Potterton Boiler Spares: Finding the Right Component

Potterton boilers have heated British homes for over 150 years, and that longevity means millions of units still operate across the UK. When one breaks down, finding the correct spare part quickly becomes the difference between a few hours without heating and days of disruption.

Potterton boiler spares are supplied daily, and the most common issue isn't availability; it's identification. Customers often know something's broken but struggle to pinpoint which component they need. This wastes time and money on incorrect orders.

Why Potterton Part Numbers Matter

Every Potterton component carries a specific part number, typically a combination of letters and digits like 5114062 or 407677. This number identifies the exact specification, including materials, dimensions, and compatibility.

Using a part number eliminates guesswork. Potterton has manufactured numerous boiler ranges, Profile, Suprima, Gold, Titanium, Promax, and components rarely interchange between models. A pump that fits a Suprima 50 won't work in a Promax 24, even if they look identical.

The serial number plate on your boiler provides the starting point. Located on the front panel or inside the casing, it lists the model name, GC number, and serial number. Cross-reference this with Potterton's technical documentation to identify compatible parts.

The Most Frequently Replaced Components

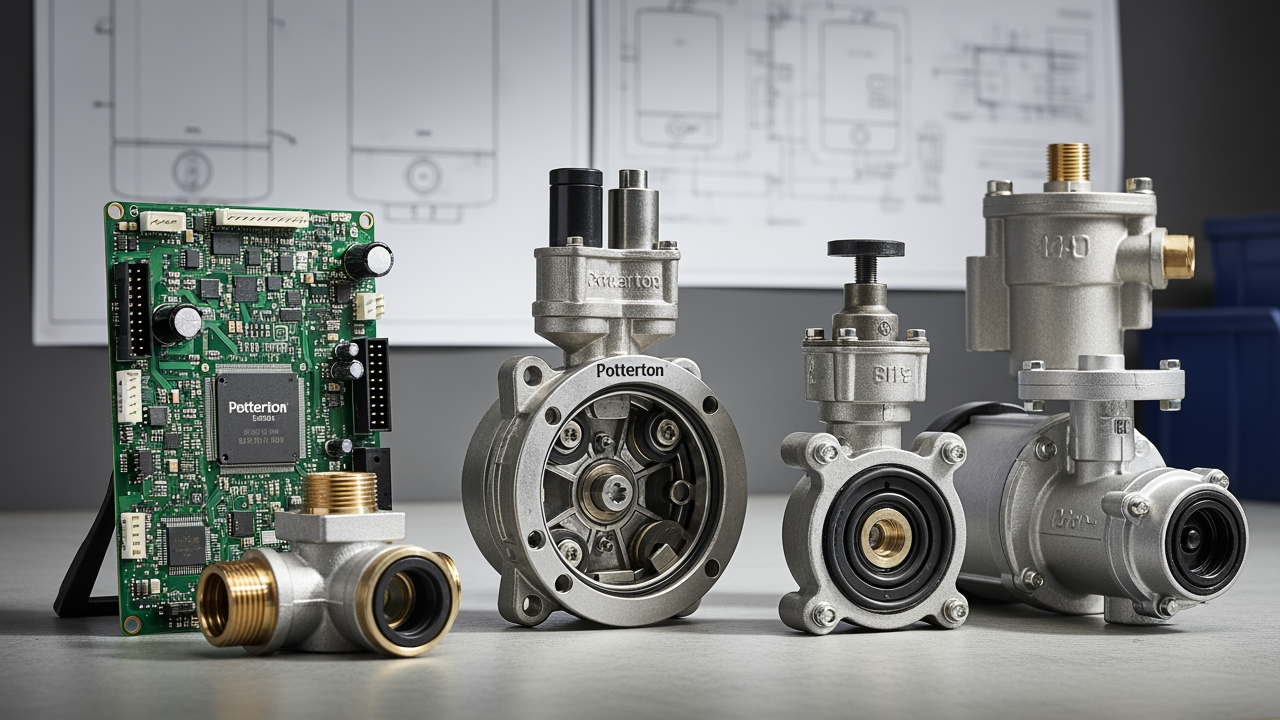

Printed Circuit Boards (PCBs) fail more than any other component. These control boards manage ignition, temperature regulation, and safety systems. When they malfunction, boilers either won't start or shut down unexpectedly.

