Temperature and Pressure Relief Valves for Hot Water Systems

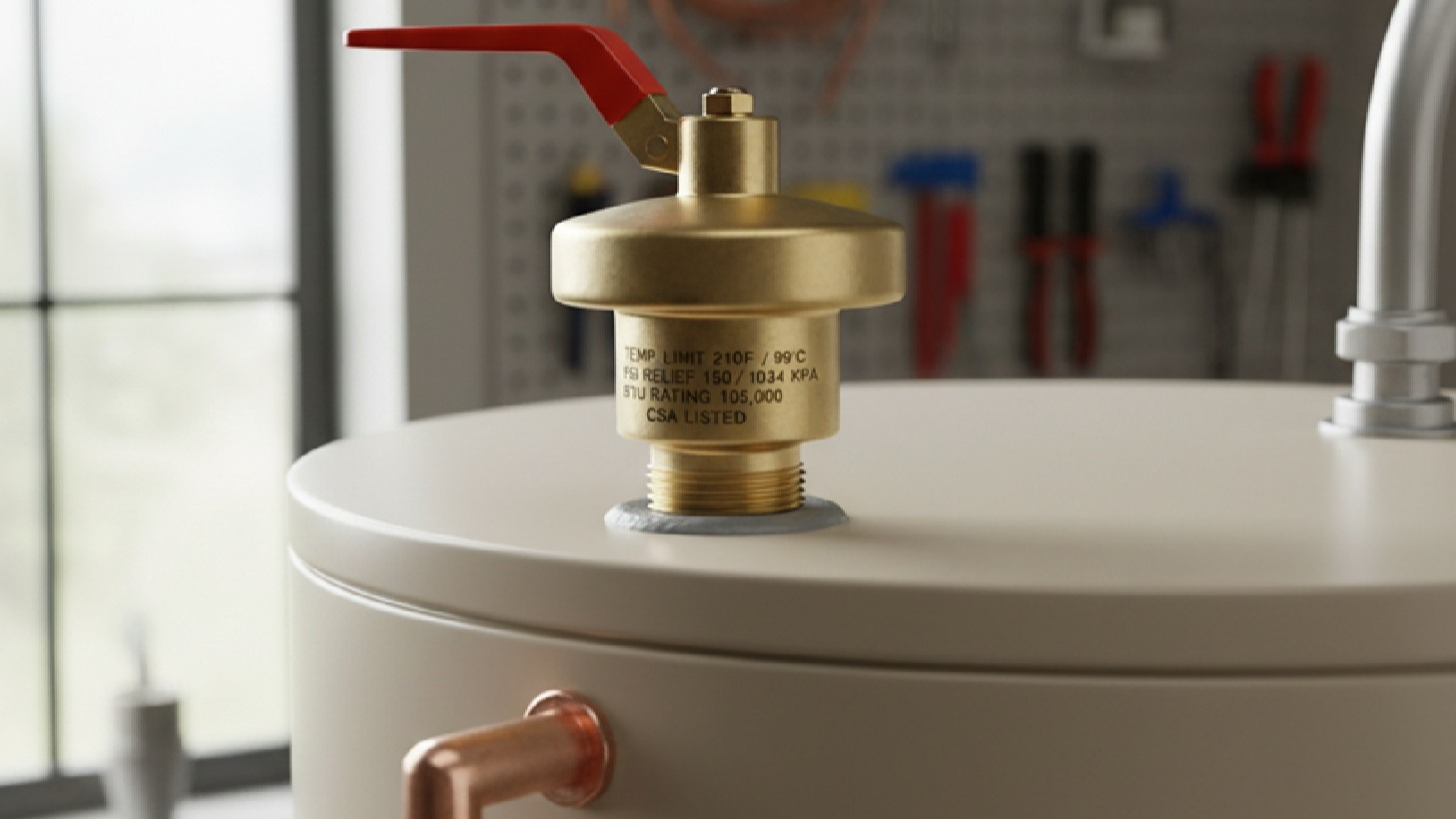

Every hot water system contains a component that most homeowners never notice until something goes wrong. The temperature and pressure relief valve (TPR valve) sits quietly on your water heater, performing a critical safety function: preventing your system from turning into a pressurised bomb.

