Worcester Bosch Greenstar Spare Parts Guide

Worcester Bosch Greenstar boilers power millions of UK homes, but when they fail, finding the right spare part quickly makes the difference between a same-day fix and days without heating. Replacement components supplied for these systems over the years show a clear pattern: 80% of service calls involve the same dozen parts.

The Greenstar range spans multiple models, from the CDi Classic to the latest i models, yet many components remain interchangeable. Understanding which Worcester Bosch parts fit your specific boiler saves time and prevents the frustration of ordering incorrect components.

The Five Parts That Fail Most Often

Based on order data from 2023, these components account for the majority of Greenstar repairs:

Diverter valves top the list. The three-way diverter valve controls whether your boiler heats water for taps or radiators. When it fails, you'll get heating but no hot water, or vice versa. The 87161429260 fits most CDi models, whilst newer i-series boilers use the 87161430450. Symptoms include the boiler firing up but only heating one system, or a clicking sound when you turn on hot water taps.

Printed circuit boards (PCBs) rank second. The main PCB acts as your boiler's brain, controlling ignition sequences, temperature regulation, and safety protocols. Early CDi models used the 8748300647, but Worcester Bosch released updated versions to fix software bugs. Always check your boiler's GC number (found on the rating plate) before ordering, as using an incompatible PCB version triggers fault codes even when physically identical.

Pressure sensors fail after 7-10 years of operation. The 87161463270 pressure transducer monitors system pressure and tells the PCB when levels drop too low. A faulty sensor causes the boiler to lock out with an EA error code, even when the pressure looks normal on the gauge. Customers often replace expansion vessels from Altecnic Ltd and pressure relief valves unnecessarily because they didn't test the sensor first.

Heat exchangers develop leaks or scale buildup, particularly in hard water areas. The primary heat exchanger (87161427450 for many CDi models) sits directly above the burner and transfers heat from combustion gases to your heating water. Pinhole leaks typically appear along brazed joints after 8-12 years. Scale accumulation reduces efficiency by up to 30% and causes the boiler to cycle on and off rapidly.