PCB failure typically stems from power surges, moisture ingress, or component degradation over 10-15 years. Replacement costs £150-£400 depending on the model. PCBs for most Potterton ranges are widely available, but older models like the Netaheat require specialist sourcing.

Diverter valves rank second. These mechanisms direct hot water either to radiators or taps. When they stick or leak, you'll get heating but no hot water, or vice versa. The Potterton Suprima series particularly suffers from diverter valve issues after 8-10 years of operation.

Pumps circulate water through the heating system. They fail gradually, starting with unusual noise, progressing to reduced flow, and eventually seizing completely. A failing pump reduces heating efficiency by 30-40% before complete failure.

Pressure relief valves and expansion vessels manage system pressure. When these fail, boilers lose pressure repeatedly, requiring constant refilling. The pressure gauge dropping below 1 bar within hours indicates one of these components needs replacement.

Heat exchangers crack due to limescale buildup in hard water areas. Replacement costs £200-£500, making it one of the more expensive repairs. If your boiler is over 12 years old, a cracked heat exchanger often signals replacement rather than repair, which makes economic sense.

How to Identify Your Required Part

Start with the fault symptoms. No heating or hot water points to different components than intermittent operation or strange noises. Error codes displayed on digital models narrow the field significantly.

Potterton error codes follow a letter-number format. E133 indicates a PCB communication fault. E128 suggests pump failure. E110 points to overheating. Your boiler manual lists these codes, or they're searchable online with your specific model number.

Physical inspection reveals obvious failures. Water leaks indicate valve or seal problems. Burnt smells suggest electrical component failure. Grinding noises point to pump or fan issues.

If you're unsure, photograph the failed component before removal. Clear images of any labels, connectors, or distinctive features help suppliers confirm the correct replacement. Photo verification has prevented dozens of incorrect orders.

Genuine Versus Compatible Parts

Potterton manufactures genuine spares, but third-party suppliers produce compatible alternatives for common components. Both have merits depending on your situation.

Genuine parts guarantee exact specifications and typically carry 12-month warranties. They cost 20-40% more than compatible alternatives but eliminate compatibility concerns.

Compatible parts from reputable manufacturers offer identical functionality at a lower cost. Thousands of compatible pumps, valves, and sensors have been fitted without issues. The key is sourcing from established suppliers who test compatibility rigorously.

Avoid unbranded components from unknown sources. A £15 saving on a pump means nothing if it fails within months or damages other system components.

Where Availability Becomes Challenging

Potterton discontinued certain ranges years ago, making Potterton replacement parts increasingly scarce. The Netaheat range, last manufactured in the 1990s, presents particular challenges. PCBs and control panels for these models require specialist refurbishment or reclaimed parts.

The Profile range, discontinued around 2005, still has reasonable parts availability for mechanical components. Electronic parts prove harder to source.

Current ranges, Titanium, Promax, and Gold, maintain full parts availability. Potterton supports these models with comprehensive spare parts for at least 10 years after discontinuation.

When parts become unavailable, three options exist: refurbishment of the failed component, sourcing reclaimed parts from decommissioned boilers, or replacement of the entire boiler. PCB refurbishment for obsolete models can extend boiler life by 3-5 years at a fraction of replacement cost.

The Economics of Repair Versus Replacement

Calculate the repair cost as a percentage of replacement value. If repairs exceed 50% of a new boiler's cost, replacement usually makes financial sense, particularly for boilers over 10 years old.

A new Potterton boiler costs £800-£2,000 depending on output and features. Installation adds £500-£1,500. Total investment: £1,300-£3,500.

If your boiler needs a £400 PCB and it's 12 years old, that's roughly 15% of the replacement cost. However, other components may fail soon, leading to multiple repair bills within 2-3 years.

