Press-Fit Connection Systems: Benefits and Product Range

Soldering copper pipes used to be the only way to create reliable plumbing and heating connections. That changed when press-fit technology emerged, cutting installation time by up to 70% while eliminating the fire risk that comes with open flames in occupied buildings.

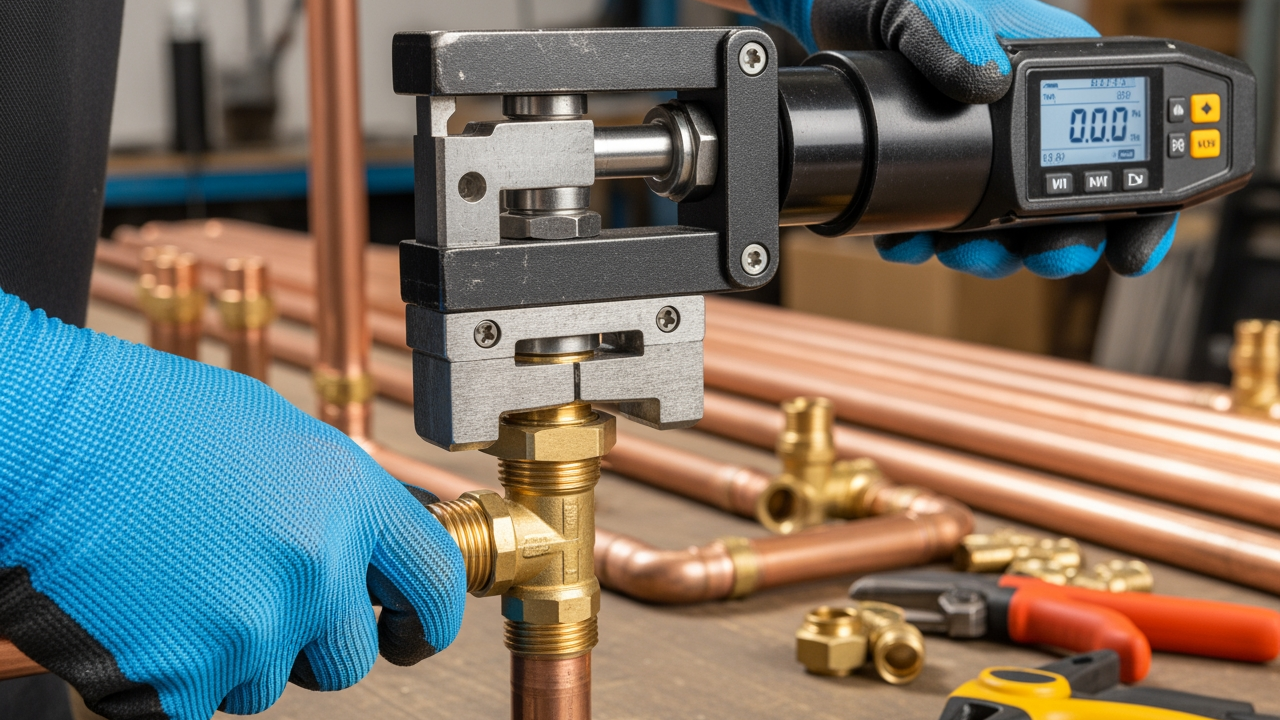

Press-fit systems use mechanical compression to create watertight seals. A hydraulic tool presses a specially designed fitting onto the pipe, deforming a sealing element, typically an EPDM or HNBR O-ring, that creates a permanent, leak-proof joint. The entire process takes 5-7 seconds per connection.

How Press-Fit Technology Works

The system relies on precise engineering. Each fitting contains a stainless steel sleeve with an internal sealing element. When the pressing tool applies force (typically 3-4 tons), it compresses the fitting onto the pipe in a specific pattern. This compression creates two distinct sealing zones: the O-ring forms the primary seal, while the mechanical deformation of the fitting body creates a secondary barrier.

The profile geometry matters. Most manufacturers use a hexagonal or M-profile pressing pattern that distributes force evenly around the pipe circumference. This prevents the pipe from collapsing while ensuring consistent seal compression across the entire joint.

Temperature resistance varies by O-ring material. EPDM seals handle water and heating applications up to 110°C, making them suitable for most residential and commercial systems. HNBR seals extend this range to 120°C and resist hydrocarbons, which makes them necessary for gas applications and industrial environments where chemical exposure occurs.

Measurable Advantages Over Traditional Methods

Installation speed creates the most immediate impact. A qualified plumber installs 8-12 press-fit connections in the time needed for one soldered joint. This matters most on large commercial projects where labour costs represent 60-70% of total installation expenses.

Fire safety eliminates significant risk. UK building regulations now restrict hot work in occupied buildings, making press-fit connection systems the only practical option for retrofit projects in hospitals, schools, and residential towers. Insurance claims data from 2023 shows that 14% of construction site fires start from soldering operations.

