Temperature Sensors: NTC Thermistors vs Standard Types

When your boiler suddenly stops heating properly or displays an error code, there's a good chance a faulty temperature sensor is to blame. These small but crucial components monitor water temperature throughout your heating system, feeding real-time data to the control board so it can make split-second decisions about when to fire up, when to modulate, and when to shut down safely.

The thing is, not all boiler temperature sensors work the same way. Walk into any heating engineer's merchant, and you'll find shelves stocked with different sensor types, each with distinct characteristics that affect accuracy, response time, and compatibility. The two most common types you'll encounter in modern heating systems are NTC thermistors and standard resistance temperature detectors (RTDs). Understanding the difference between these technologies helps you choose the right replacement part and explains why some boilers respond more precisely than others.

What Actually Happens Inside a Temperature Sensor

Before we compare specific types, it's worth understanding what these sensors actually do. At their core, all temperature sensors convert thermal energy into an electrical signal that control boards can interpret. They're essentially translators, turning the physical sensation of heat into a language your boiler's brain can understand.

When water flows past a sensor, the heat energy causes changes in the sensor's internal resistance. The control board sends a small electrical current through the sensor and measures how much resistance it encounters. More resistance means one temperature reading; less resistance indicates another. The control board then uses this information to decide whether to increase flame intensity, activate the pump, or trigger safety protocols.

The accuracy of this translation process matters enormously. A sensor that's off by even two or three degrees can cause your boiler to short-cycle, waste fuel, or fail to reach the target temperature. That's why sensor technology has evolved significantly over the past few decades, with manufacturers constantly refining how these components respond to thermal changes.

How NTC Thermistors Actually Work

NTC stands for "Negative Temperature Coefficient," which describes exactly how these sensors behave. As the temperature increases, their electrical resistance decreases. This inverse relationship creates a predictable curve that control boards can interpret with remarkable precision.

The core of an NTC thermistor consists of semiconductor materials, typically metal oxides like manganese, nickel, or cobalt. These materials are sintered together at high temperatures, creating a ceramic-like structure with specific electrical properties. When heat energy excites the electrons within this structure, more charge carriers become available to conduct electricity, which lowers overall resistance.

What makes NTC thermistors particularly useful in heating applications is their sensitivity. Even small temperature changes produce measurable shifts in resistance. A typical NTC thermistor might show 10,000 ohms at 25°C but drop to 3,600 ohms at 50°C. This dramatic change gives control boards plenty of resolution to work with, allowing for precise temperature monitoring across the operating range.

Most modern boilers from manufacturers like Andrews and Morco use NTC thermistors as their primary temperature-sensing technology. The sensors typically mount directly into the heat exchanger or flow pipe using a compression fitting, placing the sensing element in direct contact with the water flow.

Standard RTD Sensors: The Alternative Approach

Resistance Temperature Detectors (RTDs) take a fundamentally different approach to temperature measurement. Instead of using semiconductor materials with a negative temperature coefficient, RTDs use pure metals, usually platinum, with a positive temperature coefficient. As the temperature rises, resistance increases in a linear, predictable fashion.

The most common RTD configuration is the PT100, where "PT" refers to platinum and "100" indicates the sensor's resistance at 0°C (100 ohms). These sensors deliver exceptional accuracy across a wide temperature range, which is why you'll find them in industrial applications, laboratory equipment, and high-end heating systems where precision matters most.

The construction of an RTD differs significantly from that of an NTC thermistor. A fine platinum wire is either wound around a ceramic core or deposited as a thin film on a substrate. This element is then encased in a protective sheath, typically stainless steel, which shields it from moisture and mechanical damage whilst allowing thermal transfer.

RTDs respond more slowly than NTC thermistors because of their construction and the thermal mass of the protective sheath. However, they offer superior long-term stability and can maintain accuracy over many years of continuous operation. In heating systems where precise temperature control matters more than rapid response, RTDs provide reliable performance.

Response Time: Why It Matters More Than You'd Think

When you turn up the thermostat, you expect your heating system to respond reasonably quickly. The temperature sensor plays a crucial role in this response time, and the difference between sensor types can be surprisingly significant.

