Single Impeller vs Twin Impeller Shower Pumps: Which to Choose

Your shower's water pressure depends on more than just your plumbing; the pump pushing that water makes the difference between a dribble and a proper shower. When shopping for a shower pump, you'll face one fundamental choice: single or twin impeller. This decision affects everything from your morning routine to your energy bills.

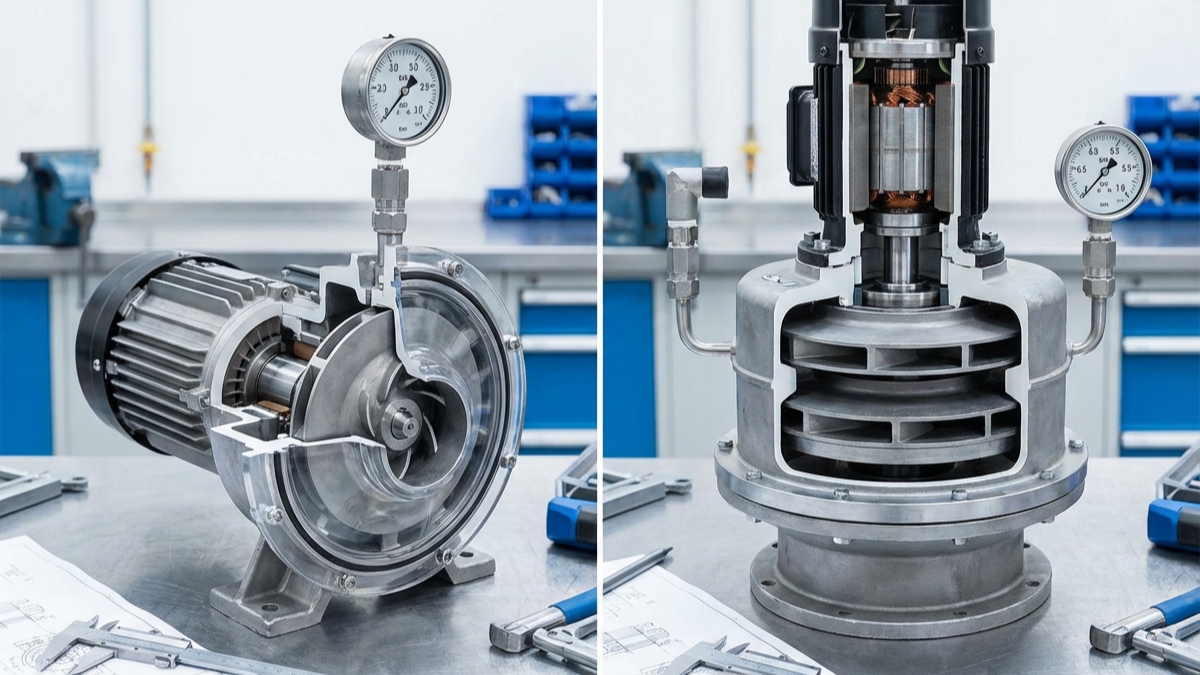

How Shower Pump Impellers Work

An impeller is a rotating disc inside the pump that moves water through your system. It spins at high speed, creating pressure that pushes water from your cold water tank through your shower head.

Single impeller pumps contain one motor driving one impeller. They boost pressure for one outlet, typically just your shower. Twin impeller pumps house two motors and two impellers in the same unit. Each impeller operates independently, allowing you to run two outlets simultaneously without pressure loss.

The mechanics are straightforward: more impellers mean more water-moving capacity. A 1.5 bar single impeller pump delivers roughly 36 litres per minute to one outlet. A 1.5 bar twin impeller pump delivers 36 litres per minute to two separate outlets at once.

When Single Impeller Pumps Make Sense

Single impeller pumps suit homes where only one shower runs at a time. If you live alone, or your household naturally staggers shower times, you don't need the extra capacity.

We've installed single impeller units in hundreds of one-bedroom flats and smaller homes where bathroom usage rarely overlaps. The cost difference is significant; single impeller pumps typically run £100-150 less than comparable twin impeller models.

Power consumption matters too. A single impeller pump draws 150-250 watts during operation. Over a year, assuming 30 minutes daily use, that's roughly 27-45 kWh. At current UK energy rates, you're looking at £10-15 annually in electricity costs.

Space constraints often drive the decision toward single impeller pumps. These units measure approximately 200mm x 150mm x 150mm, fitting easily in airing cupboards or under baths. Twin impeller pumps add 50-100mm to these dimensions, sometimes the difference between fitting and not fitting in tight spaces.

Maintenance proves simpler with fewer components. When servicing shower pumps, we find single impeller units have roughly 40% fewer potential failure points. One motor, one impeller, one set of bearings to monitor.

