Vaillant EcoTec Boiler Spares: Most Common Replacement Parts

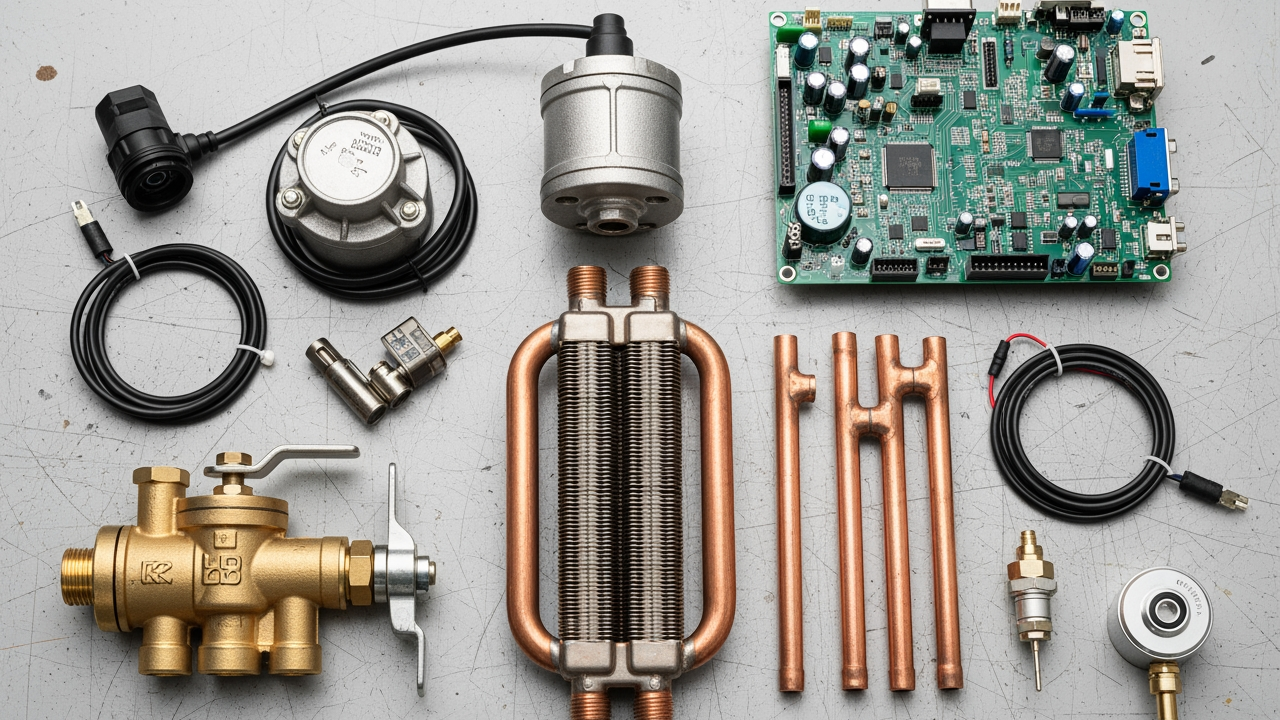

Vaillant EcoTec boilers fail in predictable ways. After servicing thousands of these units across the UK, we've identified the parts that break most often and why they fail. This covers the components you'll replace repeatedly, what causes them to wear out, and how to source them correctly.

Heat Exchangers: The £400 Problem

The primary heat exchanger fails in 12-15% of EcoTec Plus models after 7-10 years of operation. Hard water areas see this timeline compressed to 5-7 years. Scale buildup restricts water flow, forcing the exchanger to work harder and eventually crack.

We replace roughly 40 primary heat exchangers annually in EcoTec boilers. The part costs £380-£450 depending on the model, with labour adding another £200-£300. Most failures show identical symptoms: fluctuating hot water temperature, kettling noises, and pressure loss.

The secondary plate heat exchanger (used in combination boilers) fails more frequently - we see these every 5-6 years in hard water postcodes. This £120-£180 component blocks with scale, causing the boiler to overheat and shut down. Unlike primary exchangers, you can sometimes descale these successfully if caught early.

Prevention reduces replacement frequency by 60%. Annual inhibitor top-ups and system flushes every 5 years protect both exchangers. Properties with water hardness above 200ppm need scale reducers fitted at installation.

