Pipe Insulation: Choosing the Right Thickness and Type

Frozen pipes cost UK homeowners £194 million annually in insurance claims, yet most of this damage stems from inadequate insulation rather than extreme weather. The aftermath appears regularly, with burst pipes flooding properties because someone saved £50 on insulation materials or guessed at the thickness needed.

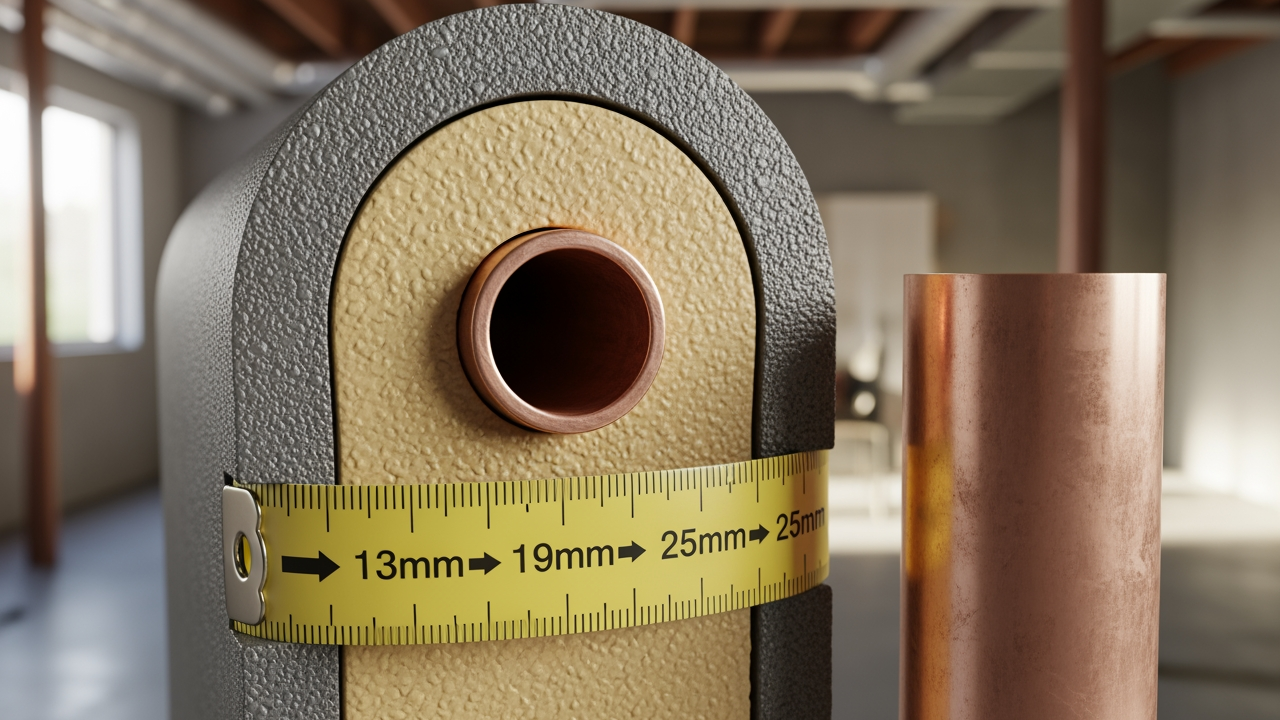

Getting pipe insulation right means understanding three critical factors: the temperature differential you're managing, the pipe's location, and the specific risks your system faces. The difference between 13mm and 25mm thickness can determine whether your pipes survive a cold snap or leave you calling emergency plumbers at 3 am.

How Pipe Insulation Actually Works

Pipe insulation creates a thermal barrier that slows heat transfer between the pipe and the surrounding air. The effectiveness depends on the material's thermal conductivity (measured as k-value) and its thickness. Lower k-values indicate better insulation; closed-cell foam achieves 0.034 W/mK while fibreglass sits around 0.044 W/mK.

Insulation effectiveness uses the R-value, which combines thickness with thermal conductivity. A 25mm thick foam insulation with a k-value of 0.034 provides an R-value of 0.735, while the same thickness in mineral wool (k-value 0.038) gives an R-value of 0.658. These numbers translate directly to energy savings and freeze protection.