When water heats beyond safe limits or pressure builds to dangerous levels, this valve opens automatically to release the excess. Without it, a standard residential water heater could rupture with enough force to demolish a house. The physics are simple: water expands when heated, and in a closed system with no outlet, that expansion creates catastrophic pressure.

How Temperature and Pressure Relief Valves Work

TPR valves operate on two independent triggers. The temperature element activates when water reaches approximately 99°C, well above the normal operating range of 60-65°C. The pressure element responds when internal pressure exceeds the valve's rating, typically 6-10 bar (600-1000 kPa) for residential systems.

Inside the valve, a spring-loaded disc sits against a seat, creating a watertight seal when either temperature or pressure exceeds safe thresholds, the disc lifts, allowing water and steam to discharge through the valve body and out the discharge pipe. Once conditions normalise, the spring forces the disc back into position, resealing the system.

This dual-trigger design provides redundancy. If a thermostat fails and stops regulating temperature, the thermal element activates. If the cold water supply develops a backflow issue that pressurises the system, the pressure element responds. You get two independent safety mechanisms in one component.

Understanding different relief valve types helps explain why TPR valves are essential. Single-function pressure relief valves protect only against overpressure, whilst temperature-only valves respond solely to heat. TPR valves combine both functions, providing comprehensive protection for hot water systems.

Required Specifications and Standards

British Standard BS 6283 governs TPR valve manufacturing and installation in the UK. Every valve must display its temperature and pressure ratings on the body, along with the manufacturer's name and the standard number.

For residential hot water systems, the standard specification is:

- Temperature rating: 99°C

- Pressure rating: 6 bar (600 kPa) or 10 bar (1000 kPa)

- Connection size: 15mm (½") or 22mm (¾") male thread

The valve must match or exceed your water heater's specifications. Installing a valve rated lower than your system's operating parameters creates a safety hazard; the valve will discharge during normal operation, wasting water and failing to protect against genuine emergencies.

Commercial and industrial systems require different specifications based on system size and operating conditions. A 400-litre commercial unit might need a 22mm valve with a 10 bar rating, whilst smaller systems work fine with 15mm valves at 6 bar. Quality cylinders from manufacturers like Gledhill or Kingspan come with appropriate TPR valve specifications clearly marked.

Installation Requirements That Actually Matter

The valve must install directly into the water heater's designated TPR port, typically located on the top or upper side of the tank. This positioning ensures the temperature sensor sits in the hottest water, hot water rises, making the top of the tank the first area to reach dangerous temperatures.

The discharge pipe connects to the valve outlet and must:

- Run continuously downward with no upward sections (prevents steam locks)

- Terminate within 150mm of floor level or into an approved drain

- Use rigid metal or approved plastic rated for high temperatures

- Match or exceed the valve's outlet diameter (no reducing the pipe size)

- Remain visible at its termination point

We've seen installations where someone ran the discharge pipe into a wall cavity or under a floor, making it impossible to see when the valve activates. This defeats the warning function; regular discharge indicates a problem that needs attention.

The discharge pipe's termination point must be safe. Discharging 99°C water onto someone's feet creates liability. Discharging into enclosed spaces can cause water damage or mould growth. The water needs somewhere safe to go, where people will notice it.

Professional-grade pipe fittings and connectors designed for high-temperature applications ensure reliable discharge pipe installations that maintain integrity under thermal stress.

Common Failure Modes and Warning Signs

TPR valves fail in two ways: they stick open and drip continuously, or they stick closed and fail to protect the system.

Continuous dripping happens when mineral deposits or corrosion prevent the disc from seating properly. In hard water areas, calcium builds up on the valve seat, creating gaps that allow water to seep through. You'll see water trickling from the discharge pipe even when the system operates normally.

Some homeowners try to stop the dripping by tightening the valve or adding washers. This doesn't work; the valve has no adjustable parts. Once it starts dripping from mineral buildup or age, replacement is the only solution. The valve has already compromised its sealing ability.

Stuck-closed failures are more dangerous because they're invisible until an emergency occurs. Corrosion can weld the disc to the seat, or mineral deposits can lock the mechanism. The valve looks fine externally, but won't open when needed.

This is why testing matters. Lift the test lever quarterly to verify that the valve opens freely and water discharges. If nothing happens or if the lever feels stuck, replace the valve immediately. Your system has no safety protection.

