Installing Radiator Reflector Panels: Do They Work?

Radiator reflector panels promise to reduce heating bills by reflecting heat back into rooms rather than allowing it to escape through external walls. These simple aluminium or foil-backed panels fit behind radiators and claim to improve energy efficiency by up to 20%. But do radiator reflector panels actually deliver on these promises, and is reflective radiator panel installation worth the investment?

This comprehensive guide examines the science behind heat reflection, installation methods, real-world performance data, and whether these affordable upgrades genuinely reduce heating costs for UK homeowners.

Understanding How Radiator Reflector Panels Work

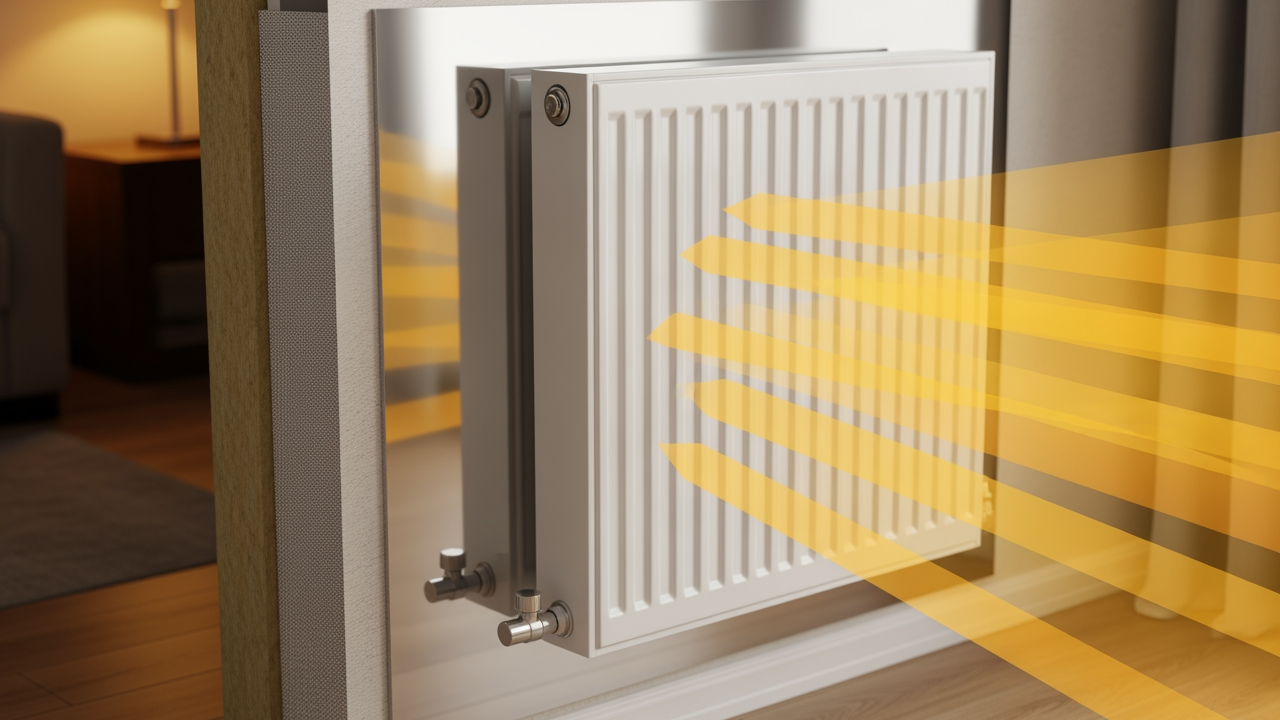

Radiators mounted on external walls lose significant heat through the wall itself, particularly in older properties with solid walls or inadequate insulation. Standard brick or plaster walls absorb radiant heat and conduct it outdoors, wasting energy that should warm living spaces.

Radiator reflector panels address this problem through a simple principle: reflective surfaces bounce radiant heat back into rooms. The panels feature an aluminium or metallic coating that reflects infrared radiation emitted by radiators. Rather than warming the wall behind the radiator, this heat returns to the room where occupants benefit from increased warmth.

The effectiveness depends on several factors. Wall composition matters significantly - solid brick walls without cavity insulation allow more heat loss than modern insulated walls. Radiator positioning also affects performance, with panels delivering better results when radiators mount flush against external walls rather than internal partition walls.