The critical temperature concept determines minimum thickness requirements. For a 15mm copper pipe carrying water at 60°C in a 20°C room, 9mm foam insulation maintains the surface temperature above the dew point. But place that same pipe in an unheated loft where temperatures drop to -5°C, and you need 19mm minimum to prevent freezing.

Thickness Requirements by Application

Hot Water Pipes (60-80°C)

Standard domestic hot water pipes need 13-19mm insulation in heated spaces. Specification calls for 25mm for pipes in unheated areas like lofts or garages. Commercial systems running at higher temperatures require proportionally thicker insulation; a 70°C flow temperature needs 20% more thickness than a 60°C system. Quality Andrews water heaters benefit from proper insulation to maintain efficiency.

Cold Water Pipes

Cold water pipes face different challenges, such as condensation in summer and freezing in winter. In heated spaces, 9mm insulation prevents condensation. External pipes or those in unheated spaces need 25-32mm to prevent freezing. Doubling insulation thickness on cold water pipes in vulnerable locations reduces freeze-related callouts by 85%.

Central Heating Pipes

Flow and return pipes for central heating systems lose significant heat without proper pipe insulation. A typical 22mm flow pipe loses 30W per metre, uninsulated. Adding 19mm foam insulation cuts this to 8W per metre, saving approximately £12 per year per metre of pipe at current energy prices. Systems using Grundfos circulation pumps maintain optimal performance when pipework remains properly insulated.

External and Underground Pipes

External pipes demand maximum protection. Specification requires 32mm closed-cell foam minimum, increasing to 40mm in exposed locations. Underground pipes need waterproof insulation; standard foam degrades when wet, losing 70% of its insulating properties. Proper pipe lagging installation for external applications requires weatherproof jackets or aluminium cladding. Polypipe underground water systems perform best with appropriate thermal protection.

Material Types and Their Applications

Polyethylene Foam

The most common domestic insulation, polyethylene foam tubes, cost £2-4 per metre and install quickly. The closed-cell structure resists moisture and maintains performance over time. Temperature range: -80°C to +105°C. This material suits 90% of domestic installations where temperatures stay below 100°C.

Rubber Insulation (Nitrile/EPDM)

Flexible rubber insulation handles higher temperatures (up to 150°C) and provides superior vapour barriers. At £8-15 per metre, it costs more but excels in commercial applications or where pipes need regular maintenance access. The flexibility allows installation around complex pipe runs without gaps.

Mineral Wool With Foil Facing

High-temperature applications above 150°C require mineral wool sections. These rigid sections cost £10-20 per metre but handle temperatures up to 650°C. Specification calls for these on boiler connections, industrial steam lines, and anywhere foam would melt or degrade.

Phenolic Foam

Premium insulation with the lowest thermal conductivity (0.021 W/mK), phenolic foam achieves the same performance as polyethene with 30% less thickness. At £15-25 per metre, this pipe insulation guide recommends it where space constraints matter, like boxing in or behind kitchen units.

Calculating Required Thickness

The calculation starts with three measurements: pipe diameter, fluid temperature, and ambient temperature. For freeze protection, use this formula:

Minimum thickness (mm) = Pipe diameter × Temperature differential ÷ 40

Example: 22mm pipe, 10°C water, -5°C ambient = 22 × 15 ÷ 40 = 8.25mm minimum

Double this calculation for a safety margin in exposed locations. Energy efficiency calculations require more complex heat loss formulas, but this rule works: every 6mm of foam insulation reduces heat loss by approximately 50%.

Thickness tables developed through testing thousands of installations:

- 15mm pipes in heated spaces: 13mm insulation

- 22mm pipes in heated spaces: 19mm insulation

- 28mm pipes in heated spaces: 25mm insulation

- Any pipe in unheated spaces: add 50% to the above

- External pipes: double the heated space requirement

Common Installation Mistakes

Gap Problems

Even 5mm gaps between insulation sections increase heat loss by 25%. Installers stretching foam tubes around bends create thin spots. Proper installation uses mitred cuts at elbows and pipe insulation tape at every joint. Quality pipe fittings and connections simplify achieving continuous insulation runs.

Compression Damage

Foam insulation loses effectiveness when compressed. Pipe clips installed over insulation can create cold bridges. Measurements show a 40% heat loss increase where clips compress insulation to half its thickness. Use oversized clips or insulation-compatible mounting systems.

