Non-Return Valves: Preventing Backflow in Heating Systems

Backflow in heating systems causes more than inconvenience; it creates inefficiency, noise, and equipment damage that costs hundreds in preventable repairs. A non-return valve, also called a check valve, stops heated water or coolant from flowing backwards through your system when pumps shut off or pressure drops.

Without this simple component, gravity pulls water back through pipes, creating hammer effects that stress joints and radiators. Pumps work harder on restart because they're fighting reverse flow. Boilers cycle inefficiently because they can't maintain proper circulation patterns.

How Non-Return Valves Work

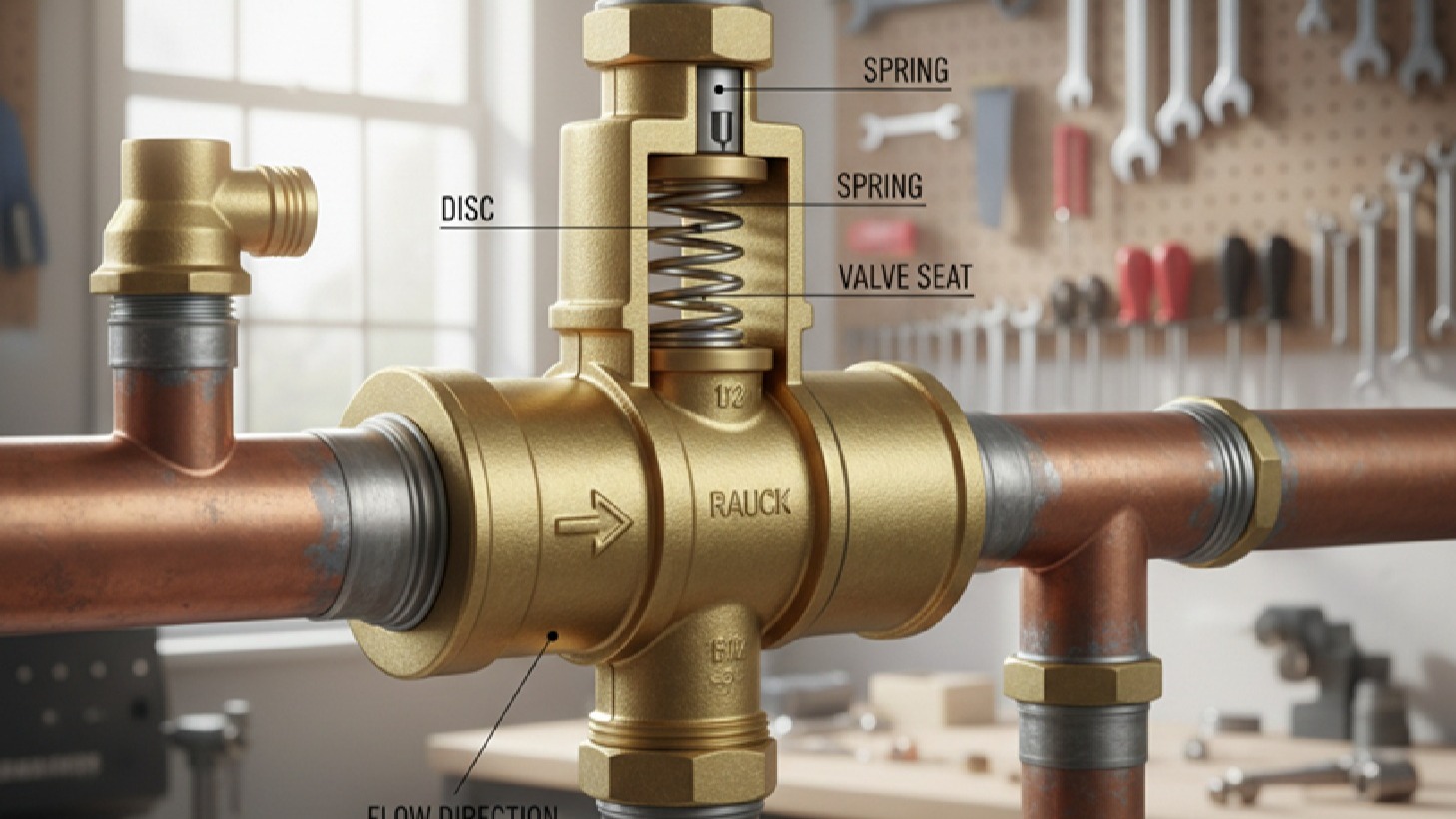

A non-return valve contains a spring-loaded disc or flap that opens when water flows in the correct direction. Pressure from the pump pushes the disc open, allowing water through. When the flow stops or reverses, the spring snaps the disc shut, creating a seal that blocks backward movement.

The mechanism responds instantly, within milliseconds of pressure change. This speed matters because water hammer (the banging noise from sudden flow reversal) develops in fractions of a second. A delayed response means the valve can't prevent the pressure spike that damages pipes and fittings.

