Push-Fit Plumbing Fittings: Reliability and Best Practices

Push-fit plumbing fittings transformed the industry when they arrived, cutting installation time by 60% compared to traditional soldered joints. After fitting thousands of these connections across residential and commercial projects, we've learned exactly when they excel and where they fall short.

The technology works through a simple mechanism: push the pipe into the fitting until it clicks, and an internal grab ring locks it in place whilst O-rings create a watertight seal. No torch, no flux, no waiting for joints to cool. A connection that would take 5 minutes with solder takes 30 seconds with push-fit.

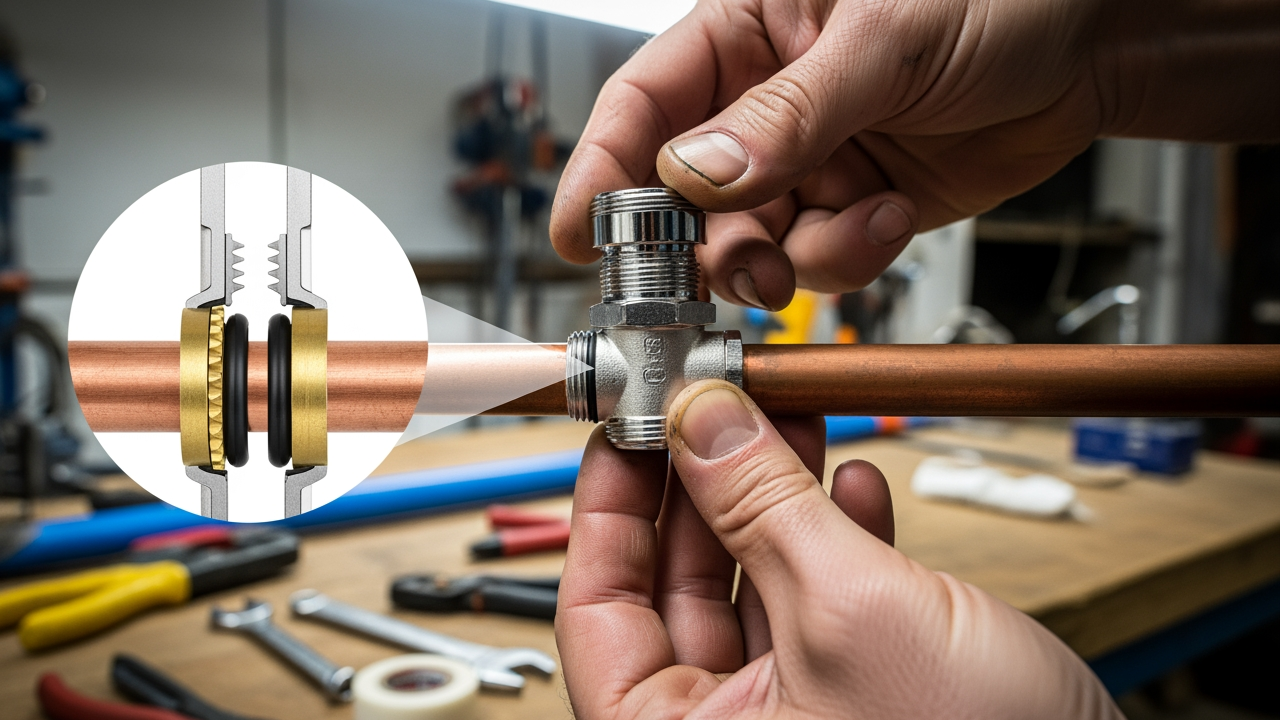

How Push-Fit Technology Actually Works

The push fit reliability of plumbing connections depends on three components working together. The grab ring, a stainless steel collar with internal teeth, grips the pipe when you insert it and prevents withdrawal. The O-ring (typically EPDM rubber) creates the watertight seal. The fitting body, made from brass, polymer, or composite materials, houses both components and withstands system pressure.

When you push a pipe into the fitting, it compresses the O-ring and passes the grab ring teeth. Any attempt to pull the pipe out causes the teeth to bite harder into the pipe surface. This design handles up to 10 bar pressure in most residential applications, more than sufficient for typical domestic water systems running at 3-4 bar.

The weakness appears in the O-ring. Temperature fluctuations cause rubber to expand and contract. After 15-20 years in hot water systems cycling between 10°C and 65°C daily, we've seen O-rings lose elasticity. This doesn't mean immediate failure, but it creates the potential for weeping joints that traditional soldered connections simply don't experience.

