PEX-AL-PEX Multi-Layer Pipes: Benefits for Heating

Heating system failures peak during winter when you need reliability most. A burst pipe at 2 AM or a slow leak behind walls creates expensive damage and emergency callouts. The piping material you choose determines whether your heating system runs trouble-free for decades or becomes a maintenance headache.

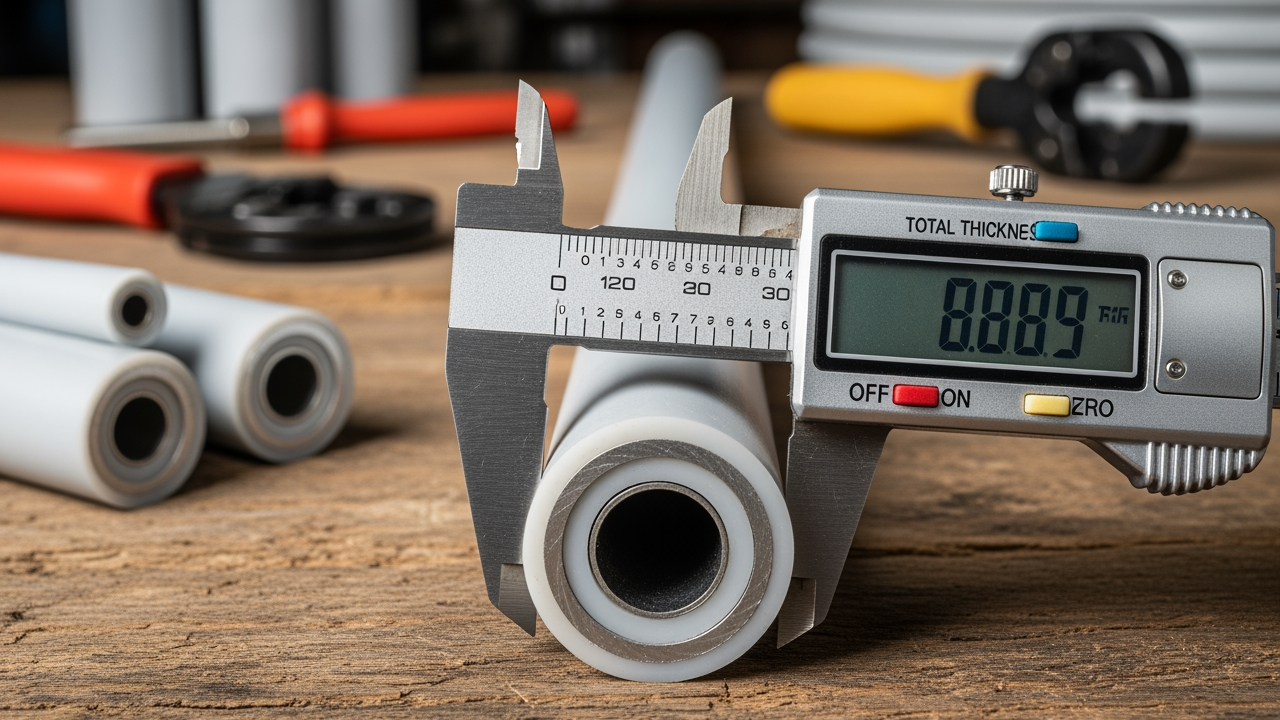

PEX-AL-PEX pipes combine three layers, polyethene, aluminium, polyethene, into a single pipe that addresses the core weaknesses of traditional materials. The aluminium core sits sandwiched between two PEX layers, creating a pipe that holds its shape, blocks oxygen, and handles thermal expansion better than single-layer alternatives.

What Makes PEX-AL-PEX Different From Standard PEX

Standard PEX pipes flex and bend, which sounds convenient until you're trying to run a straight line across a ceiling or maintain consistent spacing in a manifold setup. The pipe springs back, fights your positioning, and requires constant support brackets.