Modern valves use different internal designs:

Spring-loaded disc valves work in any orientation and handle high pressures up to 16 bar. The spring provides a consistent closing force regardless of installation angle.

Swing check valves use a hinged flap that gravity helps close. They're reliable but must be installed horizontally or they won't seal properly.

Ball check valves use a weighted ball that rolls into a seat when flow stops. These handle dirty water better because debris doesn't jam the mechanism as easily.

Where Non-Return Valves Prevent Problems

Gravity circulation systems need check valves on each radiator circuit. Without them, hot water from upper floors flows backwards through lower circuits when the pump stops, creating uneven heating. We've measured temperature differences of 8-12°C between floors in systems missing these valves.

Zone valve systems require check valves on each zone's supply line. When one zone closes, pressure differences can push water backwards through inactive zones. This causes radiators to heat when they shouldn't, wasting energy and confusing thermostats.

Solar thermal systems use check valves to prevent thermosiphoning at night. Hot water in collectors would naturally rise into storage tanks, then cool and sink back down, creating a circulation loop that drains stored heat. A single check valve on the collector return line stops this cycle. Systems incorporating Kingspan cylinders benefit from proper backflow prevention.

Combination boiler systems need check valves between the heating circuit andthe hot water heat exchanger. Without separation, pressure from the mains water supply can force water into the heating circuit, overpressurising the system and triggering safety valves.

Sizing Non-Return Valves for Your System

Valve size must match pipe diameter and flow rate. An undersized valve creates resistance that reduces system efficiency. An oversized valve may not seal properly at low flow rates.

Most domestic heating systems use 22mm or 28mm copper pipe with flow rates between 10 and 30 litres per minute. A 22mm valve handles up to 25 litres per minute with minimal pressure drop (typically 0.1 bar at 15 litres per minute). A 28mm valve manages 40 litres per minute.

Calculate your system's flow rate by dividing total heat output (in kW) by the temperature difference between flow and return pipes:

Flow rate (L/min) = (Heat output in kW × 14.3) ÷ Temperature difference (°C)

For a 15kW system with a 20°C temperature difference: (15 × 14.3) ÷ 20 = 10.7 litres per minute

This system needs a 22mm valve. Installing a 15mm valve here would create a 0.3-0.4 bar pressure drop, forcing the pump to work 20-30% harder.

Installation Position Affects Performance

Flow direction matters absolutely. Every valve has an arrow stamped or moulded into the body showing the correct flow direction. Install it backwards, and you've created a permanent blockage; the valve stays closed under all conditions.

Orientation affects some valve types. Spring-loaded valves work in any position because the spring provides closing force. Swing check and ball check valves need specific orientations: horizontal for swing checks, vertical with flow upward for ball checks. Ignore these requirements and the valve won't close reliably.

Straight pipe runs before and after the valve improve performance. Install valves at least 5 pipe diameters (110mm for 22mm pipe) from elbows or tees. Turbulent flow from nearby fittings prevents the disc from seating properly, allowing minor backflow.

Access for maintenance determines long-term reliability. Valves eventually need cleaning or replacement. Installing one inside a wall cavity or under a fixed floor means future problems require destructive access. Position valves near service points or in accessible pipe runs.

Common Installation Mistakes That Cause Failures

Installing valves in the wrong circuit location tops the failure list. We've seen check valves placed on boiler returns instead of circuit supplies. This position can't prevent backflow through individual radiator loops; it only stops reverse flow through the boiler itself.

Using cheap valves in high-temperature circuits leads to rapid failure. Budget valves use rubber seals rated to 80°C. Heating systems regularly hit 85-90°C, causing seals to harden and leak within months. Valves rated to 110°C cost £3-5 more but last longer.

Forgetting to flush the system before installing new valves introduces debris that prevents sealing. Installation debris, old flux, and magnetite sludge lodge in the valve seat. The disc can't form a seal, allowing continuous backflow. Flush circuits thoroughly before fitting new components.

Over-tightening compression fittings distorts the valve body on brass valves. This warps the internal seat, preventing the disc from closing completely. Tighten compression fittings 1.5 turns past hand-tight, no more. Use a wrench on the valve body to prevent it from twisting.

Maintenance Requirements and Service Life

Non-return valves need inspection every 3-5 years in clean systems, annually in systems with recurring sludge problems. Signs that maintenance is overdue include:

- Radiators heating when zones should be closed

- Water hammer noises when pumps stop

- Uneven heating between floors

- Pumps are struggling to start after idle periods

Servicing involves isolating the valve section, draining it, removing the valve, and cleaning the disc and seat. Magnetite buildup (black sludge from internal corrosion) commonly prevents proper sealing. A wire brush and cleaning solution remove deposits.

Replace the valve if the seat shows pitting or the spring has weakened. Test spring tension by pressing the disc; it should snap back firmly when released. A weak spring allows backflow at low pressure differentials.

