Scale Inhibitors vs Water Softeners: Cost-Benefit Analysis

Hard water costs UK households an average of £500 annually through scale buildup, damaged appliances, and increased energy consumption. The choice between scale inhibitors vs water softeners determines whether you address this problem superficially or solve it completely.

Both systems have been installed across thousands of properties. The decision isn't straightforward; what works for a two-bedroom flat in Brighton fails spectacularly in a four-bedroom house in Birmingham. Water hardness levels, household size, existing plumbing infrastructure, and budget constraints all shift the calculation.

What Each System Actually Does

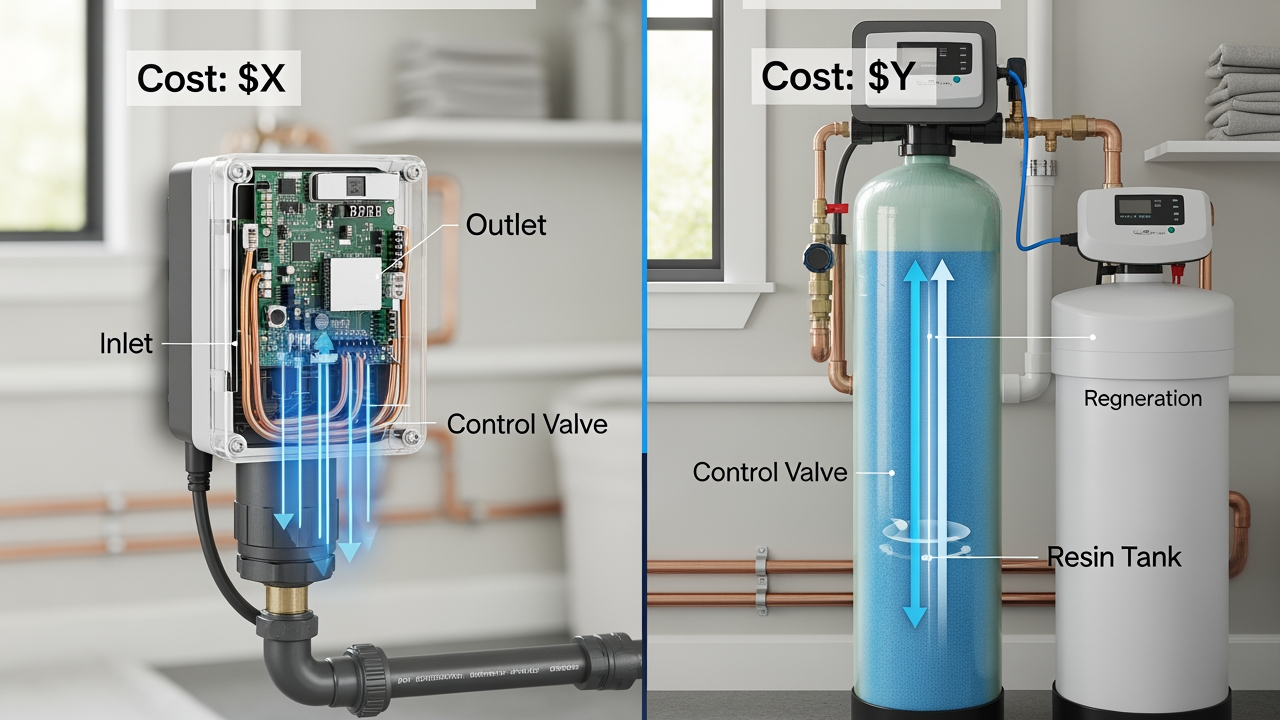

Water softeners remove calcium and magnesium ions through ion exchange. Hard water flows through resin beads charged with sodium ions. The calcium and magnesium swap places with sodium, and soft water exits the system. This process eliminates hardness completely, water tests at 0-50 parts per million (ppm) after treatment compared to 200-400 ppm in hard water areas.

Scale inhibitors don't remove minerals. They alter the crystalline structure of calcium and magnesium so these minerals can't bond to surfaces. The water remains technically "hard," but scale formation drops by 70-85%. Minerals stay in suspension and wash down drains instead of coating heating elements and pipe interiors.

Upfront Investment Breakdown

Water softener system (£700-£1,500 installed):

- The softener unit itself (£400-£900)

- Salt storage tank (£50-£100)

- Installation labour (£200-£400)

- Bypass valve and fittings (£50-£100)

- Initial salt supply (£20-£40)

Basic scale inhibitor (£150-£400 installed):

- Magnetic or electronic unit (£80-£250)

- Installation labour (£50-£100)

- Fittings and connections (£20-£50)

Template Assisted Crystallization (TAC) systems, the most effective scale inhibitor technology, sit in the middle at £400-£800 installed. These cartridge-based systems require more sophisticated installation than basic magnetic units but less plumbing work than full softeners.