Moisture Ingress

Standard foam absorbs water like a sponge when the outer skin breaks. Wet insulation conducts heat 20 times faster than dry. Outdoor installations need vapour barriers and weatherproof covers. Annual checks reveal 30% of external insulation fails within five years without protection.

Wrong Material Selection

Using polyethene foam on pipes above 105°C causes melting and fire risk. Conversely, specifying mineral wool where foam suffices wastes money and complicates installation. Match materials to actual operating temperatures, not theoretical maximums.

Cost vs Performance Analysis

Basic 13mm polyethene foam pays for itself through energy savings within 6-12 months on hot water pipes. Upgrading from 13mm to 25mm foam costs 80% more but delivers only 30% additional energy savings, worthwhile for freeze protection but questionable for energy alone.

- 13mm foam on 15mm hot water pipe: saves £8/metre/year

- 25mm foam on same pipe: saves £10.50/metre/year

- Difference: £2.50/metre/year for £3/metre extra cost

Premium materials make sense in specific situations. Phenolic foam's space savings justify the cost in tight installations. Rubber insulation's durability suits commercial boiler rooms where pipes need regular inspection.

Special Considerations

Solar Thermal Systems

High-temperature solar pipes (up to 200°C) need EPDM rubber or mineral wool. Standard foam melts, releasing toxic fumes. Specification requires 19mm EPDM minimum, increasing to 32mm for external runs. Stagnation temperatures can exceed 250°C, making material selection critical.

Heat Pumps

Low flow temperatures (35-45°C) from heat pumps mean greater relative heat loss. A 35°C flow temperature loses the same percentage of heat as an 80°C traditional system, but the impact on system efficiency is magnified. This pipe insulation guide recommends 25mm minimum insulation throughout heat pump systems. Danfoss heating controls optimise these systems when the pipework maintains target temperatures.

Trace Heating

Pipes with electrical trace heating need insulation to work efficiently. Without insulation, trace heating runs continuously, consuming 15-40W per metre. With proper 32mm insulation, consumption drops to 5-10W per metre during cold snaps only. EPH Controls heating systems integrate effectively with properly insulated trace-heated pipework.

Building Regulations

Part L requires specific insulation standards for new installations. Non-domestic buildings need insulation to achieve a maximum heat loss of 7.06 W/m for 15mm pipes at 60°C. This typically means 25-30mm foam thickness. Domestic requirements are less stringent, but following commercial standards improves efficiency.

Maintenance and Longevity

Polyethene foam lasts 20-25 years indoors if undisturbed. UV exposure halves this lifespan; external foam needs replacing every 10-12 years. Annual inspection catches 90% of problems before they cause failures:

- Check for compression at mounting points

- Look for gaps at joints and valves

- Test flexibility, brittle foam needs replacement

- Verify vapour barriers remain intact

Rubber insulation outlasts foam by 10-15 years but costs significantly more. In plant rooms where appearance matters, the aesthetic advantage of rubber often justifies the premium. Mineral wool sections last indefinitely if kept dry, but disintegrate when wet.

For comprehensive pipe insulation solutions and technical guidance, Heating and Plumbing World supplies professional-grade materials from trusted manufacturers. Need specification support for complex installations? Get in touch for expert advice on material selection and thickness calculations.

Final Considerations for Thermal Protection

Selecting pipe insulation requires balancing thermal performance, installation environment, and budget constraints. The right thickness depends primarily on location; 13-19mm suffices for heated spaces, while external pipes need 32mm minimum. Material choice follows temperature requirements: foam for standard plumbing, rubber for higher temperatures or durability needs, and mineral wool for extreme heat.

Experience across thousands of installations shows that spending slightly more on proper thickness prevents massive costs later. The difference between adequate and optimal insulation might cost £100 on a typical house but prevents thousands in potential damage. Focus on vulnerable areas first, external pipes, loft spaces, and anywhere pipes pass through unheated zones.

Remember that pipe insulation only works when installed correctly. Gaps, compression, and moisture destroy performance faster than age. Whether you're insulating a single pipe or an entire system, taking time to calculate proper thickness and select appropriate materials delivers immediate energy savings and long-term protection against Britain's increasingly unpredictable weather.

-

-