Oil Supply Lines: Single Pipe vs Two Pipe Systems

When you're standing in front of an oil-fired boiler that won't fire, the problem often traces back to something deceptively simple: how the fuel gets from the tank to the burner. The difference between a single pipe system setup and a two pipe oil supply system isn't just a technical detail; it's the difference between a system that works reliably for decades and one that causes endless headaches.

Countless installations use the wrong configuration, leading to airlocks, pump failures, and frustrated homeowners. The choice between these two oil supply line configurations depends on factors that many installers overlook: tank location, lift height, and the specific demands of the burner itself.

What Makes Single Pipe Systems Tick

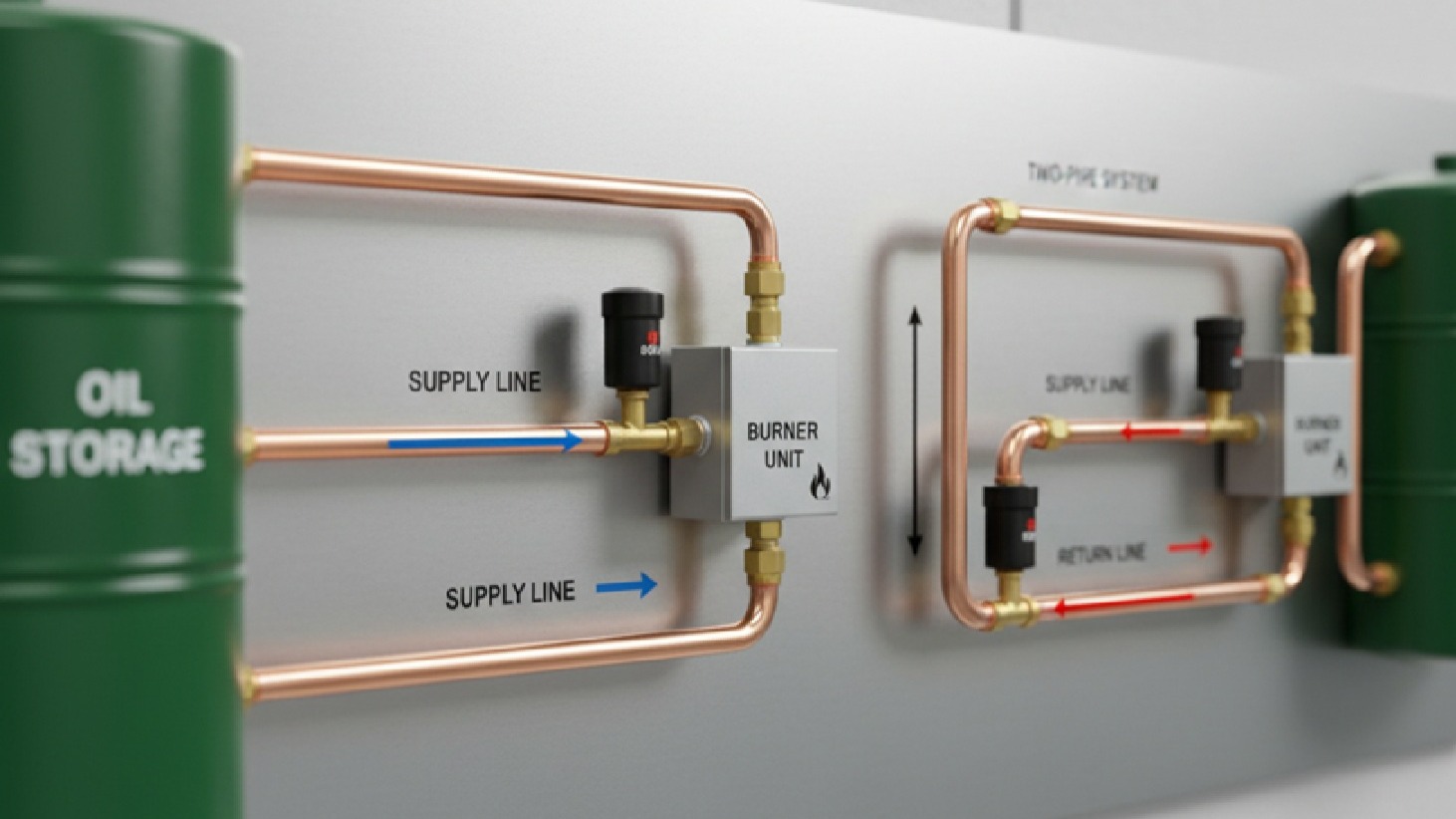

A single pipe system setup does exactly what its name suggests: one pipe runs from the oil tank to the burner. The pump draws fuel through this line, and any excess oil that doesn't get burned simply recirculates within the burner unit itself, never returning to the tank.

