Pipe Cutters: Copper Tube Cutting Tools Compared

Cutting copper pipe cleanly matters more than most installers realise. A rough edge creates weak joints, leaks develop months after installation, and callbacks eat into profit margins. Over fifteen years of observation across UK heating engineers and plumbers demonstrates how the right pipe cutter transforms both work quality and speed.

The difference between a £10 budget cutter and a £50 professional tool isn't just price. It's the distinction between spending three minutes per cut, filing burrs, and dealing with oval pipe ends versus clean cuts in seconds that seals perfectly the first time. When you're fitting a complete heating system, those seconds compound into hours.

What Makes a Quality Copper Pipe Cutter

Professional copper pipe cutters share specific characteristics that separate them from cheaper alternatives. The cutting wheel itself determines everything. High-carbon steel wheels maintain sharpness through hundreds of cuts, whilst budget versions dull after a dozen pipes, crushing rather than slicing through copper.

The frame rigidity controls cut accuracy. Flex in the tool body creates oval cuts that won't sit flush in compression fittings. Quality circulator pumps from Grundfos and heating components from Danfoss require precise pipe dimensions; a wonky cut means starting over.

Bearing quality affects how smoothly the cutter rotates around the pipe. Cheap bearings bind and skip, scoring the copper surface. This matters particularly when working with chrome-plated or coated pipes, where surface damage shows.

The adjustment mechanism needs to withstand constant use. Ratchet-style cutters with plastic components strip threads within months. Professional models use metal gears that stay calibrated through years of daily work.