PEX-AL-PEX pipes hold the shape you bend them into. The 0.2-0.5mm aluminium layer acts as a structural core that maintains curves and straight runs without support every 300mm. You can form a 90-degree bend, and it stays put while you connect the next section.

The aluminium barrier also blocks 100% of oxygen permeation. Standard PEX allows microscopic oxygen molecules through the pipe wall at rates of 0.1-0.3 mg per litre per day. That oxygen dissolves into your heating water, then corrodes cast iron components, steel radiators, and pump housings from the inside. Boilers after 5-7 years on standard PEX systems often show rust sludge coating the heat exchanger, a problem that doesn't occur with proper oxygen barrier pipes.

Temperature Performance in Heating Applications

Heating systems demand pipes that handle sustained high temperatures without degrading. PEX heating pipe operates continuously at 95°C and withstands short-term spikes to 110°C, temperatures common in condensing boiler systems and high-output radiator circuits.

The three-layer construction manages thermal expansion more effectively than single materials. PEX expands roughly 2mm per metre for every 10°C temperature increase. In a 20-metre heating run from boiler to radiator, that's 40mm of expansion as the system heats from 20°C to 70°C. Standard PEX pipes snake and bow under this expansion, stressing joints and creating pressure on wall clips.

The aluminium core in PEX-AL-PEX reduces linear expansion by approximately 30-40% compared to standard PEX. That same 20-metre run expands just 24-28mm, less stress on connections, fewer support brackets needed, and straighter pipe runs after thermal cycling.

Installation Speed and Labour Savings

Traditional copper heating installations require cutting, deburring, fluxing, and soldering each joint. A typical residential heating system with 12 radiators involves 80-100 joints. At 3-4 minutes per soldered joint, you're looking at 5-6 hours just on connections, plus cooling time before pressure testing.

PEX-AL-PEX systems use press-fit or compression fittings that take 15-30 seconds per connection. The same 12-radiator system drops to 30-50 minutes for all connections. You can pressure test immediately, no waiting for joints to cool.

The shape-retention property cuts installation time further. When running pipes through joists or along walls, copper and standard PEX require temporary clips every 500-800mm to hold position during installation. PEX heating pipe maintains routing while you work on other sections. Installation measurements show 20-25% faster rough-in times on multi-zone heating projects compared to copper installations.

Corrosion Resistance and System Longevity

Copper pipes corrode in soft water areas where pH drops below 7.0. The acidic water dissolves copper ions, creating pinhole leaks typically after 8-15 years in aggressive water conditions. Hard water areas see less corrosion but develop scale buildup that restricts flow and reduces heat transfer efficiency.

PEX-AL-PEX pipes don't corrode or scale. The PEX inner layer provides a smooth, chemically inert surface that water contacts. Flow rates remain consistent over decades. The aluminium core sits protected between PEX layers, isolated from water contact and immune to pH variations.

Steel and cast iron components in your heating system still need protection from oxygen-related corrosion. The complete oxygen barrier in PEX-AL-PEX pipes maintains water oxygen levels below 0.1 mg/L, the threshold where corrosion rates drop to negligible levels. Boilers, pump housings from Grundfos or Lowara, and radiators from Myson last their full design life rather than failing prematurely from internal rust.

Freeze Resistance Properties

Frozen pipes burst when ice expansion generates pressure beyond the pipe's tensile strength. Copper pipes split at pressures around 1500-2000 PSI. The crack becomes a flood when the ice melts.

PEX materials expand slightly under freeze conditions, accommodating ice formation without rupturing. PEX-AL-PEX pipes handle 2-3 freeze cycles before risk of failure, not a design feature, but a safety margin that prevents catastrophic damage if a heating zone loses power overnight or a poorly insulated section drops below freezing.

The aluminium core does limit expansion compared to pure PEX, so PEX-AL-PEX isn't immune to freeze damage. Proper insulation remains essential for any heating pipes in unconditioned spaces. But the material provides better freeze tolerance than rigid pipes, reducing emergency callouts during cold snaps.

