Shower Pump Accumulators: Reducing Cycling and Noise

Shower pumps that cycle on and off every few seconds create more than just an annoyance; they waste energy, shorten pump lifespan, and signal a system working harder than it should. A pump accumulator tank solves this by storing pressurised water, reducing the frequency of pump activation by up to 80% in typical residential installations.

The constant clicking and motor noise from a cycling pump stems from pressure fluctuations. Every time you adjust a tap slightly or a toilet fill valve closes, the pump detects the pressure drop and fires up again. This happens because most shower pumps operate on pressure switches set to narrow bands, typically activating at 1.5 bar and cutting out at 3 bar. Without a buffer, even minor water movement triggers the cycle.

How Accumulator Vessels Work

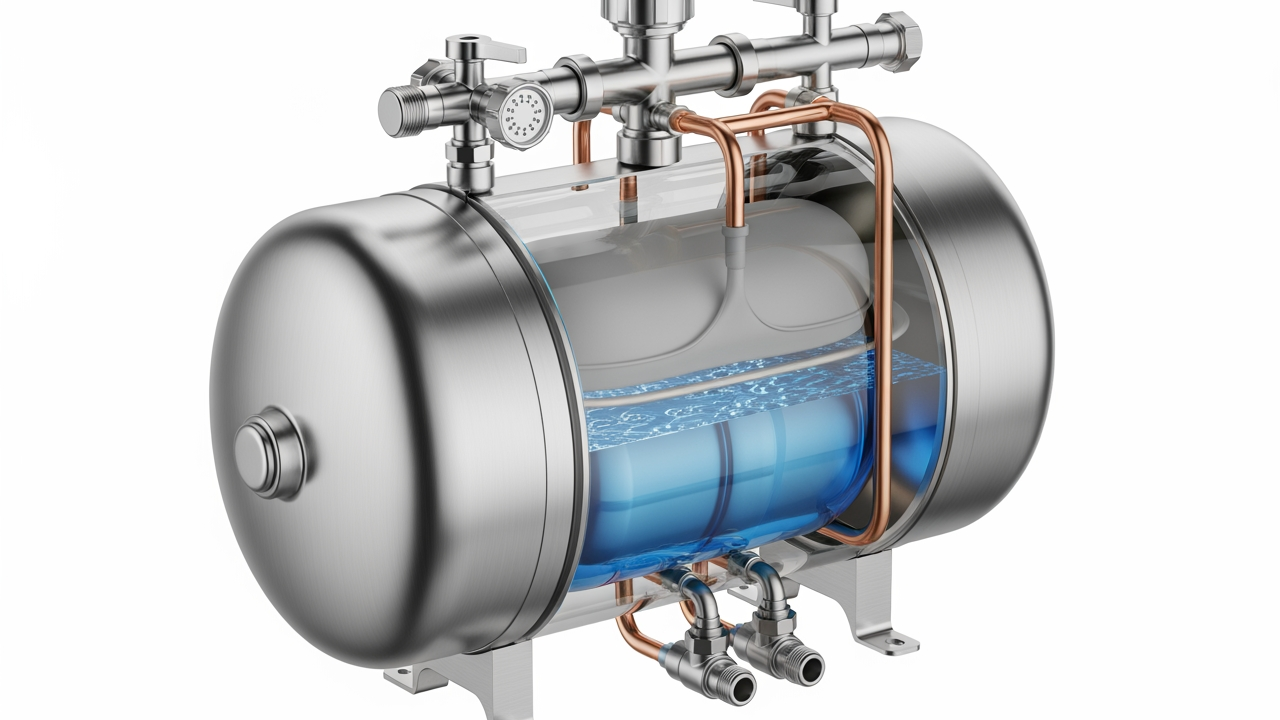

An accumulator vessel contains a flexible diaphragm or bladder that separates pressurised water from compressed air. When the pump runs, it fills the water side whilst compressing the air chamber. This stored pressure maintains water flow even after the pump stops, creating a buffer that handles small demands without reactivating the motor.

The air pressure pre-charge typically sits at 70-80% of the pump's cut-in pressure. For a pump that starts at 1.5 bar, you'd pre-charge the accumulator to roughly 1.1 bar. This ensures the diaphragm positions correctly and maximises usable water storage. A 2-litre accumulator in a standard domestic system can reduce pump starts from 15-20 per shower down to 2-3.

The physics are straightforward: water barely compresses, but air does. When you open a tap, the compressed air pushes water out of the vessel before pressure drops enough to trigger the pump. The larger the vessel and the greater the pressure differential between cut-in and cut-out, the more water it delivers per cycle.

