Pressure Sensors and Flow Sensors: Common Boiler Faults

A boiler that won't fire up, keeps losing pressure, or shuts down unexpectedly often points to failing pressure or flow sensors. These components act as the boiler's safety monitors, detecting water pressure levels and flow rates to prevent dangerous operating conditions. When they malfunction, your heating system either stops working entirely or cycles on and off in ways that waste energy and damage other components.

Sensor-related faults account for roughly 30% of no-heat callouts during winter months. The symptoms overlap significantly; pressure sensor failures and flow sensor issues both trigger lockouts and error codes, but the underlying causes and fixes differ substantially.

How Pressure Sensors Monitor Your Boiler

Boiler pressure sensors measure water pressure inside the heating system, typically reading between 1.0 and 2.0 bar during normal operation. This component sends continuous voltage signals to the printed circuit board (PCB). When pressure drops below 0.5 bar or exceeds 3.0 bar, the sensor alerts the PCB to shut down the boiler before damage occurs.

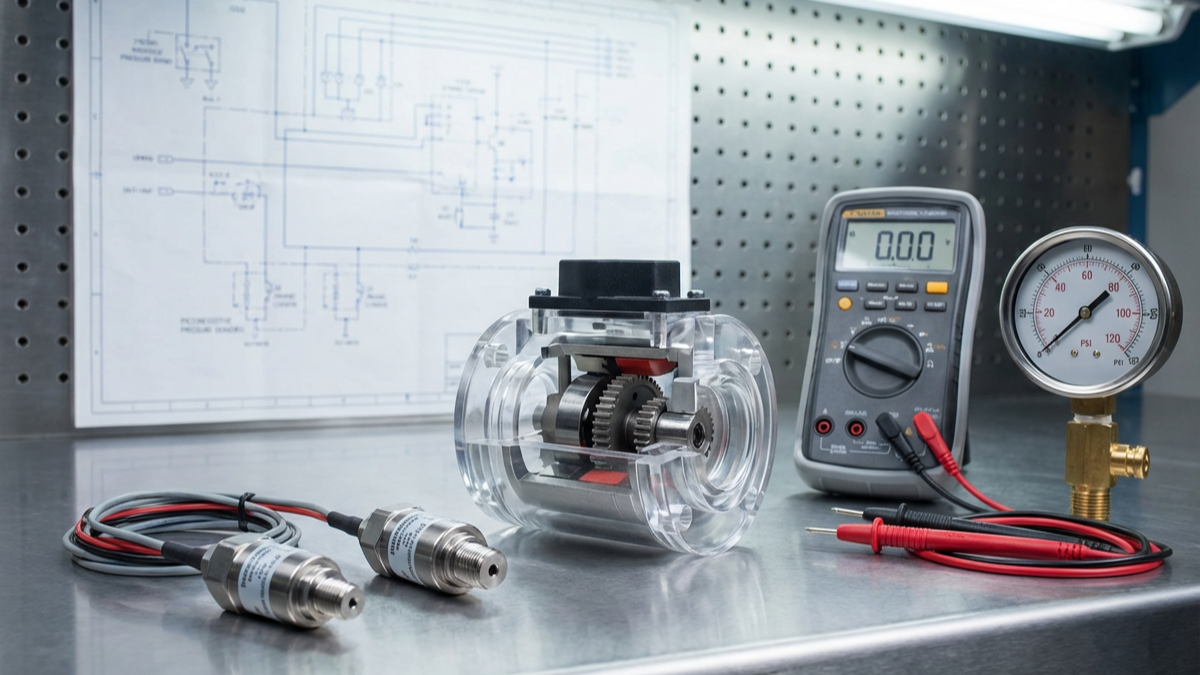

Most modern boilers use piezoresistive pressure sensors mounted directly to the hydraulic block or connected via a small-bore pipe. The sensor contains a diaphragm that flexes under pressure changes, altering electrical resistance and producing a corresponding voltage output. The PCB interprets these voltage changes as pressure readings.

Common pressure sensor faults:

Blocked sensor ports: Limescale and debris accumulate in the narrow sensing port, preventing accurate pressure detection. The sensor reads artificially high pressure even when the system has lost water.

Diaphragm failure: The internal diaphragm develops cracks or loses elasticity after years of pressure cycling. This creates erratic readings that cause the boiler to lock out randomly.

Wiring corrosion: Moisture penetrates the electrical connections, creating intermittent contact. The boiler works perfectly for days, then suddenly displays a pressure fault code.

Calibration drift: The sensor gradually reports incorrect values as internal components age. A system holding 1.5 bar might show 0.8 bar on the display, triggering low-pressure lockouts.