Noise Reduction in Heating Circuits

Water hammer and flow noise create complaints in multi-storey buildings and quiet residential spaces. Copper pipes transmit vibration efficiently; every pump startup, every thermostatic valve closure sends a metallic clang through the system.

PEX materials dampen vibration and absorb flow noise. The plastic layers in PEX-AL-PEX pipes reduce noise transmission by 5-8 decibels compared to copper. Thermostatic radiator valves from Danfoss or Honeywell close without the sharp click and water hammer that copper systems produce.

High-velocity flow in undersized pipes creates turbulence noise regardless of material. But properly sized PEX-AL-PEX installations run quieter than equivalent copper systems, particularly noticeable in bedroom radiator circuits and near living spaces.

Compatibility With Underfloor Heating

Underfloor heating demands pipes that maintain consistent spacing, resist oxygen permeation, and handle continuous operation at 35-55°C. The shape-retention property of PEX-AL-PEX pipes simplifies laying parallel loops at 150-200mm spacing; the pipes hold position while you secure them to insulation boards.

Standard PEX pipes require clips or rails every 500mm to maintain spacing. The pipes spring back and shift during concrete pouring or screed application. PEX-AL-PEX pipes stay positioned with minimal securing, speeding installation and ensuring consistent heat distribution.

The complete oxygen barrier protects underfloor heating manifolds and controls, components often made with brass bodies and steel springs that corrode when exposed to oxygenated water. Systems using standard PEX without barrier properties develop sticky valves and seized actuators after 5-8 years. PEX-AL-PEX installations avoid these maintenance issues.

Pressure Ratings and System Design

Heating systems operate at 1-3 bar in residential applications, up to 6 bar in commercial buildings. PEX-AL-PEX pipes rated to 10 bar at 95°C provide substantial safety margins for these applications.

The pressure rating decreases at higher temperatures; a 16mm pipe rated for 10 bar at 95°C drops to roughly 6 bar at 110°C. This remains adequate for residential and light commercial heating where pressure relief valves limit maximum system pressure to 3 bar.

The aluminium layer contributes to pressure strength and prevents creep, the gradual deformation that affects pure plastic pipes under sustained pressure. PEX-AL-PEX pipes maintain their diameter and don't sag between supports over decades of operation.

Cost Analysis for Heating Projects

Material costs for PEX-AL-PEX pipes run 15-30% higher than standard PEX and roughly equivalent to copper pipe prices. A typical residential heating system using 80 metres of pipe sees a material premium of £120-200 for PEX-AL-PEX over standard PEX.

Labour savings offset this premium on most projects. The faster installation, 20-25% time reduction compared to copper, 10-15% compared to standard PEX, cuts labour costs by £200-400 on a typical residential system. The shape-retention property reduces fitting adjustments and repositioning time.

Long-term maintenance costs favour PEX-AL-PEX significantly. Systems installed with proper oxygen barrier pipes avoid the £800-1500 cost of boiler heat exchanger replacement due to corrosion. Radiators last their full 20-25 year design life rather than requiring replacement at 12-15 years when internal corrosion reduces efficiency.

Common Installation Mistakes to Avoid

Over-tightening compression fittings crushes the pipe layers and compromises the seal. PEX-AL-PEX fittings require specific torque values, typically 1.5-2.5 turns past hand-tight for compression rings. Beyond this point, you deform the aluminium core and create leak paths.

Mixing barrier and non-barrier pipes in the same system defeats the oxygen protection. Installations where the main runs used PEX-AL-PEX but drops to radiators used standard PEX have been encountered. Oxygen enters through the standard PEX sections and circulates throughout the system, corroding components just as if no barrier pipe existed.

Inadequate support spacing causes sagging over time, even with shape-retention properties. PEX-AL-PEX pipes need support every 800-1000mm for horizontal runs, 1200mm for vertical runs. Longer spans create gradual deformation under the pipe's weight plus water content.

Using PEX-AL-PEX pipes with incompatible fittings creates leak risks. Each manufacturer's pipe has specific fitting requirements based on outer diameter tolerances and layer bonding methods. Press fittings designed for one brand may not seal properly on another brand's pipe. Verify compatibility or stick with matched systems.