This simplicity makes single pipe systems appealing for straightforward installations. When the tank sits below the burner (a gravity-fed scenario), or when it's positioned no more than 1.5 metres above the burner, a single pipe configuration often works perfectly well. The pump only needs to overcome minimal resistance, and air bubbles naturally rise back to the tank rather than getting trapped in the system.

The real advantage shows up during installation. You're running one pipe instead of two, which means less material cost, fewer fittings that could potentially leak, and faster completion times. For a basic domestic installation where the tank sits in the garden just outside the boiler room, this approach makes complete sense.

But here's where many installations go wrong: installers choose single pipe systems for convenience when the physical setup actually demands a two pipe solution. Systems where the burner keeps locking out because air is trapped in the line experience a problem that wouldn't exist with the correct configuration. Think of it like trying to drink through a straw from a bottle far away. The further the liquid and the higher you have to lift it, the harder the pump works and the more likely air gets sucked in.

Understanding Two Pipe System Benefits

Two pipe systems run a supply line from the tank to the burner and a return line back to the tank. The pump pushes more oil than the burner needs, and the excess flows back through the return line, creating continuous circulation.

This circulation solves several problems that plague poorly configured single-pipe systems. Any air bubbles in the fuel get carried back to the tank rather than accumulating at the pump. The constant flow prevents sludge from settling in the lines. Two pipe systems handle challenging installation scenarios that would defeat a single pipe setup.

When your oil tank sits significantly above the burner, say, mounted on a stand in the garden, the boiler lives in a basement, and he fuel arrives at the pump under pressure. This positive head pressure can actually damage single-pipe pumps over time, causing seal failures and reducing lifespan. A two-pipe system handles this pressure differential without complaint because the return line balances the system.

The same applies when tanks are positioned far from the burner. Beyond about 10 metres of horizontal run, or when vertical lifts exceed 1.5 metres, a two pipe system becomes essential. The return line ensures consistent flow regardless of distance, while a single pipe system would struggle to maintain prime.

For installations requiring quality heating components from Heating and Plumbing World, understanding these system requirements prevents costly callbacks and ensures long-term reliability.

When Height and Distance Matter

The physics of oil supply lines comes down to three measurements: vertical lift, horizontal run, and the combination of both. Get these wrong, and no amount of quality components will make the system work properly.

Vertical Lift Challenges

Vertical lift presents the biggest challenge. When a pump must lift oil more than 1.5 metres vertically, a single pipe system starts struggling. The pump works harder, draws more current, and generates heat. Over time, this shortened duty cycle leads to premature failure. Pumps barely two years old require replacement because they've been fighting gravity every firing cycle.

Two pipe systems eliminate this problem by keeping the pump primed. Even when the burner isn't running, oil fills both lines. When the system calls for heat, the pump immediately has fuel available rather than having to draw it up from the tank. This reduces starting current, extends pump life, and ensures reliable ignition.

Horizontal Distance Considerations

Horizontal distance adds resistance through friction. Every metre of pipe, every elbow, and every fitting creates a pressure drop. Calculate the total equivalent length (actual run plus the equivalent length of all fittings), and you'll often find that what looks like a simple 8-metre run actually equals 12 metres once you factor in the bends.

Single pipe systems handle short runs well, but beyond 10 metres of equivalent length, flow rates start dropping. The pump pulls harder, potentially creating negative pressure that allows air to be drawn in through microscopic imperfections in fittings. Two pipe systems maintain positive pressure throughout, preventing this issue.

Combined challenges multiply rather than add. A tank that sits 2 metres above the boiler and 15 metres away presents both positive head pressure and significant resistance. This scenario absolutely requires a two-pipe configuration, yet single-pipe installations still attempt to manage these conditions.

For systems requiring reliable pump solutions from Grundfos, matching the pipe configuration to the physical installation parameters ensures optimal performance.

Installation Differences That Matter

The practical differences between installing these systems extend beyond simply running an extra pipe. Each configuration requires specific attention to details that affect long-term performance.

Filter Placement

Filter placement changes between systems. In a single pipe setup, the filter sits between the tank and the pump, catching debris before it reaches the pump. Simple enough. But in a two-pipe system, you need a filter on the supply line and potentially a second filter on the return line if the tank is particularly old or contaminated. This dual filtration prevents debris from circulating endlessly through the system.