Sizing Accumulators for Different Applications

A 2-litre accumulator suits most single-shower installations with pumps rated between 1.5 and 3 bar. This size provides enough buffer for typical flow variations, adjusting temperature, someone flushing a toilet elsewhere in the house, or brief pauses during showering.

Multi-bathroom homes need a larger capacity. A 5-litre vessel works better when two showers might run simultaneously, or when the system serves three or more outlets. 8-litre shower pump accumulators work well in larger properties where pump cycling becomes excessive despite properly sized pumps, particularly in systems with multiple bathrooms across different floors.

The calculation isn't just about vessel size; the pump's pressure differential matters equally. A pump with a 1-bar differential (say, 1.5 to 2.5 bar) delivers less usable water per cycle than one with a 1.5-bar differential (1.5 to 3 bar). The formula involves the vessel volume, pre-charge pressure, and operating pressures, but practical experience shows that doubling vessel size doesn't double performance; you typically gain 60-70% more capacity.

Commercial applications like small hotels or gym facilities require purpose-built accumulator sizing. A 24-litre vessel paired with a 4-bar pump can serve 4-6 shower heads with minimal cycling, but only when the pump flow rate matches peak demand. Undersized pumps cause cycling regardless of accumulator size because the vessel depletes faster than the pump can refill it.

Installation Requirements and Positioning

Mount the accumulator vertically with the connection pointing down. This orientation prevents air from becoming trapped in the water chamber and ensures the diaphragm moves freely through its full range. Horizontal mounting works but reduces effective capacity by 15-20% because the diaphragm can't expand evenly.

Position the vessel as close to the pump outlet as practical, ideally within 500mm. This minimises the dead volume of water in connecting pipes that must move before the accumulator responds. Every metre of 22mm pipe between pump and accumulator adds roughly 380ml of incompressible water that provides no buffering effect.

The connection size matters. Most domestic accumulators use 1/2" or 3/4" BSP fittings. Match this to your system's pipe diameter; undersizing creates a restriction that defeats the purpose. A 22mm system (roughly 3/4") should connect to a 3/4" accumulator port. Reducers add turbulence and pressure loss. Polypipe supplies barrier pipe suitable for pump installations, whilst quality fittings ensure leak-free connections.

Support the vessel independently rather than relying on pipe connections to hold its weight. A 5-litre accumulator filled with water weighs around 5.5kg plus the vessel itself. Pipe joints weren't designed as structural supports, and vibration from pump operation can work fittings loose over time. Simple brackets or a shelf beneath the vessel prevent this.

Pre-charging and Pressure Adjustment

New accumulators arrive with factory pre-charge, but this rarely matches your specific pump settings. Check the pressure using a standard tyre gauge on the Schrader valve, usually located on top or side of the vessel. Release or add air to achieve 70-80% of your pump's cut-in pressure.

For a pump that activates at 2 bar, target 1.5 bar in the pump accumulator tank. This pre-charge must be checked with the system depressurised and the pump off. Water-side pressure affects the reading, giving false high values if you measure whilst the system is pressurised.

Under-inflated accumulators feel "spongy" and provide minimal benefit. The diaphragm sits mostly on the air side, leaving little room for water storage. Over-inflation does the opposite; the diaphragm stays compressed against the water inlet, and the vessel can't accept water until system pressure exceeds the air charge. This causes the pump to cycle normally until pressure builds high enough, then suddenly the accumulator engages. The result feels erratic.

Pressure naturally drops over time as air permeates through the diaphragm, typically 0.1 to 0.2 bar per year. Annual checks take two minutes and prevent the gradual return of cycling problems. If pressure drops faster, the diaphragm likely has a small leak and needs replacement.

Noise Reduction Beyond Cycling

Accumulators dampen water hammer, the sharp bang when valves close suddenly. The compressible air cushion absorbs the pressure spike that would otherwise slam back through the pipes. This proves especially valuable with modern quarter-turn ceramic disc taps that close almost instantaneously.

Pump vibration transmits through rigid pipe connections into the building structure, turning walls into soundboards. Whilst the accumulator doesn't directly reduce pump vibration, fewer starts mean less total noise exposure. A pump running for 30 seconds once per shower instead of cycling 15 times for 2 seconds each produces the same total runtime but concentrates it into a single, less intrusive period.

The pressure buffer also smooths flow variations. Without an accumulator, the flow rate drops noticeably as the pump approaches its cut-out pressure, then surges when it restarts. This manifests as temperature fluctuations in thermostatic showers or pulsing flow in standard mixers. The accumulator maintains more consistent pressure between pump cycles, creating steadier flow.

