradation through intelligent design and proactive maintenance cycles.

Automated Filtration Technology

Advanced filtration systems incorporate self-flushing capabilities that periodically reverse flow direction to dislodge trapped particles. Magnetic filters automatically capture metallic debris from system water, preventing circulation through sensitive components like boiler spares and heat exchangers. Some designs feature motorised cleaning cycles that scrub filter media whilst the system remains operational, eliminating the need for manual removal and washing.

Continuous filtration monitoring uses pressure differential sensors to detect when cleaning cycles should activate. This responsive approach ensures filters never become sufficiently clogged to impact system performance, maintaining consistent water flow and heat distribution throughout the property.

Heat Exchanger Self-Cleaning Features

Heat exchangers benefit from ultrasonic cleaning technology that generates high-frequency vibrations to prevent scale adhesion. These systems activate periodically, breaking down mineral deposits before they form substantial barriers to heat transfer. Chemical-free cleaning cycles use controlled temperature fluctuations and flow reversals to naturally dislodge accumulated debris, which is then captured by downstream filtration.

Descaling automation employs targeted acid injection systems that introduce precise amounts of descaling solution during low-demand periods. The solution circulates through the heat exchanger, dissolving mineral buildup before being neutralised and flushed from the system. This process maintains heat exchanger efficiency without requiring disassembly or manual intervention.

Key Innovations in Automated HVAC Cleaning

Modern automated HVAC cleaning technology extends beyond individual components to encompass whole-system monitoring and maintenance. These innovations represent the convergence of sensor technology, artificial intelligence, and mechanical engineering.

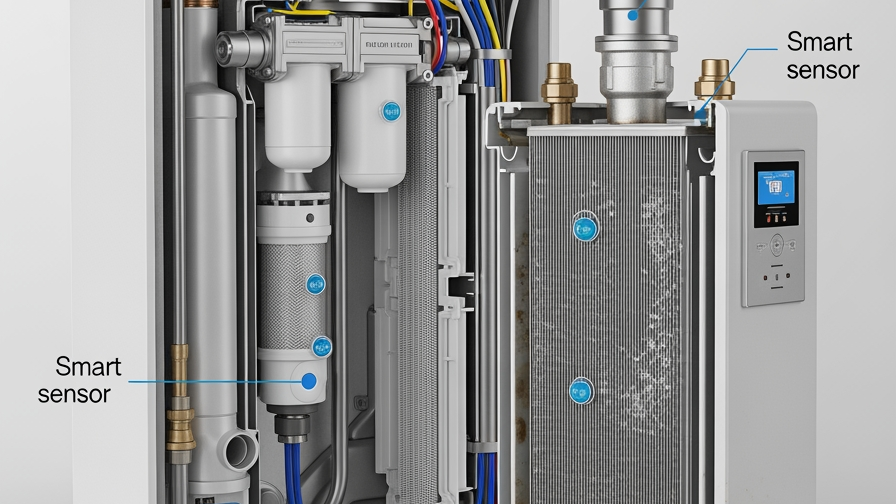

Smart Sensor Integration

Real-time monitoring systems track multiple performance indicators, including flow rate, temperature differential, pressure, and combustion efficiency. Machine learning algorithms analyse this data to identify patterns that indicate emerging maintenance needs. When sensors detect efficiency decline or abnormal operating parameters, the system can initiate targeted cleaning cycles or alert homeowners to required intervention before problems escalate.

Predictive maintenance capabilities forecast component wear and optimal cleaning schedules based on usage patterns and historical data. This intelligence-driven approach minimises unnecessary maintenance whilst preventing the performance degradation associated with delayed servicing. Systems learn from each cleaning cycle, continuously refining their algorithms to optimise maintenance timing and methods.

Self-Maintaining Components

Burners equipped with automated cleaning mechanisms use compressed air pulses to remove carbon deposits during shutdown cycles. This prevents the accumulation that traditionally requires annual manual cleaning. Some advanced designs incorporate ceramic coatings that resist buildup, extending intervals between required interventions.

Condensate management systems now include self-cleaning pumps that periodically flush themselves to prevent biofilm growth and blockages. These pumps integrate sensors that detect flow restrictions and automatically initiate extended cleaning cycles when needed. Expansion vessels with self-monitoring pressure capabilities alert systems to membrane failures or air loss, whilst automated air purge valves eliminate trapped gases without manual bleeding.

Benefits of Self-Cleaning Heating Technology

The adoption of self-cleaning heating systems delivers measurable advantages across efficiency, cost, and reliability metrics. These benefits compound over time as systems maintain peak performance throughout their operational lifespan.

Energy Efficiency Improvements

Self-cleaning heating systems sustain optimal combustion efficiency by preventing the carbon buildup that increases fuel consumption. Clean heat exchangers maintain maximum thermal transfer rates, ensuring that generated heat effectively warms the property rather than escaping through the flue. Studies indicate that automated cleaning maintains efficiency within 2-3% of factory specifications, compared to 15-25% degradation in manually maintained systems between service intervals.

Consistent performance translates directly to reduced energy bills. A typical household heating system operating at 90% efficiency instead of 75% saves approximately 15-20% on annual heating costs. Over a system's 15-20 year lifespan, these savings substantially exceed the premium for self-cleaning technology. Reduced energy consumption also lowers carbon emissions, supporting environmental sustainability goals.

