Sealing Leaky Pipe Joints with Plumber's Tape

Dripping pipes are more than just an annoyance - they waste water, increase utility bills, and can cause significant damage to homes if left unaddressed. Many homeowners face leaky pipe joints in kitchens, bathrooms, and heating systems, often unsure how to tackle the problem effectively. The good news is that sealing leaky pipe connections doesn't always require expensive professional intervention. With the right technique and materials, particularly plumber's tape, many common joint leaks can be resolved quickly and reliably.

Heating and Plumbing World offers a comprehensive range of plumbing supplies and heating components to help homeowners and professionals maintain leak-free systems. This guide explains how to use thread seal tape properly to stop leaks at pipe joints, when this method works best, and when professional assistance may be necessary.

What Is Plumber's Tape and How Does It Work?

Understanding PTFE Tape

Plumber's tape, also known as PTFE tape or thread seal tape, is a thin film made from polytetrafluoroethylene. This material has unique properties that make it ideal for creating watertight seals at threaded pipe connections. When wrapped around pipe threads, the tape fills microscopic gaps and irregularities, preventing water from seeping through the joint.

The tape comes in different colours for specific applications: standard white tape for water lines, yellow tape rated for gas lines, and pink tape for water systems. Each type has different thickness and density specifications designed for particular pressure ratings and pipe materials.

When to Use Plumber's Tape

Thread seal tape works best on threaded pipe connections where metal surfaces screw together. These include tap connectors, radiator valves, showerhead fittings, and various joints throughout plumbing and heating systems. The tape creates a seal by filling the spiral gap between male and female threads, preventing fluid escape while maintaining the mechanical strength of the threaded connection.

Sealing leaky pipe threads with PTFE tape is particularly effective for preventative maintenance during new installations or when replacing components like boiler spares or radiator valves. Applying tape correctly during initial assembly often prevents leaks from developing.

Identifying Leaky Pipe Joints That Need Sealing

Common Signs of Pipe Joint Leaks

Before attempting repairs, confirm that threaded joints are actually the leak source. Common indicators include visible water droplets forming at connection points, moisture or water stains on pipes or surrounding surfaces, gradually decreasing water pressure, and unusual hissing or dripping sounds near pipe fittings.

Check joints carefully when the system is pressurised - many small leaks only become apparent when water flows through the pipes. For heating systems, examine radiator valve connections and boiler pipe joints when the system is hot and pressurised, as thermal expansion can reveal otherwise hidden leaks.

Types of Joints Suitable for Tape Application

Plumber's tape works exclusively on threaded connections. These joints feature spiral grooves that allow two pipe sections or fittings to screw together. The tape is appropriate for metal-to-metal threaded joints, including brass, copper, steel, and galvanised iron connections.

However, sealing leaky pipe joints with tape won't work for compression fittings, soldered joints, or push-fit connections - these require different repair methods. Attempting to use PTFE tape on non-threaded connections wastes time and materials without solving the leak problem.

Step-by-Step Guide to Sealing Leaky Pipe Joints

Preparation and Safety

Before beginning any sealing leaky pipe repair, turn off the water supply to the affected section. For heating system repairs, switch off the boiler and allow the system to cool completely. Locate the isolation valve for the specific pipe section if possible, or shut off the main stopcock if necessary.

Drain water from the pipes by opening taps at low points in the system. This prevents water spillage when disconnecting joints and ensures dry threads for proper tape adhesion. Clean the pipe threads thoroughly with a wire brush or cloth to remove old tape residue, corrosion, or debris that could interfere with the new seal.

Proper Tape Application Technique

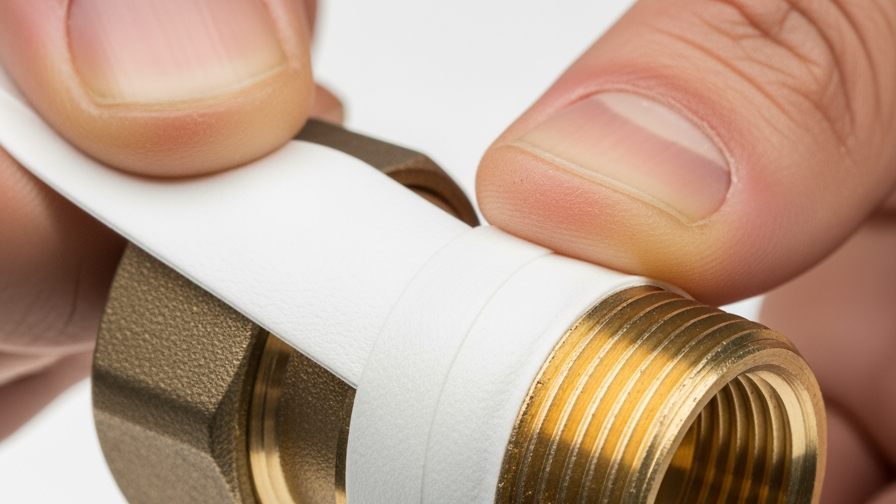

Hold the pipe fitting so the thread end faces you. Starting at the second thread from the end (not the very first thread), wrap plumber's tape clockwise around the threads. This direction is crucial - clockwise wrapping prevents the tape from unravelling when screwing the joint together.

Apply steady tension while wrapping, stretching the tape slightly so it conforms to the thread profile. Overlap each wrap by approximately half the tape width, creating three to five complete wraps around the threads. More wraps aren't necessarily better - excessive tape can actually prevent threads from engaging properly and create gaps.

