Integrating Old and New Plumbing Systems Seamlessly

Combining old and new plumbing infrastructure presents technical challenges that require careful planning and appropriate materials. Whether extending existing pipework for home additions, replacing deteriorated sections, or upgrading to modern fixtures, successful plumbing system integration depends on understanding material compatibility, using proper connection techniques, and preventing long-term corrosion issues.

Many UK properties contain pipework installed decades ago, often in imperial sizing with materials no longer commonly used. Connecting old pipes to new during renovations or repairs demands expertise to ensure leak-free joints that withstand years of service without deterioration.

Understanding Compatibility Between Old and New Pipe Materials

Material compatibility forms the foundation of successful integration work. Incompatible materials connected directly create galvanic corrosion, leading to premature failure regardless of installation quality.

Identifying Your Existing Pipe Types

Older properties may contain several pipe materials throughout the system. Lead pipes, recognisable by their dull grey colour and soft texture, require complete replacement rather than integration due to health risks. Attempting to connect modern materials to lead serves no purpose when the lead itself poses dangers.

Galvanised steel pipes, common in pre-1970s installations, corrode internally over time despite an external appearance suggesting good condition. These pipes use threaded connections with imperial sizing that don't match modern metric pipes. Copper pipes vary between Type A (thinner walls for above-ground installation) and Type B (thicker walls for buried applications), affecting connection choices.

Imperial sizing complicates matters significantly. A 1/2-inch pipe doesn't equal 15mm, despite a common assumption. These measurement differences require specific adapters ensuring proper flow and secure connections. Professional assessment identifies existing materials and sizing before attempting any plumbing system integration work.

Modern Pipe Material Options

Copper remains the preferred choice for connecting to existing copper systems due to material consistency and proven longevity. Type A copper suits most domestic applications, whilst Type B provides enhanced durability for underground connections or areas prone to physical damage.

PEX (cross-linked polyethylene) offers flexibility and freeze resistance but requires special adapters when connecting to metal pipes. Push-fit systems using these adapters simplify installation, though professional plumbers often prefer soldered or compression fittings for permanent installations requiring maximum reliability.

Stainless steel provides excellent corrosion resistance for specific applications, particularly in heating systems or areas with aggressive water chemistry. However, its higher cost limits widespread use to situations where other materials prove unsuitable. Quality Worcester Bosch boiler spares ensure heating system connections maintain manufacturer specifications.

Why Direct Connections Often Fail

Connecting dissimilar metals without proper isolation creates galvanic corrosion. This electrochemical reaction occurs when two different metals contact in the presence of an electrolyte (water), causing accelerated deterioration of the more reactive metal. Copper connected directly to galvanised steel corrodes the steel rapidly, creating leaks within months.

Thermal expansion rates differ between materials. Copper expands significantly when heated, whilst plastic materials expand even more. Direct connections between materials with different expansion rates create stress at joints, eventually causing leaks. Using proper transition fittings accommodates this movement.

Thread incompatibility between imperial and metric fittings prevents secure connections. Forcing mismatched threads damages both components and creates immediate or delayed leaks. Compression fittings or purpose-designed adapters solve this issue when connecting old pipes to new with different threading standards.

Essential Techniques for Plumbing System Integration

Proper technique matters more than expensive materials when integrating old and new pipework. Understanding correct methods prevents failures that damage property and require costly repairs.