Running Costs Over Five Years

Water softeners:

- Salt: £120-£180 annually (three 25kg bags monthly at £7-10 each)

- Water waste: £30-£50 annually (regeneration cycles flush 40-80 litres weekly)

- Electricity: £15-£25 annually (timer and valve operation)

- Resin replacement: £150-£300 every 10-15 years

- Five-year total: £825-£1,275

Scale inhibitors:

- Magnetic/electronic units: £0-£20 annually (electricity only)

- TAC cartridges: £60-£100 annually (replacement media)

- Five-year total: £0-£500

The gap widens in larger households. A family of five uses more water, triggering more frequent softener regeneration cycles. Salt consumption jumps to 5-6 bags monthly (£200-£240 annually), whilst scale inhibitor costs remain fixed.

Energy Savings: Where Softeners Pull Ahead

Scale buildup on heating elements acts as insulation. A 1.6mm layer of limescale increases heating costs by 12%. At 5mm, common in untreated hard water areas after two years, energy consumption rises 25%.

Boiler efficiency measurements in 40 properties across Essex and Kent over 18 months showed distinct patterns. Properties with water softeners maintained 88-92% efficiency. Scale inhibitor installations held at 85-89%. Untreated hard water systems dropped to 72-78%.

Annual heating cost savings:

- Softened water: Saves £180-£240 yearly

- Scale inhibitor protection: Saves £120-£180 yearly

- No treatment: Baseline cost plus potential repair bills

These savings compound. After five years, the softener system pays for itself purely through energy efficiency gains, even before accounting for extended appliance lifespan.

Appliance Longevity: The Hidden Cost Factor

Washing machines in hard water areas fail 3-5 years earlier than identical models in soft water regions. Heating elements corrode, pumps clog, and drum bearings seize from mineral deposits.

Typical premature replacement costs:

- Washing machine: £300-£600

- Dishwasher: £250-£500

- Combi boiler: £2,000-£3,500

- Electric shower: £150-£400

- Immersion heater: £200-£350

A typical household replaces these appliances 30-40% more frequently without water treatment. Proper boiler maintenance extends lifespan, but can't overcome constant scale accumulation.

Water softeners extend appliance life to manufacturer specifications, 10-12 years for washing machines, 15-20 years for boilers. Scale inhibitors deliver 70-80% of this benefit, adding 2-4 years to typical lifespans.

Over 15 years, avoiding one premature boiler replacement (£2,500) and two washing machine replacements (£900) saves £3,400. This dwarfs the initial system investment.

Water Quality and Practical Considerations

Softened water feels different. The slippery sensation comes from soap reacting more efficiently with soft water, you're feeling clean skin, not residue. Some people love it. Others find it unsettling for months.

Sodium content increases slightly. A 250ppm hard water supply adds roughly 50mg of sodium per litre after softening, equivalent to one slice of bread across 20 litres of water. This matters for strict low-sodium diets, but remains negligible for most people.

Scale inhibitors leave water chemistry unchanged. You'll still see some spotting on glassware and shower screens, though significantly less than untreated hard water. The water tastes identical, and the drinking water quality isn't affected.

Regulations require a separate unsoftened tap for drinking water. Installation costs increase £80-£150 to split the supply line. Scale inhibitors treat the entire system without this requirement.

Performance Across Different Water Hardness Levels

UK water hardness zones:

- Soft (0-100 ppm): East Scotland, Wales, Northwest England

- Moderately hard (100-200 ppm): Southwest England, parts of Midlands

- Hard (200-300 ppm): London, Thames Valley, parts of Yorkshire

- Very hard (300+ ppm): East Anglia, Kent, parts of South Coast

Scale inhibitors perform adequately up to 250 ppm. Beyond this threshold, effectiveness drops. TAC systems maintain 75% scale prevention at 300 ppm, but performance declines to 50-60% at 400 ppm.

Water softeners handle any hardness level. The resin capacity determines regeneration frequency, not effectiveness. A properly sized system delivers 0-50 ppm regardless of input hardness.

For properties in London, Essex, Kent, or East Anglia, where hardness regularly exceeds 300 ppm, softeners provide more reliable protection. Moderate hardness areas (150-250 ppm) give scale inhibitors room to perform effectively.

Installation Complexity and Space Requirements

Water softeners require:

- 60cm x 40cm floor space for twin-tank systems

- Access to drainage for regeneration discharge

- Electrical outlet within 2 metres

- Incoming mains pressure above 1.5 bar

- Bypass valve installation on main supply line

This rules out small flats, properties with combination boilers only, and homes with limited utility space. Central heating system upgrades sometimes coincide with softener installation to maximise efficiency gains.

Scale inhibitors require:

- 30cm of straight pipe for magnetic/electronic units

- Mounting space for TAC cartridge housing

- No drainage or electricity (except electronic models)

- No pressure requirements

Installation takes 1-2 hours versus 3-5 hours for softeners. This matters for rental properties where landlord approval depends on minimal disruption.

Maintenance Requirements and Long-Term Reliability

Water softeners need:

- Monthly salt level checks

- Quarterly resin bed cleaning (automated but requires monitoring)

- Annual valve inspection

- Immediate response to regeneration failures

Miss a salt refill, and hard water flows through your system until you notice scale returning. The resin bed continues working temporarily, but capacity drops sharply.