NTC thermistors typically respond faster than RTDs because of their smaller thermal mass and direct exposure to the measured medium. A quality NTC thermistor can detect a 1°C change in water temperature within one to two seconds, allowing the control board to make rapid adjustments to burner modulation.

This rapid response becomes particularly important during the initial heating phase. When cold water first enters the heat exchanger, the sensor needs to detect this temperature drop immediately so the boiler can ramp up flame intensity. A slow-responding sensor creates a lag between actual conditions and perceived conditions, leading to temperature overshoot or inefficient cycling.

RTDs, with their protective sheaths and larger sensing elements, typically take three to five seconds to register the same 1°C change. In most domestic heating applications, this difference barely matters. However, in systems with sophisticated weather compensation or load anticipation features, that extra second or two can affect overall efficiency and comfort.

Modern Honeywell controls often pair with fast-response NTC sensors to enable advanced modulation algorithms that continuously adjust flame intensity based on real-time demand. This pairing between responsive sensors and intelligent controls explains why newer boilers can maintain steadier temperatures whilst using less fuel than older models.

Accuracy Across the Operating Range

Heating systems don't operate at a single temperature. Your boiler might fire up at 20°C, heat water to 75°C for radiators, or push temperatures even higher for domestic hot water. The sensor needs to maintain accuracy across this entire range, and different sensor types excel in different portions of the temperature spectrum.

NTC thermistors are non-linear devices, meaning their resistance doesn't change at a constant rate as temperature increases. The resistance curve is steepest at lower temperatures and flattens out as the temperature rises. This characteristic actually works well for heating applications because it provides maximum sensitivity in the 40-80°C range where most systems operate.

RTDs offer linear response across their entire range, which simplifies calibration and calculations. A PT100 sensor increases its resistance by approximately 0.385 ohms per degree Celsius, regardless of whether you're measuring 10°C or 100°C. This linearity makes RTDs easier to work with in systems requiring precise temperature control across wide ranges.

For typical domestic heating, the non-linearity of NTC thermistors isn't problematic because modern control boards compensate mathematically. They're programmed with the sensor's characteristic curve and can convert resistance readings to temperature values with excellent accuracy throughout the normal operating range.

Integration With Control Systems

Today's heating controls are remarkably sophisticated, with features like weather compensation, load anticipation, and remote monitoring via smartphone apps. These advanced functions depend on accurate, reliable temperature data, and the sensor needs to communicate effectively with the control board.

Most residential boilers use control systems specifically designed around NTC thermistors. The control board includes the necessary circuitry and programming to excite the sensor, measure its resistance, and convert that reading into a temperature value. Brands like EPH Controls and Danfoss design their control systems with specific NTC characteristics in mind, optimising the entire signal chain for this sensor type.

You can't simply swap an NTC thermistor for an RTD sensor without changing the control board as well. The two sensor types require different excitation voltages, different measurement circuits, and different conversion algorithms. They're fundamentally incompatible at the hardware level.

This compatibility requirement means that when you're replacing a faulty sensor, you need to match not just the physical dimensions and thread size, but also the electrical characteristics. A 10K NTC thermistor isn't interchangeable with a 5K NTC thermistor, even if they look identical. The control board expects a specific resistance curve, and using the wrong sensor will produce inaccurate readings.

What This Means for Replacement and Maintenance

Understanding these differences becomes practical when you're faced with a faulty sensor that needs replacing. The error codes on your boiler display might indicate a sensor problem, or perhaps you've noticed erratic behaviour like short cycling or failure to reach target temperature.