The joints don't require a cooldown time. With soldered connections, installers wait 10-15 minutes before pressure testing. Press-fit systems allow immediate testing, which accelerates project timelines and reveals installation errors before walls close up.

Material waste drops substantially. Soldering requires flux, solder, sandpaper, and cleaning materials for each joint. Press-fit eliminates these consumables entirely. A 500-connection commercial project saves approximately £800 in materials alone.

System Compatibility and Pipe Materials

Press-fit fittings work with multiple pipe types, though compatibility requirements differ. Copper pipes from 15mm to 108mm diameter accept press fittings, provided the wall thickness meets minimum specifications. Type B (medium wall) and Type A (thick wall) copper both work; Type C (thin wall) typically doesn't provide enough material for reliable compression.

Stainless steel requires different fitting profiles. The harder material needs higher pressing forces and modified jaw geometries. Most manufacturers produce separate fitting ranges for stainless applications, marked clearly to prevent cross-installation errors.

Multilayer composite pipes pair with specific press systems. These pipes, typically consisting of an aluminium core between polymer layers, need fittings designed for their expansion characteristics. The pressing profile must compress all layers uniformly without crushing the aluminium core. Modern composite pipe systems from Polypipe demonstrate compatibility with advanced press-fit technologies.

Carbon steel applications exist but remain less common in UK markets. These systems serve industrial environments where mechanical strength outweighs corrosion resistance concerns. The fittings use deeper pressing profiles to accommodate the material's different mechanical properties.

Product Range Breakdown

Standard fittings cover everyday installation needs. This includes elbows (45° and 90°), tees, reducers, and couplings in sizes from 15mm to 54mm. These fittings handle 95% of residential and light commercial applications.

Extended ranges address specific requirements. Equal and reducing tees allow branch connections without multiple fittings. Fixed-angle elbows (22.5°, 67.5°) reduce the fitting count in tight spaces. Wall plates with integrated press connections simplify radiator installations.

Transition fittings bridge different pipe materials or connection types. Press-to-thread adapters connect to valves, manifolds, and equipment. Press-to-compression fittings interface with existing installations. Press-to-push-fit adapters allow mixing connection methods within a single system.

Gas-rated components require additional certification. These fittings use yellow identification marks and HNBR seals rated for natural gas and LPG. They meet EN 10226 standards and carry G20/G25 approval for UK gas installations. The pressing profile differs slightly; deeper compression creates redundant sealing zones that satisfy gas safety requirements.

Pre-insulated press fittings reduce labour on heating systems. The factory-applied insulation eliminates the need for site-applied lagging around joints. This cuts installation time by an additional 30% on heating mains and reduces heat loss at connection points.

Quality plumbing fittings from Heating and Plumbing World ensure reliable press-fit performance across all application types.

Tool Requirements and Investment Considerations

Manual pressing tools suit small-scale work and repair jobs. These lever-operated tools handle pipes up to 28mm in diameter and cost £300-600. They require significant hand force; the mechanical advantage makes pressing possible, but it is physically demanding for multiple connections.

Battery-powered tools dominate professional installations. Modern 18V systems press pipes up to 54mm diameter and complete 200-300 connections per charge. Tool costs range from £800-1,500, with jaw sets adding £150-300 per size range. The investment breaks even after approximately 40 labour hours compared to soldering.

Hydraulic tools handle large-diameter applications. These mains-powered or petrol-driven units press pipes from 54mm to 108mm in diameter. They cost £2,000-4,000 but become essential for commercial mechanical services where large heating and chilled water mains require press connections.

Jaw compatibility varies between manufacturers. Most brands use proprietary jaw systems that don't interchange. This creates vendor lock-in; once you invest in a tool platform, switching brands means replacing the entire toolset. Some manufacturers offer adapters, but these add bulk and reduce reliability.

Calibration requirements affect long-term costs. Professional tools need annual calibration to maintain pressing force accuracy. Out-of-specification tools create weak joints that may not leak immediately but fail prematurely. Calibration services cost £80-150 annually per tool.

Installation Standards and Quality Control

Visual inspection catches most errors. Properly pressed joints show consistent deformation around the entire circumference. The pressing profile should be clearly visible with no gaps or incomplete sections. Unpressed joints look identical to hand-assembled fittings; the lack of deformation makes them obvious.

Some systems include safety features that prevent unpressed joints. These fittings have small holes in the fitting body that leak deliberately if not pressed. This "press-or-leak" design eliminates the risk of leaving connections unpressed, which has caused significant water damage in commercial installations.

Pressure testing follows standard procedures. BS EN 806 requires testing at 1.5 times the maximum operating pressure for 30 minutes. Press fit systems perform identically to soldered connections in these tests; the failure rate runs below 0.01% when properly installed.

Pipe preparation affects joint integrity. The pipe end must be clean, dry, and cut square. Burrs or debris prevent proper O-ring seating. Dents or out-of-round sections within 50mm of the joint compromise seal compression. Most manufacturers specify a maximum allowable deviation of 0.3mm.