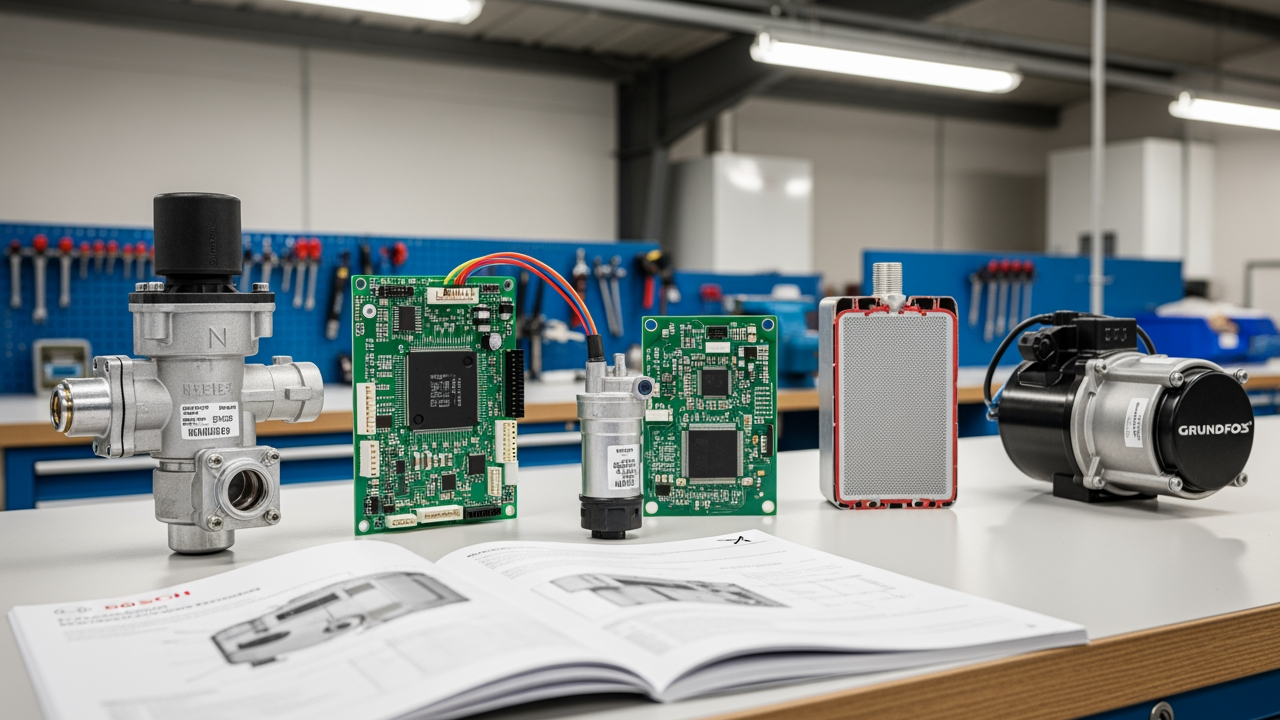

Pumps wear out from continuous operation. The Grundfos or Wilo circulation pump moves heated water through your system. Bearing failure produces a humming sound without water movement, whilst seized pumps prevent the boiler from starting. The 87161408380 fits most Greenstar models, though some installations use external pumps that require different replacements.

Identifying Your Exact Boiler Model

Worcester Bosch produced multiple Greenstar variants, and using parts from the wrong series causes compatibility issues. The rating plate inside the boiler casing contains three critical identifiers:

The GC number (like 4131166) tells you the specific boiler variant. Worcester Bosch sometimes changed internal components between production runs without changing the model name. Two Greenstar 30CDi boilers might require different PCBs based on their GC numbers.

The serial number indicates the production date. Components manufactured before certain dates use older specifications. Situations occur where Worcester Bosch issued technical bulletins requiring different parts for boilers made before or after specific serial number ranges.

The model designation appears clearly, but can be misleading. A "Greenstar 30CDi" could be a Classic, Conventional, or System boiler, each using different components. The letters after the model number matter: CDi, Si, Ri, or i indicate different generations with distinct parts.

Take a photo of the complete rating plate before ordering. Cross-referencing all three identifiers ensures compatibility, which prevents the 15-20% return rate from customers who order based solely on model name.

CDi vs i-Series: What Changed

Worcester Bosch redesigned the Greenstar line when launching the i-series, affecting parts compatibility across the board.

Hydraulic components received the most significant updates. The i-series uses a different diverter valve assembly with an integrated flow sensor, replacing the separate components in CDi models. You cannot retrofit an i-series diverter valve into a CDi boiler without also replacing the manifold assembly, a £400+ job versus a £180 diverter valve replacement.

Electronics architecture has changed completely. CDi models use separate PCBs for different functions (main board, display board, interface board), whilst i-series boilers integrate these into a single control unit. This reduces failure points but increases replacement cost when the board does fail. The i-series PCB costs £320 versus £180 for a CDi main board.

Ignition systems moved from piezo to direct spark ignition. CDi models use the 87161165680 ignition electrode assembly with separate leads, whilst i-series boilers incorporate electrodes into the burner assembly. When I-series electrodes fail, you often need to replace the entire burner door assembly rather than just the electrode.

Gas valves switched from Honeywell to SIT components in many i-series models. The gas valve controls fuel flow to the burner, and the newer SIT valves use different electrical connections. Engineers attempting to fit CDi-era Honeywell valves into i-series boilers find they physically fit but won't communicate properly with the PCB.

Expansion vessels increased in size. CDi models typically use 8-10 litre expansion vessels, whilst i-series boilers incorporate 12 litre vessels to reduce pressure fluctuations. You can fit a larger vessel to a CDi boiler for improved performance, but you cannot use a smaller CDi vessel in an i-series installation without causing repeated pressure loss.

Common Fault Codes and Their Parts

Greenstar boilers display alphanumeric codes that point to specific component failures:

EA (temporary fault) indicates low system pressure, but the cause varies. Check the pressure gauge first; if it shows below 1 bar, you likely have a leak or need to repressurise. If the gauge shows correct pressure but the EA code persists, replace the pressure sensor (87161463270). Hundreds of these cases occur where customers spend days searching for nonexistent leaks because they trusted the faulty sensor reading.

E9 (permanent fault) signals flame detection failure. The boiler ignites, but the flame sensor doesn't detect combustion, causing immediate shutdown. This fault stems from three components: the flame detection electrode (87161165680), the ignition lead, or the PCB. Test the electrode with a multimeter for continuity before replacing the board; the electrode costs £25 versus £180+ for a PCB.

