Internal vs External Drainage: UK Building Standards

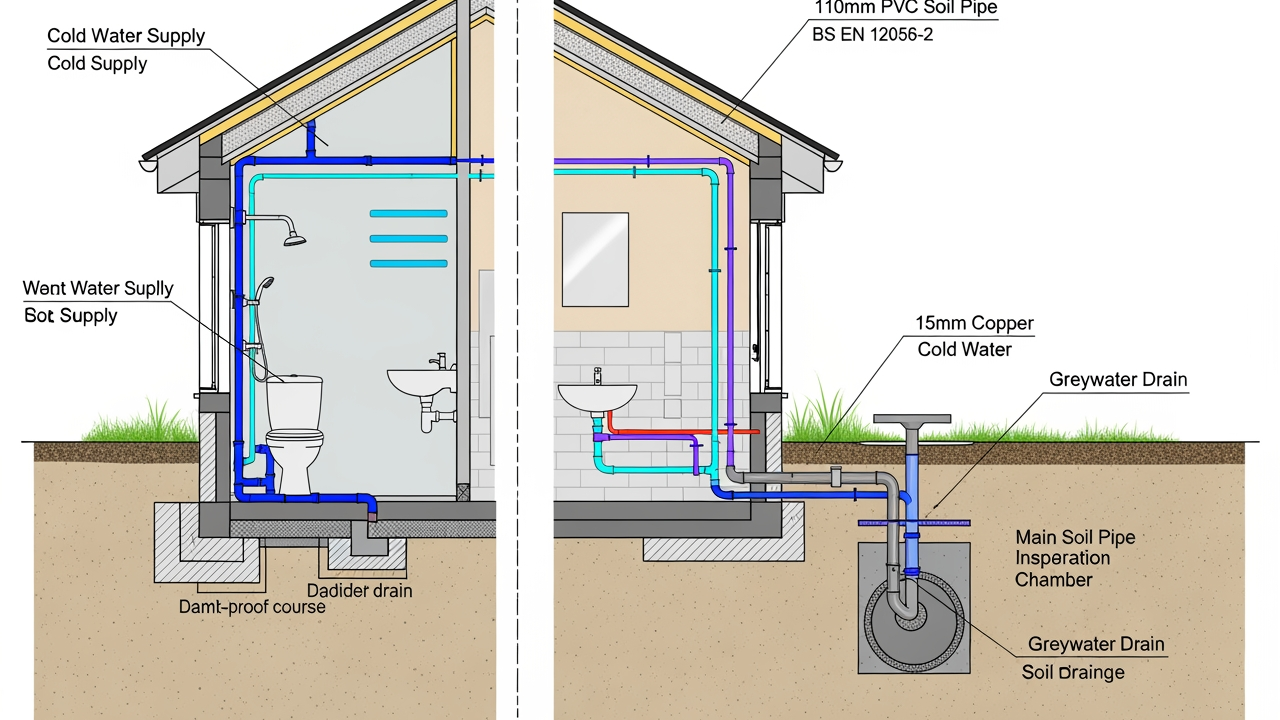

Drainage systems are separated into two distinct categories in UK construction: internal drainage handles water and waste inside the building envelope, while external drainage manages surface water and sewage outside it. The distinction between internal vs external drainage matters because different regulations, installation requirements, and maintenance responsibilities apply to each system under drainage standards UK professionals must follow.

Building Control approval requirements differ significantly between these systems. Internal drainage alterations typically require approval under Part H of the Building Regulations, while external drainage work often needs additional checks under Part C (site preparation) and may require consent from your local water authority.

What Counts as Internal Drainage

Internal drainage encompasses all pipework, fixtures, and fittings that collect and transport water within your building's structure. This includes:

Sanitary appliances and their immediate connections: toilets, sinks, baths, showers, bidets, and urinals. The pipework runs from the appliance trap to the point where it exits the building envelope.

Waste pipes: the 32mm to 50mm diameter pipes that carry water from basins, sinks, baths, and showers. These typically run at a gradient of 18-90mm per metre, depending on diameter.

Soil pipes: the 100mm to 110mm diameter pipes that transport toilet waste. These require a minimum gradient of 18mm per metre to prevent blockages.

Internal rainwater pipes: where downpipes run inside the building structure before connecting to external drainage.

The building envelope defines the boundary. Once pipework passes through the external wall, foundation, or floor slab to the outside, it becomes external drainage. The transition point typically occurs at the external face of the wall, though Building Control may interpret this differently depending on construction type.

