Soil Stacks vs Waste Pipes: Understanding the Difference

Your home's drainage system relies on two distinct types of pipes that work together but serve different purposes. Soil stacks handle waste from toilets, while waste pipes carry water from sinks, baths, and showers. Mix them up during installation or repair, and you'll face blocked drains, foul odours, and potentially serious building regulation violations.

What Makes Soil Stacks Different

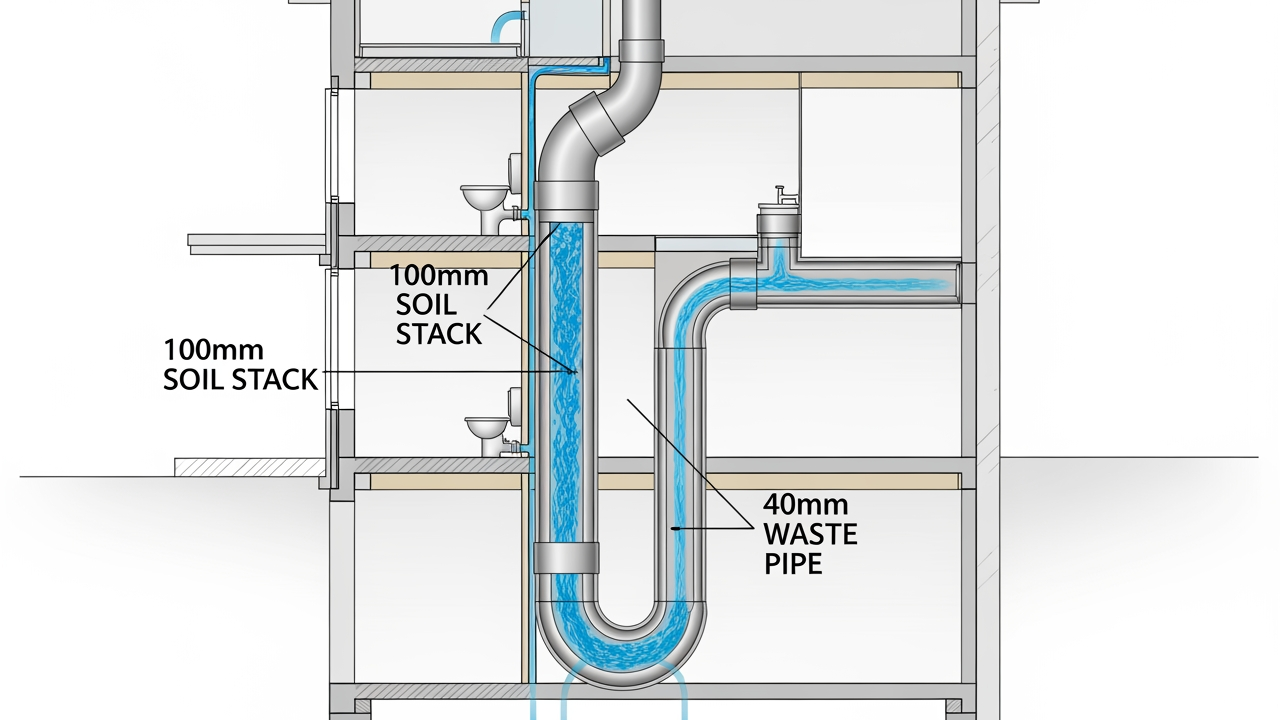

Soil stacks are vertical pipes that transport toilet waste, known as "black water", from your bathroom to the underground drainage system. These pipes run from ground level up through the building and extend above the roofline to create proper ventilation.

The diameter matters significantly. Soil stacks typically measure 100mm (4 inches) in diameter, sized to handle solid waste and toilet paper without blockages. This width also accommodates the volume of water flushed from toilets, which can reach 6-9 litres per flush in modern systems.

Ventilation sits at the core of soil stack design. The pipe extends above the roof to create an air admittance valve effect, allowing air into the system as waste flows down. Without this ventilation, the rushing water would create a vacuum that sucks water from U-bends and P-traps throughout your home, eliminating the water seal that prevents sewer gases from entering living spaces.

How Waste Pipes Function Differently

Waste pipes carry "grey water" from baths, showers, washing machines, kitchen sinks, and bathroom basins. These pipes transport water containing soap, detergent, food particles, and hair, but no toilet waste.

The diameter runs smaller, typically 32mm-50mm, depending on the fixture. A bathroom basin might connect to a 32mm waste pipe, while a kitchen sink requiresa 40mm pipe to handle food waste and grease. Shower traps usually connect to 40mm pipes, and bath waste pipes measure 40-50mm.