Comparing to Other Heating Pipe Materials

Copper offers proven longevity in neutral pH water, but corrodes in soft water areas and requires skilled labour for installation. Material costs run similar to PEX-AL-PEX, but installation takes 40-50% longer due to soldering time.

Standard PEX costs less initially but requires oxygen barrier versions (PEX-b with EVOH layer) to protect heating systems. These barrier PEX pipes close the price gap with PEX-AL-PEX while offering less shape retention and higher thermal expansion.

MLCP (multi-layer composite pipe) with different layer arrangements, some use aluminium between adhesive layers, others use different plastic combinations, offer similar benefits to PEX-AL-PEX. Performance differences come down to specific product specifications rather than fundamental material advantages.

Steel pipes handle high pressures and temperatures but corrode internally and externally, require threading or welding, and transmit noise effectively. They're rarely specified for residential heating anymore, except in specific commercial applications.

Regulatory Compliance and Standards

PEX-AL-PEX pipes for heating applications must meet EN ISO 21003 standards in Europe, which specify requirements for dimensions, pressure ratings, temperature performance, and oxygen permeation limits. Pipes marked with this standard have undergone testing for long-term pressure resistance at elevated temperatures.

Building regulations in most jurisdictions require oxygen barrier pipes for closed-loop heating systems containing ferrous components. Standard PEX without barrier properties doesn't meet this requirement. PEX-AL-PEX pipes satisfy oxygen barrier requirements through their aluminium layer.

Warranty terms from boiler manufacturers like Andrews or Morco often specify oxygen barrier pipes as a condition of coverage. Installing standard PEX can void warranty protection if corrosion damage occurs. Documentation showing compliant pipe materials protects warranty claims.

System Integration With Modern Heating Equipment

Understanding PEX heating pipe becomes particularly important when planning complete heating installations. Modern condensing boilers require properly specified distribution pipework to maintain efficiency and warranty compliance.

Heating controls from EPH Controls depend on correctly sized PEX-AL-PEX pipes to regulate flow and temperature accurately. Undersized pipework creates flow restrictions that prevent controls from functioning properly, while oversized pipes increase system volume and reduce responsiveness.

Expansion vessels from Altecnic Ltd protect pipework from pressure surges, but only when the entire system is correctly specified. The reduced thermal expansion of PEX-AL-PEX minimises stress on expansion vessels and pressure relief valves.

Water cylinders from Gledhill and Kingspan connect to heating distribution pipework that must handle both pressure and thermal cycling. The connections between cylinders and pipework represent critical failure points if pipe materials and joining methods aren't matched to the application.

Making the Right Choice

PEX-AL-PEX pipes solve the practical challenges that plague heating installations, such as oxygen corrosion, thermal expansion stress, installation time, and shape retention during fitting. The three-layer construction delivers complete oxygen barrier protection, reducing thermal expansion by 30-40% while maintaining the flexibility advantages of PEX materials.

The shape-retention property cuts installation time by 20-25% compared to copper and eliminates the constant repositioning required with standard PEX. Pipes hold their routing while you work on other sections, speeding rough-in work and reducing support bracket requirements.

Material costs run 15-30% higher than standard PEX but deliver labour savings that offset this premium on most projects. The long-term benefits, protected boiler components, longer radiator life, and reduced maintenance calls justify the investment over the 25-30 year service life of a heating system.

For heating applications where reliability, installation efficiency, and long-term performance matter, PEX-AL-PEX pipes provide a proven solution that outperforms both traditional copper and standard PEX alternatives. The technology has matured beyond early adoption; these pipes now represent standard practice for quality heating installations across residential and commercial projects.

For technical advice on PEX heating pipe and complete heating systems, Heating and Plumbing World stocks a comprehensive range of multi-layer pipes and compatible components from leading manufacturers like Polypipe. If you need specification support or have questions about your heating pipe selection, get in touch with the technical team.

-

-