Push-Fit Valve Installation: Best Practices and Limitations

Push-fit valves transformed plumbing installations when they entered the market, eliminating the need for soldering and specialised tools. Hundreds of these connections are installed annually across residential and commercial projects, and while they offer genuine advantages in specific scenarios, they're not the universal solution many installers assume them to be.

Understanding proper push-fit valve installation techniques and recognising the technology's boundaries separates reliable installations from expensive callbacks.

What Makes Push-Fit Technology Work

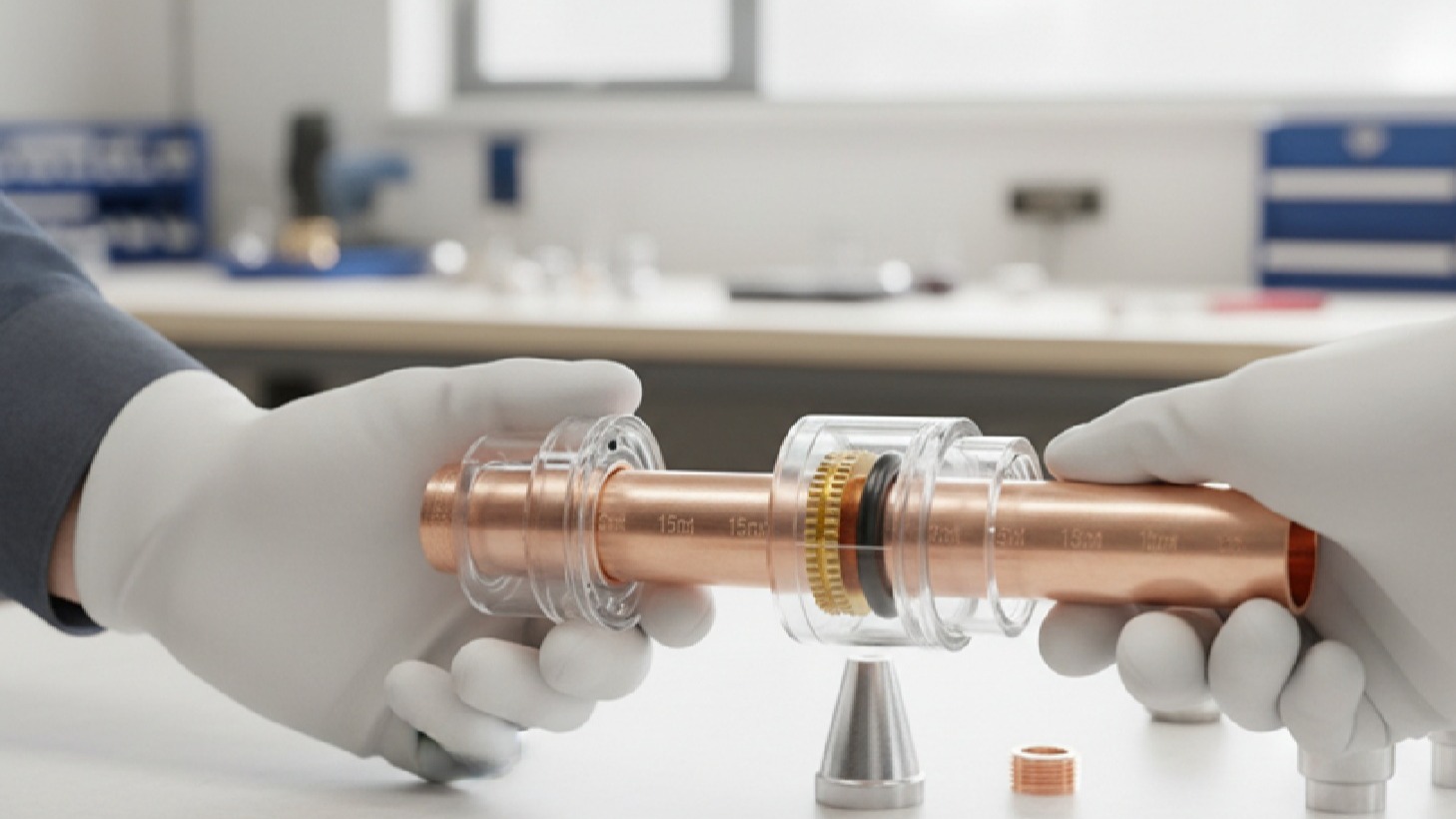

Push-fit valves use a grab ring and O-ring system to create watertight seals. When you insert the pipe into the fitting, a stainless steel grab ring grips the pipe whilst an O-ring creates the seal. The mechanism is simple: push the pipe fully into the fitting until it seats against the internal stop, typically 25-28mm deep depending on pipe diameter.

The technology works reliably when three conditions align: proper pipe preparation, compatible materials, and appropriate application environments. Miss any of these, and you're setting up callbacks.

Where Push-Fit Valves Excel

Specific push-fit valve installation scenarios genuinely outperform traditional methods.