Waste pipes don't always need the same ventilation requirements as soil stacks. Many waste systems use trapped connections that maintain water seals without requiring direct ventilation to the roof. However, longer waste pipe runs may still need air admittance valves to prevent slow drainage and gurgling sounds.

Material Specifications and Standards

Modern soil stacks and waste pipes predominantly use uPVC (unplasticised polyvinyl chloride) in the UK. This material replaced cast iron in most residential applications because it weighs less, costs significantly less, and resists corrosion.

Cast iron still appears in older properties and some commercial buildings. If you're working on a Victorian or Edwardian property, you'll likely encounter cast-iron soil stacks. These pipes last 80-100 years when properly maintained, but eventually corrode from the inside out. When replacing sections of cast iron, you'll need specialist connectors from suppliers like Polypipe and adaptors to join the old cast iron to new uPVC sections.

The British Standard BS EN 12056 governs both soil and waste systems, specifying minimum pipe diameters, maximum slopes, and ventilation requirements. Local Building Control must approve any changes to soil stacks or waste pipe configurations, particularly when you're adding new bathrooms or moving existing toilets.

Understanding Soil Stack Types

Different properties require different soil stack configurations based on building height, layout, and drainage requirements. Single-stack systems dominate modern residential construction, where one main vertical pipe handles all toilet waste and accepts connections from waste pipes through swept junctions.

Two-pipe systems separate soil stacks from waste pipes entirely, with each running independently to the underground drainage. You'll find these in older properties and some commercial buildings where maintenance access and system separation matter more than installation economy.

Ventilated discharge branch systems use a main soil stack with secondary ventilation pipes running parallel to horizontal waste branches. This configuration prevents trap seal loss in properties with long waste pipe runs or multiple bathrooms on the same floor.

Installation Requirements That Matter

Soil Stack Positioning

Building regulations specify that soil stacks must be positioned at least 3 metres away from any opening window when they terminate above roof level. This distance prevents sewer gases from entering the building. Where 3 metres isn't achievable, you'll need a charcoal filter cowl on the stack terminal.

The stack must extend at least 900mm above any window within 3 metres horizontally. Countless installations fail inspection because installers don't account for dormer windows or roof lights when calculating stack height.

Waste Pipe Gradient

Waste pipes require a fall of 18-90mm per metre. Too shallow and water sits in the pipe, creating blockages and bacterial growth. Too steep and water rushes away, leaving solid matter behind, a problem called "self-siphonage" that also breaks the trap seal.

A 40mm waste pipe from a bathroom basin typically runs at 20-40mm per metre. Kitchen sinks need steeper gradients (40-60mm per metre) because grease and food particles require faster water flow to prevent accumulation.

Common Connection Points and Configurations

Direct vs Indirect Connection

Toilets always connect directly to soil stacks, no exceptions. The connection uses a pan connector that creates a watertight seal between the toilet outlet and the soil pipe inlet.

Waste pipes from other fixtures can connect to soil stacks indirectly through a hopper head (common in older properties) or directly through swept junctions. Modern installations favour direct connections using boss adaptors or solvent-weld branches that maintain smooth internal surfaces. Quality fittings from established manufacturers ensure reliable, leak-free connections.

Stack Ventilation

Every soil stack needs ventilation at the top, but not every waste pipe requires individual venting. A properly designed system uses the soil stack as the primary ventilation point, with waste pipes connecting at appropriate angles to prevent trap seal loss.

Air admittance valves (AAVs) offer an alternative to traditional roof-level ventilation for waste pipes. These one-way valves allow air into the system without requiring a pipe through the roof. However, Building Control doesn't always accept AAVs as the sole ventilation method; you'll typically need at least one traditionally vented stack per property.

Problems That Signal Confusion Between Systems

Undersized Pipes

Connecting a toilet to a 50mm waste pipe instead of a 100mm soil stack guarantees blockages. The pipe simply cannot handle the volume and solid content. This error appears in DIY bathroom installations where homeowners assume any drain pipe would work.

Missing Ventilation

Installing a soil stack without proper roof-level ventilation creates immediate problems. Toilets flush slowly, gurgling sounds echo through the bathroom, and water disappears from sink traps. The vacuum effect pulls water from every trap connected to the system.

Incorrect Gradients

Running waste pipes too flat allows debris to settle and accumulate. Kitchen waste pipes suffer particularly, as grease solidifies in standing water, creating blockages that require professional jetting to clear. The correct gradient keeps water moving fast enough to carry waste but slow enough to maintain trap seals.

Maintenance and Inspection Differences

Soil stacks require different maintenance approaches than waste pipes. The larger diameter and vertical orientation mean blockages happen less frequently, but when they occur, they're more serious.

Soil Stack Maintenance

Inspect the stack terminal annually for bird nests, leaves, and debris. Pigeons particularly favour soil stack terminals as nesting sites. A blocked terminal prevents ventilation, causing the same problems as a missing vent.

