U-Bends and P-Traps: How They Prevent Drain Odours

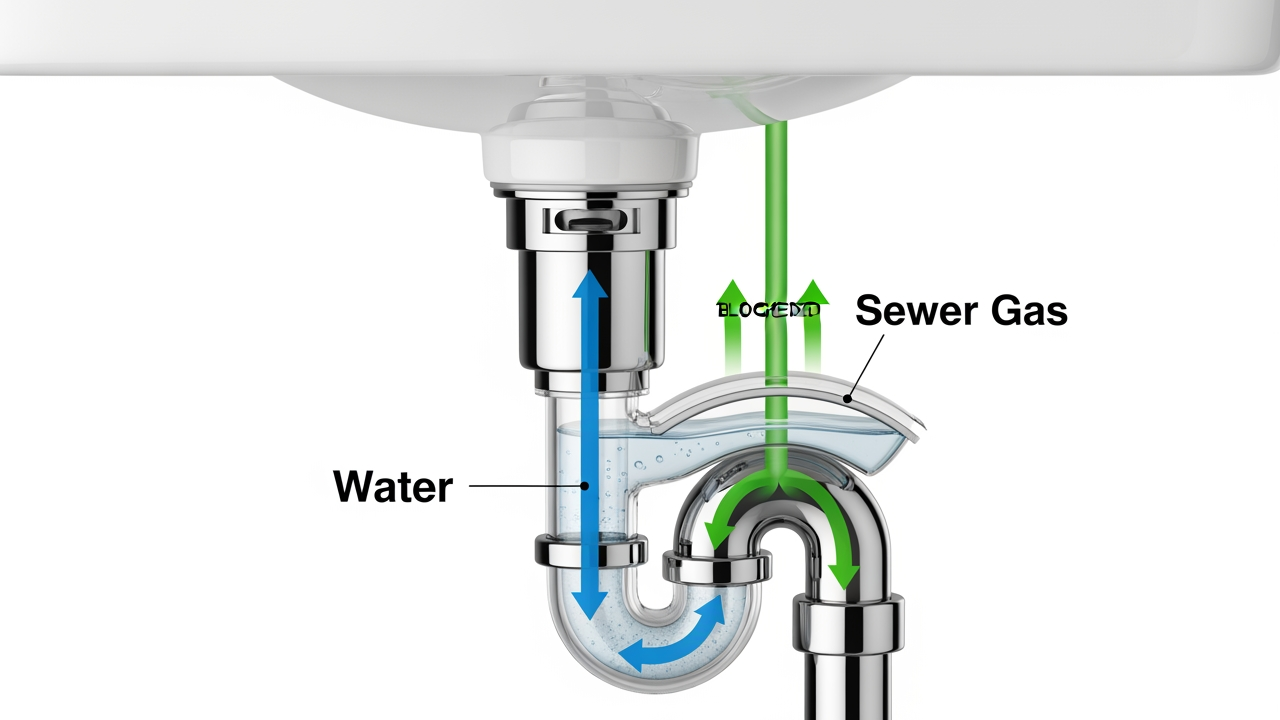

Every plumbing system contains a simple curved pipe that stops sewer gases from entering your home. Without this bend filled with water, your bathroom would smell like the main sewer line within hours.

U-bends and P-traps create a water seal that blocks gases while allowing waste to flow through. The design hasn't changed significantly since Alexander Cumming patented the S-trap in 1775, because it works.

How the Water Seal Works

The trap holds approximately 50-75mm of water in its lowest point. When you run a tap or flush a toilet, new water pushes the old water through while leaving enough behind to maintain the seal. This standing water creates a physical barrier between your living space and the drainage system.

Sewer gases contain hydrogen sulphide, methane, and ammonia. Hydrogen sulphide smells like rotten eggs and becomes toxic at concentrations above 100 parts per million. The water seal blocks these gases completely when functioning correctly.

Three primary causes of seal failure:

Evaporation: Water slowly disappears from traps that aren't used regularly

Siphonage: Negative pressure pulls water out of the trap

Blockages: Debris prevents proper water flow through the trap

A trap that's lost its seal allows sewer gases to enter immediately. Hydrogen sulphide levels can spike from zero to 30 ppm within minutes of a seal failure in residential properties.

U-Bends vs P-Traps: The Structural Difference

U-bends and P-traps both create water seals, but their orientation differs. A U-bend curves like the letter U with both ends pointing upward. A P-trap resembles the letter P, with one end horizontal and one vertical.