Maintenance Cost Reduction

Automated maintenance dramatically reduces the frequency of engineer callouts. Traditional systems require annual servicing plus emergency repairs when neglected maintenance causes breakdowns. Self-cleaning heating systems extend service intervals to 18-24 months whilst reducing the likelihood of unexpected failures. This reliability proves particularly valuable during winter months when heating demand peaks and engineer availability diminishes.

Component lifespan extends significantly when systems operate consistently within design parameters. Heat exchangers, burners, and pumps subject to regular automated cleaning experience less stress and wear than those cycling through periods of heavy contamination. Quality Worcester Bosch boiler spares and other premium components further enhance longevity when protected by automated cleaning systems.

Compatibility with Existing Systems

Property owners can access self-cleaning heating benefits through both retrofit solutions and new system installations. Each approach offers distinct advantages depending on current equipment condition, budget, and performance requirements.

Retrofit Options

Many automated cleaning technologies integrate with existing heating systems through add-on modules. Magnetic self-cleaning filters install inline with minimal pipework modifications, immediately improving water quality throughout the system. Ultrasonic descaling devices attach externally to pipes, generating vibrations that prevent scale formation without requiring system drainage or component replacement.

Smart monitoring systems are retrofitted to existing boilers through sensor installation at key points and integration with building management systems. These upgrades provide predictive maintenance capabilities and automated alerts without replacing functional equipment. However, retrofit solutions cannot address inherent design limitations in older systems, such as heat exchanger geometry that promotes scale accumulation or burner designs prone to carbon buildup.

New Installation Advantages

Purpose-built self-cleaning heating systems incorporate automated maintenance from the design stage. Integrated sensors, cleaning mechanisms, and control systems work together seamlessly, optimising maintenance effectiveness whilst minimising complexity. Manufacturers engineer components specifically to complement automated cleaning cycles, using materials and geometries that enhance self-maintenance capabilities.

New installations also benefit from proper system sizing and hydraulic balancing, which reduces the contamination load on cleaning systems. Modern condensing boilers with integrated self-cleaning features achieve efficiency ratings above 95%, maintaining these levels throughout their service life. When combined with automated water treatment, pressure relief valves, and comprehensive system protection, new installations represent the most reliable and efficient approach to self-maintaining heating.

Choosing the Right Self-Cleaning System

Selecting appropriate self-cleaning heating technology requires careful evaluation of property requirements, usage patterns, and budget considerations. Both residential and commercial applications benefit from automated maintenance, though specific needs vary substantially.

Residential Applications

Homeowners should prioritise systems that balance initial investment against long-term savings and convenience. Smaller properties may achieve adequate results from magnetic filtration and basic water treatment, whilst larger homes with complex heating demands benefit from fully integrated self-cleaning heating systems with smart monitoring capabilities.

Consider the existing system's age and condition when evaluating retrofit versus replacement options. Systems approaching 15 years old with declining efficiency may justify replacement with modern self-cleaning models. Newer systems in good condition gain immediate benefit from add-on automated cleaning modules without the expense of complete replacement.

Budget considerations should account for the total cost of ownership rather than the initial purchase price alone. Calculate potential energy savings, reduced maintenance costs, and extended component lifespan against the premium for self-cleaning technology. Most residential installations achieve payback within 5-7 years through these combined savings.

Commercial Considerations

Commercial properties face heightened heating demands and greater consequences from system downtime. Automated HVAC cleaning becomes essential in high-demand environments where heating systems operate continuously or near-continuously. Hotels, healthcare facilities, and manufacturing operations particularly benefit from the reliability and consistent performance that self-cleaning systems deliver.

Compliance with safety and efficiency standards often mandates more frequent maintenance in commercial settings. Self-cleaning heating systems help organisations meet these requirements whilst minimising operational disruption. Automated monitoring provides documentation of system performance and maintenance activities, supporting regulatory compliance and insurance requirements.

Large commercial installations should engage specialist heating engineers to design integrated self-cleaning solutions tailored to specific operational demands. These systems may incorporate redundancy, staged cleaning cycles that maintain heating availability, and centralised monitoring of multiple heating zones. The complexity and investment scale of commercial projects justify a comprehensive analysis to optimise system selection and configuration.

Conclusion

Self-cleaning heating systems represent the future of efficient, reliable heating technology. By automating the maintenance tasks that traditionally require manual intervention, these innovations sustain optimal performance whilst reducing operational costs and environmental impact. Whether through retrofit solutions or new installations, property owners can now access heating systems that maintain themselves with minimal human involvement.

The technology continues advancing, with emerging innovations in sensor accuracy, cleaning effectiveness, and artificial intelligence-driven optimisation. Early adopters gain immediate benefits whilst positioning themselves to leverage future developments in automated heating management. As energy costs rise and environmental regulations tighten, automated HVAC cleaning transitions from a luxury feature to an essential capability.

For expert guidance on implementing self-cleaning technology or sourcing quality heating components, contact us to discuss your specific requirements. Professional advice ensures optimal system selection and configuration for lasting performance and value.

-

-