Using Transition Fittings and Adapters

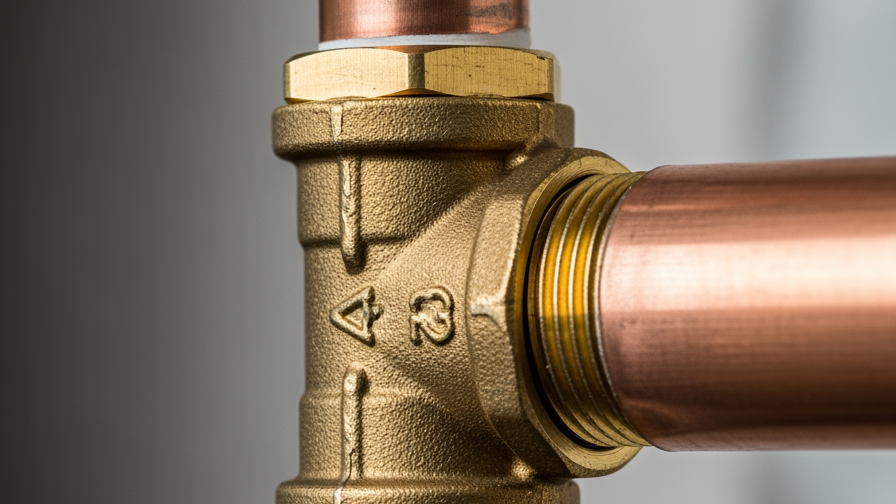

Dielectric unions provide the essential barrier between dissimilar metals. These fittings incorporate non-conductive gaskets and sleeves separating the metals whilst maintaining watertight seals. Copper-to-steel connections always require dielectric unions to prevent galvanic corrosion.

Push-fit adapters accommodate connections between plastic and metal pipes without specialist tools. These fittings incorporate internal grab rings and O-ring seals, requiring only proper pipe preparation and full insertion depth. Whilst convenient, ensuring adequate pipe support prevents stress on these connections.

Compression fittings offer versatile solutions for plumbing system integration projects. The mechanical seal created by tightening the compression nut forms reliable joints on various pipe materials. These fittings allow disassembly for future modifications, unlike soldered connections, which require pipe cutting for removal.

Reducing couplers addresses size transitions between old and new sections. However, each size reduction creates a pressure drop, potentially affecting performance. Planning pipe routes to minimise size changes maintains optimal flow rates. Professional suppliers like those offering Baxi boiler spares stock appropriate fittings for various integration scenarios.

Converting Imperial to Metric Sizing

Imperial-to-metric conversions create frequent challenges. A 1/2-inch BSP (British Standard Pipe) thread measures approximately 20.96mm externally, significantly different from 15mm metric pipe. Purpose-designed adapters bridge this gap, incorporating threads matching both standards.

Maintaining adequate flow rates requires attention to internal diameters rather than just external measurements. A 15mm copper pipe provides similar flow capacity to 1/2-inch imperial piping, but adapters may introduce restrictions. Calculating cumulative pressure drops across multiple adapters ensures system performance meets requirements.

Professional measurement eliminates guesswork. Vernier callipers accurately determine existing pipe dimensions, whilst thread pitch gauges identify thread types. This information guides adapter selection, preventing expensive mistakes from purchasing incompatible components.

Proper Joint Preparation

Success begins with thorough preparation. Cutting old pipes produces burrs that damage seals and O-rings during fitting installation. Deburring tools remove these sharp edges, creating smooth surfaces for reliable connections.

Scale and corrosion removal prove essential for compression and push-fit connections. Wire brushes or emery cloth clean external pipe surfaces, whilst internal cleaning tools remove deposits that reduce bore diameter. Clean surfaces allow fittings to seat properly, preventing leaks.

Testing pipe wall thickness identifies pipes that are too corroded for reliable connections. Ultrasonic thickness gauges measure the remaining wall without cutting pipes, determining whether sections require replacement before attempting connections. This precaution prevents wasted effort connecting to pipes that fail shortly after integration work completes.

Managing Galvanic Corrosion Risks

Galvanic corrosion poses the greatest long-term threat to mixed plumbing systems. Understanding and preventing this electrochemical process ensures decades of reliable service.

Understanding Metal Compatibility

The galvanic series ranks metals by their electrical potential. Metals far apart in this series react strongly when connected, whilst adjacent metals show minimal interaction. Copper and galvanised steel sit far apart, creating a high corrosion risk. Copper and brass, being similar, connect safely without special precautions.

Water chemistry affects corrosion rates significantly. Soft water accelerates galvanic corrosion, whilst hard water forms protective scale deposits that slow deterioration. Properties with water softeners require additional attention when connecting old pipes to new with dissimilar metals.

Environmental factors, including temperature, oxygen content, and pH levels, influence corrosion rates. Hot water systems experience faster corrosion than cold water pipework. Understanding these factors helps predict potential problem areas requiring enhanced protection.

Protection Methods

Dielectric isolators separate dissimilar metals whilst maintaining electrical continuity through the building's earth bonding system. These devices incorporate plastic or rubber gaskets with metal washers on each side, preventing direct metal-to-metal contact whilst satisfying electrical safety requirements.