Common Installation Mistakes

Installing the accumulator on the pump inlet rather than the outlet ranks as the most frequent error. The inlet side operates under negative pressure (suction), where the accumulator provides no benefit. It must sit on the pressurised discharge side to store and release water effectively.

Forgetting the isolation valve creates maintenance headaches. Install a valve between the pump and accumulator so you can isolate and depressurise the vessel without draining the entire system. This allows pressure checks and eventual diaphragm replacement without major disruption.

Some installers add accumulators to systems with failing pumps, hoping to cure problems that stem from worn impellers or faulty pressure switches. An accumulator can't fix a pump that doesn't build proper pressure or one with a malfunctioning switch. Address pump issues first, then add the accumulator to optimise performance. Grundfos and Lowara manufacture reliable shower pumps designed for long service life.

Mixing incompatible pressure ratings causes problems. If your pump operates at 3 bar but you install an accumulator rated for 2 bar maximum, the diaphragm fails prematurely. Always match or exceed the pump's maximum pressure rating. Most domestic accumulators handle 8-10 bar, well above typical shower pump pressures.

Maintenance and Lifespan

Check pre-charge pressure annually. This takes less time than changing a tap washer and prevents performance degradation. Keep a log of readings; consistent pressure suggests a healthy diaphragm, whilst declining pressure indicates deterioration.

Diaphragms typically last 5-8 years in residential applications with proper pre-charge maintenance. Hard water doesn't affect the diaphragm directly since it operates on the air side, but sediment in the water chamber can prevent full movement. If your system has no filtration and significant sediment, consider adding a strainer before the pump.

Replacement diaphragms cost £15-30 for most domestic accumulators and take 15 minutes to fit. This beats replacing the entire vessel at £60-120. Some manufacturers use proprietary designs that require complete replacement, so check availability before purchase.

External corrosion affects steel vessels in damp locations. Most modern accumulators use stainless steel or have protective coatings, but older painted steel vessels deteriorate in humid pump cupboards. Surface rust doesn't immediately compromise function, but if corrosion pits through the shell, the vessel must be replaced; there's no reliable repair.

When Accumulators Don't Solve the Problem

If cycling continues after proper accumulator installation, the pump likely oversizes the application. A 3-bar twin-impeller pump serving a single shower with good mains pressure will cycle because it reaches cut-out pressure almost immediately. The accumulator helps, but right-sizing the pump solves it completely.

Pressure switch differential that's too narrow causes excessive cycling regardless of accumulator size. Some pumps allow adjustment of the cut-in and cut-out points. Widening the differential from 1 bar to 1.5 bar significantly improves performance. Check the pump manual; many installers don't realise this adjustment exists.

Air locks in the system mimic cycling symptoms but stem from trapped air pockets that compress and expand, creating pressure fluctuations that the pump responds to. Bleed the system properly before assuming the accumulator has failed or been sized incorrectly.

Leaking valves or toilet fill mechanisms create continuous small demands that eventually trigger the pump. An accumulator extends the time between cycles, but can't overcome constant water loss. A toilet flapper that leaks 10ml per minute will empty a 2-litre accumulator in just over three hours, causing the pump to run periodically even when no taps are open.

Conclusion

Shower pump accumulators transform a shower pump system from an intrusive, energy-wasting setup into a quiet, efficient installation. The 2-litre size handles most single-shower applications, whilst larger homes benefit from 5-8 litre capacity. Proper sizing, correct positioning on the discharge side, and maintaining the right pre-charge pressure deliver the full benefits, reduced cycling, lower noise, smoother flow, and extended pump life.

The installation takes 30-45 minutes and requires basic plumbing skills: a tee fitting in the pump discharge line, appropriate pipe connections, and a few minutes with a tyre gauge to set pre-charge. The improvement is immediate and measurable. Systems that cycled 15-20 times per shower drop to 2-3 cycles, noise decreases proportionally, and the pump experiences far less wear from constant starting.

Annual pressure checks keep the system performing optimally, and when the diaphragm eventually needs replacement after 5-8 years, the modest cost and simple procedure make it a routine maintenance item rather than a major repair. For anyone dealing with a cycling, noisy shower pump, a pump accumulator tank delivers results that justify its cost several times over through energy savings and extended equipment life alone; the peace and quiet comes as a bonus.

Heating and Plumbing World stocks shower pump accumulators and compatible components from leading manufacturers. For technical advice on selecting the right accumulator for your pump system, contact us to discuss your specific requirements.

-

-