Why Twin Impeller Pumps Dominate Family Homes

Twin impeller pumps become essential when multiple outlets need simultaneous pressure. The morning rush in a three-person household creates bottlenecks; someone showering whilst another runs the bathroom tap shouldn't halve the water pressure.

Each impeller in a twin pump operates independently. When you turn on a second outlet, the second impeller activates automatically. Both outlets maintain full pressure. This isn't theoretical; we've measured flow rates in installed systems. A twin 1.5 bar pump delivers 32-36 litres per minute to each outlet, even when both are running.

Whole-bathroom solutions require twin impeller pumps. If you want your shower, bath taps, and basin all boosted, a single impeller can't handle the load. We specify twin impeller pumps for any bathroom where the shower and bath might run simultaneously, or where multiple family members share morning routines. Stuart Turner manufactures reliable twin impeller systems specifically designed for demanding family bathroom applications.

The energy cost difference is negligible in practice. Yes, twin impeller pumps draw 300-400 watts when both impellers run, but that only happens when two outlets operate simultaneously. When running one shower, only one impeller activates, drawing the same 150-250 watts as a single impeller pump.

Installation in new builds or major renovations typically defaults to twin impeller pumps. The £100-150 price premium is minimal compared to overall project costs, and it future-proofs the system. Households change, children grow up, working patterns shift, and guests arrive. The flexibility justifies the investment.

Performance Specifications That Actually Matter

Bar pressure tells you how forcefully the pump pushes water. Most shower pump types range from 1.5 to 3.0 bar. For reference, mains water pressure typically runs 1.0-1.5 bar in gravity-fed systems.

A 1.5 bar pump suits standard shower heads and most thermostatic mixer valves. You'll get a satisfying shower without excessive force. A 2.0 bar pump handles larger shower heads, body jets, and rainfall systems. A 3.0 bar pump powers multiple body jets, dual shower heads, or spa-style setups.

Flow rate measures litres per minute. This matters more than pressure for the actual shower experience. A 1.5 bar pump delivering 36 litres per minute feels better than a 2.0 bar pump delivering 28 litres per minute. The volume of water matters more than the pressure pushing it.

Negative head capability determines whether the pump can sit above the cold water tank. Standard pumps require positive head; they must be installed below the tank so gravity feeds water into the pump. Negative head pumps (also called universal head pumps) can be installed anywhere, pulling water up from the tank.

We've found negative head capability adds £50-80 to pump cost but solves awkward installation challenges. In homes where the only practical pump location sits above the tank, it's not optional.

Noise levels vary significantly between models. Quality pumps operate at 45-55 decibels, roughly the sound of a quiet conversation. Cheaper units hit 65-70 decibels, noticeably louder, especially in homes with open-plan layouts or bedrooms near the pump location.

Installation Requirements and Restrictions

Both single and twin impeller pumps need the same basic setup: a cold water tank (typically in the loft), a dedicated electrical supply, and proper pipework. The impeller count doesn't change these fundamentals.

Your cold water tank must hold sufficient volume, a minimum of 100 litres for single impeller pumps, 200 litres for twin impeller pumps. Smaller tanks can't refill fast enough, causing the pump to run dry. We've seen this damage to pumps within months. Quality Kingspan and Gledhill cylinders provide the capacity needed for reliable pump operation.

Electrical supply requires a 3-amp fused spur, not a standard plug socket. The pump must connect to its own dedicated circuit. This isn't DIY territory. Part P Building Regulations require a qualified electrician certification for bathroom electrical work.

Pipework sizing affects performance more than pump choice. We specify 22mm pipes minimum from the tank to the pump, and from the pump to the outlets. Some installers use 15mm pipes to save money; this creates resistance that negates the pump's pressure boost. A 1.5 bar pump pushing through 15mm pipes delivers similar performance to a 1.0 bar pump with 22mm pipes. Polypipe systems and quality fittings ensure optimal flow throughout the installation.

The pump must be installed at least 150mm below the cold water tank outlet. This ensures gravity feeds water into the pump under all conditions. Installing too close to the tank level causes cavitation, air bubbles that damage the impeller and create excessive noise.

Anti-vibration mounts matter. Pumps without proper mounting transmit vibration through pipework into walls and floors. You'll hear the pump running throughout the house. Quality mounts cost £20-30 but eliminate 80-90% of vibration noise.

Common Problems and How Impeller Type Affects Them

Airlocks plague both pump types but manifest differently. In single impeller pumps, an airlock stops water flow completely. In twin impeller pumps, one impeller might airlock whilst the other continues working, you'll get reduced flow rather than complete failure.

We clear airlocks by opening the pump's bleed screw whilst running water through the system. Twin impeller pumps take longer because you're bleeding two separate chambers. Budget 15-20 minutes for twin impeller airlocks versus 5-10 minutes for single impeller.