Why Valves Fail Prematurely

Water chemistry determines valve lifespan more than any other factor. Hard water with high mineral content deposits calcium and magnesium inside the valve body, gradually restricting movement. Acidic water corrodes brass components, weakening springs and eroding sealing surfaces.

Standard residential valves last 5-8 years in moderate water conditions. In areas with very hard water, we see failures within 3-4 years. Extremely soft or acidic water can corrode valves even faster.

Temperature cycling accelerates wear. Systems that frequently heat to maximum temperature and cool down stress the valve components more than systems that maintain steady temperatures. Solar thermal systems, which experience wider temperature swings, often need more frequent valve replacement.

The valve's position matters too. Valves installed horizontally wear faster than those installed vertically because sediment settles on the disc seat, accelerating erosion. British Standards require vertical installation with the discharge outlet pointing downward for this reason.

Understanding Different Relief Valve Types

Temperature and pressure relief valves represent just one category of safety valves used in heating and hot water systems. Understanding the full range of relief valve types helps you appreciate why TPR valves are specified for hot water applications.

Pressure-only relief valves protect against overpressure but don't respond to temperature. These suit systems are designed for situations where temperature control is managed separately and pressure protection is the primary concern. You'll find them on expansion vessels and system components from suppliers like Altecnic.

Temperature-only valves respond solely to heat, opening when water exceeds safe temperatures regardless of pressure. These are less common in residential systems but appear in some commercial applications where pressure is managed through other means.

Combined TPR valves offer the best protection for domestic hot water systems because they address both failure modes: thermostat malfunction (temperature) and closed system pressure buildup (pressure). This dual protection makes them mandatory under Building Regulations Part G for unvented hot water storage.

Proper Testing Procedures

Testing a TPR valve takes 30 seconds and prevents catastrophic failures. Lift the brass test lever on top of the valve about halfway; you should hear water rushing into the discharge pipe and see it flowing from the termination point.

Release the lever. Water flow should stop immediately. If water continues trickling, the valve has failed and needs replacement. If no water flows when you lift the lever, the valve has stuck closed, also requiring immediate replacement.

Never test a valve on a system that's been sitting cold. Heat the water to normal operating temperature first. Testing a cold system might not fully open the valve, giving false confidence that it works.

Some plumbers skip this test during service calls, assuming the valve works because it's not dripping. This assumption kills people. A valve that looks fine externally can be completely seized internally. The only way to know is to test it.

Replacement Guidelines and Timing

Replace TPR valves every 5 years regardless of apparent condition. This preventive schedule costs less than dealing with a failed valve during an emergency.

Replace immediately if:

- The valve drips continuously

- Testing produces no discharge

- The test lever won't move

- Corrosion appears on the valve body

- The discharge pipe shows signs of frequent activation (mineral staining, water damage)

Replacement requires shutting off power to electric systems or gas supply to gas systems, then draining the tank below the valve level. The old valve unscrews from the tank port; most require a large pipe wrench and significant force if they've been installed for years.

New valves need thread sealant rated for potable water. Don't use PTFE tape on TPR valves; the tape can block the valve mechanism. Use liquid thread sealant or paste specifically approved for drinking water systems.

Tighten the valve firmly, but don't overtighten. Brass threads strip easily, and a stripped tank port means replacing the entire water heater. Hand-tight plus one full turn with a wrench is sufficient.

The Cost of Ignoring This Component

A TPR valve costs £25-60, depending on specifications. Professional installation adds £100-20,0 including labour and compliance certification. Total investment: under £300 for a critical safety component.

A ruptured water heater destroys everything within 10 metres. The combination of explosive pressure release, scalding water, and flooding causes structural damage, destroys possessions, and creates injury liability. Insurance companies have paid claims exceeding £400,000 for single incidents caused by TPR valve failure.

Beyond property damage, people die from water heater explosions. The tank becomes a missile when pressure is released asymmetrically. Scalding water causes third-degree burns instantly. These aren't theoretical risks; they're documented incidents that happen when safety systems fail.

Integration with System Design

TPR valves work as part of a complete safety system. They're the last line of defence, not the primary control. Properly functioning thermostats from manufacturers like Honeywell or Danfoss should prevent temperatures from reaching the valve's activation point. Expansion vessels should manage pressure increases from thermal expansion.