Common Applications and System Design

Heating systems represent the largest application. Press-fit connections handle flow and return pipework, radiator tails, and manifold connections. The speed advantage matters most on multi-unit residential projects where hundreds of radiators need connecting within tight construction schedules.

Reliable circulation pumps from Grundfos integrate seamlessly with press-fit heating installations, ensuring optimal system performance.

Potable water systems use press-fit throughout. Cold water distribution, hot water circulation, and boosted water systems all benefit from the installation speed and reliability. The elimination of flux contamination provides an additional advantage: no cleaning cycles are needed before commissioning.

Premium water boosting systems from Stuart Turner pair effectively with press-fit connection systems for enhanced performance in low-pressure applications.

Chilled water and cooling systems increasingly specify press connections. The leak-free joints prevent condensation-related problems that plague threaded connections in air conditioning applications. The speed advantage becomes significant on large commercial HVAC installations with extensive pipework.

Solar thermal systems benefit from the high-temperature capability. EPDM seals handle the elevated temperatures in collector loops and primary circuits. The rapid installation reduces labour costs on roof-mounted collector arrays where working conditions limit productivity.

Cost Analysis and Project Economics

Material costs run 15-25% higher than soldered fittings. A standard 22mm elbow costs £3-4 in press-fit versus £0.80-1.20 for a solder fitting. This price gap narrows on larger diameters where fitting complexity increases.

Labour savings offset material premiums on projects exceeding 50 connections. A typical residential heating installation with 80 press connections saves 6-8 labour hours compared to soldering. At £45-60 per hour, this represents £270-480 in labour cost reduction against approximately £160-200 in additional material costs.

Tool investment amortises over time. A professional installer completing 2,000 connections annually recovers a £1,200 tool investment in saved labour within 3-4 months. After this point, the speed advantage translates directly to increased productivity or reduced project costs.

Maintenance and repair costs drop significantly. Press-fit systems allow easy disconnection by cutting the pipe and installing a new fitting. This eliminates the heat damage and time requirements of soldering in occupied spaces. Emergency repairs take 10-15 minutes versus 45-60 minutes for soldered alternatives.

Material Specifications and Longevity

O-ring materials determine service life. EPDM seals carry 50-year design life ratings in potable water and heating applications within their temperature range. HNBR seals offer similar longevity with extended chemical resistance. Both materials resist chlorine, chloramine, and typical water treatment chemicals at standard concentrations.

Fitting body materials affect corrosion resistance. Copper and bronze fittings match pipe material properties and eliminate galvanic corrosion concerns. Stainless steel fittings provide superior corrosion resistance in aggressive water conditions but cost 40-60% more than copper equivalents.

Dezincification resistance matters in brass fittings. Quality manufacturers use DZR-compliant brass alloys (CW602N or equivalent) that resist the selective corrosion that affects standard brass in soft water. Non-compliant fittings fail within 5-10 years in vulnerable water conditions.

Regulatory Compliance and Approvals

WRAS approval confirms potable water suitability. All press-fit systems for drinking water must carry Water Regulations Advisory Scheme approval. This certification verifies that materials don't leach contaminants and that joints remain watertight under thermal cycling and pressure fluctuations.

Gas-rated systems require additional certification. Fittings for natural gas and LPG installations need approval under the Gas Safety (Installation and Use) Regulations 1998. This requires third-party testing that verifies leak-free performance under pressure cycling and elevated temperatures.

Building regulations accept press-fit as equivalent to traditional methods. Part G (Sanitation, hot water safety and water efficiency) and Part L (Conservation of fuel and power) recognise press connections as compliant installation methods. No special provisions or additional approvals are needed beyond standard plumbing practices.

Professional heating controls from manufacturers like Honeywell complement press-fit installations by providing comprehensive system management and monitoring capabilities.

Professional Installation for Modern Plumbing

Press-fit connection systems deliver measurable advantages that justify their material premium on most commercial and residential projects. The 70% reduction in installation time translates to direct labour savings, while the elimination of hot work removes fire risk and regulatory complications in occupied buildings.

The technology suits installers ready to invest in proper tooling and training. A battery-powered pressing tool costs roughly the same as a quality soldering kit, but the speed advantage recovers this investment within months for working professionals. The learning curve runs shorter than developing competent soldering skills; most installers achieve proficiency after 50-100 connections.

Material selection matters. EPDM seals handle standard heating and plumbing applications reliably, while HNBR becomes necessary for gas systems and industrial environments. Fitting quality varies between manufacturers; established brands with comprehensive approvals cost more but deliver consistent performance across tens of thousands of installations.

The system isn't universal. Small repair jobs and specialised applications may still favour traditional methods. But for new installations, renovations, and commercial mechanical services, press-fit technology represents the current standard. The combination of speed, safety, and reliability makes it the default choice for professional installers working under time and budget constraints.

For expert advice on press fit systems or to source professional-grade components, contact the team at Heating and Plumbing World for tailored recommendations on your specific installation requirements.

-

-