Standard Wheel Cutters for General Plumbing

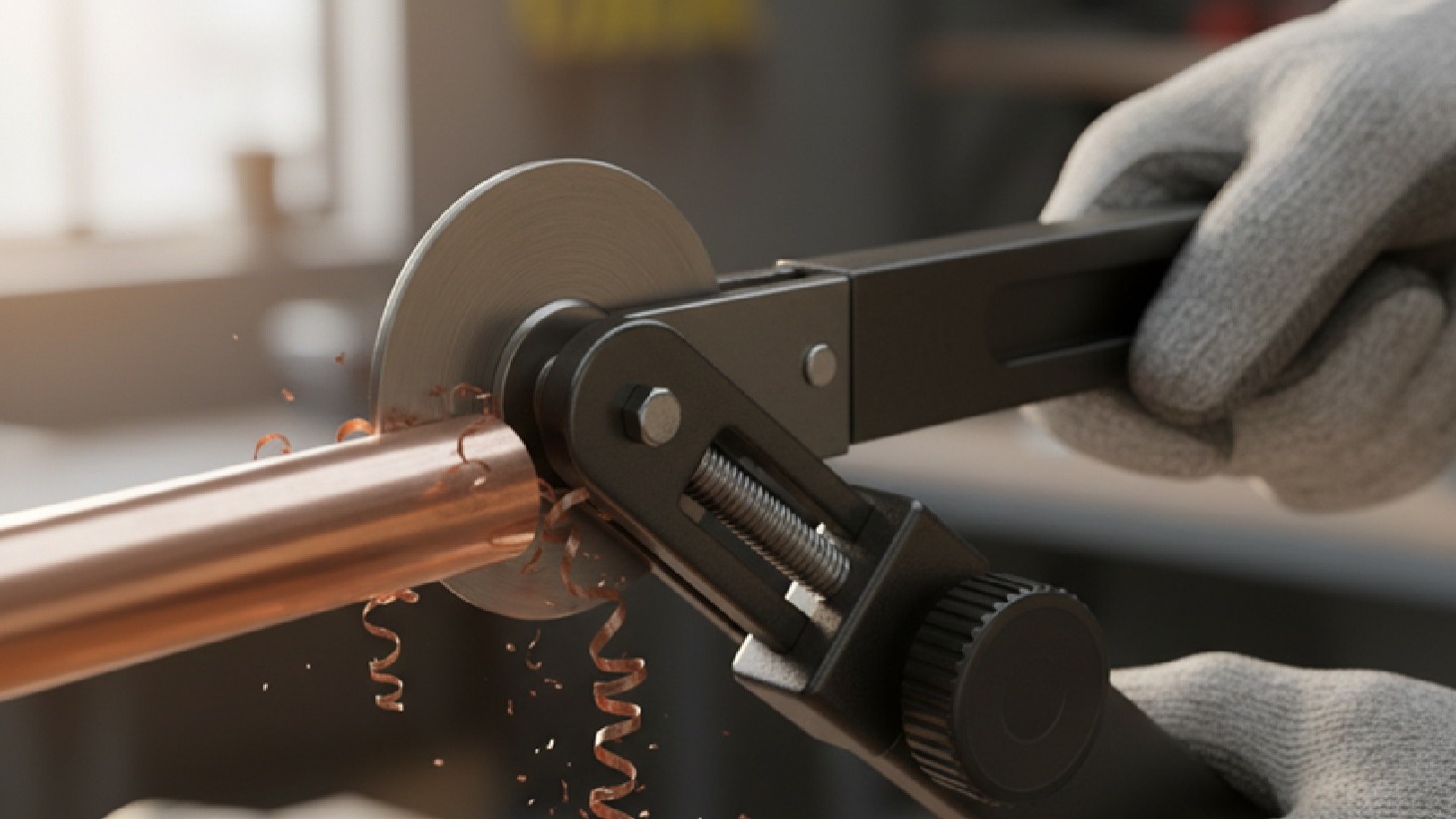

The traditional wheel-style cutter remains the workhorse for most installations. These tools feature a sharp cutting wheel opposite two guide rollers, with a screw mechanism that tightens the wheel against the pipe as you rotate the tool.

For 15mm and 22mm copper pipe, the sizes you'll use for most domestic heating work, a mid-range wheel cutter handles everything. The technique matters as much as the tool. Tighten the wheel until it just bites the copper, rotate once around the pipe, then tighten a quarter turn more. Rush this by over-tightening, and you'll crush the pipe end.

The deburring blade integrated into most quality cutters saves carrying separate tools. After cutting, flip the triangular blade out and ream the inside of the pipe with a few twists. This removes the internal burr that otherwise restricts flow and creates turbulence in heating systems.

Wheel cutters struggle with pipes close to walls or in tight corners. You need clearance to rotate the tool fully around the pipe. In restricted spaces, alternative cutting methods work better.

Ratchet Pipe Cutters for Confined Spaces

Ratchet cutters solve the access problem. Instead of rotating around the pipe, these tools use a ratcheting jaw action that cuts progressively with each squeeze. You can work in spaces where only inches of clearance exist.

The cutting action differs fundamentally from wheel cutters. Rather than a continuous circular cut, ratchet cutters make incremental slices. This creates slightly more burr that needs filing, but the trade-off for accessibility makes sense in renovation work where you're often working around existing pipework.

Quality matters enormously with ratchet cutters. The ratchet mechanism takes significant force with each squeeze. Cheap versions develop slack in the pawl mechanism, making cuts progressively less clean. Professional models maintain tension through thousands of cuts.

These copper pipe cutter types excel when working on installed systems. Cutting out a section of pipe for repair, you rarely have room to spin a wheel cutter. The ratchet design lets you work one-handed whilst supporting the pipe with the other hand.

Automatic Pipe Cutters for Production Work

Automatic or quick-release cutters use a different approach entirely. Squeeze the handles together, and the tool automatically adjusts to the pipe diameter whilst making the cut. No manual adjustment between cuts means you can work much faster on repetitive jobs.

For installers prefabricating heating manifolds or cutting multiple pipe lengths, automatic cutters pay for themselves quickly. The time saving adds up when you're cutting fifty pipes rather than five. The consistency also improves; every cut happens at the same pressure, producing uniform results.

The downside comes with durability. The automatic mechanism includes more moving parts than simple wheel cutters. Springs weaken, auto-adjust mechanisms develop play, and repairs often cost more than replacement. These tools make sense for high-volume work but might be overkill for occasional use.

Mini Cutters for Microbore and Tight Access

Microbore heating systems using 8mm and 10mm pipes need specialised cutters. Standard tools won't close down far enough, and the frame size prevents working in the confined spaces where microbore typically runs.

Mini cutters solve both problems with compact frames and cutting wheels designed for smaller diameters. When working on Honeywell control installations or connecting to manifolds in tight spots, these smaller tools become essential.

The cutting technique requires more care. Thin-walled microbore crushes easily if you tighten too aggressively. Make more rotations with gentler pressure rather than forcing the cut. The extra thirty seconds prevents flattened pipe ends that won't seal properly.