Where Push-Fit Fittings Deliver Maximum Value

Retrofit and repair work represent the ideal application. When you're working in occupied properties, eliminating hot work permits and open flames removes significant hassle. We completed a 24-unit apartment block re-pipe in three days using push-fit plumbing fittings, the same job would have taken six days with soldered joints, plus the fire watch requirements would have doubled the labour cost.

Concealed locations under floors or behind bath panels suit push-fit technology well, contrary to some opinions. The fittings require zero maintenance once installed correctly. We've opened walls after 10 years to find push-fit connections in perfect condition. The key is proper installation; the pipe must be cut square, deburred, and pushed fully home until it bottoms out in the fitting.

Plastic pipe systems work exceptionally well with push-fit fittings. MLCP (multi-layer composite pipe) and PEX expand slightly when inserted, creating additional pressure against the O-ring. We've tested connections made with these materials to 15 bar without leakage. The pipe flexibility also means fewer fittings overall, as gentle curves replace multiple elbows. Polypipe offers comprehensive plastic piping systems designed to work seamlessly with push-fit technology.

Emergency repairs become manageable for building maintenance teams without specialised skills. A facilities manager can shut off water, cut out a damaged section, and install a new pipe with push-fit couplings in 15 minutes. This capability reduces callout costs and minimises downtime in commercial buildings.

Critical Installation Requirements

The difference between a reliable connection and a callback comes down to preparation. Cut quality matters more than installers expect. A pipe cut with worn cutters creates an oval end that won't seal properly. We replace pipe cutters every 200 cuts. The cost of a new cutter is £15, whilst a callback for a weeping joint costs £120 in labour alone.

Deburring is non-negotiable. The internal burr from cutting scrapes the O-ring as you insert the pipe, creating a leak path. External burrs prevent the pipe from seating fully. We use a dedicated deburring tool that chamfers both inside and outside edges in one motion. This takes 5 seconds per cut.

Insertion depth determines push fit reliability. Most push-fit fittings have witness marks showing proper insertion depth, typically 25mm for 15mm pipe, 28mm for 22mm pipe. If the pipe doesn't reach these marks, the grab ring may not engage fully. We mark the correct depth on the pipe with a pencil before insertion, then verify that the mark has disappeared into the fitting.

Pipe condition affects long-term performance. Scratches, dents, or out-of-round sections compromise the seal. We've found that copper pipe stored outdoors develops surface oxidation that interferes with O-ring contact. A quick wipe with wire wool restores the clean surface needed for proper sealing.

Material Compatibility and System Design

Push-fit plumbing fittings handle mixed-material systems better than any other connection method. Connecting copper to plastic, or plastic to MLCP, requires no special adapters; the same fitting accepts any pipe of the correct diameter. This flexibility speeds up installations where you're extending existing copper systems with plastic pipe.

Temperature and pressure ratings vary by manufacturer and material. Standard brass push-fit fittings handle 10 bar at 20°C and 6 bar at 65°C. Polymer fittings typically rate to 8 bar at 20°C and 4 bar at 65°C. For heating systems running at 80°C, specialised high-temperature fittings maintain 6 bar rating. We've learned to check actual specifications rather than assuming all push-fit fittings are equivalent.

UV exposure degrades polymer fittings rapidly. We installed push-fit connections in a plant room with skylights, after 18 months, the polymer fittings showed surface cracking. The same fittings in a windowless room remained perfect. Any push-fit connection exposed to sunlight needs brass fittings or UV-protective wrapping.

Chemical compatibility requires attention in commercial settings. Standard EPDM O-rings resist chlorine and most water treatment chemicals, but some industrial additives attack rubber. A food processing plant we service uses demineralised water with specific additives. We switched to Viton O-ring fittings after the standard O-rings swelled and leaked within six months.

Common Failure Modes and Prevention

Weeping joints after 2-3 years typically indicate incomplete insertion. The pipe moved 2-3mm during pressure testing or initial use, enough to compromise the O-ring seal but not enough to fully disengage. Prevention requires checking the insertion depth after pressurising the system. We mark pipes before testing, then verify the marks haven't moved afterwards.

Sudden leaks during freezing weather happen when ice forms inside the pipe and pushes the pipe out of the fitting slightly. This affects push-fit connections more than soldered joints because the grab ring can't resist the sustained force of expanding ice. We insulate all push-fit connections in unheated spaces and advise clients to drain systems in vacant properties during winter.