Tear the tape cleanly and press the end firmly against the threads. The finished application should show tape completely covering the threads without bunching or gaps. When done correctly, you should still be able to see the thread profile through the translucent tape.

Reassembly and Testing

Screw the joint together by hand initially, ensuring threads engage correctly without cross-threading. The joint should turn relatively easily at first. Once hand-tight, use appropriate tools - such as wrenches or adjustable spanners - to tighten further. Most threaded joints require one to two additional turns beyond hand-tight to achieve proper seal compression.

Avoid over-tightening, which can damage threads or crack fittings. For brass fittings in particular, excessive force easily causes cracks. Restore water pressure gradually and check the joint for leaks. If minor seepage appears initially, slight additional tightening often resolves it. Persistent leaks indicate improper tape application or damaged threads requiring joint disassembly and re-taping.

Different Scenarios for Using Plumber's Tape

Kitchen and Bathroom Applications

Kitchen and bathroom plumbing systems frequently require thread seal tape for tap connectors, flexible hose connections to mixer taps, and showerhead attachments. These joints experience regular use and movement, making proper initial sealing essential for long-term leak prevention.

Under-sink connections, including waste trap joints and supply line connectors, benefit from careful tape application. Ensure compression fittings - which use rubber washers rather than thread sealing - are not confused with threaded connections requiring tape.

Central Heating System Repairs

Central heating systems contain numerous threaded joints at radiator valve connections, boiler pipe connections, and system component interfaces. These joints operate under pressure and elevated temperatures, making secure seals critical for system efficiency and safety.

When working on heating systems, particularly older installations, inspect expansion vessels and pressure relief valves for threaded connections that may need resealing. If replacing components like radiator valves or pressure sensors, apply fresh tape to all threaded connections during reassembly.

Emergency Temporary Fixes

Plumber's tape provides effective temporary solutions for minor leaks discovered outside normal working hours or when replacement parts aren't immediately available. While properly applied tape can last for years in appropriate applications, treating some repairs as temporary allows time to assess whether joint replacement or professional evaluation is warranted.

For persistent problems or leaks in critical system areas, particularly those involving gas lines or high-pressure water supplies, contact professional help rather than relying solely on temporary tape repairs. Knowing the limitations of DIY solutions prevents minor issues from becoming major problems.

Common Mistakes to Avoid

Application Errors

The most common mistake when sealing leaky pipe connections is wrapping tape anti-clockwise (counter-clockwise), which causes the tape to unwind when screwing joints together. Always wrap clockwise when viewing the thread end.

Using insufficient tape - typically fewer than three wraps - fails to fill thread gaps adequately, allowing leaks to persist. Conversely, applying too many wraps (more than six) can prevent threads from engaging properly, actually increasing leak risk. Find the balance with three to five firm, overlapping wraps.

Never apply PTFE tape over damaged, corroded, or worn threads. The tape cannot compensate for missing thread material or deep corrosion. Such joints require thread repair, replacement, or professional evaluation. Similarly, don't combine thread seal tape with pipe joint compound (also called pipe dope) unless specifically required by the fitting manufacturer - mixing sealing methods often reduces effectiveness rather than improving it.

Wrong Situations for Tape Use

Thread seal tape has pressure and temperature limitations. Standard white tape suits typical household water systems but may fail in high-pressure applications or extremely hot environments. Consult tape specifications and select appropriate grades for specific applications.

Never use standard white plumber's tape on gas line connections - this application requires special yellow tape rated and certified for gas service. Using incorrect tape types on gas fittings creates serious safety hazards. Similarly, compression fittings, flare fittings, and push-fit connections don't require or benefit from thread seal tape - these joint types use entirely different sealing mechanisms.

When Professional Help Is Needed

Signs the Problem Is Beyond DIY

If leaks persist after correctly applying fresh plumber's tape, the joint likely has deeper problems. Damaged threads, cracked fittings, or corrosion may require joint replacement rather than resealing. Attempting repeated repairs on faulty joints wastes time and risks causing additional damage.

Major system leaks, particularly those from non-threaded joints or pipe bodies rather than connections, require professional plumbing assessment. Gas line leaks, identified by distinctive smell or hissing sounds, demand immediate professional attention - never attempt DIY gas pipe repairs.

For complex heating system issues, particularly those involving boiler components or sealed system pressurisation, professional expertise ensures safe and compliant repairs. Quality boiler replacement parts and correct installation techniques prevent recurring problems and maintain system efficiency.

Preventative Maintenance

Regular inspection of pipe joints throughout plumbing and heating systems helps identify potential leaks before they cause damage. Check visible threaded connections periodically for moisture, corrosion, or loosening. Early intervention - including preventative resealing during system maintenance - proves far simpler than emergency repairs.

Annual professional servicing of heating systems includes checking all critical joints and connections. Gas Safe-registered engineers inspect and maintain boiler pipe connections, ensuring safety and compliance. This professional oversight complements homeowner maintenance efforts and identifies issues requiring specialist attention.

Conclusion

Mastering the proper technique for sealing leaky pipe joints with plumber's tape empowers homeowners to tackle common plumbing problems confidently and cost-effectively. By understanding when and how to apply PTFE tape correctly - wrapping clockwise, using appropriate wrap counts, and ensuring clean threads - most threaded joint leaks can be resolved successfully without professional assistance.

However, recognising the limitations of thread seal tape and knowing when situations require professional expertise remains equally important. Damaged threads, high-pressure applications, gas line connections, and persistent leaks despite correct tape application all signal the need for professional evaluation.

For quality plumbing components, heating system parts, and expert advice on maintaining leak-free systems, contact us for assistance with your plumbing and heating needs.

-

-