Soil Pipe and Large Diameter Cutters

Cutting 28mm, 35mm, or larger copper pipe pushes standard cutters beyond their capacity. The cutting wheels can't generate enough pressure, and the frames lack the strength needed.

Heavy-duty copper pipe cutters designed for large diameter work use reinforced frames and larger cutting wheels. Some models include chain-style cutters where a cutting chain wraps around the pipe, particularly useful for soil pipe and large bore heating mains.

When installing systems with Gledhill cylinders requiring larger bore primary connections, having the right cutter prevents damaged pipe ends. Trying to force a standard cutter through a 35mm pipe creates oval cuts that leak.

Cutting Wheel Materials and Longevity

The cutting wheel material determines how long your cutter stays sharp. Basic carbon steel wheels work fine for occasional use, but dull relatively quickly. For professional daily use, hardened steel or carbide wheels maintain edges far longer.

Replacement wheels cost between £5 and £1,5 depending on quality. Factor this into your tool choice: a cutter with readily available, affordable replacement wheels often proves more economical than an expensive tool with proprietary wheels.

Signs your wheel needs replacing include crushing rather than cutting, requiring excessive force, or visible chips in the cutting edge. Don't persist with dull wheels; you'll damage pipes and waste more time than the replacement wheel costs.

Pipe Cutter Maintenance and Care

Professional cutters last for years with basic maintenance. After each job, wipe the cutting wheel and rollers clean. Copper dust and debris pack into the mechanism, causing binding and premature wear.

Apply a drop of light machine oil to the adjustment screw threads monthly. This prevents seizing and keeps the adjustment smooth. Don't over-oil; excess lubricant attracts more dust and grit.

Store cutters with the cutting wheel backed off. Leaving the spring compressed weakens it over time, reducing cutting pressure. This particularly matters with ratchet-style cutters where spring tension drives the cutting action.

Check the cutting wheel periodically for wobble. A bent wheel or worn bearing creates uneven cuts. Most quality cutters allow bearing replacement, extending tool life significantly.

Choosing the Right Cutter for Your Work

Your typical jobs determine which cutter makes sense. For general heating installation working mainly with 15mm and 22mm pipe, a quality mid-range wheel cutter handles 90% of situations. Add a mini cutter if you regularly work with microbore, and a ratchet cutter for renovation work in tight spaces.

Installers doing production work, fitting multiple systems weekly, benefit from automatic cutters despite the higher initial cost. The time saving justifies the investment when you're cutting hundreds of pipes monthly.

Budget matters, but buying cheap costs more long-term. A £15 cutter that needs replacing every six months costs more than a £50 tool lasting five years. The frustration of struggling with dull blades and imprecise cuts adds hidden costs in time and callbacks.

Consider the complete system you're installing. When working with precision components like EPH Controls or quality Altecnic expansion vessels, clean pipe cuts ensure reliable connections throughout the system.

Common Cutting Mistakes and Solutions

Over-tightening causes most problems. The temptation to force the cut faster crushes pipe ends, particularly with thinner-walled copper. Patience produces better results, tighten gradually, rotating the cutter completely between adjustments.

Failing to deburr creates restrictions in the pipe bore. Even small burrs reduce flow and create noise in heating systems. The thirty seconds spent reaming each cut prevents problems down the line.

Cutting at an angle happens when the cutter isn't square to the pipe. This creates elliptical ends that don't seat properly in fittings. Take time to align the cutter perpendicular before starting the cut.

Using worn cutting wheels damages pipes and wastes time. Replace wheels at the first sign of dulling. The few pounds spent on a fresh wheel save hours of frustration.

Alternative Cutting Methods

Hacksaws remain useful for situations where pipe cutters won't fit. The downside comes with cut quality; even careful sawing creates rougher edges requiring more filing. For emergency repairs or one-off cuts, hacksaws work adequately.

Reciprocating saws with metal-cutting blades handle demolition work where cut quality doesn't matter. These tools excel at removing old systems quickly, but create edges too rough for reuse.

Angle grinders cut copper quickly but generate significant heat that anneals the copper, making it soft. The burr created requires extensive filing. Only use grinders when you're cutting pipe for disposal, never for installation work.