Systems with proper water treatment and magnetic filtration produce minimal sludge. Valves in these systems often run 10-15 years without service. Systems without treatment need valve maintenance every 2-3 years as sludge accumulates.

Choosing Between Valve Types for Different Applications

Standard heating circuits work well with spring-loaded brass valves. These handle the pressure (typically 1-3 bar) and temperature (70-85°C) of domestic systems. Cost runs £8-15 for quality units with replaceable internals.

Underfloor heating systems need low-resistance valves because flow rates are higher, but pressure differentials are lower. Ball check valves work better here; they open fully at lower pressures and create less resistance. Expect to pay £12-20 for suitable models.

Commercial systems above 10 bar require heavy-duty valves with metal-to-metal seating instead of rubber seals. These cost £40-80 but handle the pressure cycling that destroys standard valves in months. The metal seats tolerate temperatures above 100°C without degrading.

Solar thermal circuits experience extreme temperature swings (10-120°C) and stagnation conditions. Use valves specifically rated for solar applications with EPDM seals that remain flexible across this temperature range. Solar-rated valves cost £15-25 but prevent the failures that plague standard valves in these conditions.

Troubleshooting Backflow Problems

Intermittent water hammer suggests a valve that's sticking partially open. The disc catches on debris or corrosion, allowing some backflow before suddenly closing. This creates the pressure spike that causes banging. Remove and clean the valve, or replace it if the seat is damaged.

Continuous backflow means complete valve failure. The disc is jammed open, the spring has failed, or debris prevents sealing. Test by isolating the circuit and checking if water flows backwards when the pump stops. Replace the valve; cleaning rarely fixes complete failures.

Radiators heating in closed zones indicate that check valves on zone supplies have failed or are missing. Map your zone valve locations and verify each has a functioning check valve on its supply line. Systems installed before 2000 often lack these valves because older zone valves had built-in checks (which have since failed).

Uneven heating between floors in gravity-affected systems points to missing or failed check valves on individual radiator circuits. The solution requires installing valves on the flow or return of each radiator on upper floors to prevent reverse circulation through lower floors.

Integration With Modern System Controls

Smart heating controls and weather compensation systems rely on precise flow control. Non-return valves ensure these systems work as designed by preventing unintended circulation.

Weather compensation adjusts flow temperature based on outdoor conditions. Without check valves, residual heat circulation during off-cycles confuses the system's calculations. The controller sees higher return temperatures than expected and reduces flow temperature further, leading to underheating. Modern controls from Honeywell and EPH Controls depend on proper valve installation.

Load compensation in heat pump systems balances flow between multiple zones. Backflow through inactive zones throws off the calculations, causing the heat pump to cycle inefficiently. Check valves maintain zone isolation, allowing accurate load measurement.

Smart TRVs and zone controls close radiators and zones based on room temperature. These only work properly when check valves prevent backflow through closed circuits. Without this protection, hot water bypasses the controls, wasting energy and overheating rooms. Quality TRVs from Danfoss work best when paired with proper non-return valves.

Cost-Benefit Analysis

A quality non-return valve costs £10-20. Installation takes 30-45 minutes, including draining and refilling the circuit. Total cost including labour runs £60-90.

The savings appear in several areas:

Energy efficiency improves 5-8% in multi-zone systems by eliminating unwanted circulation. For a typical home spending £1,200 annually on heating, that's £60-96 saved per year.

Pump longevity increases because the motor doesn't fight reverse flow on startup. Pumps from manufacturers like Grundfos or Lowara in systems with proper check valves last 12-15 years versus 8-10 years in systems with backflow problems. Replacing a pump costs £200-300, including labour.

Component protection prevents pressure spikes that damage radiator valves, zone valves, and pipe joints. Water hammer stress causes pinhole leaks in copper pipes and cracks in radiator valve bodies. A single leak repair costs £100-200, and severe water hammer can cause multiple failures.

The valve pays for itself within the first year through energy savings alone. Over a 10-year period, proper check valve installation saves £800-1,200 in energy costs plus £300-500 in prevented repairs.

Ensuring System Reliability

Non-return valves solve backflow problems that reduce efficiency, damage equipment, and create noise in heating systems. These simple devices respond instantly to pressure changes, preventing reverse flow that undermines system performance.

Proper selection requires matching valve type and size to your specific application, spring-loaded valves for standard heating, ball checks for underfloor systems, and specialised units for solar thermal or high-pressure commercial installations. Installation position and orientation determine whether the valve functions correctly, whilst regular maintenance ensures long-term reliability.

The modest investment in quality check valves returns value through improved efficiency, extended equipment life, and eliminated repair costs. Systems designed with proper backflow prevention work as intended, delivering consistent comfort whilst minimising energy waste. Whether you're installing a new system or troubleshooting existing problems, correctly specified and positioned non-return valves form an essential part of reliable heating system operation.

For quality heating components, including non-return valves and related pipework, Heating and Plumbing World supplies trade professionals throughout the UK. Technical guidance on valve selection and system design is available. Get in touch for expert support.

-

-