The Science Behind Heat Reflection Technology

Heat transfers through three methods: conduction, convection, and radiation. Radiators primarily warm rooms through convection, where heated air rises and circulates. However, approximately 20-30% of heat output consists of radiant energy that travels in straight lines until absorbed by surfaces.

Without reflector panels, external walls absorb this radiant heat. Solid Victorian brick walls, common across UK housing stock, conduct heat particularly efficiently. A typical uninsulated external wall might have an R-value of just 0.5, meaning heat passes through rapidly. By comparison, modern cavity walls with insulation achieve R-values of 2.0 or higher.

Reflective radiator panel installation creates a barrier that bounces radiant heat backwards. Quality panels use materials with high reflectivity ratings - typically 90-95% for aluminium foil or metallised surfaces. This means most radiant energy returns to the room rather than heating brickwork.

The air gap between the panel and the wall enhances performance. A small cavity (typically 5-10mm) provides additional insulation value while allowing reflected heat to circulate. Without this gap, the panel conducts heat directly to the wall, reducing effectiveness.

Real-World Performance: Energy Savings Data

Independent testing reveals radiator reflector panels can reduce heating costs, though savings vary considerably based on property characteristics. The Energy Saving Trust estimates panels save £15-£30 annually per radiator in properties with solid walls and no insulation. For average UK homes with 8-10 radiators on external walls, this translates to £120-£300 in annual savings.

However, properties with modern insulation see minimal benefit. Cavity wall insulation already prevents most heat loss, leaving little for reflector panels to address. In well-insulated homes built after 2000, panels might save just £5-£10 annually per radiator - insufficient to justify installation costs and effort.

Room temperature measurements show modest improvements. Studies document 1-2°C temperature increases in rooms with panels fitted to external wall radiators. This allows homeowners to achieve comfortable temperatures while reducing boiler firing times, directly lowering energy consumption.

The payback period depends on the installation method. DIY reflective radiator panel installation using affordable materials costs £5-£15 per radiator, paying back within 1-2 heating seasons. Professional installation at £30-£50 per radiator extends payback to 3-5 years, though quality improves with professional fitting.

Thermal imaging confirms performance differences. Infrared cameras reveal external walls behind radiators without panels that glow warm - visible evidence of wasted heat. Walls with properly installed panels remain cooler, indicating heat stays within living spaces rather than escaping through brickwork.

Installation Methods: DIY vs Professional Fitting

Reflective radiator panel installation suits confident DIYers with basic tools. The process requires measuring radiator dimensions, cutting panel material to size, and securing it behind the radiator using appropriate fixing methods.

DIY Installation Process

Purchase pre-cut panels sized for standard radiators or buy rolls of radiator foil from builders' merchants. Heating and Plumbing World stocks various heating system accessories that complement panel installations for optimal central heating performance.

Measure radiator width and height, subtracting 50mm from each dimension to ensure panels don't extend beyond radiator edges. Cut reflective material using sharp scissors or a craft knife against a metal straightedge. Precision cutting prevents visible foil edges that appear untidy.

Clean the wall surface thoroughly, removing dust and cobwebs that prevent proper adhesion. Dry the wall completely before proceeding - moisture under panels causes mould growth and reduces effectiveness.

Apply double-sided tape or adhesive strips around panel edges, keeping the reflective surface facing outward toward the radiator. Position the panel centrally behind the radiator, pressing firmly to secure adhesion. Alternatively, use small panel pins or tacks in inconspicuous locations if the wall surface doesn't suit adhesive mounting.

Maintain a 5-10mm air gap between panel and wall for optimal insulation value. Some panels include built-in spacers; otherwise, small adhesive foam pads create necessary separation. This gap allows air circulation while maximising heat reflection benefits.

Professional Installation Considerations

Professional installers ensure correct positioning and secure mounting that withstands radiator heat cycles. Experienced fitters assess wall conditions, recommend appropriate materials, and complete installations efficiently without removing radiators from brackets.