Retrofit Work in Occupied Spaces

When replacing a failed valve in an occupied home or office, push-fit connections eliminate hot work permits and fire watch requirements. A job that would take 45 minutes with soldering takes 15 minutes with push-fit, and you're not introducing flame hazards near furnishings or in ceiling voids.

Temporary or Modular Systems

Exhibition spaces, temporary facilities, and modular construction benefit from push-fit technology's reversibility. Entire manifold systems can be installed and later relocated without cutting a single pipe, something impossible with soldered or compression joints.

Areas Prone to Vibration

Push-fit joints handle vibration better than rigid soldered connections. In plant rooms with pumps or near mechanical equipment, the slight flexibility in push-fit joints absorbs movement that would stress rigid connections over time. Quality pumps from Grundfos or Lowara pair well with properly installed push-fit systems in these applications.

Critical Installation Steps

The difference between a reliable connection and a future leak comes down to preparation.

Pipe Cutting and Deburring

Cut pipes with a proper pipe cutter, not a hacksaw. Hacksaw cuts create oval pipe ends that prevent proper seating. After cutting, deburr both inside and outside edges thoroughly. A burr as small as 0.5mm can score the O-ring during insertion, creating a leak path.

A dedicated deburring tool, an £8 investment, prevents callbacks worth hundreds in labour and reputation damage.

Insertion Depth Marking

Mark the insertion depth on the pipe before assembly. For 15mm copper, mark 25mm from the cut end. Insert the pipe fully until it bottoms out against the internal stop, then verify your mark sits flush with the fitting body. If it doesn't, the pipe isn't fully seated. Think of it like posting a letter; you can't just push it halfway through the slot and expect it to be delivered.

Support and Clipping

Push-fit joints aren't structural supports. Clip pipes within 300mm of each push-fit connection to prevent stress on the joint. Unsupported spans longer than 1.2m for 15mm pipe or 1.5m for 22mm pipe will sag, placing shear stress on connections.

Material Compatibility Requirements

Push-fit valves work with specific materials, and mixing incompatible combinations causes failures.

Copper Pipe Standards

Use only Table X or Table Y copper pipe. Table Z (microbore) has thinner walls that may not provide adequate grip for the grab ring. The pipe must be clean; oxidation, flux residue, or old solder prevent proper O-ring sealing.

Plastic Pipe Limitations

Plastic barrier pipe requires pipe inserts to prevent collapse under the grab ring pressure. Skip the insert, and the pipe deforms, compromising both seal and grip. Installers who omit inserts to save 30 seconds per connection spend hours diagnosing weeping joints weeks later.

CPVC and PEX-AL-PEX work with most push-fit systems, but verify compatibility with the specific manufacturer. Some grab ring designs don't grip plastic pipe surfaces effectively. Heating and Plumbing World stocks compatible barrier pipe and inserts specifically matched to push-fit systems.

Chrome and Stainless Tube Issues

Chrome-plated copper and stainless steel tubing present problems. Chrome plating increases surface hardness, reducing grab ring effectiveness. Stainless steel's lower friction coefficient means O-rings don't seal as reliably. If you must use these materials, specify push-fit fittings explicitly rated for them; standard fittings will fail.

Temperature and Pressure Boundaries

Every push-fit valve has operating limits, and exceeding them causes rapid failure.

Temperature Limitations

Most push-fit valves are rated to 90-95°C continuous operation. This works for standard domestic heating systems running at 70-80°C flow temperatures. However, systems running at higher temperatures, some commercial installations or older systems designed for 90°C+, sit too close to the limit.

Flow temperatures of 98°C in poorly controlled commercial systems cause O-ring deterioration within 18-24 months instead of the expected 10-15-year service life. Proper temperature control using quality thermostats from Honeywell or Danfoss protects push-fit installations.

Pressure Ratings

Typical push-fit valves rate to 10-16 bar depending on size and manufacturer. Domestic systems run 1.5-3 bar, providing an adequate safety margin. Unvented hot water systems can spike to 6 bar during heating cycles, still within limits, but leaving less margin for pressure surges.

The critical issue: pressure ratings often apply to cold water. Some manufacturers derate fittings to 10 bar at elevated temperatures. A fitting rated "16 bar" might only handle 10 bar at 80°C.

Push Fit Limitations: Applications Where They Fail

Specific scenarios demand alternative connection methods regardless of convenience.

Concealed Installations

Push-fit joints don't belong behind tiles, under screed, or buried in walls. The joints require periodic inspection, O-rings can deteriorate, and grab rings can lose tension over the years. When a concealed push-fit joint fails, you're breaking out finishes to access it.

Building regulations in many regions prohibit concealed push-fit joints for this reason. Where they don't explicitly prohibit them, insurance implications should. Insurers have denied claims for water damage from failed concealed push-fit connections, arguing negligent installation.

High-Temperature Applications

Don't use standard push-fit valves on primary circuits of thermal stores, biomass boilers, or solid fuel systems. These systems can exceed 100°C during fault conditions. Even if normal operation stays within limits, fault conditions cause catastrophic O-ring failure.