Diverter Valves: Why They Stick

The three-way diverter valve accounts for 18% of our EcoTec callouts. This £85-£140 component switches water flow between heating and hot water circuits. The motor assembly wears out after 15,000-20,000 cycles, typically 6-8 years in a family home.

Common symptoms include: Hot water works but heating doesn't (or vice versa) The valve makes grinding noises when switching Hot water takes 2+ minutes to arrive at taps

We stock three variants of this part because Vaillant changed the design in 2012 and again in 2018. The wrong valve will physically fit but won't seal properly, causing intermittent heating. Always match the part number stamped on your existing valve - don't rely on boiler model numbers alone.

Sludge in the system kills these valves prematurely. We've replaced valves after just 3 years in systems without magnetic filters. Installing a magnetic filter during boiler commissioning extends diverter valve life by 40%.

Pumps: The 8-Year Replacement Cycle

Grundfos pumps fitted to EcoTec boilers last 8-10 years on average. The bearing assembly fails first, creating a humming noise without water movement. This £140-£180 part fails faster in systems with:

Insufficient inhibitor (bearing corrosion accelerates) Oversised or poorly designed pipework (pump works harder) Repeated air ingress (cavitation damages impellers)

The EcoTec Plus 831, 835, and 837 models use a specific Grundfos 15-60 pump that's not interchangeable with standard heating pumps. We've seen installers fit incorrect pumps that physically connect but run at wrong speeds, causing the boiler to lock out on overheat.

Speed setting matters. Most EcoTec systems run optimally on speed 2 (medium). Setting speed 3 doesn't improve heating - it just wears the pump faster and increases electricity consumption by 30%.

Expansion Vessels: The Hidden Failure

Expansion vessel failure causes 90% of pressure loss problems we diagnose. The internal diaphragm splits after 6-8 years, losing the air charge that cushions pressure changes. This £60-£90 component sits behind the boiler casing on most EcoTec models. Quality Altecnic expansion vessels offer reliable alternatives for replacement installations.

Testing takes 30 seconds: press the Schrader valve on top of the vessel. Water spraying out means the diaphragm has failed. You should only see air (or nothing if the charge has leaked).

The vessel needs 0.75-1.0 bar pre-charge when empty. Installers frequently skip this step, causing premature boiler pressure problems. We check and adjust pre-charge on every vessel we fit - it prevents callbacks.

External expansion vessels last longer than internal ones. If you're replacing the vessel anyway, fitting a larger external unit (8-12 litres) reduces pressure fluctuation and extends lifespan to 12-15 years. This costs an extra £40-£60 but pays back in reduced service visits.

Gas Valves: When Electronics Fail

Gas valve failure is catastrophic - the boiler won't fire at all. These £180-£240 components contain solenoids and electronic controls that regulate gas flow. We replace 2-3 monthly across our service area.

The EcoTec Plus range uses Honeywell VK4105 or VK8515 valves depending on output. Both fail in similar ways:

Complete failure to open (no ignition attempt) Partial opening (boiler lights then immediately cuts out) Stuck open (extremely dangerous - requires immediate shutdown)

Electrical spikes during power cuts damage these valves. Properties without surge protection see valve failures 3x more often. A £25 surge protector on the boiler's electrical supply prevents this.

Never attempt gas valve replacement without Gas Safe registration. The component requires specific torque settings and gas-tight sealing. Incorrect fitting causes carbon monoxide leaks.

Printed Circuit Boards: The £300 Gamble

PCB failure costs £280-£350 for the part alone. These boards control everything from ignition timing to pump speed. We see failures after 10-12 years, though some fail earlier due to:

Water ingress from leaking heat exchangers or condensate traps Power surges Corrosion from condensation inside the boiler casing

The EcoTec Plus 824, 831, 835, 837, 937, and 938 models each use different PCBs. They're not interchangeable. Vaillant stopped making boards for pre-2005 models, forcing boiler replacement.

Refurbished boards cost £180-£220 and carry 12-month warranties. We've fitted hundreds with a 5% failure rate - acceptable given the 40% cost saving. New boards make sense for boilers under 8 years old; refurbished units work fine for older boilers approaching end-of-life.

Protect the PCB by maintaining proper condensate drainage. Blocked condensate traps cause water backup that damages electronics. We clean traps during annual services, preventing 70% of water-related PCB failures.