Professional reflective radiator panel installation typically includes:

- Wall assessment for dampness or structural issues

- Selection of appropriate panel materials and thickness

- Precise cutting and fitting around pipes and brackets

- Secure mounting using suitable fixings for the wall type

- Quality checks ensuring proper air gaps and coverage

While more expensive than DIY approaches, professional installation guarantees results and often includes warranties on materials and workmanship. For homeowners lacking confidence with DIY projects or dealing with complicated radiator configurations, professional fitting proves worthwhile.

Choosing the Right Reflector Panel Materials

Material quality significantly affects radiator reflector panels' performance. Premium options deliver better heat reflection and durability compared to budget alternatives.

Aluminium Foil Panels

Basic radiator foil consists of heavy-duty aluminium foil backed with cardboard or thin foam. These affordable panels cost £5-£10 per radiator and suit budget-conscious installations. However, durability concerns exist - thin foil tears easily during installation and may deteriorate over time from heat exposure.

Better quality foil panels use thicker gauge aluminium (typically 50-100 microns) laminated to rigid backing boards. The backing prevents damage during handling and maintains shape behind radiators. Reflectivity ratings reach 90-95%, effectively bouncing radiant heat into rooms.

Metallised Plastic Panels

Modern alternatives use metallised plastic films that resist tearing while maintaining high reflectivity. These panels typically feature bubble wrap or foam cores for added insulation value. The plastic construction withstands moisture better than cardboard-backed foils, preventing degradation in humid conditions.

Costs range from £10-£20 per panel depending on size and insulation thickness. The investment delivers improved longevity compared to basic foil options, though reflective performance remains similar.

Purpose-Made Radiator Panels

Specialist radiator panels from heating manufacturers represent premium options. These engineered products feature rigid construction, pre-cut sizes for standard radiators, and built-in mounting systems. Materials include aluminium sheets, metallised boards, or advanced composite materials.

Premium panels cost £15-£30 each but offer superior durability and performance. Built-in spacers ensure correct air gaps, while rigid construction prevents sagging or warping over time. For homeowners prioritising long-term performance over upfront costs, purpose-made panels justify the investment.

Maximising Energy Efficiency Beyond Reflector Panels

Radiator reflector panels form part of broader energy efficiency strategies for heating systems. Combined approaches deliver greater savings than any single measure.

System Maintenance and Optimisation

Regular central heating maintenance ensures boilers operate efficiently, maximising heat output while minimising fuel consumption. Annual servicing identifies issues affecting performance, including scale buildup, failing components, or incorrect pressure settings.

Bleeding radiators removes trapped air that prevents proper heat distribution. Air pockets cause cold spots and reduce radiator efficiency, forcing boilers to work harder. Bleeding takes minutes but significantly improves radiator performance throughout heating seasons.

System components require periodic inspection and replacement. Expansion vessels maintain correct system pressure, preventing efficiency losses from pressure variations. Pressure relief valves protect systems from over-pressure conditions while ensuring safe operation.

Heating Controls and Programming

Smart thermostats and programmable controls reduce heating costs more substantially than reflector panels alone. Modern controls adjust temperatures based on occupancy patterns, weather conditions, and user preferences. Research shows smart controls save 10-20% on heating bills - double or triple the savings from reflector panels.

Thermostatic radiator valves (TRVs) on individual radiators allow room-by-room temperature control. Bedrooms require less heating during daytime hours, while living spaces need warmth during evenings. TRVs automatically adjust radiator output based on room temperatures, preventing energy waste from overheating unused spaces.

Zone controls divide properties into separate heating areas with independent temperature settings and schedules. This approach suits larger homes where different areas have varying heating requirements throughout the day.

Boiler Efficiency and Upgrades

Modern condensing boilers achieve 90-95% efficiency compared to 60-70% for older non-condensing models. Replacing boilers over 15 years old delivers substantial savings that dwarf reflector panel benefits. Annual fuel savings of £200-£400 make boiler upgrades financially attractive despite higher upfront costs.

Quality boiler components ensure reliable operation and maintained efficiency. Worcester Bosch boiler spares and Baxi spares keep popular boiler models running optimally. Using genuine replacement parts prevents efficiency losses from inferior components.

Insulation Priorities

Wall insulation delivers far greater savings than radiator reflector panels. Cavity wall insulation costs £500-£1,500 for typical properties but saves £100-£300 annually - paying back within 5-10 years while dramatically improving comfort.