External Drainage Categories

External drainage divides into two separate systems under current UK standards:

Foul water drainage carries sewage and wastewater from sanitary appliances to the public sewer or private treatment system. This includes everything from toilets, sinks, baths, showers, washing machines, and dishwashers.

Surface water drainage handles rainwater from roofs, paved areas, and other hard surfaces. Building Regulations now strongly discourage connecting surface water to the foul sewer system.

The separation exists for good reason. Combined systems (where surface water and foul water share pipes) overload sewage treatment plants during heavy rainfall, leading to untreated discharge into rivers and coastal waters. Since 2020, Building Regulations have required surface water disposal through sustainable drainage systems (SuDS) wherever possible.

Building Regulations Part H Requirements

Part H of the Building Regulations sets minimum standards for internal vs external drainage systems. The 2015 edition (with 2016 amendments) remains current as of 2024.

For Internal Sanitary Pipework:

Traps must maintain a water seal of at least 25mm under working conditions. Most modern traps provide 75mm seals, offering protection against seal loss from self-siphonage or induced siphonage.

Waste pipes require adequate ventilation to prevent trap seal loss. This typically means extending the soil stack above roof level or installing air admittance valves where extending the stack isn't practical.

Branch discharge pipes connecting to stacks should enter at angles not exceeding 45 degrees to the vertical. Connections at sharper angles create turbulence that can cause blockages.

For External Drainage:

Pipes must withstand expected loads without deformation. Beneath driveways and parking areas, this typically requires rigid pipes in concrete surrounds or flexible pipes with engineered bedding, materials available from suppliers like Polypipe, who specialise in plastic piping systems for drainage applications.

Minimum pipe falls depend on diameter and expected flow. For 100mm foul drains, the minimum gradient is 1:40 (25mm per metre). For 150mm pipes, it drops to 1:150 (6.7mm per metre).

Access points must allow rodding of the entire system. Rodding eyes, inspection chambers, or manholes are required at changes of direction, changes of gradient, junctions, and at maximum intervals of 45 metres on straight runs.

Inspection Chamber and Manhole Standards

Access points in external drainage follow specific dimensional requirements based on depth:

Inspection chambers (up to 600mm deep) need a minimum internal diameter of 190mm for rodding access only. Where someone needs to work at the chamber, the minimum dimensions increase to 450mm x 450mm.

Shallow manholes (600mm to 1.2m deep) require 1200mm x 750mm minimum internal dimensions. This provides enough space for a person to work from the surface using equipment.

Deep manholes (over 1.2m deep) need 1200mm x 750mm minimum, with access shafts of at least 600mm diameter. Step irons or ladder access becomes mandatory when the depth exceeds 1m.

Cover and frame assemblies must meet the load class for their location. Class B125 (12.5 tonne load) suffices for pedestrian areas and car parks. Class D400 (40 tonne load) is required for roads and areas where heavy vehicles travel.

Surface Water Disposal Hierarchy

Building Regulations establish a clear preference order for surface water disposal:

First preference: infiltration to the ground through soakaways, infiltration trenches, or permeable paving. This approach recharges groundwater and reduces flood risk.

Soakaways must be at least 5 metres from buildings and 2.5 metres from boundaries. Size calculations depend on soil percolation rate, rainfall intensity, and contributing roof area. A typical three-bedroom house with 100m² of roof area requires a soakaway of approximately 2.5m³ capacity in medium permeability soil.

Second preference: discharge to a surface water body (watercourse, canal, or lake) with appropriate consent from the Environment Agency or local authority.

Third preference: discharge to a surface water sewer if available.

Last resort: discharge to a combined sewer, and only where no other option exists. Water companies can refuse connection or impose strict flow rate limits.

Flow attenuation often becomes mandatory when connecting to sewers. This means installing storage tanks that release water slowly, preventing system overload during heavy rainfall. Typical requirements limit discharge to 5 litres per second or less, regardless of contributing area. Kingspan offers suitable storage cylinders for attenuation systems.

Private vs Public Drainage Responsibility

The distinction between private and public drainage determines who maintains and repairs the system.

Private drains serve a single property and remain the property owner's responsibility throughout their length. This includes the section running under public highways to the connection point.

Private sewers serve multiple properties but aren't adopted by the water company. All connected property owners share maintenance responsibility, though disputes about cost allocation are common.

Public sewers belong to the water company, which maintains them at no direct cost to property owners. Since 2011, most private sewers serving multiple properties transferred to water company ownership under the Transfer of Private Sewers Regulations.