Pressure Sensors and Transducers

The water pressure sensor (£35-£55) fails every 5-7 years. This component tells the PCB when pressure drops too low, triggering a lockout. Scale and debris block the sensor port, causing false readings.

Common symptoms include: F.22 error code (low water pressure) when pressure gauge shows 1.0+ bar Boiler cutting out randomly during heating cycles Pressure reading fluctuating wildly

Cleaning the sensor port resolves 30% of cases - actual sensor replacement needed for the rest. The part takes 15 minutes to change once you've drained the boiler.

The differential pressure sensor (£45-£70) monitors flow through the heat exchanger. This fails less often but causes identical symptoms to blocked heat exchangers. We test this sensor before condemning expensive heat exchangers - it's saved customers £300+ multiple times.

Ignition Components: Leads, Electrodes, and Transformers

Ignition leads (£15-£25 per pair) crack after 8-10 years, causing intermittent ignition failure. The boiler sparks but won't light, or takes multiple attempts. Replace leads in pairs - mixing old and new causes mismatched resistance.

Ignition electrodes (£20-£35) corrode from combustion byproducts. The gap between electrode and burner increases beyond spec, weakening the spark. We measure this gap annually - it should be 3-4mm. Beyond 5mm, ignition becomes unreliable.

The ignition transformer (£60-£90) converts mains voltage to the high voltage needed for sparking. These rarely fail - we replace perhaps 5 annually - but when they do, there's no spark at all. Testing requires a multimeter and knowledge of safe high-voltage procedures.

Condensate Traps and Siphons

The condensate trap blocks more than any other component. Acidic condensate dissolves organic matter and scale, creating sludge that clogs the trap. This causes F.28 or F.29 error codes and costs nothing if caught early.

Cleaning procedure: Remove trap from underside of boiler Rinse thoroughly with warm water Check siphon tube for blockages Refill with water before refitting

Replacement traps cost £35-£55 and last indefinitely if maintained. Frozen condensate pipes cause winter lockouts - insulate external condensate runs with 19mm foam to prevent this. Quality Polypipe fittings ensure proper condensate drainage.

Sourcing Parts: OEM vs Pattern

Genuine Vaillant boiler spares carry 12-month warranties and guaranteed compatibility. We use OEM parts for safety-critical components (gas valves, PCBs, heat exchangers) and pattern parts for wear items (pumps, sensors, electrodes).

Pattern parts cost 20-40% less but vary in quality. We've tested multiple suppliers and stick with established brands:

Pumps: Grundfos or Wilo only Expansion vessels: Zilmet or Reflex Sensors: Vaillant OEM (pattern sensors fail frequently) Electrodes and leads: Pattern parts perform identically

Order parts using the boiler's GC number (found on the data badge inside the casing), not the model name. The EcoTec Plus 831 has three different variants with different parts - the GC number specifies which one you have.

Maintaining Your Vaillant System

Vaillant EcoTec boilers require predictable parts replacement throughout their 15-20 year lifespan. Heat exchangers, diverter valves, and pumps account for 60% of component failures we see. Most Vaillant spare parts last 6-10 years before wearing out, though water quality and system maintenance significantly impact longevity.

Stock the five most common parts if you service multiple EcoTec boilers: diverter valves, pressure sensors, ignition leads, condensate traps, and expansion vessels. These cover 70% of callouts and cost under £400 to keep on hand. For expensive components like heat exchangers and PCBs, next-day delivery from specialist suppliers works fine - these failures don't require immediate parts availability.

Proper system maintenance extends part life by 40-60%. Annual services should include inhibitor testing, magnetic filter cleaning, and condensate trap maintenance. Properties in hard water areas need scale reduction at installation - this single measure prevents premature heat exchanger failure worth £600+ in parts and labour.

The EcoTec range remains one of the most reliable condensing boilers we service, but only when maintained properly and repaired with correct parts. Cutting corners on part quality or skipping preventive maintenance creates expensive problems within 2-3 years.

For comprehensive ranges of Vaillant boiler spares and compatible heating components from brands like Danfoss controls and Myson radiators, Heating and Plumbing World stocks everything needed for professional installations and repairs. Should you need technical guidance on sourcing the correct parts for your specific EcoTec model, get in touch with our heating specialists.

-

-