Pipe Sizing

Pipe sizing follows different rules. Single pipe systems typically use 10mm copper or equivalent barrier pipe. The pump must pull fuel through this entire length, so minimising resistance matters. Two pipe systems often run 8mm supply and return lines because the pump pushes rather than pulls, making flow easier to maintain through smaller diameter pipe.

Nozzle Selection

Nozzle selection depends on your pipe configuration. Single pipe systems require nozzles designed for suction operation, while two pipe systems use nozzles optimised for positive pressure delivery. Use the wrong nozzle type, and you'll get poor atomisation, incomplete combustion, and sooty deposits that reduce efficiency.

De-Aerating the System

De-aerating the system differs dramatically. Single pipe systems can be nightmares to bleed because air has nowhere to go except through the nozzle. You're running the burner, watching for smoke to clear, and hoping air bubbles work their way through. Two pipe systems include a bleed screw on the pump that lets you purge air directly back to the tank in minutes.

Hours spent de-aerating poorly designed single pipe systems would have taken 10 minutes with a proper two pipe configuration. That time costs money on every service call and frustrates customers who just want heat.

Valve Requirements

Valve requirements add another layer. Two pipe systems need a return line valve at the tank, creating a second penetration point that must be sealed properly. This doubles the potential leak points at the tank, though modern compression fittings make this less concerning than it once was.

For installations using quality plumbing components, proper configuration ensures these fittings perform as designed rather than fighting against system limitations. Danfoss offers reliable components specifically designed for oil heating applications.

Common Problems and Solutions

Air Lock Issues

Air locks plague single pipe systems more than any other problem. Air enters through microscopic leaks in fittings or gets introduced during tank filling. In a single pipe system, this air has limited escape routes. It accumulates at high points in the line or at the pump, preventing fuel flow.

The solution? Either meticulously seal every connection and maintain perfect system integrity (difficult), or install a two pipe system where air naturally purges back to the tank through the return line (straightforward).

Pump Cavitation

Pump cavitation occurs when the pump creates such negative pressure that fuel vaporises inside the pump chamber. This creates noise, reduces flow, and damages pump internals. Single pipe systems working near their lift limits experience this regularly, especially in hot weather when fuel viscosity drops.

Two pipe systems prevent cavitation by maintaining positive pressure. The pump pushes rather than pulls, eliminating the negative pressure that causes vaporisation.

Cold Weather Starting

Cold weather starting becomes problematic when heavy oil must be drawn through long pipe runs. The increased viscosity makes the pump work harder, often exceeding its capabilities. The burner attempts to start, fails, locks out, and leaves the property without heat on the coldest day of the year.

Two pipe systems handle cold weather better because circulation keeps oil moving even when the burner isn't firing. This movement prevents waxy deposits from forming and ensures fuel remains pumpable.

Filter Restriction

Filter restriction affects both systems but manifests differently. In a single pipe system, a partially blocked filter gradually reduces pump performance. The system slowly degrades until it fails completely, often at the most inconvenient time.

Two pipe systems show filter problems more obviously. Performance drops noticeably, making the issue clear before complete failure occurs. This early warning allows preventative maintenance rather than emergency repairs.

Maintenance Implications

Annual servicing differs between systems. Single pipe setups require careful attention to filter condition because any restriction directly impacts pump performance. You're checking for air leaks in fittings, verifying pump pressure, and ensuring the system still pulls fuel efficiently. This takes time and requires specific testing equipment.

Two pipe systems simplify servicing. You're still checking filters and pump pressure, but the system either works or it doesn't; there's less grey area. Air problems are obvious and easily resolved. Flow issues point clearly to blockages rather than multiple possible causes.

Component Lifespan

Component lifespan varies significantly. Single pipe pumps working near their operational limits might last 5-7 years before requiring replacement. Two-pipe pumps in properly configured systems regularly exceed 15 years. That's more than double the lifespan from a configuration choice made during installation.

Filter replacement frequency depends on oil quality and tank condition, but two pipe systems show problems earlier. When a filter starts restricting flow, you'll notice performance degradation immediately rather than a gradual decline. This early warning prevents pump damage from contaminated fuel.

Seasonal preparation becomes simpler with two pipe systems. You're not worrying about whether the pump can handle cold-weather viscosity or whether air might accumulate during idle periods. The system maintains prime regardless of temperature or usage patterns.