Plastic liner inserts provide additional protection in threaded connections. These liners prevent direct contact between metal threads, reducing corrosion risk. Combined with dielectric washers, they offer comprehensive protection for critical connections.

Heating systems benefit from sacrificial anodes that corrode preferentially, protecting system components. Magnesium or aluminium anodes attract corrosive action, requiring periodic replacement but extending system life significantly. Quality oil burners and heating components incorporate corrosion protection features.

Regular inspection protocols identify developing corrosion before failures occur. Annual visual checks of exposed connections reveal discolouration or scale buildup, indicating electrochemical activity. Early detection allows preventive maintenanc,e preventing expensive emergency repairs.

Pressure and Flow Considerations

Successful plumbing system integration maintains consistent pressure and adequate flow throughout mixed old-new systems. Mismatched components create bottlenecks affecting performance.

Matching System Pressures

Older low-pressure systems designed for gravity-fed cold water and vented hot water cylinders operate at substantially lower pressures than modern mains-pressure systems. Connecting high-pressure supplies to vintage fixtures risks damage or failure. Pressure-reducing valves installed at integration points protect sensitive components.

Modern combination boilers provide mains-pressure hot water, often exceeding older pipework design pressures. The increased stress accelerates the deterioration of marginal pipe sections and stresses soldered joints made decades ago. Assessing existing pipework condition before connecting new high-pressure sources prevents subsequent failures. Reliable fire valves and safety devices maintain system integrity.

Installing pressure regulators creates zones within mixed systems, allowing modern components to operate at optimal pressure whilst protecting vintage elements. These regulators require periodic adjustment to maintain the correct output pressure as conditions change.

Maintaining Adequate Flow Rates

Bottlenecks occur when new large-diameter pipes connect to undersized existing sections. A modern 22mm supply pipe feeding into original 15mm pipework creates a pressure drop, limiting flow to fixtures. Strategic replacement of bottleneck sections maintains performance without complete re-piping.

Calculating pressure drops across connections and adapters ensures adequate flow reaches endpoints. Each connection introduces minor losses; multiple adapters in series compound these losses significantly. Planning routes that minimise transitions maintains system performance.

Balancing flow across mixed systems requires understanding cumulative effects. Testing flow rates at various taps and appliances after integration identifies underperforming areas requiring attention. Electronic flow meters provide accurate measurements guiding remedial work.

Building Regulation Compliance

Mixed old-new systems must meet current building regulations despite incorporating older components. Understanding requirements prevents non-compliant installations.

Notification Requirements for Mixed Systems

Heating and Plumbing World professionals ensure all integration work complies with Water Supply Regulations and Building Regulations. Installing new connections to existing systems typically falls under competent person schemes, allowing registered installers to self-certify work without separate Building Control applications.

However, substantial modifications, including re-routing waste pipes, altering system types (gravity to mains pressure), or crossing compartment boundaries, require formal notification. Professional installers handle these notifications routinely, providing necessary documentation for homeowner records and future property sales.

Water Supply Regulations require notification to water companies for various works, including installing new connections to mains supplies or significantly altering internal distribution. Compliance ensures water quality protection through appropriate backflow prevention and material specifications.

Safety Standards for Integration Work

Backflow prevention proves critical in mixed systems where pressure differences might reverse normal flow direction. Double-check valves or reduced-pressure zone devices prevent contaminated water from entering mains supplies. Modern fixtures typically incorporate internal check valves, but older components may require separate backflow preventers.

Adequate support for new pipe sections prevents stress on connections to old pipework. Support spacing varies by material - copper requires supports every 1.2 metres horizontally, whilst plastic needs closer spacing due to greater flexibility. Proper support prevents sagging that stresses joints over time.

Emergency isolation valves must remain accessible without removing permanent fixtures. Planning valve locations during integration work prevents situations where shutting off supplies requires extensive dismantling. This consideration proves particularly important in rented properties where tenants need emergency access.

Common Integration Scenarios

Different situations require tailored approaches. Understanding common scenarios helps homeowners and installers plan effective solutions.

Extending Existing Copper Systems

Connecting new copper to existing copper pipework offers the most straightforward integration. Soldered joints provide permanent connections matching original installation methods. End-feed fittings require skill in applying solder, whilst solder-ring fittings simplify the process for less experienced installers.

