Robotics in Pipe Maintenance and Leak Detection

The heating and plumbing industry has witnessed remarkable technological advancements in recent years, with robotics emerging as a game-changing solution for pipe maintenance and leak detection. Traditional methods of identifying pipe problems often require extensive excavation, costly repairs, and significant disruption to properties. Modern pipe maintenance robots and robotic leak detection systems offer a smarter, more efficient alternative that saves time, money, and preserves property integrity.

Understanding Pipe Maintenance Robots

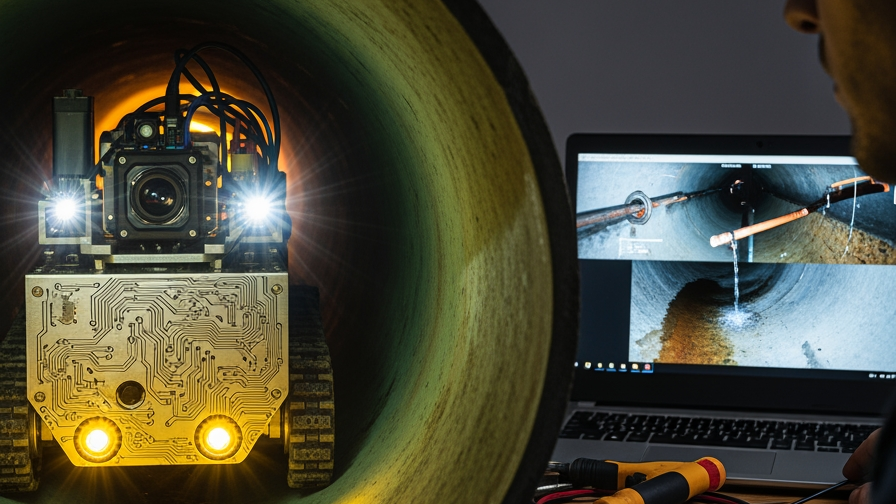

Pipe maintenance robots represent a sophisticated fusion of engineering and technology designed to navigate complex pipe networks. These compact, remotely operated devices can traverse pipes as small as 50mm in diameter, equipped with high-definition cameras, sensors, and lighting systems that provide detailed visual inspection of internal pipe conditions.

The technology behind these robots has evolved significantly. Modern systems feature flexible designs that navigate bends, junctions, and vertical sections with ease. Advanced models incorporate 360-degree camera rotation, allowing comprehensive inspection of pipe walls, joints, and connections. For heating engineers and property owners, this means accurate assessment of pipe integrity without destructive investigation methods.

Different types of pipe maintenance robots serve specific purposes. Crawler robots excel in horizontal pipe inspection, whilst tethered systems provide stable power and data transmission for extended surveys. Self-propelled units offer greater autonomy in complex network mapping, particularly valuable for commercial heating systems and large-scale installations.

Robotic Leak Detection Technology

Robotic leak detection has revolutionised how heating and plumbing professionals identify system failures. These systems employ multiple detection methods simultaneously - acoustic sensors detect the sound of escaping water or gas, thermal imaging identifies temperature variations indicating leaks, and moisture sensors pinpoint exact problem locations.

The precision of robotic leak detection far exceeds traditional methods. Where manual inspection might require multiple site visits and educated guesswork, robotic systems provide definitive evidence within hours. Real-time data transmission allows engineers to view pipe conditions remotely, making informed decisions about repair requirements before committing to invasive work.

For properties with boiler spares and complex central heating networks, robotic leak detection offers particular advantages. The technology identifies deteriorating components before catastrophic failure occurs, enabling proactive replacement of parts and preventing costly emergency repairs. This predictive capability transforms maintenance from reactive firefighting to strategic planning.

Applications in Residential and Commercial Settings

Residential applications of pipe maintenance robots have grown substantially. Homeowners benefit from non-invasive inspection of underground heating pipes, domestic water supplies, and drainage systems. When purchasing older properties, robotic inspection provides comprehensive pipe condition reports, helping buyers make informed decisions about potential renovation costs.

Central heating systems particularly benefit from robotic inspection. Modern combi boilers and conventional systems rely on extensive pipe networks, and any degradation affects efficiency and safety. Regular robotic surveys identify scale buildup, corrosion, and joint deterioration before problems escalate. Worcester Bosch boiler spares often last longer when pipe systems receive proper maintenance through regular robotic inspection.

Commercial and industrial settings present even greater opportunities for robotic technology. Large office buildings, manufacturing facilities, and multi-occupancy residential developments feature complex pipe networks spanning multiple floors and zones. Traditional inspection methods prove impractical at this scale, whilst pipe maintenance robots efficiently survey entire systems, generating comprehensive condition reports and maintenance recommendations.

Benefits of Robotic Pipe Maintenance

Cost savings represent perhaps the most compelling advantage of robotic pipe maintenance. Traditional leak detection often requires exploratory excavation, damaging floors, walls, or landscaping based on educated guesses about problem locations. Robotic systems eliminate this wasteful approach, pinpointing exact problem areas and minimising repair costs. Property owners save thousands of pounds by avoiding unnecessary excavation and restoration work.