Under a kitchen sink, you'll find a P-trap connecting the vertical tailpiece to the horizontal waste pipe. The trap's outlet runs horizontally into the wall or floor. Toilet pans have built-in P-traps or S-traps (a P-trap with a vertical outlet).

U-bends appear in older installations and specific applications where both inlet and outlet pipes run vertically. Most modern plumbing uses P-traps because they connect more easily to standard waste pipes.

The trap depth matters more than its shape. UK building regulations require a minimum seal depth of 75mm for most applications and 50mm for washbasins. Shallow traps lose their seals faster through evaporation and siphonage.

Why Traps Lose Their Seals

Evaporation in unused fixtures accounts for most seal failures. A bathroom sink used once per month loses approximately 5mm of water per week through evaporation. The entire seal disappears in 10-15 weeks.

Holiday homes and guest bathrooms develop drain odours because their traps run dry. Running water in every fixture for 30 seconds monthly maintains seals. Some facilities install trap primers, devices that automatically add water to traps.

Siphonage and Pressure Problems

Siphonage occurs when negative pressure pulls water from the trap. Poor venting causes this problem. Every drainage system needs air to flow freely behind the water. Without proper venting, water rushing down a pipe creates suction that can empty nearby traps.

A classic example: flushing a toilet pulls water from the adjacent shower trap, creating a gurgling sound. The toilet's discharge creates negative pressure in the shared waste pipe. If the system lacks adequate venting, this pressure differential empties the shower trap partially or completely.

Self-siphonage happens in individual fixtures with incorrectly sized traps. A 40mm waste pipe shouldn't connect to a 32mm trap; the restriction causes the draining water to pull the seal through. Matching trap and waste pipe diameters prevents this.

Blockages and Seal Renewal

Blockages prevent seal renewal. A partially blocked trap might hold water, but won't refresh properly. Old water becomes stagnant and produces its own odours. Hair, soap scum, and grease accumulate in traps over time, reducing their effective volume.

Installing Traps Correctly

Trap installation determines long-term performance. The outlet must maintain a continuous fall toward the main waste pipe, typically 18-90mm per metre. A trap installed level or with a backward slope won't drain completely, leaving stagnant water.

The vertical distance between the trap's weir (the highest point water can reach) and the waste pipe connection affects seal retention. This distance shouldn't exceed 3 metres for a 32mm pipe or 4 metres for a 40mm pipe without intermediate venting.

Bottle traps look cleaner than P-traps because they're compact and chrome-plated. They fit under pedestal basins where space is limited. However, they block more easily than tubular traps because waste must change direction twice inside the bottle chamber. Hair and debris accumulate in the inner chamber, requiring more frequent cleaning.

Tubular P-traps are installed wherever possible because they're easier to clear and less prone to blockage. The smooth, curved pipe allows debris to flow through more readily. Quality plumbing fittings ensure reliable connections and long-term performance.

Trap depth affects seal retention. A 75mm seal resists siphonage better than a 50mm seal and takes longer to evaporate. Commercial installations often specify 100mm seals for fixtures used infrequently.

Venting: The Critical Partner to Traps

Proper venting maintains atmospheric pressure in the drainage system, preventing siphonage. Every trap needs air to enter the waste pipe behind the water discharge.

Single-stack drainage systems, common in modern UK homes, rely on careful pipe sizing and gradient to allow air circulation. The main stack extends through the roof, providing air inlet and outlet. Branch waste pipes connect to this stack at specific angles and distances.

Air admittance valves (AAVs) provide venting where traditional stack venting isn't practical. These one-way valves open when negative pressure develops, allowing air to enter but preventing gases from escaping. AAVs work effectively for individual fixtures or small groups of fixtures.

Building regulations restrict AAV use; they can't replace the main stack vent, only supplement it. A system relying entirely on AAVs has no positive pressure relief when multiple fixtures discharge simultaneously.

Signs of inadequate venting include:

- Gurgling sounds when fixtures drain

- Slow drainage despite clear pipes

- Intermittent drain odours

- Toilets with weak or incomplete flushes

Venting issues occur in 40% of properties reporting persistent drain odours. The traps work correctly, but siphonage empties them periodically.

Maintaining Traps and Preventing Odours

Run water through every fixture monthly. This simple practice prevents 90% of seal-loss problems in occasional-use fixtures. Set a calendar reminder for guest bathrooms, utility sinks, and floor drains.

Clean accessible traps quarterly. Most P-traps under sinks have a removable section secured by hand-tight unions. Place a bucket underneath, unscrew the unions, and remove the trap. Flush it with hot water and scrub the interior with a bottle brush. This removes accumulated biofilm that produces odours even when the seal remains intact.