Loft insulation represents the most cost-effective upgrade, with 270mm thickness saving £200-£300 yearly in detached homes. Installation costs remain modest, and many homeowners complete loft insulation as DIY projects.

Draft proofing around doors and windows prevents heat loss through gaps and cracks. Inexpensive draft excluders and sealants reduce heating bills by 5-10% with minimal investment.

Common Mistakes and Installation Problems

Several errors reduce the radiator reflector panels' effectiveness or create maintenance issues.

Inadequate Wall Preparation

Installing panels over dirty or damp walls leads to adhesion failures and potential mould growth. Moisture trapped behind panels creates ideal conditions for mould development, particularly in older properties with porous brickwork. Always clean and dry walls thoroughly before installation.

Missing Air Gaps

Pressing panels flat against walls eliminates the insulating air cavity that enhances performance. Without air gaps, panels conduct heat directly to walls, reducing reflective benefits. Use spacers or adhesive foam pads to maintain 5-10mm separation.

Incorrect Panel Sizing

Oversized panels extending beyond radiator edges look unsightly and may interfere with wall decorations or furniture. Undersized panels fail to cover the full wall area heated by radiators, allowing heat loss around panel edges. Measure carefully and cut panels 50mm smaller than radiator dimensions.

Using Low-Quality Materials

Cheap kitchen foil or basic aluminium sheets lack durability and reflective properties of purpose-made panels. Kitchen foil tears easily and won't withstand radiator heat cycles. Invest in proper radiator foil or metallised panels designed for heating applications.

Blocking Radiator Convection

Panels extending above radiator tops or around sides obstruct convection currents that circulate warm air. Radiators need clear airflow paths above and to the sides for optimal performance. Restrict panels to wall areas directly behind radiators.

Property Types: Where Panels Deliver Best Results

Radiator reflector panels suit certain properties better than others. Understanding building characteristics helps determine whether installation proves worthwhile.

Solid Wall Properties Pre-1920

Victorian and Edwardian homes with solid brick walls benefit most from panels. Single-skin brickwork offers minimal insulation, allowing significant heat loss through external walls. Panels installed behind every external wall radiator deliver measurable savings in these properties.

Period properties often feature large single-pane windows and high ceilings that increase heating demands. Every efficiency improvement matters in these challenging thermal environments. Combining panels with other upgrades creates cumulative savings that substantially reduce heating costs.

1920s-1970s Cavity Wall Properties

Mid-century homes with cavity walls but no cavity insulation represent good candidates for reflector panels. The air gap within cavity walls provides some insulation, but filling cavities with foam or bead insulation improves performance dramatically. Before installing panels, consider cavity wall insulation as a higher-value investment.

If cavity insulation proves impractical or has already been installed, panels offer supplementary benefits. Savings remain modest compared to solid wall properties, but the low cost and simple installation still deliver positive returns.

Modern Properties Post-2000

Contemporary homes built to modern building regulations include extensive insulation in walls, roofs, and floors. Double or triple glazing further reduces heat loss. In well-insulated properties, radiator reflector panels deliver minimal benefit - perhaps 1-2% heating cost reduction.

For new builds, invest resources in heating controls and efficient boilers rather than reflector panels. Smart thermostats and weather compensation controls offer better returns in thermally efficient properties.

Flats and Apartments

Flats with radiators on external walls benefit from panels, though internal walls separating flats don't require treatment since heat warms neighbouring properties rather than escaping outdoors. Focus panel installation on genuine external walls only.

Upper-floor flats lose less heat than ground-floor properties due to heat rising from lower levels. However, external walls still conduct heat outwards, making panels worthwhile investments. Top-floor flats benefit from additional loft insulation if accessible.

Cost-Benefit Analysis: Are Panels Worth Installing?

Financial analysis reveals whether radiator reflector panels justify the investment based on property characteristics and installation costs.

Upfront Investment Requirements

DIY installations using basic foil panels cost £5-£10 per radiator. For typical homes with 6-8 radiators on external walls, the total investment reaches £40-£80. Premium panels increase costs to £10-£20 each, raising typical project costs to £80-£160.

Professional reflective radiator panel installation adds labour charges of £20-£30 per radiator, bringing total costs to £160-£320 for standard homes. This premium buys guaranteed results and professional finish quality.