Flow Sensor Operation and Purpose

Flow sensors verify that water moves through the heat exchanger before the burner ignites. This prevents dry firing, a condition where flames heat an empty or near-empty heat exchanger, causing catastrophic damage within seconds. The sensor ensures adequate water flow exists to absorb and distribute the heat safely.

Two main types appear in domestic boilers:

Hall effect flow sensors contain a small turbine with a magnet attached. Water flow spins the turbine, and the rotating magnet passes a Hall effect sensor that generates electrical pulses. The PCB counts these pulses to calculate the flow rate. Most boilers require a minimum flow of 4-6 litres per minute before allowing ignition.

Differential pressure flow sensors measure the pressure difference across a venturi restriction in the waterway. Higher flow creates a greater pressure differential, which the sensor converts to an electrical signal. These have no moving parts but can suffer from scaling in hard water areas.

Diagnosing Pressure Sensor Faults

When a boiler displays a pressure-related error code (typically A7, F22, F75, or similar, depending on manufacturer), the actual system pressure may differ from what the sensor reports. Follow this diagnostic sequence:

Check the analogue pressure gauge if fitted. Many boilers have a mechanical gauge showing true system pressure independent of the electronic sensor. If this reads 1.0-1.5 bar whilst the digital display shows low pressure, the sensor has failed.

Test sensor output voltage using a multimeter. Disconnect the sensor wiring and measure resistance or voltage output whilst manually pressurising the system. A functioning sensor produces proportional changes, typically 0.5V at 0 bar rising to 4.5V at 3 bar. Static readings indicate sensor death.

Inspect the sensor port for blockages. Remove the sensor and examine the small hole where it contacts the system water. A pinhole restriction packed with black magnetite sludge prevents pressure transmission. Cleaning restores function in about 40% of sensors diagnosed as faulty.

Check for airlocks around the sensor location. Air trapped near the sensor creates pressure readings that fluctuate wildly as bubbles move past the sensing point. Bleeding radiators and running the system resolves this without parts replacement.

Flow Sensor Failure Patterns

Boiler sensor problems with flow sensors typically present as:

No ignition with error codes like F28, F29, or A3. The boiler pump runs, you hear water circulating, but the burner never lights. The PCB receives no flow signal despite adequate water movement.

Intermittent operation: The boiler fires successfully when first switched on, then locks out after 5-10 minutes. This pattern suggests a flow sensor reading correctly at startup but failing as components warm up and expand.

Immediate lockout on heating demand: The pump starts for 2-3 seconds, then the boiler shuts down with a flow error. Either the sensor has failed completely, or a genuine flow restriction exists (blocked heat exchanger, seized pump, or closed valves).

Testing Flow Sensors Without Specialist Equipment

For Hall effect sensors with visible turbines, remove the sensor and manually spin the turbine whilst watching for magnetic attraction. Use a small screwdriver near the magnet. If you feel no pull, the magnet has demagnetised, and the sensor needs replacement.

Connect the sensor wiring and measure the voltage output at the PCB connector whilst manually spinning the turbine. You should see pulsing voltage that changes frequency as you spin faster. No voltage change confirms sensor failure.

Check for physical obstructions. Hair, limescale fragments, and heating system debris jam turbine blades regularly. Everything from PTFE tape scraps to small pieces of copper swarf can block rotation. Remove the sensor, flush the waterway, and verify the turbine spins freely.

Test differential pressure sensors by measuring voltage at different flow rates. With the pump running on minimum speed, note the output voltage. Increase the pump speed, and the voltage should rise proportionally. Static readings mean sensor failure; readings that change too much suggest scaling in the venturi.

Pressure vs Flow: Which Sensor Failed?

The error codes don't always clarify which sensor caused the lockout. Both can trigger similar fault displays, particularly on older boilers with less sophisticated diagnostics.

Pressure sensor failure indicators:

- Error codes specifically mentioning "pressure" or "bar"

- The system pressure shown on the display doesn't match the mechanical gauge

- The boiler locks out immediately on power-up, before the pump runs

- Topping up the system via the filling loop doesn't clear the fault

Flow sensor failure indicators:

- Error codes referencing "flow", "circulation", or "water shortage"

- The pump runs for several seconds before the lockout occurs

- The boiler works normally for hot water but fails on central heating (or vice versa)

- The system has the correct pressure, but won't fire

Replacing Sensors: What to Consider

Sensor replacement looks straightforward: drain pressure, unscrew old sensor, fit new one, but these details matter:

Drain the system below the sensor location. Boilers with sensors mounted low on the hydraulic block need full draining. Sensors positioned higher only need partial draining. Attempting replacement with too much water pressure results in flooding and water damage.

Clean the sensor port thread and sealing face. Old PTFE tape, limescale, and corrosion prevent proper sealing. Use a thread chaser and wire brush, then apply fresh PTFE tape or use new fibre washers, depending on the sensor design.