D5 (temporary fault) means the pump isn't moving water properly. Remove the front panel and listen; a humming pump with no water flow indicates a seized rotor. The 87161408380 pump assembly includes the motor and housing. Some engineers try to free seized pumps with a screwdriver through the front access port, which works temporarily, but the pump typically fails again within weeks.

224 (fault code) appears when the boiler overheats. The primary cause is circulation failure, either a seized pump or a blocked heat exchanger. Scale buildup in the heat exchanger restricts water flow, causing localised boiling. If the pump operates normally, you need either a heat exchanger flush with descaling chemicals or full heat exchanger replacement (87161427450 for most CDi models).

F9 (permanent fault) indicates gas valve failure. The PCB commands the valve to open, but no gas flows to the burner. The Honeywell gas valve (87161078130) used in CDi models costs £120-150, whilst SIT valves in i-series models run £140-180. Before replacing the valve, verify that the gas supply reaches the boiler and the isolation valve sits fully open; a lack of gas supply generates the same fault code as valve failure.

OEM Parts vs Compatible Alternatives

Not all components require genuine Worcester Bosch parts, but choosing compatible alternatives needs careful consideration:

PCBs must be genuine. Compatible circuit boards exist, but software compatibility issues cause intermittent faults that are difficult to diagnose. The £40-60 saved on a compatible PCB isn't worth the risk of callbacks and warranty complications.

Pumps work reliably as compatibles. Grundfos and Wilo manufacture pumps for Worcester Bosch but also sell identical units under their own branding at lower prices. A genuine Worcester-branded Grundfos pump costs £180, whilst the same Grundfos pump without Worcester branding costs £120-140. The part numbers match, and performance is identical.

Heat exchangers should be genuine. Compatible heat exchangers exist, particularly for older CDi models, but material specifications and manufacturing tolerances vary. Inferior alloys corrode faster, and poor brazing develops leaks within 2-3 years. The £60-80 saving disappears when you replace the heat exchanger again.

Small components offer savings. Items like ignition electrodes, thermistors, and pressure relief valves function identically whether branded Worcester or sold as compatibles. A genuine Worcester pressure relief valve costs £45, whilst a compatible part costs £25, same valve, different packaging.

Parts That Need Simultaneous Replacement

Certain components wear together, and replacing only one part sets you up for a second failure within months:

The diverter valve and actuator motor share mechanical wear. The actuator motor (87161165150) drives the diverter valve between heating and hot water positions thousands of times yearly. When the valve develops stiff spots from scale or debris, the motor works harder and wears faster. Motors fail three months after diverter valve replacement because the new valve's tighter tolerances increase motor load. Replace both together, or at a minimum, test the motor's operation after fitting a new valve.

The heat exchanger and pump affect each other's lifespan. A failing pump reduces flow through the heat exchanger, causing localised overheating and scale formation. Conversely, a scaled heat exchanger increases resistance, forcing the pump to work harder. When replacing a heat exchanger due to scale damage, inspect the pump for bearing wear and reduced flow rate. If the pump contributed to the heat exchanger failure, it's likely near the end of its life.

PCB and pressure sensor create diagnostic confusion when both fail. A faulty pressure sensor sends incorrect readings to the PCB, which responds with error codes. If the PCB has been operating with bad sensor data for months, its response algorithms can become corrupted. Situations occur where replacing the obviously faulty sensor didn't clear faults because the PCB had logged permanent errors. When dealing with long-standing pressure faults, budget for both components.

Ignition electrode and lead fail together from heat exposure. The electrode sits directly in the combustion chamber, and the high-temperature lead connects it to the PCB. Heat degrades the lead insulation over 8-10 years, causing intermittent sparking issues. Replacing just the electrode leaves the degraded lead, which fails weeks later. The combined electrode and lead assembly (87161165680) costs only £12 more than the electrode alone.

Maintenance Parts Worth Stocking

If you service Greenstar boilers regularly, keeping these consumables prevents return trips:

Combustion door seals (87161190250) degrade from repeated heating and cooling cycles. A compressed or cracked seal causes combustion gases to leak, triggering CO alarms and reducing efficiency. These get replaced during annual services on boilers over five years old, even if they appear intact; the £8 cost prevents callbacks for combustion faults.

Pressure relief valve (87161068270) should discharge occasionally when the system overheats or overpressures. Calcium deposits prevent the valve from seating properly after discharge, causing continuous dripping. Testing the PRV during service by lifting the test lever identifies valves that don't reseal cleanly. Replace any valve that continues dripping for more than 30 seconds after testing.