When a TPR valve activates regularly, it signals problems elsewhere in the system. The thermostat might be failing, allowing temperatures to climb too high. The expansion vessel might have lost its air charge, forcing the TPR valve to handle all thermal expansion. The cold water supply might have check valves creating a closed system without proper expansion accommodation.

Treating regular TPR discharge as normal wastewater indicates you're operating without proper system protection. The valve should activate once during initial testing, then remain inactive during normal operation. Anything else requires investigation.

System Pressurisation and Safety

Modern unvented cylinders require comprehensive pressure management. Whilst temperature and pressure relief valves provide emergency protection, the primary pressure control comes from properly sized expansion vessels and pressure reducing valves working together.

Quality system components work in harmony. Expansion vessels from Altecnic accommodate thermal expansion under normal conditions, preventing the TPR valve from activating unnecessarily. The TPR valve then serves its intended purpose: emergency protection when other controls fail.

Understanding this hierarchy of safety prevents misdiagnosis. If your TPR valve discharges regularly, don't just replace the valve; investigate why it's activating. Check system pressure, test the expansion vessel, verify thermostat operation, and ensure pressure-reducing valves function correctly.

Boiler and Cylinder Compatibility

Different water heating systems require different TPR valve specifications. Traditional vented cylinders with open vent pipes don't typically need TPR valves because the vent provides overpressure protection. Unvented cylinders must have TPR valves by law.

Combination boilers from manufacturers like Andrews or Morco incorporate their own pressure relief systems, but these protect the boiler, not the hot water circuit. If you add an unvented storage cylinder downstream, it needs its own TPR valve.

System boilers paired with indirect cylinders require careful specification. The cylinder needs a TPR valve rated appropriately for the boiler's maximum output temperature and the system's maximum working pressure. Undersized valves discharge prematurely; oversized valves may not activate when needed.

Selecting the Right Valve for Your System

Match the valve's specifications to your water heater's requirements. Check the manufacturer's plate on your water heater; it lists the required TPR valve rating.

- A 15mm valve at 6 bar works for most residential installations

- 22mm valve at 6 bar for systems with high recovery rates

- 22mm valve at 10 bar for commercial or high-capacity systems

The connection thread must match your water heater's port. Most UK water heaters use BSP (British Standard Pipe) threads. Verify before purchasing; mixing thread standards creates leaks and safety hazards.

Buy from reputable suppliers who stock BS 6283 certified valves. Cheap imported valves often lack proper certification or use materials that corrode rapidly in UK water conditions. The £15 you save buying an uncertified valve isn't worth the risk.

Compliance and Building Regulations

Building Regulations Part G3 governs unvented hot water systems in England and Wales. Similar regulations apply in Scotland and Northern Ireland. These regulations mandate specific safety devices, including TPR valves, and specify their installation requirements.

Non-compliance isn't just about breaking rules; it's about insurance coverage. If a water heater explodes and investigators find an improperly installed or maintained TPR valve, insurance companies routinely deny claims. The £300 saved by skipping professional installation becomes a £400,000 liability.

Only G3-qualified engineers should work on unvented systems. This isn't DIY territory. The qualification ensures engineers understand the safety principles, know current regulations, and can properly commission systems, including TPR valves.

Achieving Reliable Protection

Temperature and pressure relief valves represent the minimum viable safety system for hot water installations. They prevent catastrophic failures that destroy property and endanger lives, yet most people never think about them until something goes wrong.

The maintenance requirement is simple: test quarterly, replace every five years, and investigate immediately if the valve activates during normal operation. This schedule costs less than £80 annually, including professional replacement every five years, trivial compared to the protection it provides.

If you can't remember the last time someone tested your TPR valve, test it today. If you don't know how old your valve is, assume it's overdue and schedule replacement. These aren't optional maintenance tasks you can defer; they're the difference between a functioning safety system and a disaster waiting to happen.

The valve sitting on your water heater right now is either protecting your property and family, or it's a corroded piece of brass that will fail when you need it most. Thirty seconds of testing tells you which one you have.

For quality TPR valves and hot water system components that meet British Standards, Heating and Plumbing World supplies certified products suitable for both residential and commercial installations. If you need specific advice on valve selection or system safety requirements, get in touch for expert guidance on protecting your hot water system.

-

-