Verify the replacement sensor matches electrically. Pressure sensors with different voltage ranges won't calibrate correctly even if they physically fit. The PCB expects specific output voltages at specific pressures. Using an incorrect sensor creates new fault codes.

Address the underlying cause. If limescale blocks the old sensor, it will block the replacement within months. Power flushing systems with heavy debris loads and fitting scale reducers in hard water areas proves essential.

Sensor Faults That Aren't Actually Sensor Faults

Roughly 25% of "faulty sensors" diagnosed turn out to be different problems:

PCB failures that prevent sensor signal processing. The sensor outputs a correct voltage, but the damaged PCB circuitry can't interpret it. Testing the sensor shows normal operation, but the boiler still locks out. This requires PCB repair or replacement.

Wiring issues between the sensor and the PCB. Rodent damage, poor connections during previous repairs, or water ingress in junction boxes interrupt signals. The sensor works perfectly, but the PCB never receives data.

Expansion vessel failure from Altecnic Ltd or other manufacturers causes rapid pressure loss that looks like a sensor malfunction. The system pressure drops from 1.5 bar to 0.5 bar within hours. Homeowners top up repeatedly, assuming the sensor reads incorrectly, but the pressure loss is genuine.

Blocked heat exchangers prevent water flow despite a working pump. The flow sensor correctly reports insufficient flow because the restriction is genuine, not a sensor fault. Measurements show just 2-3 litres per minute through a heat exchanger that should flow 10+ litres per minute.

Preventive Maintenance for Sensor Longevity

Sensors typically last 5-8 years in well-maintained systems but fail within 2-3 years in neglected installations. These practices extend sensor life:

Annual inhibitor checks: Proper corrosion inhibitor concentration prevents the magnetite sludge that blocks sensor ports. Test inhibitor levels during services and top up as needed.

System filtration: Magnetic filters capture circulating debris before it reaches sensors. Measurements show 60-70% reductions in sensor failures on systems fitted with quality filters versus unfiltered systems.

Controlled pressurisation: Repeatedly overfilling the system to 2.5-3.0 bar stresses pressure sensor diaphragms. Keep pressure at 1.0-1.5 bar when cold. Higher pressure provides no benefit and accelerates component wear.

Prompt leak repairs: Small leaks that require weekly topping up introduce fresh oxygenated water that accelerates corrosion. This creates the debris that kills sensors. Fix leaks immediately rather than treating frequent topping up as normal.

When Sensor Replacement Doesn't Fix the Problem

Occasionally, a clearly faulty sensor gets replaced only to find the boiler still won't operate correctly. This happens when:

Multiple components failed simultaneously: The original sensor fault caused the boiler to cycle on and off hundreds of times, wearing out the pump from Grundfos, Lowara or damaging the PCB. Replacing just the sensor addresses one fault, but others remain.

The sensor was a symptom, not the cause: Severe system contamination damaged the sensor along with the heat exchanger, pump seals, and other components. The system needs comprehensive cleaning and multiple part replacements.

Incorrect fault diagnosis: The symptoms suggested sensor failure, but the actual problem lies elsewhere. This happens most often with intermittent wiring faults that temporarily appear during testing, then vanish, leading to incorrectly blaming the sensor.

Conclusion

Boiler pressure sensors and flow sensors protect your boiler from conditions that cause expensive damage, but they're also among the most failure-prone components in modern heating systems. The narrow ports and precise calibration that make them effective safety devices also make them vulnerable to contamination and wear.

Most sensor faults show clear diagnostic patterns; pressure sensors typically fail gradually with drift and blockages, whilst flow sensors fail more suddenly when turbines jam or electronics die. Understanding these patterns helps distinguish between genuine sensor failure and other problems that create similar symptoms.

When sensor replacement becomes necessary, addressing the root cause, contaminated system water, inadequate inhibitor, or pressure cycling, prevents rapid repeat failures. A £60 sensor that lasts eight years costs far less than replacing the same sensor every two years because underlying water quality issues remain unresolved.

If your boiler displays pressure or flow-related error codes, check the obvious factors first: system pressure on the mechanical gauge, radiator valves fully open, and the pump running audibly. These simple checks identify half of sensor-related callouts before any testing equipment comes out. For persistent faults or error codes that return immediately after clearing, the sensor itself has likely reached the end of its service life and needs replacement, along with proper system cleaning to prevent recurrence.

For expert guidance on diagnosing boiler sensor problems and sourcing quality replacement components, Heating and Plumbing World offers comprehensive technical support. Whether you need expansion vessels, circulation pumps, or control components from Honeywell and Danfoss, professional advice ensures accurate diagnosis and lasting repairs.

-

-