Expansion vessel diaphragm failures aren't repairable; you need a complete vessel replacement (87161190490 for most models). The diaphragm separates water from pressurised air inside the vessel, and when it ruptures, the vessel fills with water and stops functioning. Systems without working expansion vessels experience rapid pressure increases during heating, triggering the PRV. Check vessel pre-charge pressure annually and replace vessels that have lost air pressure or show water discharge from the Schrader valve.

Auto air vent (87161165230) releases trapped air from the system automatically. The internal float mechanism can stick open, causing pressure loss, or stick closed, allowing air accumulation. Dozens of "mystery" pressure loss cases resolve after replacing a leaking auto air vent. At £18, it's worth replacing every 5-7 years during service rather than troubleshooting intermittent pressure problems.

Where to Source Parts Reliably

Finding genuine Worcester boiler spares quickly determines how fast you complete repairs:

Worcester Bosch Direct supplies trade customers but requires account setup and often has 2-3 day lead times for non-stock items. Their pricing sits at full RRP, making them suitable for warranty work but expensive for private repairs.

Plumbing merchants stock common Greenstar parts but rarely carry the full range. Merchants typically hold diverter valves, pumps, and basic PCBs, but also special-order heat exchangers, gas valves, and model-specific components. Their trade pricing typically runs 20-30% below Worcester RRP.

Specialist online suppliers like Heating and Plumbing World maintain a deeper inventory across all Greenstar models. Stock includes parts for discontinued models like the 24i Junior and 28i Junior that merchants no longer carry. Systems that cross-reference GC numbers ensure compatibility, reducing the 15-20% return rate common with parts suppliers who match by model name only.

eBay and Amazon marketplace sellers offer both genuine and compatible parts, but quality control varies dramatically. "Genuine" Worcester parts from marketplace sellers sometimes arrive as poor-quality copies with forged packaging. If buying from these platforms, verify the seller's return policy and inspect parts carefully on arrival.

Warranty Considerations

Worcester Bosch provides 2-10 year warranties depending on installation date and registration status, but warranty coverage has specific requirements:

Only approved installers can conduct warranty repairs. If you're not on Worcester's approved installer list, using genuine parts doesn't matter; the warranty becomes void when a non-approved person works on the boiler. Homeowners attempting DIY repairs with genuine parts still invalidate warranty coverage.

Parts must be genuine Worcester Bosch for warranty work. Using compatible components, even high-quality alternatives, voids the warranty completely. Cases occur where engineers fitted compatible pumps to 18-month-old boilers, then needed PCB replacements six months later. Worcester refused warranty coverage because service records showed non-genuine parts installation.

Installation must follow MI guidelines exactly. Worcester's Manufacturer Instructions specify required system components, water treatment, and installation procedures. Failures caused by incorrect installation, like heat exchanger scale damage from untreated hard water, aren't covered even within the warranty period.

Conclusion

Worcester Bosch Greenstar spare parts availability makes these boilers economical to maintain long-term, but success depends on identifying the correct component for your specific model. The GC number, serial number, and model designation together determine compatibility; never order based on model name alone.

The five most common failures, diverter valves, PCBs, pressure sensors, heat exchangers, and pumps, account for 80% of repairs. Understanding the fault codes these components generate speeds diagnosis and prevents unnecessary part replacement. Always test the pressure sensor before searching for leaks, verify pump operation before replacing the PCB, and clean flame sensors before condemning the gas valve.

OEM versus compatible parts requires component-specific decisions. PCBs must be genuine, but pumps and small components work reliably as compatibles. When replacing major components like heat exchangers or diverter valves, inspect related parts that share wear patterns; simultaneous replacement prevents repeat failures within months.

Stock maintenance consumables like combustion seals, pressure relief valves, and auto air vents if you service multiple Greenstar boilers. These £8-25 parts prevent callbacks and take minutes to replace during annual service visits. The investment in inventory pays for itself by eliminating return trips for minor component failures.

For reliable Worcester Bosch parts across all Greenstar variants, including discontinued models, Heating and Plumbing World provides comprehensive stock with GC number cross-referencing. Whether you need circulation pumps, control components from Danfoss, or specialist parts from Halstead Spares, expert technical support ensures you order the correct Worcester boiler spares the first time.

-

-