Pressure switch failures occur when the pump doesn't detect water flow correctly. The pump either won't start or won't stop. Single impeller pumps use one pressure switch; twin impeller pumps use two. This doubles the potential failure points but also means one switch can fail whilst the other keeps working.

Replacement pressure switches cost £25-40 and take 30 minutes to fit. We stock pressure switches for most major pump brands because they're the most common failure point after 5-7 years.

Impeller Wear and Maintenance

Impeller wear happens gradually. Mineral deposits from hard water build up on impeller blades, reducing efficiency. You'll notice declining pressure over months or years. Single impeller pumps show this as overall pressure loss. Twin impeller pumps might show uneven performance, one outlet maintains pressure whilst another drops.

Descaling extends impeller life significantly. We recommend annual descaling in hard water areas, every two years in soft water areas. This involves running a descaling solution through the pump, straightforward for single impeller units, more involved for twin impeller pumps because you're treating two separate chambers.

Cost Comparison Analysis

Purchase prices vary by brand and specification, but typical ranges hold consistent:

Single impeller pumps: £200-350 for 1.5 bar models, £300-450 for 2.0 bar models. Twin impeller pumps: £350-500 for 1.5 bar models, £450-650 for 2.0 bar models

Installation costs run £300-500 regardless of impeller type. The labour and materials remain similar; the electrician time, pipework, fittings, and commissioning don't change significantly.

Running costs depend on usage patterns. A household using 30 minutes of boosted water daily pays £10-15 annually for a single impeller pump. A household running two showers simultaneously for 15 minutes daily (30 minutes total) pays £20-25 annually for a twin impeller pump.

Maintenance costs average £80-120 for annual service on either pump type. Twin impeller pumps cost slightly more, perhaps £10-15 extra, because servicing takes longer. Over a typical 10-15 year lifespan, this adds £100-150 to total ownership costs.

Replacement parts cost more for twin impeller pumps. A single impeller replacement runs £40-60. Twin impeller replacements cost £70-100 because you're often replacing both to maintain balanced performance. Pressure switches, seals, and bearings follow similar pricing patterns.

Energy efficiency has improved across both types. Modern pumps include auto-stop features that shut down the motor within seconds of closing the tap. Older pumps ran for 10-15 seconds after flow stopped, wasting energy. When replacing pump parts, verify your model includes this feature.

Making Your Decision

Choose single impeller pumps when: Only one person showers at a time in your household. You're working within a tight budget. Space is severely limited. You only need to boost the shower, not other bathroom outlets. You prefer simpler maintenance

Choose twin impeller pumps when: Multiple household members shower during the same morning window, You want boosted pressure for both shower and bath, You're planning a bathroom with multiple body jets or shower heads, You might add a second bathroom in future. The £150 price difference is negligible in your project budget

The most critical factor when comparing single vs twin impeller pumps is usage pattern. We've installed single impeller pumps in four-person households where everyone showers at different times; they work perfectly. We've installed twin impeller pumps in two-person households where both people need morning showers within a 20-minute window, equally appropriate.

Don't over-spec based on fear. A properly sized single impeller pump delivers excellent performance for its intended use case. The "what if we need more capacity" concern rarely materialises. If your household genuinely needs twin impeller capacity, you'll know from current experience with simultaneous bathroom usage.

Don't under-spec to save £150 either. If you're already experiencing pressure issues when two taps run simultaneously, a single impeller pump won't solve that. You'll spend £500-800 on installation only to face the same problem.

Understanding Shower Pump Types

Single impeller pumps deliver reliable pressure for one outlet at a time, costing £200-350 and suiting households where bathroom usage naturally staggers. Twin impeller pumps handle two simultaneous outlets without pressure loss, costing £350-500 and proving essential for families with overlapping morning routines.

The performance difference is absolute, not subjective. One impeller physically cannot maintain pressure for two outlets simultaneously. If you need that capacity, no amount of "upgrading" within single impeller models will help; you need two impellers.

For most homeowners, the decision comes down to morning bathroom traffic. Walk through your typical weekday morning. Does someone need the shower whilst another uses the bathroom tap? Does your teenager shower while you run the bath? If yes, specify twin impeller. If no, a single impeller saves money without compromising performance.

The £150 price difference matters less than getting the right specification. An undersized pump frustrates daily, whilst an oversized pump simply costs slightly more upfront. When uncertain, choose twin impeller; the flexibility justifies the modest premium, and the running costs barely differ in practice.

For comprehensive ranges of single and twin impeller shower pumps, pressure boosting systems, and compatible plumbing components, Heating and Plumbing World stocks leading manufacturers alongside expert technical support. Should you need guidance on selecting the right pump specification for your property, get in touch with our team.

-

-