The transfer didn't include drains serving single properties, lateral drains connecting to the sewer at boundaries, or treatment plants. Property owners retain responsibility for these elements.

You can check ownership through your water company's sewer map, available by request. The map shows public sewers and typically indicates the connection point where private drainage meets the public system.

Separate vs Combined Systems

UK drainage systems follow two main configurations:

Separate systems use distinct pipes for foul water and surface water. Modern developments universally adopt this approach. The foul sewer connects to treatment works, while surface water sewers discharge to rivers or the sea with minimal treatment.

Combined systems carry both foul water and surface water in the same pipes. Most Victorian and early 20th-century developments used combined drainage. These systems remain widespread in older urban areas.

Combined sewers create problems during heavy rainfall. Treatment works can't process the volume, forcing water companies to discharge excess flow through combined sewer overflows (CSOs) directly into watercourses. In 2023, CSOs discharged untreated sewage for over 400,000 hours across England.

Building Regulations now prohibit new connections of surface water to combined sewers unless you can prove no alternative exists. Even then, you must minimise flow rates through attenuation storage.

Testing Requirements for New Installations

All new drainage installations require testing before Building Control signs off the work.

Air testing involves sealing all pipe openings except one, then using a pump to create 100mm water gauge pressure (approximately 10 millibars). The system must maintain at least 75mm water gauge for three minutes.

Water testing fills the system to the crown of the highest access point. Water level must not drop more than 10mm in 30 minutes for a 6-metre test length.

Testing occurs before backfilling trenches, allowing repairs without excavation. Building Control officers typically witness tests or require photographic evidence showing pressure gauges and timestamps.

Drainage contractors use specialised testing equipment, including inflatable drain stoppers, pressure gauges, and water pumps. DIY installations can use the same equipment hired from tool rental companies. Stuart Turner manufactures pressure testing equipment alongside their pumping solutions.

Common Installation Mistakes to Avoid

Insufficient fall: pipes laid too flat don't self-cleanse, leading to gradual solid accumulation and eventual blockage. Always verify gradients with a spirit level during installation.

Inadequate bedding: pipes laid directly on stony ground or backfilled with unsuitable material can crack under load. Use pea gravel or sand for bedding and initial backfill, compacted in 150mm layers.

Poor joint sealing: push-fit joints need proper cleaning and lubrication. Solvent-weld joints require correct primer and cement application with adequate curing time. Failed joints allow root ingress and leak wastewater into the surrounding ground. Quality fittings ensure reliable connections that withstand pressure testing and long-term service.

Missing access points: saving money by omitting inspection chambers creates expensive problems when blockages occur. The cost of excavating to clear a blockage far exceeds the installation cost of proper access.

Wrong pipe materials: using standard underground drainage pipe above ground exposes it to UV degradation. Above-ground sections require UV-resistant pipe or protective coating.

When Building Control Approval Is Required

You need Building Control approval for:

- Installing new sanitary appliances and associated drainage

- Replacing or altering existing internal drainage pipework

- Installing or altering external drainage systems

- Connecting to public sewers (also requires water company consent)

- Installing septic tanks or treatment plants

You don't need approval for:

- Like-for-like replacement of sanitary appliances using existing connections

- Unblocking or repairing existing drains without alteration

- Maintaining existing systems

The approval process involves submitting plans showing proposed drainage layouts, pipe sizes, gradients, and access points. Building Control reviews plans for compliance, then inspects at key stages: before backfilling trenches, at completion, and after testing.

Costs vary by local authority but typically range from £150 to £400 for small domestic projects. The investment prevents costly mistakes and ensures proper documentation for future property sales.

Conclusion

Understanding the distinction between internal vs external drainage systems helps you navigate drainage standards UK regulations effectively and avoid expensive mistakes. Internal drainage operates within your building envelope under controlled conditions, while external drainage faces ground loads, root ingress, and weather exposure, requiring different materials and installation standards.

The regulatory framework exists to protect public health, prevent flooding, and maintain water quality. Separating foul and surface water reduces sewage overflows into rivers. Proper testing ensures systems work correctly from day one. Adequate access points allow maintenance without excavation.

Whether you're planning a bathroom renovation, extending your property, or installing new drainage, early consultation with Building Control saves time and money. They clarify which regulations apply to your specific project and identify potential issues before you start work. Most importantly, proper compliance protects property value and prevents the legal complications that arise when selling a property with undocumented drainage alterations.

For additional plumbing system components and materials, Heating and Plumbing World stocks a comprehensive range of drainage products from trusted manufacturers.

-

-