Check trap water levels by shining a torch into the drain opening. You should see standing water approximately 25-50mm below the waste outlet. No visible water means the seal has failed.

Avoid chemical drain cleaners in traps with slow drainage. These products generate heat that can damage plastic traps and rubber seals. They're also ineffective against hair blockages, the most common trap obstruction. Mechanical cleaning with a drain snake or trap removal works better.

Pour a thin layer of vegetable oil into traps for fixtures unused for extended periods. The oil floats on the water surface and significantly slows evaporation. This technique works well for holiday homes. Use approximately 50ml of cooking oil per trap before leaving the property vacant.

Effective trap odour prevention relies on consistent maintenance routines rather than reactive repairs. Professional plumbing supplies from Heating and Plumbing World provide the quality components needed for reliable drainage systems.

Common Problems and Solutions

Odours from a trap with visible water indicate either a partial blockage with stagnant water or a cracked trap allowing gases to bypass the seal. Remove and inspect the trap. Hairline cracks in plastic traps aren't always visible; replace any trap more than 10 years old if odours persist despite cleaning.

Persistent gurgling without odours suggests venting issues rather than seal failure. The system needs air circulation improvement. This might require installing an AAV, modifying the waste pipe gradient, or addressing blockages in the main stack.

Seasonal odour problems point to evaporation in occasional-use fixtures. Identify which fixtures aren't used regularly and implement a monthly running schedule. Floor drains in garages and utility rooms commonly cause this problem.

New odours after plumbing work often result from installation errors. Check that all traps are properly filled, correctly oriented, and adequately vented. A trap installed backwards (outlet higher than inlet) won't seal properly.

When Traps Aren't the Problem

Not all drain odours originate from failed trap seals. Biofilm buildup on pipe walls produces sulphurous smells, particularly in shower wastes and kitchen sinks. The trap works correctly, but bacteria colonising the pipe above the water line generate odours.

Flush waste pipes with hot water and biological drain cleaner monthly. These enzyme-based products break down organic matter without damaging pipes. Pour the treatment directly into the overflow hole; this cleans the pipe section above the trap where biofilm accumulates.

Blocked or damaged vent pipes allow sewer gases to enter through the roof stack, which then infiltrate the property through gaps around pipe penetrations. Inspect the roof vent for blockages, birds' nests, and debristhat can obstruct the opening.

Cracked waste pipes behind walls or under floors leak sewer gases into the building fabric. These leaks often produce odours that seem to come from drains but persist despite trap maintenance. Pressure testing the waste system identifies hidden leaks. Modern pipe systems from suppliers like Polypipe offer improved durability and leak resistance.

The Economics of Proper Trap Design

A correctly installed trap with adequate venting requires minimal maintenance and prevents odour problems for decades. The initial cost difference between proper and minimal installation is negligible, perhaps £50-100 per fixture, but the long-term performance difference is substantial.

Countless incorrectly installed bottle traps in properties less than five years old require replacement. The original installer chose appearance over function, resulting in chronic blockages and odour problems. The replacement cost, including labour and property access, typically exceeds £150 per trap.

Proper venting adds approximately £200-400 to a bathroom installation but eliminates 95% of future drainage problems. Properties without adequate venting require repeated service calls that cost more than a correct initial installation.

Quality components from reputable suppliers like Myson ensure reliable performance and reduce long-term maintenance costs. Professional-grade materials withstand daily use and thermal stress better than economy alternatives.

Maintaining an Odour-Free Drainage System

U-bends and P-traps prevent drain odours through a simple water seal that blocks sewer gases from entering your property. This seal requires regular water flow to prevent evaporation, proper venting to resist siphonage, and periodic cleaning to remove blockages.

Most drain odour problems trace to seal loss from evaporation in unused fixtures or inadequate venting, causing siphonage. Running water through every fixture monthly and ensuring proper system venting prevents 90% of these issues.

The trap's basic design has remained unchanged for over 200 years because it works reliably when installed correctly and maintained minimally. Understanding how U-bends and P-traps function helps you identify problems early and implement effective trap odour prevention strategies.

Inspect your traps quarterly, clean accessible ones twice yearly, and address any gurgling or slow drainage immediately. These simple practices maintain the water seals that keep sewer gases where they belong, in the sewer, not your home.

For expert guidance on drainage solutions or to source quality plumbing components, contact drainage and plumbing specialists who can provide tailored recommendations for your property's specific requirements.

-

-