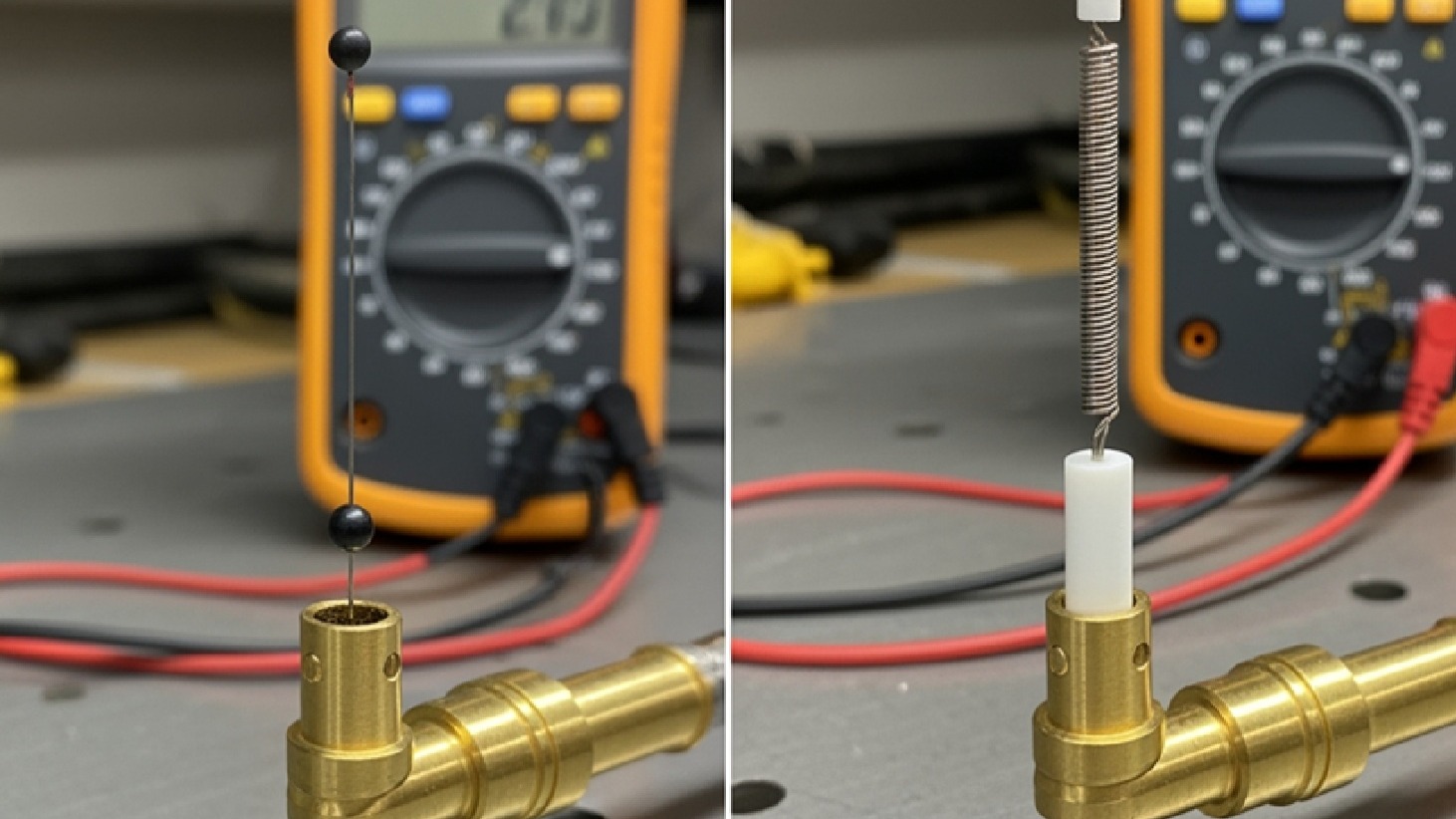

When sourcing a replacement sensor for NTC thermistor replacement, you need three pieces of information: the sensor type (NTC or RTD), the resistance value at a reference temperature (usually 25°C for NTC or 0°C for RTD), and the physical specifications (thread size, immersion length, cable length). Using an incorrect sensor will either prevent the boiler from operating or cause inaccurate temperature control.

For most domestic installations, you'll be replacing an NTC thermistor. The Halstead spares range includes various NTC sensors designed for specific boiler models, ensuring proper fit and electrical compatibility. Generic sensors exist, but using manufacturer-specified parts eliminates compatibility concerns.