Annual Savings Estimates

Solid wall properties without insulation save £15-£30 annually per radiator with panels fitted. Eight radiators deliver £120-£240 in yearly savings. DIY installations pay back within 4-12 months, while professional fitting extends payback to 18-30 months.

Cavity wall properties with partial insulation save £10-£15 per radiator yearly. Total annual savings of £80-£120 mean DIY installations break even within 6-12 months. Professional installations require 2-3 years to recoup costs.

Modern insulated properties save minimal amounts - perhaps £5-£10 per radiator annually or £40-£80 total. Even DIY installations need 12-18 months to break even. Professional installation rarely proves financially justified in well-insulated homes.

Long-Term Value Considerations

Beyond direct fuel savings, panels potentially increase property values by demonstrating energy efficiency improvements. EPC ratings improve when homes implement multiple efficiency measures, making properties more attractive to buyers concerned about running costs.

Comfort improvements have financial value that's harder to quantify. Rooms staying 1-2°C warmer create better living environments without increasing boiler output. This enhanced comfort justifies panel costs even when pure financial returns appear modest.

Panels last 10-20 years with minimal maintenance, providing ongoing benefits long after initial costs are recovered. Unlike consumable efficiency measures requiring regular replacement, reflector panels represent one-time investments delivering sustained performance.

Expert Recommendations and Best Practices

Heating professionals offer practical guidance for homeowners considering radiator reflector panels.

Prioritise High-Impact Measures First

Address major heat loss sources before installing panels. Loft insulation, cavity wall insulation, and modern double glazing deliver far greater savings than reflector panels. If the budget allows only one improvement, choose insulation over panels every time.

Boiler upgrades trump panels for properties with boilers over 15 years old. Modern condensing boilers save more fuel than panels ever could. However, panels and boiler upgrades work well together - new boilers plus panels maximise overall efficiency.

Target External Wall Radiators Only

Internal partition walls don't require panels since heat warms adjacent rooms rather than escaping outdoors. Installing panels behind radiators on internal walls wastes money and delivers zero benefit. Map all external walls in properties and treat only radiators mounted on these surfaces.

Ground floor radiators on external walls provide the best returns since ground-level rooms lose more heat than upper floors. If budget constraints limit installations, start with downstairs external wall radiators before treating upper floors.

Combine with Other Radiator Improvements

Clean radiators before installing panels. Dust and debris on radiator surfaces reduce heat output by obstructing convection and radiation. Vacuum radiator fins and gaps, then wipe surfaces with damp cloths. This simple maintenance improves performance at zero cost.

Ensure radiators mount securely on wall brackets without sagging. Poorly mounted radiators create gaps between panels and walls, reducing reflective efficiency. Tighten bracket fixings and confirm radiators hang level before installing panels.

Bleed trapped air from radiators to eliminate cold spots that reduce output. Air pockets force boilers to work harder while delivering less heat to rooms. This quick maintenance task takes minutes but dramatically improves radiator performance.

Getting Professional Advice and Support

For homeowners uncertain whether radiator reflector panels suit their properties, professional assessments provide clarity and guidance.

Qualified heating engineers evaluate properties and recommend appropriate efficiency improvements based on building characteristics, existing insulation levels, and heating system conditions. This expert perspective prevents wasted investment in measures that deliver minimal returns while highlighting high-impact upgrades.

Energy audits identify where properties lose heat most significantly. Thermal imaging cameras reveal heat loss patterns invisible to occupants, showing precisely which improvements deliver best value. Armed with this information, homeowners make informed decisions about radiator panels and other efficiency measures.

The evidence clearly demonstrates radiator reflector panels work effectively in specific circumstances - primarily older properties with solid walls and limited insulation. Homes built before 1920 typically save £100-£250 annually when panels are fitted to all external wall radiators, making them worthwhile investments that pay back quickly through reduced heating costs.

However, modern well-insulated properties see minimal benefit from panels, with annual savings insufficient to justify installation effort and costs. Focus resources on heating controls, system maintenance, and boiler upgrades instead.

For advice tailored to specific properties and heating systems, contact us to discuss efficiency improvements that deliver maximum value for your home.

-

-