Emergency troubleshooting in the middle of winter at 2 am becomes much easier with two pipe configurations. You can quickly verify fuel supply, bleed air if necessary, and get the system running. Single pipe problems often require extended diagnosis, and the house gets colder.

For systems using quality heating spares from Halstead, proper pipe configuration ensures these components operate within their design parameters, maximising lifespan and reliability.

The Real Cost of Getting It Wrong

Technical details matter, but the practical impact of wrong pipe configuration affects real people trying to heat their homes.

A rural cottage had its boiler replaced five years ago. The installer placed the oil tank 20 metres from the house and 2 metres higher than the boiler, mounted on a concrete pad to meet setback requirements. He chose a single pipe system to save time and materials, roughly £120 in costs. The system worked acceptably for two years, then problems started.

First came occasional lockouts on cold mornings. Then, there are more frequent issues. Three emergency callouts over one winter cost £360. The pump failed after four years, and it cost £280 for replacement. Performance continued to degrade until a different engineer diagnosed the fundamental problem: a completely wrong pipe configuration. Converting to two pipes costs £450, bringing the total additional cost to £1,090 plus years of unreliable heating. The original £120 "saving" proved expensive indeed.

These aren't rare scenarios. They represent common outcomes when the pipe configuration doesn't match the installation parameters. The initial cost saving evaporates quickly when measured against reduced reliability and increased maintenance.

Professional reputation suffers too. An installer who consistently chooses inappropriate configurations builds a reputation for problematic work. Customers remember the engineer who fixed the problem, not the one who installed it cheaply. Significant business comes simply from converting poorly configured systems to proper two-pipe setups.

Energy efficiency takes a hit when systems run incorrectly. A pump struggling to draw fuel consumes more electricity. Poor atomisation from inconsistent fuel pressure reduces combustion efficiency. These losses compound over the years, costing more than the installation savings.

Insurance implications matter for commercial installations. If a system repeatedly fails and causes property damage, insurers examine whether it was installed correctly. A single pipe system in an application that clearly required a two pipe configuration might affect claim outcomes.

Practical Guidance for Real Installations

When you're standing in front of an actual installation rather than reading about theory, certain practical considerations guide decision-making.

Measure everything carefully. Don't estimate vertical lift or horizontal run. Use a tape measure and calculate equivalent length, including fittings. That 90-degree elbow adds about 1 metre of equivalent length. Multiple bends accumulate quickly.

Consider future changes. Will the homeowner potentially move the tank? Add a second zone? Upgrade the boiler? Installing two pipe infrastructure now accommodates these changes without major rework.

Check tank condition. Older tanks with visible sediment or rust strongly suggest a pipe configuration. The return line prevents debris from accumulating at the pickup point.

Evaluate usage patterns. Holiday homes or properties with seasonal use benefit from two pipe systems that maintain prime during idle periods.

Calculate total cost. Include material, labour, and expected maintenance over 10 years. The configuration that costs more initially often proves cheaper long-term.

Document the installation. Label pipes clearly, note the configuration type on the boiler, and provide information to the homeowner. Future service engineers will appreciate knowing what they're working with.

Test thoroughly. Don't just get the system running; verify it operates across the full range of conditions it will face. Check cold start performance, verify consistent operation through multiple cycles, and ensure air bleeding works properly.

For installations incorporating modern heating controls from EPH Controls, ensuring the fuel supply system provides consistent pressure allows these controls to manage the system effectively.

Matching Configuration to Requirements

The choice between single and two pipe oil supply lines comes down to matching the configuration to physical requirements. Single pipe system setup works beautifully in straightforward installations with favourable geometry. Two pipe systems handle challenging scenarios that would defeat single pipe configurations.

Converting problematic installations reveals clear patterns. When tank location, distance, or lift height push beyond single pipe capabilities, fighting against physics with pump upgrades or oversized pipe doesn't solve the fundamental problem. Proper configuration does.

The modest additional cost of two pipe installation prevents years of reliability issues, extends component life, and ensures consistent performance regardless of weather or usage patterns. For many installations, this represents the only sensible choice despite the temptation to save money with simpler configurations.

Whether you're planning a new installation or troubleshooting an existing system, understanding these configuration differences helps you make informed decisions that balance initial cost against long-term performance. The goal isn't the cheapest installation; it's a system that works reliably for decades without constant intervention.

Choose the configuration that matches your installation parameters, install it properly with quality components, and you'll build systems that keep homes warm without drama. That's what good heating engineering looks like.

For technical guidance on oil heating system configuration or component selection, contact us for expert support from experienced heating engineers.

-

-