Soldered or brazed connections belong on any circuit that might exceed 90°C under any operating condition.

Locations Exposed to UV

UV radiation degrades the plastic bodies of push-fit valves and hardens O-rings. External installations or locations with direct sunlight exposure need UV-rated fittings or alternative connection methods. Standard push-fit valves in conservatories or near south-facing windows have failed within 3-5 years in documented cases.

Aggressive Water Chemistry

Water with a pH below 6.5 or above 8.5 accelerates O-ring degradation. Areas with aggressive water chemistry need chemical-resistant O-rings, typically EPDM rather than standard nitrile. Check your local water quality report before specifying push-fit for large installations.

Inspection and Testing Protocol

Push-fit installations require different testing approaches than soldered systems.

Pressure Testing Procedure

Pressure test at 1.5x operating pressure for 30 minutes minimum. Watch specifically for pressure drop in the first 10 minutes; this indicates incomplete insertion or damaged O-rings. A slow, steady pressure drop suggests a weeping joint that will worsen over time.

Don't confuse thermal expansion pressure changes with leaks. Test at a stable temperature, allowing 15 minutes for the system to stabilise before starting the formal test period.

Visual Inspection Points

Check that the insertion depth marks align with the fitting bodies. Misalignment indicates incomplete insertion. Inspect for pipe ovality; if the pipe isn't round, the O-ring won't seal properly. Check that support clips are present and correctly positioned.

Look for signs of stress: pipes pulling away from fittings, unsupported spans, or connections bearing weight. These indicate future failure points.

An apprentice once installed 30 push-fit connections on a manifold system without marking insertion depths. Three months later, the customer reported mysterious drips. Every single joint needed remaking because none had seated fully, the grab rings held temporarily, but the O-rings wept under pressure. Two hours of careful preparation would have prevented eight hours of remedial work.

Long-Term Maintenance Considerations

Push-fit valves require maintenance planning that soldered joints don't.

Service Life Expectations

O-rings in properly installed push-fit valves last 10-15 years in typical domestic heating applications. Commercial applications with higher cycling rates or temperatures may see 7-10 years. This means push-fit joints are serviceable items, not fit-and-forget components.

Plan for inspection at 8-10 year intervals. Look for weeping, corrosion around joints, or visible O-ring deterioration. Budget for eventual replacement, the convenience of push-fit installation becomes a liability when you're replacing 40 valves in a manifold system.

System Inhibitor Compatibility

Some heating system inhibitors attack O-ring materials. Verify inhibitor compatibility with your push-fit manufacturer before dosing the system. Complete O-ring failure within 18 months from incompatible inhibitor chemistry has occurred; every push-fit joint in affected systems wept simultaneously as O-rings hardened and cracked.

Cost Analysis: True vs. Perceived Savings

Push-fit valves cost 2- 3x more than soldered alternatives. A 15mm push-fit isolation valve costs £8-12 versus £3-5 for a compression valve or £2-3 for a solder-end valve.

The labour saving is real but smaller than assumed. Installing a soldered valve takes 6-8 minutes, including preparation and cooling time. A push-fit valve takes 2-3 minutes. On a single valve, you save 4-5 minutes. On a full heating system with 15-20 valves, you save 60-90 minutes.

Calculate whether 90 minutes of labour time justifies £100-150 in additional materials cost. For emergency repairs or retrofit work, yes. For new construction with accessible pipework, often no.

Quality brands available through Heating and Plumbing World offer reliable performance when properly installed, but material costs remain significantly higher than traditional methods.

Regulatory and Insurance Implications

Building regulations don't prohibit push-fit valves, but they impose restrictions. Most jurisdictions require accessible joints; push-fit connections must remain inspectable. Document push-fit locations in installation records, particularly in commercial buildings where future contractors need to locate and assess joints.

Some insurance policies specifically exclude coverage for water damage from push-fit joints in certain applications. Commercial property policies may require notification of push-fit use in primary heating circuits. Verify coverage before specification.

For guidance on compliance requirements for your specific installation, contact us for technical support.

Making the Right Connection Choice

Push-fit valves solve specific problems exceptionally well: retrofit work, vibration-prone locations, and temporary installations. They fail when installers treat them as universal solutions, using them where traditional methods perform better.

Professional installations use push-fit technology for roughly 20% of valve installations, the applications where it genuinely excels. The remaining 80% use soldered, brazed, or compression connections because they're more appropriate for the application, environment, or service life requirements.

The key isn't choosing push-fit versus traditional methods universally; it's matching connection technology to application requirements. Understand the push-fit limitations, respect the installation requirements, and push-fit valves deliver reliable service. Ignore the constraints, and you're creating callbacks and failures that damage both client relationships and professional reputation.

Proper push-fit valve installation demands careful material selection, meticulous pipe preparation, and honest assessment of whether the application suits the technology. When conditions align, push-fit connections offer speed and convenience without compromising reliability. When conditions don't align, traditional methods remain superior despite requiring more time and skill.

-

-