The replacement process itself is straightforward for a competent person, though it does involve draining down part of the system and ensuring proper sealing when reinstalling. The sensor typically threads into the heat exchanger or a pocket in the flow pipe, with a copper washer or O-ring providing the seal. Proper torque matters here because over-tightening can damage the sensor, whilst under-tightening leads to leaks.

After installation, the system needs purging to remove any air introduced during the replacement. Some control boards require a reset or relearning procedure after sensor replacement, though most will automatically calibrate once the system returns to normal operation.

Pumps, Sensors, and System Integration

Boiler temperature sensors don't work in isolation. They're part of an integrated system where pumps, valves, and controls all respond to the temperature data being gathered. Understanding this integration helps explain why sensor accuracy and response time matter so much.

Consider what happens when your heating system first fires up. The boiler ignites, and hot water begins flowing through the heat exchanger. The temperature sensor detects this rising temperature and signals the control board. Once the water reaches a certain threshold, the control board activates the system pump, sending hot water to your radiators or underfloor heating.

Quality pumps from manufacturers like Grundfos or Lowara respond immediately to these control signals, but they're entirely dependent on accurate temperature data. If the sensor is reading low, the pump might activate too late, allowing the heat exchanger to overheat. If the sensor is reading high, the pump might run unnecessarily, wasting electricity and causing premature wear.

In systems with variable-speed pumps, the integration becomes even more sophisticated. The pump speed adjusts based on temperature differential, flow requirements, and system demand. All of these calculations start with accurate temperature data from sensors positioned at key points throughout the system.

Similarly, expansion vessels and other system components rely on proper temperature management. Excessive temperatures can cause premature pressure relief valve operation or damage to plastic components, whilst insufficient temperatures mean poor heat delivery and wasted fuel.

Making the Right Choice for Your System

For most residential heating applications, the choice between NTC thermistors and RTDs has already been made by the boiler manufacturer. Your system is designed around one technology, and that's what you'll continue using for replacements and repairs.

However, if you're specifying a new system or designing a custom installation, understanding these differences helps you make informed decisions. NTC thermistors offer excellent performance for standard residential applications at a reasonable cost. They respond quickly, provide adequate accuracy, and integrate seamlessly with modern control systems.

RTDs make sense in commercial applications, industrial heating systems, or situations where long-term stability and maximum accuracy justify the additional expense. They're also the preferred choice in systems subject to regulatory oversight or where temperature documentation is required.

The sensor itself is just one component in a properly functioning heating system. Pairing a quality sensor with appropriate controls, proper installation, and regular maintenance delivers reliable performance regardless of which technology you choose.

Understanding Component Compatibility

Boiler temperature sensors might be small components, but they play an outsized role in how your heating system performs. NTC thermistors dominate the residential market because they offer the right balance of performance, cost, and compatibility with modern control systems. Their rapid response time and sensitivity in the typical operating range make them ideal for domestic boilers.

RTDs provide superior accuracy and long-term stability, which is why they appear in commercial installations and high-end systems where these characteristics matter most. The additional cost and slower response time aren't drawbacks in applications where precision trumps speed.

When you're maintaining or repairing your heating system, using the correct sensor type isn't optional. The control board expects specific electrical characteristics, and using an incompatible sensor will cause problems ranging from inaccurate temperature control to complete system failure. Whether you're working with heating components, quality fittings, or complete system installations, matching sensor specifications to manufacturer requirements ensures reliable operation.

The next time your heating system acts up and a technician mentions the temperature sensor, you'll understand why this seemingly simple component deserves attention. It's the sensory organ of your heating system, constantly monitoring conditions and feeding data to the control brain. Get this right, and everything else falls into place. Get it wrong, and even the best boiler, pump, and controls can't deliver the performance you expect.

For professional-grade boiler temperature sensors and NTC thermistor replacement components, Heating and Plumbing World stocks genuine manufacturer parts for all major boiler brands. Technical guidance on sensor compatibility and installation is available. Get in touch for expert support.

-

-