Efficiency matters too. Modern condensing boilers achieve 92-94% efficiency compared to 70-80% for models over 15 years old. A household spending £1,200 annually on heating could save £200-£300 yearly with a new boiler, recovering replacement costs within 5-7 years.

DIY Versus Professional Installation

Some Potterton replacement parts suit DIY replacement: pressure relief valves, expansion vessels, and basic sensors. These require basic tools and no gas work.

Components involving gas connections, burners, gas valves, and injectors require Gas Safe-registered engineers. Attempting these repairs yourself risks carbon monoxide poisoning, explosions, and invalidates home insurance.

Electrical components like PCBs sit in a grey area. Physically replacing them is straightforward, but diagnosing whether the PCB actually caused the fault requires expertise. Customers have replaced PCBs when the actual fault lay in wiring or sensors, wasting £300 on unnecessary parts.

Water-side components, pumps, diverter valves, and heat exchangers need system draining and refilling. While not requiring gas qualifications, incorrect installation causes leaks, airlocks, and system imbalance.

Ordering Process and Lead Times

Stock items ship same-day for next-day delivery. Inventory is maintained for current Potterton ranges and common parts for discontinued models.

Non-stock items require ordering from Potterton's distribution network, typically arriving within 3-5 working days. Obsolete parts may take 2-3 weeks if refurbishment is needed.

Provide complete information when ordering: boiler model, serial number, GC number, and part number if known. This eliminates back-and-forth and speeds delivery.

Returns policies vary by supplier. Returns on unused parts are typically accepted within 30 days, but electrical components like PCBs are often non-returnable once packaging is opened due to potential static damage.

Preventive Maintenance to Reduce Spare Part Needs

Annual servicing by a Gas Safe engineer catches problems before they cause breakdowns. Services cost £70-£120 but prevent 60-70% of emergency repairs.

Maintaining correct system pressure prevents pump and valve strain. Check the pressure gauge monthly; it should read 1.0-1.5 bar when cold. Top up if it drops below 1.0 bar.

Bleeding radiators annually removes air pockets that force pumps to work harder. This simple task extends pump life by 2-3 years on average.

Installing a magnetic filter captures metal particles before they damage valves and heat exchangers. Filters cost £100-£150 installed and reduce component failures by approximately 40% over a boiler's lifetime.

Treating systems with an inhibitor prevents internal corrosion and limescale buildup. This chemical treatment costs £30-£50 and should be refreshed every 5 years.

Understanding Warranty Coverage

New Potterton boilers carry 2-10 year warranties, depending on the model and whether installation was by an approved installer. Warranties cover manufacturing defects but exclude wear-and-tear items like seals and certain sensors.

Warranty claims require proof of annual servicing. Missing even one service voids most warranties, leaving you liable for all repair costs.

Parts purchased separately carry their own warranties, typically 12 months for genuine Potterton components. Labour isn't covered, so you'll pay installation costs even for warranty parts.

Extended warranties are available through some installers, covering both parts and labour for 5-10 years. These cost £200-£500 upfront but provide peace of mind, especially for older households where heating failure poses health risks.

Finding the right Potterton boiler spares starts with accurate identification, knowing your model, locating the serial number plate, and obtaining the specific part number when possible. This eliminates costly mistakes and speeds up repairs.

Stock availability remains strong for current models and reasonable for discontinued ranges from the past 15 years. Older models require more effort but aren't impossible to repair if you work with suppliers who understand the Potterton product range.

Weigh repair costs against replacement value, particularly for boilers over 10 years old. Sometimes spending £300 on parts makes sense; other times, that money should go towards a new, more efficient boiler.

Whether you're replacing a simple sensor or a complex PCB, using the correct part number and understanding what you're buying prevents the frustration of ordering twice. Take time to identify components properly, consult with knowledgeable suppliers when uncertain, and your Potterton boiler will continue heating your home reliably for years to come.

Heating and Plumbing World stocks Potterton boiler spares and components from leading manufacturers, including Grundfos pumps, Honeywell controls, Danfoss valves, and Altecnic pressure vessels. For expert assistance in identifying the correct Potterton replacement parts for your boiler, get in touch with the technical team.

-

-