Discoloured water after installation indicates inadequate pipe cleaning. Cutting oil, swarf, or storage dirt enters the system and accumulates at the O-ring, creating a leak path. Flushing the system before making final connections prevents this. We run water through each section for 30 seconds before fitting the last connection.

Fitting body cracks occur when someone uses the fitting as a pipe support or applies lateral force. The fitting body isn't designed to bear weight; it only holds the pipe connection. We install proper pipe clips within 300mm of each push-fit connection to prevent stress on the fitting body. Quality fittings from reputable manufacturers ensure consistent performance across thousands of installations.

When to Avoid Push-Fit Fittings

External pipework needs protection from UV and temperature extremes that push-fit plumbing fittings can't reliably handle. We've replaced push-fit connections on external taps after 3-4 years when O-rings failed from UV exposure and freeze-thaw cycles. Compression fittings or soldered joints last for decades in these locations.

High-vibration environments like pump rooms cause push-fit connections to work loose over time. The constant movement fatigues the grab ring's grip. A boiler room installation developed three weeping joints within 18 months, we replaced all push-fit connections with soldered joints and haven't had issues since. Grundfos pumps generate minimal vibration, but proper isolation remains essential for push-fit connections near any pumping equipment.

Fire-rated penetrations often prohibit push-fit fittings in building codes. The polymer components don't meet fire resistance requirements for services passing through fire-rated walls or floors. Check local regulations before specifying push-fit fittings in these locations.

Long-term installations in inaccessible locations create risk. Whilst push-fit fittings can last 20+ years, they have a higher failure rate than soldered joints after 15 years. For pipes that will be buried in concrete or encased in structural elements, the extra 30 minutes to solder joints eliminates potential future excavation costs.

Maintenance and Inspection Protocols

Push-fit plumbing fittings require annual visual inspections in commercial buildings. We check for water staining around fittings, verify pipe clips remain secure, and look for any pipe movement at connections. This 10-minute inspection per zone catches developing problems before they become failures.

Pressure testing after any building work protects against accidental damage. Vibration from nearby construction can loosen push-fit connections that were previously secure. We test to 1.5x operating pressure for 30 minutes; any pressure drop indicates a compromised connection.

O-ring replacement isn't practical in most cases because disassembling the connection often damages the grab ring. If a push-fit joint develops a minor weep, we replace the entire fitting rather than attempting repair. The fitting costs £3-8, whilst the labour to disassemble and reassemble is the same whether replacing the O-ring or the whole fitting.

Cost Analysis and Decision Framework

Material costs favour push-fit fittings by 15-20% over compression fittings but run 40-50% higher than soldered joints. A 15mm push-fit elbow costs £2.20 versus £0.40 for a solder fitting. On a typical bathroom installation using 30 fittings, that's £54 extra in materials.

Labour savings reverse this calculation. The same bathroom takes 4 hours with push-fit versus 6.5 hours with soldered joints. At £45/hour labour rate, push-fit saves £112.50 in labour whilst costing £54 more in materials, a net saving of £58.50 per bathroom.

Long-term reliability adds an intangible cost. Soldered joints have a 0.1% failure rate over 20 years in our experience. Push-fit fittings show 2-3% failure rate in the same period. On a 100-connection installation, you might expect 2-3 callbacks with push-fit versus zero with soldered joints. Each callback costs £120-150 in labour and materials.

The decision framework we use: choose push-fit for retrofit work, occupied properties, and installations where access remains available. Choose soldered joints for new-build work, permanent installations, and locations where future access is difficult or impossible.

Conclusion

Push-fit plumbing fittings deliver genuine value when matched to appropriate applications. They've eliminated most of the callbacks we used to receive for soldered joints that failed during installation, and they've cut our installation time significantly on retrofit projects. The technology works reliably when you follow proper installation procedures, square cuts, thorough deburring, and verified insertion depth.

The limitations matter as much as the benefits. These fittings don't suit every application, and treating them as universal replacements for traditional joints creates problems. We've learned to assess each project individually, considering access requirements, expected service life, and operating conditions before specifying connection methods.

After a decade working with push-fit technology across hundreds of installations, our approach has settled into a clear pattern: use them where they excel, avoid them where they don't, and never compromise on installation quality regardless of which method you choose. The fittings themselves demonstrate strong push-fit reliability; most failures trace back to poor installation technique or inappropriate application rather than inherent product defects.

For a comprehensive range of plumbing components and connection systems, Heating and Plumbing World stocks products from trusted manufacturers that meet UK Building Regulations standards.

-

-