Compression fittings offer alternatives to avoid heat and naked flames near combustible materials. These mechanical connections prove particularly useful in occupied properties where soldering risks damaging finishes or disturbing residents. Quality compression fittings provide decades of reliable service when properly tightened.

Push-fit systems accommodate copper-to-copper connections with minimal tools. Proper pipe preparation remains essential - cutting square, deburring thoroughly, and inserting to full depth ensures reliable seals. Some installers prefer traditional methods for permanent installations, reserving push-fit for temporary or accessible locations.

Connecting Plastic to Metal Pipes

Plastic-to-metal transitions require careful material selection. Brass adapters suit most applications, providing threaded connections for metal pipes and push-fit or compression ends for plastic pipes. Avoiding direct plastic-to-steel contact prevents galvanic corrosion between steel and brass components.

Thermal stress affects these connections significantly. Hot water systems require adapters and pipes rated for continuous high temperatures. Using inadequate materials causes premature failure as thermal cycling weakens connections and softens plastic. Professional installations specify appropriate materials for intended applications, including those involving photo cells in heating control systems.

Long-term reliability depends on proper support. Plastic expands more than metal when heated, potentially stressing connections if pipe movement isn't accommodated. Expansion loops or flexible sections absorb this movement, protecting critical joints.

Replacing Sections While Preserving Original Runs

Selective replacement balances cost against reliability. Replacing deteriorated sections whilst preserving sound pipework proves economical for extensive systems. Planning cuts at logical points - isolation valves, tees, elbows - simplifies connections and maintains system functionality during work.

Phased approaches minimise disruption in occupied properties. Completing one section before starting the next maintains partial system function throughout renovations. This strategy suits rental properties or situations where alternative accommodation isn't feasible during work completion.

Strategic planning identifies critical sections requiring replacement before less important areas. Main supply lines warrant priority over branch feeds to individual taps. Addressing structural issues first builds solid foundations for the remaining system life.

Testing and Commissioning Mixed Systems

Thorough testing proves integration work reliability before concealing pipes behind finishes. Shortcuts during this phase create expensive problems discovered only after damage occurs.

Pressure Testing Procedures

Pressure testing exceeds normal operating pressure, revealing weaknesses in connections before they fail in service. Standard tests apply 1.5 times maximum working pressure for 30 minutes minimum, monitoring pressure gauges for drops indicating leaks.

Isolating sections allows focused testing on new integration work without pressurising entire systems unnecessarily. This approach identifies problems quickly whilst avoiding stress on sound existing pipework unrelated to current work.

Rectification before concealment remains far easier than discovering leaks after plastering and decorating. Identifying and repairing issues during testing prevents expensive repairs and property damage. Professional installers never proceed to concealment without satisfactory test results.

Leak Detection Best Practices

Visual inspection reveals obvious issues - weeping joints, moisture accumulation, and discolouration. Examining all accessible connections under pressure identifies problems that immediate rectification can address. Using paper towels to wipe joints reveals minor seepage invisible to casual inspection.

Electronic leak detection equipment locates hidden leaks within walls or floors. Acoustic sensors identify characteristic sounds of escaping water, whilst moisture meters detect dampness in surrounding materials. These tools prevent guesswork when symptoms suggest problems without obvious sources.

Long-term monitoring provides confidence in work quality. Recommending homeowners check connections periodically during the first months after installation catches any delayed problems before significant damage occurs. Accessible connections in cupboards or under sinks allow easy inspection without specialist tools.

Conclusion

Successful plumbing system integration requires understanding material compatibility, using appropriate connection methods, and preventing galvanic corrosion through proper isolators and adapters. Connecting old pipes to new demands attention to pressure matching, flow maintenance, and building regulation compliance. Whether extending existing copper systems, replacing deteriorated sections, or introducing modern materials, proper techniques ensure reliable performance for decades.

Professional assessment identifies existing pipe materials and conditions, recommending integration strategies balancing cost against longevity. Quality materials, correct fitting selection, and thorough pressure testing prevent failures that damage property and require expensive emergency repairs. Mixed systems incorporating both original and new components serve reliably when integration work respects the unique challenges dissimilar materials present.

For expert guidance on plumbing system integration projects, contact us to discuss specific requirements and receive professional recommendations. Experienced installers ensure seamless connections between old and new infrastructure, delivering integrated systems that perform flawlessly whilst preserving valuable existing pipework.

-

-