The non-destructive nature of robotic inspection preserves property value and aesthetics. Gardens, driveways, and interior finishes remain undisturbed whilst thorough inspection proceeds. For commercial properties, this means avoiding business disruption and maintaining operations during maintenance periods. Tenants and customers remain unaffected by the investigation work, protecting revenue and reputation.

Accuracy improvements deliver long-term value beyond immediate cost savings. Detailed video documentation provides indisputable evidence of pipe conditions, supporting insurance claims and dispute resolution. Historical records enable trend analysis, predicting future maintenance requirements and budget planning. For heating engineers at Heating and Plumbing World, this documentation enhances professional credibility and client confidence.

Integration with Modern Heating Systems

Robotic leak detection integrates seamlessly with contemporary heating installations. Modern condensing boilers, particularly Worcester Bosch systems, feature extensive pipe networks connecting radiators, hot water cylinders, and controls. These networks require periodic inspection to maintain efficiency and safety. Robotic systems identify problems affecting boiler performance, such as circulation issues caused by partial blockages or hidden leaks, reducing system pressure.

Oil heating systems benefit significantly from robotic inspection technology. Oil burners and associated pipe networks present unique maintenance challenges, with fuel line leaks posing environmental and safety risks. Robotic detection identifies degraded seals, corroded sections, and vulnerable joints before failures occur. This proactive approach prevents costly oil spills and environmental remediation.

Smart home integration represents the next frontier for pipe maintenance robots. Advanced systems connect with building management platforms, automatically scheduling inspections and alerting homeowners to developing issues. Integration with heating controls enables automatic system shutdown when leaks are detected, preventing water damage and energy waste. These capabilities appeal particularly to landlords and property managers responsible for multiple installations.

Choosing Robotic Inspection Services

Recognising when robotic inspection provides value helps property owners make informed maintenance decisions. Unexplained increases in water consumption, persistent damp patches, reduced heating efficiency, or unusual sounds from pipe networks all warrant professional robotic investigation. Pre-purchase property surveys should routinely include robotic pipe inspection, particularly for older buildings with original heating systems.

Professional robotic inspection services follow systematic protocols. Initial consultation identifies specific concerns and system details. Technicians then deploy appropriate robotic equipment, conducting methodical surveys of accessible pipe networks. High-definition video footage captures pipe conditions, whilst sensors record additional data about leaks, blockages, and deterioration. Comprehensive reports translate technical findings into actionable recommendations, helping clients prioritise repairs and budget appropriately.

The inspection process typically completes within hours rather than days. Access points such as drain covers, radiator connections, or service hatches provide entry for robotic equipment. Minimal preparation is required, and properties remain fully operational throughout surveys. For homeowners concerned about disruption, this efficiency proves invaluable.

Future of Pipe Maintenance Technology

Emerging developments in artificial intelligence promise even greater capabilities for pipe maintenance robots. Machine learning algorithms analyse inspection data, identifying patterns and predicting future failures with increasing accuracy. These predictive systems enable truly proactive maintenance, scheduling interventions before problems develop rather than after symptoms appear.

Advanced robotic systems now incorporate limited repair capabilities. Some models dispense sealants, clean pipe walls, or install internal patches without excavation. Whilst not suitable for all repairs, these capabilities reduce costs and disruption for certain problems. Expansion vessels and other pressure-related components benefit from this approach when minor leaks develop at joints or connections.

The heating and plumbing industry continues adapting to these technological advances. Professional training programmes now include robotic equipment operation and data interpretation. Forward-thinking companies invest in robotic inspection capabilities, recognising competitive advantages in offering comprehensive, non-invasive services. Customer expectations evolve accordingly, with property owners increasingly demanding evidence-based maintenance recommendations rather than assumptions.

Maintaining System Components

Beyond pipe inspection, robotic technology supports comprehensive heating system maintenance. Components such as pressure relief valves and fire valves require periodic inspection to ensure safety and compliance. Robotic cameras verify proper installation, identify corrosion or deterioration, and document component conditions for regulatory purposes.

Water storage systems benefit similarly from robotic inspection. Water tanks and associated pipe networks develop problems over time, with sediment accumulation, bacterial growth, and structural deterioration affecting water quality and system performance. Robotic inspection identifies these issues without draining systems or disrupting water supply, enabling targeted maintenance that preserves water quality and system efficiency.

Conclusion

Robotics has fundamentally transformed pipe maintenance and leak detection, offering precision, efficiency, and cost-effectiveness that traditional methods cannot match. Pipe maintenance robots and robotic leak detection systems provide property owners and heating professionals with powerful tools for maintaining system integrity, preventing failures, and extending equipment lifespan.

The technology delivers tangible benefits - reduced costs, minimal disruption, enhanced accuracy, and comprehensive documentation. Whether managing residential heating systems or complex commercial installations, robotic inspection provides the evidence needed for informed maintenance decisions. As these systems continue evolving, their role in heating and plumbing maintenance will only expand.

For property owners seeking a reliable assessment of their heating and plumbing systems, professional robotic inspection offers peace of mind backed by concrete evidence. To discuss how robotic inspection can benefit your property or to schedule a comprehensive system survey, contact us today. Expert guidance and advanced technology ensure your heating systems operate efficiently, safely, and reliably for years to come.

-

-