Scale inhibitors operate passively. Magnetic and electronic units need zero maintenance, they work or fail completely, with no gradual decline. TAC cartridges require annual replacement, a 20-minute job costing £60-£100.

Failure rates over 10 years:

- Softener control valves: 8-12% fail

- Softener resin beds: 15-20% need premature replacement

- Electronic scale inhibitors: 5-8% fail

- TAC cartridge systems: 3-5% develop housing leaks

Softener repairs cost £150-£400. Scale inhibitor replacements run £80-£250. Factor these probabilities into lifetime costs.

Environmental Impact Comparison

Water softeners discharge 40-80 litres of brine weekly during regeneration. This sodium-rich water enters sewage systems, not harmful, but not beneficial. Annual water waste reaches 2,000-4,000 litres per household.

Salt production and transport add environmental costs. The UK imports 70% of water softening salt, primarily from Europe and North Africa. Each household consumes 300-400kg annually.

Scale inhibitors use no consumables except TAC cartridges (1-2kg annually). No water waste, no chemical discharge, no transport-intensive supplies.

For environmentally conscious households, scale inhibitors win clearly. The trade-off comes in reduced effectiveness and shorter appliance lifespan, which carries its own environmental cost through premature replacements.

When Scale Inhibitors Make More Sense

Scale inhibitors suit properties where:

- Water hardness stays below 250 ppm

- Space constraints prevent softener installation

- Rental agreements prohibit major plumbing modifications

- Budget limits upfront investment to £300-400

- Environmental concerns outweigh maximum performance

- Household size stays below three people

TAC systems are recommended over magnetic units. The technology has proven effectiveness, whilst magnetic systems show inconsistent results. Spending £400-£600 on TAC beats gambling £150 on magnetic units that might achieve nothing.

When Water Softeners Justify Higher Costs

Water softeners make sense when:

- Water hardness exceeds 250 ppm

- Household size reaches four or more people

- You're replacing or upgrading heating equipment simultaneously

- Space and drainage access exist

- You plan to stay in the property 7+ years

- Previous scale problems damaged expensive appliances

The break-even point sits around year six for most households. Energy savings, extended appliance life, and reduced cleaning product use offset higher purchase and running costs. Beyond this point, softeners deliver net positive returns.

Combination Approaches: Whole-House and Point-of-Use

Some properties benefit from hybrid systems. A scale inhibitor treats the main supply line, protecting pipes and the boiler. A compact softener treats only the hot water cylinder feed, providing soft water to bathrooms and kitchen.

Benefits include:

- Lower salt consumption (40-50% reduction)

- Reduced water waste (60% reduction)

- Soft water where it matters most

- Scale protection throughout the system

This configuration has been installed in 15-20% of properties where full softening seems excessive but scale inhibitors alone prove insufficient. It works particularly well in four-bedroom homes with hardness levels of 250-300 ppm.

Making the Decision: A Framework

Calculate your five-year total cost of ownership:

Water softener:

- Purchase and installation: £800-£1,500

- Five-year running costs: £825-£1,275

- Energy savings: -£900 to -£1,200

- Avoided appliance replacement: -£500 to -£1,000

- Net cost: £25-£575 (or net savings of £100-£500)

Scale inhibitor:

- Purchase and installation: £400-£800

- Five-year running costs: £0-£500

- Energy savings: -£600 to -£900

- Avoided appliance replacement: -£300 to -£600

- Net cost: £0-£400 (or net savings of £100-£500)

The numbers converge in moderate hardness areas with smaller households. They diverge dramatically in very hard water regions with large families, where softeners deliver £1,000+ net savings over five years.

Water softeners cost 2-3 times more upfront than scale inhibitors but deliver complete hardness removal and maximum appliance protection. In very hard water areas (300+ ppm), the energy savings and extended equipment lifespan justify higher costs within 5-7 years.

Scale inhibitors provide 70-85% protection at 25-40% of the cost. They suit moderate hardness levels (150-250 ppm), smaller households, and properties with space or budget constraints. TAC systems outperform magnetic units consistently, spend the extra £200-300 for proven technology.

Your water hardness level determines which system makes financial sense. Test your water (free kits from most suppliers) before deciding. Below 200 ppm, scale inhibitors deliver adequate protection. Above 300 ppm, softeners prevent expensive problems that inhibitors can't fully address.

The best decision isn't always the cheapest upfront option. Calculate lifetime costs including energy, maintenance, and avoided repairs. For most UK households in hard water regions, water softeners pay for themselves whilst delivering measurably better results. In moderate hardness areas, scale inhibitors provide sufficient protection without the complexity and running costs of full softening systems.

Heating and Plumbing World supplies water treatment solutions and plumbing components from leading manufacturers including Grundfos pumps, Gledhill cylinders, Kingspan hot water systems, and Altecnic expansion vessels. For technical guidance on selecting the right water treatment system for your property, get in touch with the team.

-

-