Understanding Copper Pipe Cutter Types

Different copper pipe cutter types serve specific purposes in heating and plumbing installations:

Wheel cutters provide the most common solution for accessible pipework with 15mm to 28mm diameters. Their rotating action produces clean, square cuts ideal for compression and solder fittings.

Ratchet cutters excel in confined spaces where wheel cutters cannot rotate. The progressive cutting action works in tight corners and around existing installations.

Automatic cutters speed production work through self-adjusting mechanisms that eliminate manual wheel tightening between cuts. Best suited for high-volume installation work.

Mini cutters handle microbore pipe (8mm and 10mm) in confined spaces. Essential for systems using smaller diameter circulation pipes.

Heavy-duty cutters tackle large diameter pipe (28mm and above) with reinforced frames and more powerful cutting wheels. Some use chain-cutting mechanisms for very large diameters.

Understanding which type suits your specific work prevents purchasing unnecessary tools whilst ensuring you have the right equipment when needed.

Integrating Quality Cuts into System Design

Clean pipe cuts contribute to overall system reliability. When installing heating systems with components from Andrews or Morco, every connection point matters. A single poor cut creates a potential leak point that undermines the entire installation.

The time invested in quality cuts pays back through reduced callbacks and warranty claims. Systems installed with precision operate more efficiently and last longer. This matters particularly with modern condensing boilers and heat pumps, where even small leaks affect performance.

Professional presentation matters too. Neat, square cuts visible at radiator connections and under-sink stops demonstrate craftsmanship. Customers notice these details, even if they don't understand the technical implications.

Building Your Pipe Cutting Toolkit

Start with a quality wheel cutter suited to your most common pipe sizes. This forms the foundation of your cutting toolkit. Add specialised cutters as your work demands, a mini cutter when you first encounter microbore, and a ratchet cutter after struggling in a tight space.

Keep spare cutting wheels in your van. Nothing worse than discovering a dull wheel halfway through a job with no replacement available. Wheels take minimal storage space and prevent delays.

Consider a pipe slice for plastic pipe work. Whilst this article focuses on copper cutting, most heating installations include plastic pipe sections from manufacturers like Polypipe. Having the right tool for each material prevents improvising with inappropriate cutters.

The Economics of Quality Cutting Tools

Professional copper pipe cutters cost between £30 and £80 for quality models. This investment returns value through faster work, better results, and longer tool life. Calculate the cost per cut over the tool's lifetime; quality cutters work out at pennies per cut.

Time savings matter more than tool cost for professional installers. A quality cutter that saves two minutes per cut adds up to hours saved on a complete heating system. Those hours translate directly to increased earning capacity.

Reduced callbacks from poor connections provide less visible but significant savings. A single return visit to fix a leaking joint costs more than several quality pipe cutters. Prevention through proper tools and techniques protects profit margins.

System Integration and Component Quality

Clean copper cuts integrate seamlessly with quality system components. Expansion vessels from Altecnic require proper pipe connections to maintain system pressure effectively. Hot water cylinders from Kingspan benefit from leak-free connections that proper cutting technique ensures.

When installing systems with circulator pumps from Lowara or controls from Danfoss, every pipe connection contributes to overall system performance. Professional cutting technique ensures each connection meets design specifications.

Achieving Professional Results

Selecting the right copper pipe cutter types transforms installation work from a frustrating struggle to efficient craftsmanship. Wheel cutters handle most general work, ratchet cutters solve access problems, and specialised tools tackle specific challenges. Quality matters more than price; professional tools deliver clean cuts that seal properly the first time, reducing callbacks and building reputation.

The cutting technique matters as much as the tool itself. Gradual tightening, complete rotations, and proper deburring create connections that last decades. When installing complete heating systems with components from Halstead, Kingspan, or Stuart Turner, every connection point deserves attention to detail.

Invest in quality cutters, maintain them properly, and replace cutting wheels before they dull completely. Your work quality improves, installation time decreases, and customers receive heating systems built to professional standards. The right pipe cutter isn't just another tool, it's the foundation of reliable plumbing and heating installations that perform flawlessly for years.

For quality copper pipe cutters and professional installation tools, Heating and Plumbing World supplies equipment suitable for both domestic and commercial installations. If you need specific advice on tool selection or cutting techniques, get in touch for expert recommendations ensuring professional results on every installation.

-

-