Check the base connection where the stack meets the underground drain. This junction experiences significant stress from the weight of waste flowing down from upper floors. Cracked joints here leak sewage into foundations and wall cavities.

Waste Pipe Maintenance

Hair and soap scum create the majority of waste pipe blockages. Bathroom basin and shower waste pipes need cleaning every 6-12 months using enzymatic cleaners or mechanical snakes. Chemical drain cleaners work temporarily but can damage older pipes and push blockages further into the system.

Kitchen waste pipes accumulate grease despite best efforts. Running hot water after washing up helps, but periodic professional cleaning prevents solid blockages. Regular drain maintenance costs significantly less than emergency callouts for completely blocked systems.

When to Combine or Separate Systems

Single Stack Systems

Most modern homes use single-stack systems where waste pipes connect to the soil stack through swept branches. This approach reduces materials and simplifies installation while maintaining proper function.

The critical factor is the connection angle. Waste pipes must join the soil stack at least 200mm below the lowest toilet connection and use 45-degree swept junctions rather than 90-degree elbows. This configuration prevents toilet waste from backing up into the waste pipe branches.

Separate Systems

Older properties often maintain separate systems with distinct soil stacks and waste pipes that connect to different underground drains. Combining these systems during renovation requires Building Control approval and careful hydraulic calculations to ensure adequate capacity.

Some commercial properties deliberately maintain separate systems to simplify maintenance and comply with specific health regulations. Restaurants and food preparation facilities typically separate kitchen waste from toilet waste to prevent cross-contamination during drain cleaning.

Building Regulation Compliance

Any work affecting soil stacks or waste pipes falls under Building Regulations Part H (Drainage and Waste Disposal). This includes:

- Installing new toilets or bathrooms

- Moving existing toilets

- Connecting washing machines or dishwashers

- Extending or modifying existing soil stacks

- Replacing sections of waste pipe

Building Control inspects these installations to verify correct pipe sizes, gradients, ventilation, and connection methods. Failed inspections delay projects and require expensive remedial work.

The most common compliance failures involve inadequate ventilation, incorrect pipe gradients, and missing or improperly installed traps. Understanding the fundamental differences between soil stacks vs waste pipes prevents these failures.

Upgrading and Replacement Considerations

Cast-iron soil stacks eventually need replacement. Corrosion typically starts inside the pipe, where you can't see it until leaks develop. If your property has cast iron drainage and you're planning renovations, factor in complete stack replacement rather than patching sections.

Replacing a full-height soil stack in an occupied building requires careful planning. The work affects every floor, disrupts toilet use, and often requires scaffolding for roof-level work. Most installations take 2-3 days for a standard three-storey property.

Waste pipe replacement happens more incrementally. You can replace individual sections without affecting the entire system, making it easier to upgrade during bathroom renovations or when addressing specific blockages. Modern plastic piping systems from Polypipe offer durability and ease of installation compared to older materials.

System Integration With Water Supply

Understanding soil stacks vs waste pipes becomes particularly important when planning complete bathroom installations. While soil and waste systems handle drainage, you'll also need to coordinate with incoming water supply from Gledhill cylinders or Kingspan hot water systems that feed your fixtures.

Poor drainage design affects how well taps, showers, and toilets perform. A soil stack positioned too far from a new toilet creates flushing problems regardless of water pressure. Similarly, waste pipes that don't drain quickly enough cause basins to overflow even when fed by high-pressure systems like those from Stuart Turner.

Getting the Specification Right

Soil stacks and waste pipes serve distinct functions in your drainage system, and confusing them creates serious problems. Soil stacks handle toilet waste through 100mm vertical pipes that extend above the roofline for ventilation. Waste pipes carry grey water from sinks, baths, and showers through smaller diameter pipes that connect to the soil stack or drain separately.

The diameter difference alone, 100mm for soil stacks versus 32-50mm for waste pipes, prevents interchanging them. Ventilation requirements differ fundamentally, with soil stacks requiring roof-level termination while waste pipes can use air admittance valves or rely on the main stack for ventilation.

Building regulations strictly govern both systems, requiring specific gradients, connection methods, and ventilation arrangements. Any modifications need Building Control approval to ensure compliance with BS EN 12056 standards.

Understanding these differences helps you plan bathroom installations correctly, identify drainage problems accurately, and communicate effectively with plumbers and building inspectors. Whether you're renovating an old property with cast iron drainage or installing a new bathroom in a modern home, respecting the distinct requirements of soil stack types ensures a system that functions reliably for decades.

For technical advice on drainage components and pipe systems, Heating and Plumbing World stocks a comprehensive range of soil and waste products. If you need specification support or have questions about your drainage project, get in touch with the technical team.

-

-